ORIGINAL: brice_arnold

There is something to be said about any scratch built project whether it be made from CNC or from a hack saw and file. I started out with the basic tools and my first custom car was made using a hack saw and electric drill. I made a chassis from an old street sign for my electric buggy. As I grew older and my skills progressed so did the size of my wallet and I could afford bigger and better machines. I have never forgotten where I started and carry my previous skills wiht me to the new machines and tools. When I am looking at purchasing a new tool or machine I ask myself what is this going to allow me to do? Typically a machine or tool will open up the potential for different process and may allow you to do things more elegant and with more flare.

In college I had acess to a machine shop, all manual macines. After college I was without the machine that I had grown acustomed to. I eventually picked up a bench top mill and lathe from Harbor Freight and I was back in business. One day I found an old CNC router at the company I was working for and offered them 50 buck for it. This was about three years ago. I had to make a custom serial cable for it so that I could control it from my PC. I then had to go and find the correct driver software for the machine. Learn how to convert G-code over to the machines proprietary language. I basically tought my self CNC from scratch. I still use this machine to cut anything from carbon fiber to 5/8'' thick aluminum plate.

Last year I picked up a CNC mill that I now do all of my R&D work on. This year I picked up a nicer gunsmith lathe to replace my benctop lathe. I have now outgrown my garage and am moving into a dedicated shop. All of this has been inspired by my passion for everything radio controlled from helicopters, to boats, to cars, and other strange vehicles. Because I started with the basics I can manually machine almostanything that I can do on my CNC mill. Sure it may take longer and Imight have to get a little more creative but I will always have thatoption.

I don't know where I was going with this but I don't think you can put a weight on what is hand made and what is not based on the tools used to make the part or assembly. There is just as much tallent and creativity in going from a sketch to a computer model to a cnc'd part as there in going form a sketch to a wittled out part using a hack saw and drill press. Having said that I am personally always more impressed with the guys that do the builds with out the right tools but they have the inginuity to make their vision a reality. On the other hand you don't see too many CNC custom builds simply because the machines are expensive and the cost to have a one-off made for you is also a deterent.

Enough rambling here is my most recent custom build. This was done for RCX of this year. It was inspired by the HPI baja and still uses a couple of components from the baja. There were a couple of motivations behind this project. 1. how can we get a 46cc goped motor into the baja 2. No one has ever done a tube chassis for the baja 3. Lets try and do something scale.

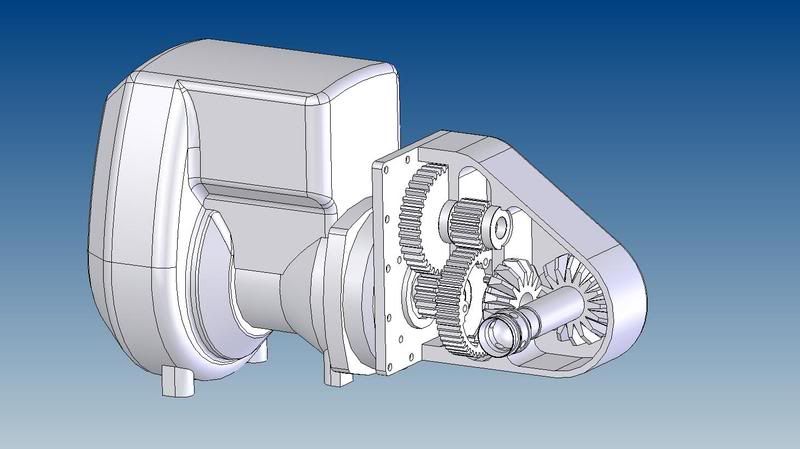

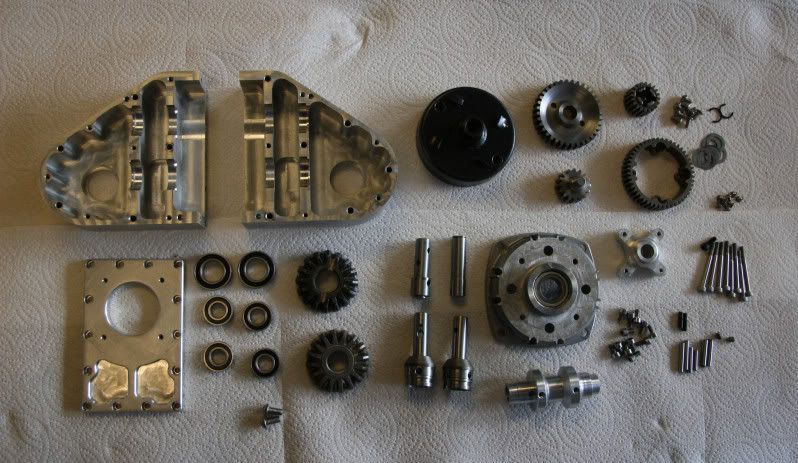

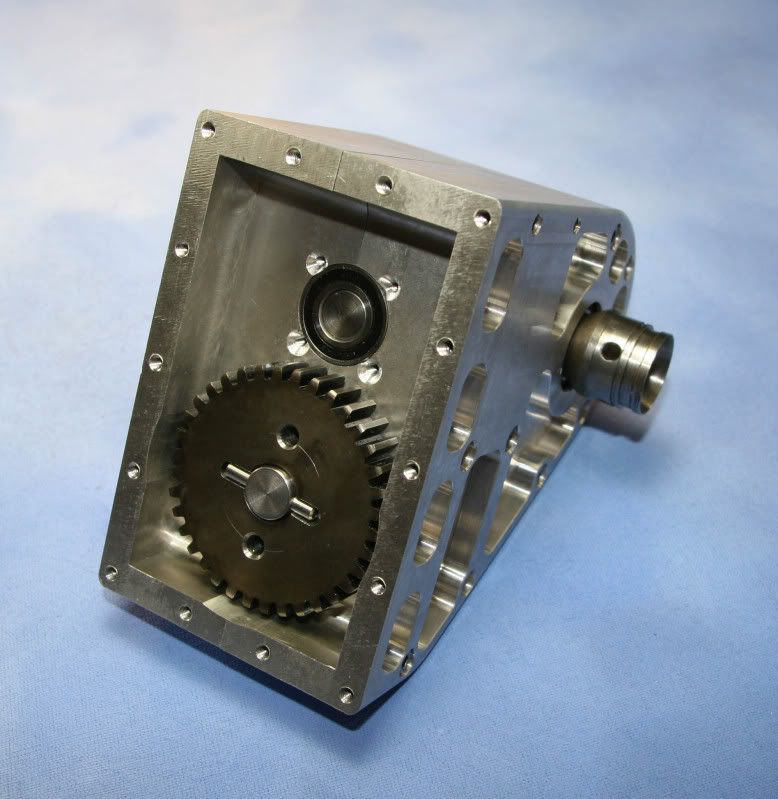

I started with the motor and designed a tranny for it.

Then I made the tranny. There is something satisfying about dreaming of a design and actuatly seeing it come to fruition and look and function the way you imagined it.

Then I built a chassis around the engine and tranny using TIG welded 4130 thin wall tubing. This is all hand work here.

Once I had the rough chassis done I did up the body pannels in aluminum. I hate working with sheet metal and trying to form it. It's the one thing I don't have a good grasp on. I wasted a lot of material to get these panels

To keep the project scale I wanted to also do the suspension arms from 4130 tubing. It was actually not as bad as I thought. I made some welding jigs so that I could get the geometry just right and and have both the left and right side come out exact.

Once I was finished getting everything welded and prepped I had it all powder coated. I finished the body pannels with some painted flames.

The rear has a pseudo trailing arm setup. Becasue I was using my CVD's for the drive-shafts I needed a telescoping driveshaft to allow for suspension travel.

Some other design features include custom machined carbon fiber chassis plates. These support the radio gear and gas tank. The strearing uses dual Rhino servos. I am also using my front and rear disk brakes at the wheels. These are actuated buy independant Hitec 7955 servos.

That's about it. I have driven here once in the grass and now she sits in a box awaiting the next show.