Ply Rolled Fuselage Part Deux - 1/2A " Mini Skorch "

#51

Thread Starter

Here I pull the pic back up and repost what was in the other thread;

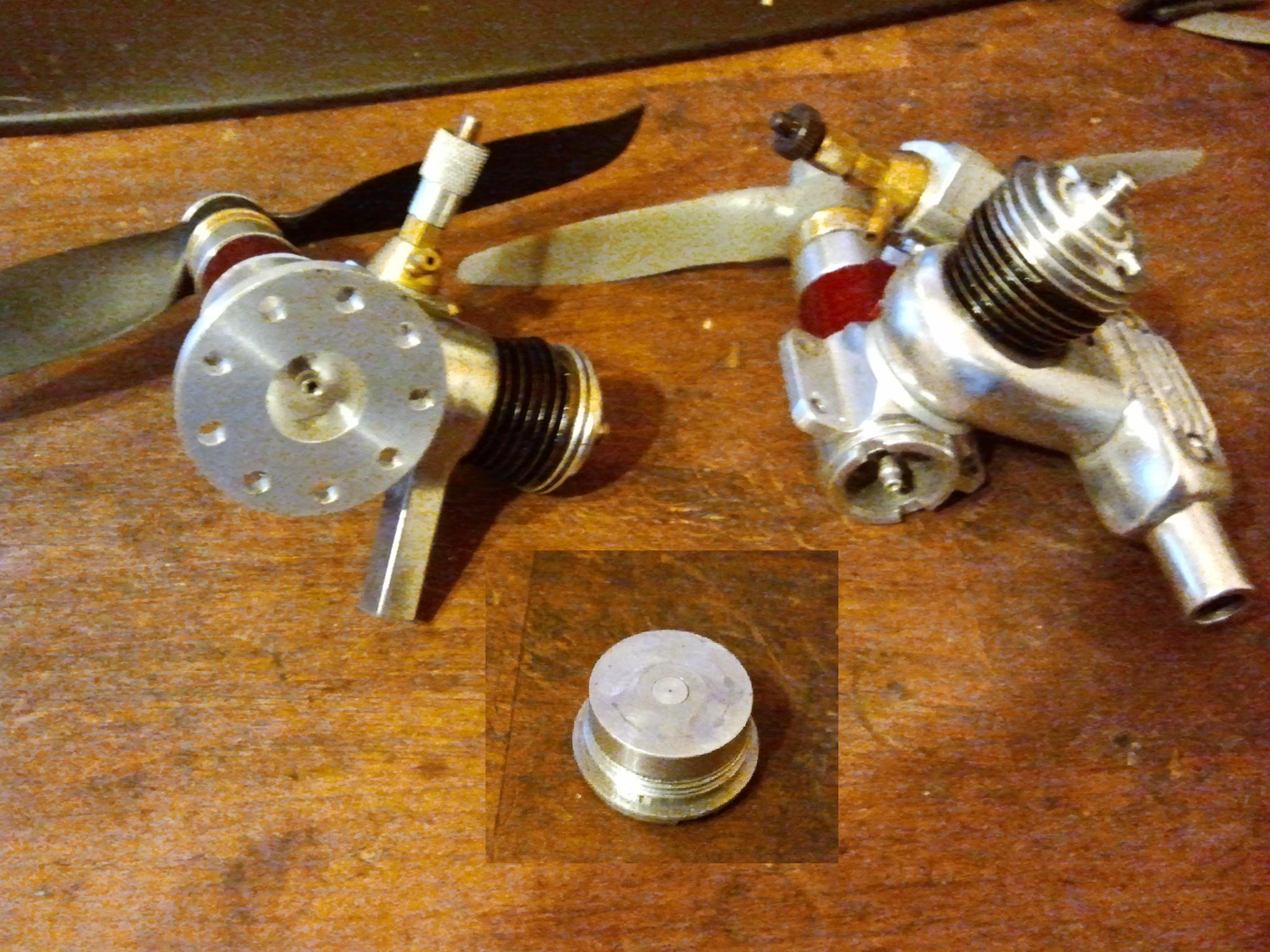

The holes are so small on the inside plate you have to use bright light to see thru or a magnifying glass. Here is a photo - KK made two types back in the day as shown. There is very little pressure feed to the tank when at idle only when you open up the throttle building engine pressure does the wee lil hole make a difference.

There is very little pressure feed to the tank when at idle only when you open up the throttle building engine pressure does the wee lil hole make a difference.

Using enameled motor winding wire:

Here are the specs based on 38g wire passing thru the hole.

0.00397 inch

0.101 mm

Also note the radial mount allowed a 34g wire to pass thru.

34g / 0.00630 in. / 0.160 mm

Here is a 2.5min vid of me setting up the low end on pressure with a 3/4oz pill tank runs the entire time mostly low idle (without flooding) before the tank runs dry. Note the additional back pressure with the exhaust extention to help keep the noise down at night (normally won't use for flying) Will post a inflight vid as this engine will be on a new plane this month. The Tarno carb has an none adjustable airbleed hole.

Needle setting was about (after messing with it) 1.3 ish turns. APC 5.7x3

The holes are so small on the inside plate you have to use bright light to see thru or a magnifying glass. Here is a photo - KK made two types back in the day as shown.

There is very little pressure feed to the tank when at idle only when you open up the throttle building engine pressure does the wee lil hole make a difference.

There is very little pressure feed to the tank when at idle only when you open up the throttle building engine pressure does the wee lil hole make a difference.Using enameled motor winding wire:

Here are the specs based on 38g wire passing thru the hole.

0.00397 inch

0.101 mm

Also note the radial mount allowed a 34g wire to pass thru.

34g / 0.00630 in. / 0.160 mm

Here is a 2.5min vid of me setting up the low end on pressure with a 3/4oz pill tank runs the entire time mostly low idle (without flooding) before the tank runs dry. Note the additional back pressure with the exhaust extention to help keep the noise down at night (normally won't use for flying) Will post a inflight vid as this engine will be on a new plane this month. The Tarno carb has an none adjustable airbleed hole.

Needle setting was about (after messing with it) 1.3 ish turns. APC 5.7x3

#52

Thread Starter

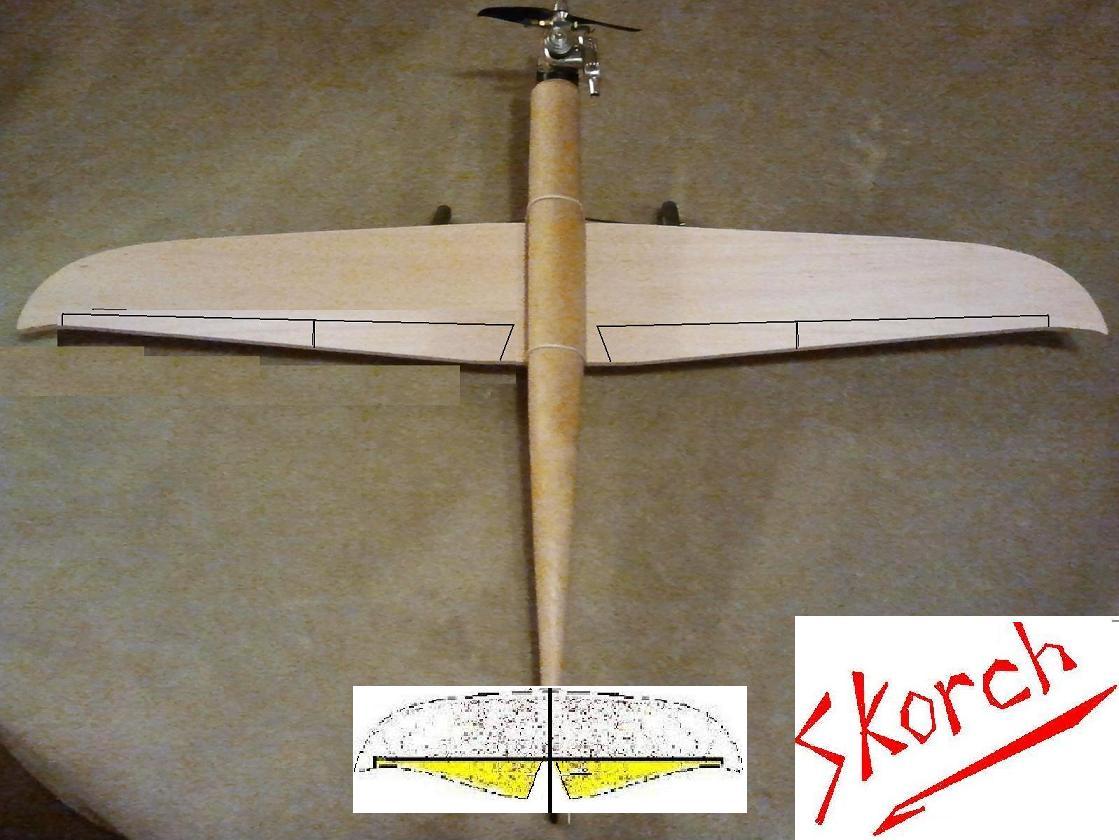

Well the wing is cut out using the template that passed my (does it look right test) I will have to figure out the squares in do time a 4 x 36 plank is 144 Sq.In. Least for now will show the shape. The plank bare from the store was 2.74oz. I had predicted 1.72oz after cut out and airfoiled.

To my surprise it was 1.82oz just from cutting out. Looks like 11oz 5ch 1/2A goal could happen the weight of the wing was a big hurdle to cross at this stage. It looks like the Lil Speedy's big brother the Skorch is getting closer to seeing some air time.

Ok took a look at the wing specs:

4 x 30in tapered swept tip wing came out at 88 SQ IN.

If at 11oz RTF 8 sq. in per oz should rip the air and float in on flaps.

To my surprise it was 1.82oz just from cutting out. Looks like 11oz 5ch 1/2A goal could happen the weight of the wing was a big hurdle to cross at this stage. It looks like the Lil Speedy's big brother the Skorch is getting closer to seeing some air time.

Ok took a look at the wing specs:

4 x 30in tapered swept tip wing came out at 88 SQ IN.

If at 11oz RTF 8 sq. in per oz should rip the air and float in on flaps.

Last edited by Pond Skipper; 08-27-2014 at 12:02 AM.

#53

Thread Starter

Ok lets see I doo like to doodle prior to hacking balsa. Mini 1/2A Skorch is looking like a pylon racer so heres a more simple solution for the flaps and rons. I will use ply 1/64th sheet in the center again to protect the balsa from the saddle and add some breaking strength to an already thick slab of balsa.

#54

My Feedback: (1)

Join Date: May 2003

Location: Orangeville, ON, CANADA

Posts: 8,658

Likes: 0

Received 2 Likes

on

2 Posts

Way cool, ought to go like a bat. You like them sweepy tips.

I've been searching for that rolled fuselage construction article - sifted through my main box of old mags and the particular issue wasn't there.. but I know it is floating around, I'll probably find it by not looking for it.

I got off my dormant (and easily distracted) butt last night and started fabbing the fuel cutoff on my 1/2A speed model, that was the only remaining slightly-technical hurdle. The rest is just getting it done during flying/goofing off season.

I've been searching for that rolled fuselage construction article - sifted through my main box of old mags and the particular issue wasn't there.. but I know it is floating around, I'll probably find it by not looking for it.

I got off my dormant (and easily distracted) butt last night and started fabbing the fuel cutoff on my 1/2A speed model, that was the only remaining slightly-technical hurdle. The rest is just getting it done during flying/goofing off season.

#55

Thread Starter

Yes helps to reduce tip vortices picks up some extra speed.

If you find a link let me know ...will be neat to see how it was done back in the day.

I like egg shell construction too - for more scale looking planes but can be made strong but not getting the straight is more fuss.

The rolled system gives you strength and an arrow straight fuselage with min. effort.

I remember the plastic shut off systems with a small control arm to connect to the servo we have all been looking forward to seeing the Screaming Toucan fly!

If you find a link let me know ...will be neat to see how it was done back in the day.

I like egg shell construction too - for more scale looking planes but can be made strong but not getting the straight is more fuss.

The rolled system gives you strength and an arrow straight fuselage with min. effort.

I remember the plastic shut off systems with a small control arm to connect to the servo we have all been looking forward to seeing the Screaming Toucan fly!

#56

My Feedback: (1)

Join Date: May 2003

Location: Orangeville, ON, CANADA

Posts: 8,658

Likes: 0

Received 2 Likes

on

2 Posts

I came up with a quickie solution using two short pieces of tubing for a fuel line support, and a pin hinge as the shutoff arm. Weighs a bit more than the glue holding it down, worked great when I jury-rigged it.

#57

Senior Member

My Feedback: (3)

If the fuel line is under pressure it takes quite a bit of a pinch to completely shut it down.

The most reliable shut off I've copied has a MW hook that pulls the fuel line into a hole in the firewall, folding [or "doubling over"] the fuel. line. This one is popular with pylon racers and I think I've seen some of the Germans using it, too.

The most reliable shut off I've copied has a MW hook that pulls the fuel line into a hole in the firewall, folding [or "doubling over"] the fuel. line. This one is popular with pylon racers and I think I've seen some of the Germans using it, too.

#58

My Feedback: (1)

Join Date: May 2003

Location: Orangeville, ON, CANADA

Posts: 8,658

Likes: 0

Received 2 Likes

on

2 Posts

That's probably a better solution than what I started putting together here. The fuel line is thin wall silicone FF stuff (it handles bladder pressure fine) and easy to pinch. I wasn't planning on a fuel cut off servo, but if I can do this with a 4-6g servo, then might.

#59

Thread Starter

After about 20mins of sanding the top foil is close for rough shape and I lost 8.4g in sawdust, in theory I should lose about the same to foil the bottom this one will get a fully symmetrical airfoil and weigh in at around 1.3oz ish prior to getting some ply in the center section and 1in strapping tape on the CG. Not really needed for a Cox .051 but it I slap on the TD .09 will be. I drew a center line on the 10mm thick planks leading and trailing edge as a guide and a light line at the CG and now with just a 5 mm leading edge awaiting another bout of sanding for the bottom. The Lil Stinker .020 wing had no leading edge treatment the wood was more dense and the covering helped. This one will get a epoxy coating along its edge and back a hair to help control any potential dings. Another way is to slit the wood for a run of thin ply then sanded for a sharp leading edge. Spruce strip would just add too much weight. At the very least run a bead of CA and smooth it on with two fingers in a small plastic bag to reduce mess.

Here is a pic showing the hand drawn airfoil at the saddle no special foil selection just one of my own only a hair gap remains at the CG with the wing on will fine tune at the end. This was some work to do even with fresh sand paper and on a aluminum T sanding bar.

Here is a pic showing the hand drawn airfoil at the saddle no special foil selection just one of my own only a hair gap remains at the CG with the wing on will fine tune at the end. This was some work to do even with fresh sand paper and on a aluminum T sanding bar.

Last edited by Pond Skipper; 08-27-2014 at 12:49 AM.

#61

Senior Member

My Feedback: (3)

I get all choked up just looking at it.

I enjoy shaping the wood but it's about time to rig up some dust control.

One of the best shaping tools I've bought is a cheap plastic razor plane that was sold by Master Airscrew. It is about the size of a pack of cigarettes and it takes nice little bites that are easy to control

I enjoy shaping the wood but it's about time to rig up some dust control.

One of the best shaping tools I've bought is a cheap plastic razor plane that was sold by Master Airscrew. It is about the size of a pack of cigarettes and it takes nice little bites that are easy to control

#62

Thread Starter

Haha yep unless you have a vent and a dust mask.

I have a Master Airscrew 1.75in razor plane too - great tool to get the meat off the potato you just have to be careful as it can cause moments of overkill.

Amazing enough they still sell them bought mine back in the 90's - http://www3.towerhobbies.com/cgi-bin/wti0001p?&I=LXAA64

I went with my 11in T Bar sander as it was already on the work bench - they dont take a standard razor blade but you can fudge one in there.

The tough plastic appears to be the same material as they use on the props.

Here's mine still kickin

I have a Master Airscrew 1.75in razor plane too - great tool to get the meat off the potato you just have to be careful as it can cause moments of overkill.

Amazing enough they still sell them bought mine back in the 90's - http://www3.towerhobbies.com/cgi-bin/wti0001p?&I=LXAA64

I went with my 11in T Bar sander as it was already on the work bench - they dont take a standard razor blade but you can fudge one in there.

The tough plastic appears to be the same material as they use on the props.

Here's mine still kickin

#63

Senior Member

My Feedback: (3)

I set up 2 cheap box fans to pull air out of a work area to the great outdoors. It works great for paint over spray and it might work for sanding balsa. Otherwise, the natural lighting outside is hard to beat and if I start using my head, I'll figure out how to make use of a fan in that setting. This way it might be possible to do away with the dust masks.

#64

Thread Starter

Right that.. anything to make the task enjoyable and comfortable enough to have you not rushing through as once it's done you're stuck with it.

I hate seeing flaws later knowing it's primarily there because I became impatient through the process.

If I had a 24in bar it would have been ideal to infuse some worry free consistency across this 30in span, even the 11in bar was worth the elbow grease forming one half of the top span at a time then feathering the two into a continuous flowing wing. Drawing down the shape without exceeding it is the key choice with a bar and leaves in maximum strength not waves or gully's.

Yes lighting is crucial I had 8 lights going a mix of 5 compact fluorescents and 3 incandescent bulbs checking the work as I went along. It is a bit of an art form to sculpt consistency from tip to tip into a triple tapered wing (graduated airfoil in thickness) and with washout makes it a keeper for a lifetime. Worth prepping the leading edge to be ding resistant monokote can hide any other dings .. A secondary follow up with a 1/2 to 1in wide female airfoil template with a strip of med grade sandpaper checking for any high spots or low spots while the wing is on a flat surface gives you extra consistency that will help to hold back speed induced flutter tip oscillation. I had a bare balsa wing explode going over 100 with a brushless motor it was in its second season and had dried out should have sealed the wood at a minimum.

I hate seeing flaws later knowing it's primarily there because I became impatient through the process.

If I had a 24in bar it would have been ideal to infuse some worry free consistency across this 30in span, even the 11in bar was worth the elbow grease forming one half of the top span at a time then feathering the two into a continuous flowing wing. Drawing down the shape without exceeding it is the key choice with a bar and leaves in maximum strength not waves or gully's.

Yes lighting is crucial I had 8 lights going a mix of 5 compact fluorescents and 3 incandescent bulbs checking the work as I went along. It is a bit of an art form to sculpt consistency from tip to tip into a triple tapered wing (graduated airfoil in thickness) and with washout makes it a keeper for a lifetime. Worth prepping the leading edge to be ding resistant monokote can hide any other dings .. A secondary follow up with a 1/2 to 1in wide female airfoil template with a strip of med grade sandpaper checking for any high spots or low spots while the wing is on a flat surface gives you extra consistency that will help to hold back speed induced flutter tip oscillation. I had a bare balsa wing explode going over 100 with a brushless motor it was in its second season and had dried out should have sealed the wood at a minimum.

#65

Thread Starter

Alright the deed is done el skorch has a wing at 37g /4 x 30in / 88sq in. 1.31oz - fun to est. I had it pegged at 1.3oz per post 59.

So recap bare from the store 2.74oz. predicted 1.72oz after cut out and airfoiled cut out at 1.82oz foiled at 1.3oz. for those pondering a plank wing build these sort of results percentages per phase can be anticipated with any wing - if fully symmetrical triple taper. +/- say 10%.

10mm leading edge is gone and I left a 1 mm trailing edge. The entire wing took from cutting out to this stage in about 1hr and 15mins of build time so much faster than cutting out ribs and all the other components prior to assembly. 1.31 oz is very acceptable- if I glass it the wing would be ready for a .15-.20 size engine. I have a Dx6i radio, I need to see what flap options I have prior to cutting the rons and flaps. The goal is stunt flap mode or 2 stage step down preset flaps for landing. I had a nice JR radio that would let me dial in the flap position on the fly for landing and for stunt mode. Not sure whats possible yet we shall see. It will determine servo arrangements.

So recap bare from the store 2.74oz. predicted 1.72oz after cut out and airfoiled cut out at 1.82oz foiled at 1.3oz. for those pondering a plank wing build these sort of results percentages per phase can be anticipated with any wing - if fully symmetrical triple taper. +/- say 10%.

10mm leading edge is gone and I left a 1 mm trailing edge. The entire wing took from cutting out to this stage in about 1hr and 15mins of build time so much faster than cutting out ribs and all the other components prior to assembly. 1.31 oz is very acceptable- if I glass it the wing would be ready for a .15-.20 size engine. I have a Dx6i radio, I need to see what flap options I have prior to cutting the rons and flaps. The goal is stunt flap mode or 2 stage step down preset flaps for landing. I had a nice JR radio that would let me dial in the flap position on the fly for landing and for stunt mode. Not sure whats possible yet we shall see. It will determine servo arrangements.

#66

Thread Starter

Just did a weigh in of the remaining parts and components looks like all up weight prediction will be around 278.7g or 9.834 oz prior to monokote wing / tail feathers and painted fuse.

#67

My Feedback: (1)

Join Date: May 2003

Location: Orangeville, ON, CANADA

Posts: 8,658

Likes: 0

Received 2 Likes

on

2 Posts

Bears a striking resemblance to a low wing version of my 5 month ARF project.. cool!

A 10oz 1/2A is a wonderful thing. I think the Screamin' Toucan will still come in around 9.5, but it's easy to tack on another 1/2 ounce if one is not careful right until the end.

A 10oz 1/2A is a wonderful thing. I think the Screamin' Toucan will still come in around 9.5, but it's easy to tack on another 1/2 ounce if one is not careful right until the end.

#68

Thread Starter

Mine is basicly the Lil Speedy up graded in size and set up for 5 channels with rudder air/ground steering and flaps.

I am asking a lot to hit 11oz

Do you recall what your squares are, looking forward to your flight vid!

Here is a pic before I sanded in the airfoil 30in span vs 21in span.

I am asking a lot to hit 11oz

Do you recall what your squares are, looking forward to your flight vid!

Here is a pic before I sanded in the airfoil 30in span vs 21in span.

Last edited by Pond Skipper; 08-28-2014 at 11:46 AM.

#71

Thread Starter

Yes makes sense as the old 200 SQ IN Quickie types are not that fast unless the airfoil is very thin.

So if constant cord 4 x 30 span for 120 sq in. is that what you're referencing?

Also for fun,,

In the early 70’s one of the "hot things" in the RC world was 1/2 A Pylon racing. These small planes were powered by a Cox TD .049/051 engines with no throttle and liked to run on 50% Nitro glow fuel. 22,000+ rpm was the norm. The minimum weight was 20 oz. and the minimum wing area was 200 sq. inches. They were controlled by elevator/rudder or elevator/aileron and required an engine shut off, which in many cases was a tank with a solid fuel pickup so the aircraft could be rolled inverted until the engine quit. The speeds were well below 100 mph but I competed in an "open" event with the only rule being that the engine could not be larger than .051. A then, young man by the name of Bob Novak (yes, the owner of Novak Electronics) put a plane in the air and it was radared at 92 mph! AMA eventually included 1/2A as a sanctioned event, but the real action was at the local club(s) flying field.

With that being said 11oz 88sq Skorch could see 100mph+ on my mint .051 with crank case pressure with my custom mix of 40% nitro.

So if constant cord 4 x 30 span for 120 sq in. is that what you're referencing?

Also for fun,,

In the early 70’s one of the "hot things" in the RC world was 1/2 A Pylon racing. These small planes were powered by a Cox TD .049/051 engines with no throttle and liked to run on 50% Nitro glow fuel. 22,000+ rpm was the norm. The minimum weight was 20 oz. and the minimum wing area was 200 sq. inches. They were controlled by elevator/rudder or elevator/aileron and required an engine shut off, which in many cases was a tank with a solid fuel pickup so the aircraft could be rolled inverted until the engine quit. The speeds were well below 100 mph but I competed in an "open" event with the only rule being that the engine could not be larger than .051. A then, young man by the name of Bob Novak (yes, the owner of Novak Electronics) put a plane in the air and it was radared at 92 mph! AMA eventually included 1/2A as a sanctioned event, but the real action was at the local club(s) flying field.

With that being said 11oz 88sq Skorch could see 100mph+ on my mint .051 with crank case pressure with my custom mix of 40% nitro.

Last edited by Pond Skipper; 08-28-2014 at 04:44 PM.

#72

Senior Member

My Feedback: (3)

Well, the talk at the time from the NASS Guys was to go below 100 sq inches..basically a guided bomb, because a G&Z .049 is a big engine that needs a big fuselage to conceal it.

When I first took a look at those 20 oz racers, they just didn't interest me. Even way back when you could use "normal" methods and wood selection and build one that weighed about 16-17 ozs. Guys were forced to layer on coats of fiberglass, bondo, epoxy paint, etc. to make minimum weight. At 20 ozs, when something goes wrong there is enough kinetic energy to really smash the plane into the ground up to the leading edge. These planes were dicey to launch, but I'll admit they flew OK once up to speed.

I had a TD .049 model with a 150 sq inch wing [1/4 inch thick sheet wing] do a little over 100 mph with the 4.2 x 4 and Nelson head. It was about 13 to 14 ozs RTF.

The Utah racers with [IIRC] a 200 sq. inch rule were reporting 110 mph with 30,000+ rpm Norvels...! I don't remember if this claim was flat out speed, or measured through the turns.

When I first took a look at those 20 oz racers, they just didn't interest me. Even way back when you could use "normal" methods and wood selection and build one that weighed about 16-17 ozs. Guys were forced to layer on coats of fiberglass, bondo, epoxy paint, etc. to make minimum weight. At 20 ozs, when something goes wrong there is enough kinetic energy to really smash the plane into the ground up to the leading edge. These planes were dicey to launch, but I'll admit they flew OK once up to speed.

I had a TD .049 model with a 150 sq inch wing [1/4 inch thick sheet wing] do a little over 100 mph with the 4.2 x 4 and Nelson head. It was about 13 to 14 ozs RTF.

The Utah racers with [IIRC] a 200 sq. inch rule were reporting 110 mph with 30,000+ rpm Norvels...! I don't remember if this claim was flat out speed, or measured through the turns.

#73

My Feedback: (1)

Join Date: May 2003

Location: Orangeville, ON, CANADA

Posts: 8,658

Likes: 0

Received 2 Likes

on

2 Posts

The Screamin Toucan is 118 sq in in one description and 108 sq in in another. The wing is really clean, max thickness about 3/8" at the root, so I have high hopes for it. I think it would top 100 on a good TD without much fuss.

#74

Thread Starter

Great info ty CP, looks like at 150 sq 11 sq per oz on your end a 4p at 26.4k gets you to 100 .

So 118 sq in if at 10oz 11.8 squares per oz.

I have a nelson head/plug adapter perhaps used with the 4.5 x 4.5 my carbon plastic prop I could do 25k / 40% nitro -which will take me to 106.

88 sq/in 8sq per oz should give me a big edge over drag. I would imagine anything over 40mph the wing is producing more than enough lift to fly near 0 incidence. I wanted the stunt flaps mixed with the elevator for fun flying but will be a must if forced to land down wind dead stick or in dead air.

Based on the Lil Speedy at 5.3oz a 6.5oz - 2ch with a cox .049 reed engine at.55 sq in wing would be 1oz per 8.46sq in.

No landing gear the bare mins. I may try a no fuss build with my modified .049 at 35.7g with prop or 7oz with a TD.

So 118 sq in if at 10oz 11.8 squares per oz.

I have a nelson head/plug adapter perhaps used with the 4.5 x 4.5 my carbon plastic prop I could do 25k / 40% nitro -which will take me to 106.

88 sq/in 8sq per oz should give me a big edge over drag. I would imagine anything over 40mph the wing is producing more than enough lift to fly near 0 incidence. I wanted the stunt flaps mixed with the elevator for fun flying but will be a must if forced to land down wind dead stick or in dead air.

Based on the Lil Speedy at 5.3oz a 6.5oz - 2ch with a cox .049 reed engine at.55 sq in wing would be 1oz per 8.46sq in.

No landing gear the bare mins. I may try a no fuss build with my modified .049 at 35.7g with prop or 7oz with a TD.

#75

Senior Member

My Feedback: (3)

I think at speeds over 90 mph in the size range we are playing with, weight isn't real critical..[with in reason]. It's nothing to obsess over unless you are doing pylon laps. No matter how small and light you go, you have already hit a wall with the "sub-sonic" 1/2 A engines at 110 mph or so, then it's time to move into the FAI 1/2 A engines to get into the next echelon of performance.

A guy who used to post here managed to hit 120 with a piped TD .049, but those results would be hard to repeat without having a briefcase full of spare engines.

Actually, the best revving Cox .049 I've ever seen was a stock KillerBee that hit 28,000 on the bench with a 4.2 x 4 prop and it really unloaded in the air. These engines came with lightened pistons, hollow crank pin and the ability to pump air a little better than the TDs apparently. I think the crank has less mass and rotational speed [if the main journal is smaller], also. The reed has no problem with supporting 30,000 rpm.

A guy who used to post here managed to hit 120 with a piped TD .049, but those results would be hard to repeat without having a briefcase full of spare engines.

Actually, the best revving Cox .049 I've ever seen was a stock KillerBee that hit 28,000 on the bench with a 4.2 x 4 prop and it really unloaded in the air. These engines came with lightened pistons, hollow crank pin and the ability to pump air a little better than the TDs apparently. I think the crank has less mass and rotational speed [if the main journal is smaller], also. The reed has no problem with supporting 30,000 rpm.