Go Brushless.com

#2

Senior Member

Join Date: Jan 2002

Location: DFW , TX

Posts: 117

Likes: 0

Received 0 Likes

on

0 Posts

A10flyer

Yes I have made a purchase from go brushless . No it's not to good to be true. If you ever read the board at rcgroups there are hundreds of post in several threads about that site ! I have rewound 6 of the cdrom drives so far and all of them out performed my expectations. Here is on of the planes I fly with a cdrom brushless motor. I really hauls. It is a popfly with 3 inches cut out of the center of the wing. Johnathan

Yes I have made a purchase from go brushless . No it's not to good to be true. If you ever read the board at rcgroups there are hundreds of post in several threads about that site ! I have rewound 6 of the cdrom drives so far and all of them out performed my expectations. Here is on of the planes I fly with a cdrom brushless motor. I really hauls. It is a popfly with 3 inches cut out of the center of the wing. Johnathan

#3

Senior Member

Join Date: Jan 2002

Location: DFW , TX

Posts: 117

Likes: 0

Received 0 Likes

on

0 Posts

The guy that runs the site is ScubaSteve on rcgroups. He just started and is selling most of the stuff imported direct from the cdrom mfg in china. Really has done a great service to the rc comunity finding these high quality stators and parts for so little cost. Johnathan

#7

Join Date: Sep 2002

Location: Nijmegen / Nederland

Posts: 628

Likes: 0

Received 22 Likes

on

17 Posts

(Re)winding_101, must read:

www.gobrushless.com

-> knowledge base

-> basic overview (1-5)

Tips and tricks, winding videos, checks and tests, may save you from frying your controller, sticky in the '[link=http://www.rcgroups.com/electric-motor-design-and-construction-361/]Motor design and construction[/link]' subforum:

http://www.rcgroups.com/forums/showthread.php?t=240993

Vriendelijke groeten Ron

Ron

www.gobrushless.com

-> knowledge base

-> basic overview (1-5)

Tips and tricks, winding videos, checks and tests, may save you from frying your controller, sticky in the '[link=http://www.rcgroups.com/electric-motor-design-and-construction-361/]Motor design and construction[/link]' subforum:

http://www.rcgroups.com/forums/showthread.php?t=240993

Vriendelijke groeten

Ron

Ron

#8

Senior Member

Join Date: Dec 2004

Location: Napoleon, OH

Posts: 1,617

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: Metallover

Old thread here, but how much wire comes on the small and 1/4lb spools? How many cd-rom motors can you get out of a small spool?

Old thread here, but how much wire comes on the small and 1/4lb spools? How many cd-rom motors can you get out of a small spool?

The length of wire required for a motor depends on the size of the wire, the thickness of your stator, and the number of turns.

You should be able to build 5 single-stator CD-ROM type motors from one small spool of Newbie wire. This assumes you'll be using a 9-pole, 17, 20, or 22.7mm stator.

If you have not wound a motor before, I strongly recommend getting three small spools (one of each color), so you can use a separate color for each phase. If you get three small spools, you'll have enough wire for approximately 15 single-stator CD-ROM type motors (or 7 double-stator motors, or 3-4 triple-stator motors).

Building your own motors is a lot of fun, in my opinion. Nowadays, you won't save any money, but you'll learn a whole lot about brushless motors.

- Jeff

And HELLO to Ron!

#9

Join Date: Sep 2002

Location: Nijmegen / Nederland

Posts: 628

Likes: 0

Received 22 Likes

on

17 Posts

Excellent info Jeff. As you probably know, I have never built or even (re)wound a motor, hence just my general motor (re)winding/building info.

Metalllover, one other advantage of (re)winding a kit/motor, your (re)wound will have higher efficiency than its factory wound siblings, because you can afford the time to cram more/thicker copper in the slot: -> lower copperwire resistance -> higher efficiency -> higher power/weight ratio and/or lower temperature. (Jeff must have read this remark many times by now I guess, ad nauseam )

)

I suggest you order the newbie wire, its insulation is thicker, less chance of a stator-wire short for the 'un-iniated'. Be sure to read the methods for preventing and detecting shorts, somewhere in the first post by yours truly:

http://www.rcgroups.com/forums/showthread.php?t=240993

Another good source for winding wire is you local motor/transformer (re)winder. Excellent quality, lots of wire gauges, and you'll probably get it for free. Don't call the front office, just go around the back and ask the grunts. Bring your along motorkit/controller/plane/Tx with you, the love a motor they can handle without an overhead crane.

Vriendelijke groeten Ron

Ron

Metalllover, one other advantage of (re)winding a kit/motor, your (re)wound will have higher efficiency than its factory wound siblings, because you can afford the time to cram more/thicker copper in the slot: -> lower copperwire resistance -> higher efficiency -> higher power/weight ratio and/or lower temperature. (Jeff must have read this remark many times by now I guess, ad nauseam

)

)I suggest you order the newbie wire, its insulation is thicker, less chance of a stator-wire short for the 'un-iniated'. Be sure to read the methods for preventing and detecting shorts, somewhere in the first post by yours truly:

http://www.rcgroups.com/forums/showthread.php?t=240993

Another good source for winding wire is you local motor/transformer (re)winder. Excellent quality, lots of wire gauges, and you'll probably get it for free. Don't call the front office, just go around the back and ask the grunts. Bring your along motorkit/controller/plane/Tx with you, the love a motor they can handle without an overhead crane.

Vriendelijke groeten

Ron

Ron

#10

Join Date: Sep 2002

Location: Nijmegen / Nederland

Posts: 628

Likes: 0

Received 22 Likes

on

17 Posts

ORIGINAL: johnathan

The guy that runs the site is ScubaSteve on rcgroups. ...

The guy that runs the site is ScubaSteve on rcgroups. ...

http://www.rcgroups.com/forums/showthread.php?t=807579

http://www.rcgroups.com/forums/showthread.php?t=1102169

http://www.rcgroups.com/forums/showthread.php?t=770832

http://www.rcgroups.com/forums/showthread.php?t=369475

http://www.rcgroups.com/forums/showthread.php?t=691109

And, judging by several posts, GoBrushless has an excellent service record.

Vriendelijke groeten

Ron

Ron

#11

Senior Member

Join Date: Jun 2007

Location: Brandon, SD

Posts: 1,684

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for all the info guys!

Here is my project, and it's not a plane. It's my one off micro-t speed demon.

(un)fortunately, one of the motor wires came off on one of the motors

Now I hope to rewind the motors. I don't know what gauge of wire to get. The stator is about 18x11mm. It's 2300kv right now, which is WAY too high; heres a link - http://www.hobbycity.com/hobbycity/s...idProduct=8478

When I drove it, it would have a very hard time starting up and syncing. Once it got movin, it was movin. One of the last runs I got to probably 40+mph and it spun out or lost range and flew almost under a guys running lawn mower.[X(] He thought I was on crack when I walked through his lawn to get it.

I would like to use it inside, so half or less kv is needed. I have no clue what gauge is on there and what gauge I need. I also don't know if it's a star or delta wind, or how many turns it is.

Your help is appreciated![8D]

Here is my project, and it's not a plane. It's my one off micro-t speed demon.

(un)fortunately, one of the motor wires came off on one of the motors

Now I hope to rewind the motors. I don't know what gauge of wire to get. The stator is about 18x11mm. It's 2300kv right now, which is WAY too high; heres a link - http://www.hobbycity.com/hobbycity/s...idProduct=8478

When I drove it, it would have a very hard time starting up and syncing. Once it got movin, it was movin. One of the last runs I got to probably 40+mph and it spun out or lost range and flew almost under a guys running lawn mower.[X(] He thought I was on crack when I walked through his lawn to get it.

I would like to use it inside, so half or less kv is needed. I have no clue what gauge is on there and what gauge I need. I also don't know if it's a star or delta wind, or how many turns it is.

Your help is appreciated![8D]

#12

Senior Member

Join Date: Dec 2004

Location: Napoleon, OH

Posts: 1,617

Likes: 0

Received 0 Likes

on

0 Posts

Just a few random thoughts. Hopefully Ron will check and confirm the accuracy of my statements. (It's been a while since I last constructed a motor.)

That motor appears to have a Delta wind. Pairs of wires are connected together and go to the speed controller. In a star (also known a Wye) termination, a single wire from each phase goes to the controller.

Rewinding with the same gauge wire and the same number of turns but using a star termination will lower kV by a factor of 1.73.

Since you plan to rewind the motor anyway, you can count the number of turns as you remove the old wire.

To determine the wire gauge of the existing windngs, obtain (buy or borrow) a caliper to measure the diameter of the wire. There are plenty of sites on the web that list the diameter for any gauge of wire. Here's one:

http://www.powerstream.com/Wire_Size.htm

And here's an good site that summarizes all of these topics:

http://www.bavaria-direct.co.za/models/motor_info.htm

To keep it simple, I'd probably use the same gauge wire and the same number of turns as the original but use a star termination instead of Delta. This will lower your kV by a factor of 1.73 and give you more torque at the expense of lower top speed.

- Jeff

That motor appears to have a Delta wind. Pairs of wires are connected together and go to the speed controller. In a star (also known a Wye) termination, a single wire from each phase goes to the controller.

Rewinding with the same gauge wire and the same number of turns but using a star termination will lower kV by a factor of 1.73.

Since you plan to rewind the motor anyway, you can count the number of turns as you remove the old wire.

To determine the wire gauge of the existing windngs, obtain (buy or borrow) a caliper to measure the diameter of the wire. There are plenty of sites on the web that list the diameter for any gauge of wire. Here's one:

http://www.powerstream.com/Wire_Size.htm

And here's an good site that summarizes all of these topics:

http://www.bavaria-direct.co.za/models/motor_info.htm

To keep it simple, I'd probably use the same gauge wire and the same number of turns as the original but use a star termination instead of Delta. This will lower your kV by a factor of 1.73 and give you more torque at the expense of lower top speed.

- Jeff

#13

Senior Member

Join Date: Jun 2007

Location: Brandon, SD

Posts: 1,684

Likes: 0

Received 0 Likes

on

0 Posts

Sweet! I just tried measuring the wire with my paper caliper and I got about .8mm. Possibly less. That means I have,, wow, about 22-20 gauge wire. Does that sound right?

GB.com only has 26 and 28gauge wire in small spools noob wire, but they have a large spool of 22g noob wire. I might go for that and terminate star. Or would it be easier to go for the smaller wire and terminate delta?

GB.com only has 26 and 28gauge wire in small spools noob wire, but they have a large spool of 22g noob wire. I might go for that and terminate star. Or would it be easier to go for the smaller wire and terminate delta?

#14

Senior Member

Join Date: Dec 2004

Location: Napoleon, OH

Posts: 1,617

Likes: 0

Received 0 Likes

on

0 Posts

As much as I like the folks at GoBrushless.com, it's not the only source for wire. For example, Don Armstrong at Strong RC Motors sells many gauges in small quantities:

http://www.strongrcmotors.com/Wire.htm

There are plenty of other places to purchase wire. Do a search for magnet wire.

You could go to #24 wire and still terminate as star. You might be able to get a few more turns with this gauge, further reducing the kV, which is one of your goals. You are always better off using the largest wire you can to accomplish your performance goal. To quote from Ron's post: "more/thicker copper in the slot: -> lower copperwire resistance -> higher efficiency -> higher power/weight ratio and/or lower temperature."

Winding with small wire may be easier on your fingers, but in this case, the larger wire is preferred.

- Jeff

http://www.strongrcmotors.com/Wire.htm

There are plenty of other places to purchase wire. Do a search for magnet wire.

You could go to #24 wire and still terminate as star. You might be able to get a few more turns with this gauge, further reducing the kV, which is one of your goals. You are always better off using the largest wire you can to accomplish your performance goal. To quote from Ron's post: "more/thicker copper in the slot: -> lower copperwire resistance -> higher efficiency -> higher power/weight ratio and/or lower temperature."

Winding with small wire may be easier on your fingers, but in this case, the larger wire is preferred.

- Jeff

#15

Senior Member

Join Date: Jun 2007

Location: Brandon, SD

Posts: 1,684

Likes: 0

Received 0 Likes

on

0 Posts

I found some at radioshack - http://www.radioshack.com/product/in...ductId=2036277

Only downside is that there isn't double thick insulation. I'll have to be careful.

No shipping looks pretty good. Free and you get it right away.

Also when you get the ends of the wire and get ready to solder, how do you get the insulation off? Scrape it? Burn it?

Only downside is that there isn't double thick insulation. I'll have to be careful.

No shipping looks pretty good. Free and you get it right away.

Also when you get the ends of the wire and get ready to solder, how do you get the insulation off? Scrape it? Burn it?

#16

Senior Member

Join Date: Dec 2004

Location: Napoleon, OH

Posts: 1,617

Likes: 0

Received 0 Likes

on

0 Posts

I've used the Radio Shack wire myself. I think the insulation is a bit thinner than on the GB Newbie wire, but otherwise it seems OK. You are limited to 22, 26, and 30 gauge in their 3-pack. Thinner insulation means you must be more careful not to short out the windings when bending the wire across sharp edges on the stator.

To remove the insulation, I scrape with an Xacto knife, sometimes cleaning up with very fine sandpaper. You can also use an aspirin tablet and a soldering iron to remove the insulation (Google for the actual technique). The fumes are dangerous, however.

- Jeff

To remove the insulation, I scrape with an Xacto knife, sometimes cleaning up with very fine sandpaper. You can also use an aspirin tablet and a soldering iron to remove the insulation (Google for the actual technique). The fumes are dangerous, however.

- Jeff

#17

Senior Member

Join Date: Jun 2007

Location: Brandon, SD

Posts: 1,684

Likes: 0

Received 0 Likes

on

0 Posts

Thanks man. I'll probably go for some wire I can find locally. I know I can get some at radio shack but I might check the computers stores and other places. I'll probably end up doing 22g star config.

I am doing two motors. If I do the same number of turns on each motor, do you think they'll be pretty close in kv and power? One goes to each wheel so it's pretty important..

I am doing two motors. If I do the same number of turns on each motor, do you think they'll be pretty close in kv and power? One goes to each wheel so it's pretty important..

#18

Senior Member

Join Date: Dec 2004

Location: Napoleon, OH

Posts: 1,617

Likes: 0

Received 0 Likes

on

0 Posts

I am doing two motors. If I do the same number of turns on each motor, do you think they'll be pretty close in kv and power? One goes to each wheel so it's pretty important.

- Jeff

#19

Senior Member

Join Date: Jun 2007

Location: Brandon, SD

Posts: 1,684

Likes: 0

Received 0 Likes

on

0 Posts

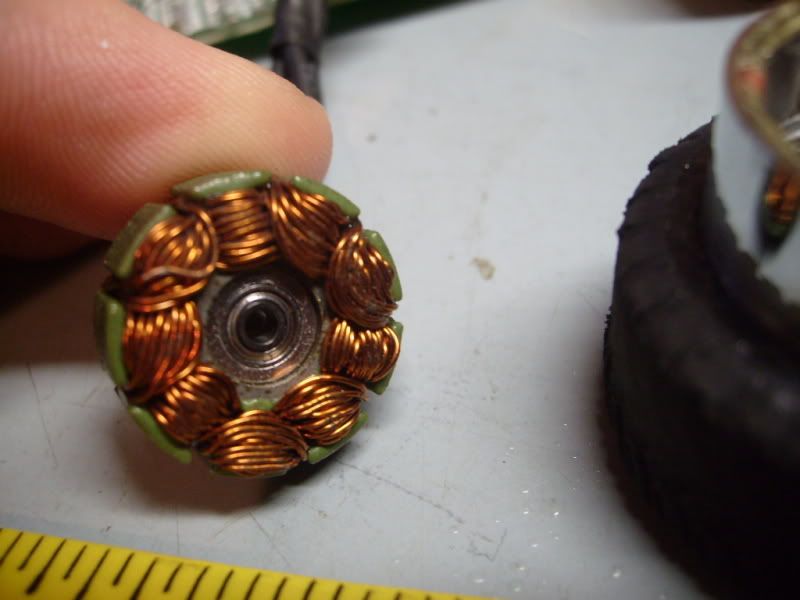

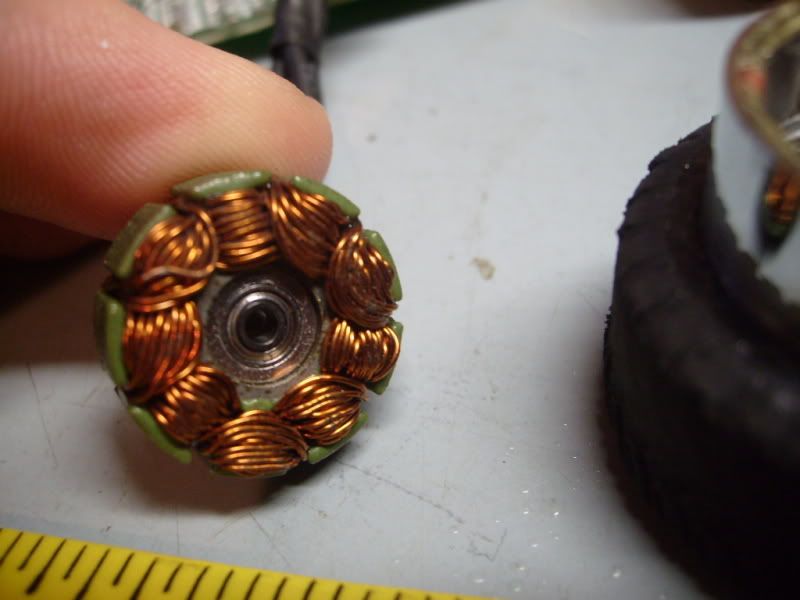

An hour and a half down. One stator clean. First 6 teeth took about 15 minutes. Next two teeth took about 45 minutes. Last tooth took 45 minutes and some serious concentration and anger management. There was some sort of epoxy or glue on the one tooth. That stator suffered a little damage, but I think it'll be ok.

I'll start winding probably tomorrow with the 26awg wire. Turns out 26awg is probably the exact size the original windings used. I hope to be around the 1000-1200kv range.

Here are some pics

And I found I was geared for 75mph with the old 2300kv. [X(]

I'll start winding probably tomorrow with the 26awg wire. Turns out 26awg is probably the exact size the original windings used. I hope to be around the 1000-1200kv range.

Here are some pics

And I found I was geared for 75mph with the old 2300kv. [X(]