Latching the bomb in the cradle on the airplane is accomplished by fitting a dowel pin with a notch in which part of the servo output arm nestles into. The servo serves double duty by driving the trapeze as well. The trapeze throws the bomb clear of the prop arc in vertical dives. Trial found that the trapeze by itself would not hold the bomb in the cradle with the engine running, hence the need for the latching dowel pin.

Since the new bomb needed a clear bore for the piston-plunger, the dowel pin required a blind hole for bonding to the center body. A new, extra short dowel pin was fashioned and attached to mate up with the servo output arm. The original "U" shaped scab plates (used to connect and release the bomb from trapeze) were removed from the discarded center body, the surface gauge was used to draw center lines on the new center body and the scab plates were bonded to it.

#1 the dowel pin with notch originally used is shown upside down here to help explain the concept without bomb for clarity. (notch is ramped to pull bomb in tight against cradle)

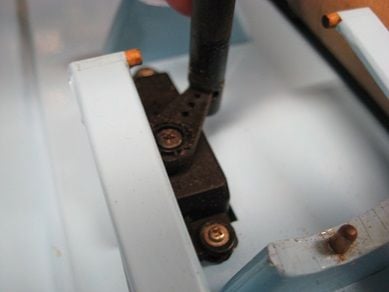

#2 shows the output arm nestled into the dowel pin notch.

#3 shows relative positions of the output arm and dowel pin during bomb release sequence - the bomb with dowel pin would actually be moving out and away with the trapeze at this point. (Note: pins in cradles keep bomb from sliding fore and aft)

#4 are the original "U" scab plates for trapeze interface salvaged from the old center body.

#5 shows center lines added to locate the scab plates.

#6 & 7 show latching dowel pin and scab plates bonded to new bomb center body.