tinting epoxy

#1

Thread Starter

Join Date: Jan 2004

Location: Mt. Vernon, IL

Posts: 491

Likes: 0

Received 0 Likes

on

0 Posts

What I want to know is there a way to tint epoxy? Just to make it easier to see how its going on. Maybe it just me but I find it hard to tell when I have enough or too much. West system with .75 cloth turn tranparent and gets lumpy if not very careful.

#2

Senior Member

Join Date: Jun 2003

Location: San Diego, CA

Posts: 691

Likes: 0

Received 0 Likes

on

0 Posts

Of course you can tint the epoxy. There are tints (powder and gel) available from composite places... and even Home Depot has little tubes of red, white, blue... etc. However, if you're working with 3/4 ounce, even tinted epoxy will be rather transparent. What's the application? Have you tried dense foam paint rollers? They work very well for getting even coverage.

-David

-David

#3

Senior Member

My Feedback: (5)

Join Date: Dec 2001

Location: League City,

TX

Posts: 1,007

Likes: 0

Received 0 Likes

on

0 Posts

I've used little 1" chip brushes that I cut the bristles down to a little more than halfway left. This makes the bristles very stiff and I use a dabbing motion to apply the epoxy over the 3/4 cloth. I only aim at getting just enough down to allow the cloth to stick. After I'm done and everything is cured I come back with a second coat of epoxy to fill in the weave, but do the same thing as mentioned previously with the brush. So far I've had very good results.

JR Gautreaux

JR Gautreaux

#4

Senior Member

My Feedback: (12)

Join Date: Nov 2002

Location: Madison, WI,

Posts: 630

Likes: 0

Received 0 Likes

on

0 Posts

The best way I have found to apply the glass cloth is to smooth out the piece as muchas possible then pour a small puddle in the middle and spread the epoxy with a credit card towards the edges. The proper amount is just enough to penetrate the cloth. The glass should not be shiny. Let dry and sand lightly with 80 grit . Next apply an additional coat and once again sand with the 80 grit. Prime and paint.

#5

My Feedback: (5)

ORIGINAL: davidfee

Of course you can tint the epoxy. There are tints (powder and gel) available from composite places... and even Home Depot has little tubes of red, white, blue... etc. However, if you're working with 3/4 ounce, even tinted epoxy will be rather transparent. What's the application? Have you tried dense foam paint rollers? They work very well for getting even coverage.

Of course you can tint the epoxy. There are tints (powder and gel) available from composite places... and even Home Depot has little tubes of red, white, blue... etc. However, if you're working with 3/4 ounce, even tinted epoxy will be rather transparent. What's the application? Have you tried dense foam paint rollers? They work very well for getting even coverage.

In my case, I once long ago tried to add West Systems pigment to Bondo-brand Marine epoxy. Long story short, the epoxy, which should have dried in 24 hours took weeks to finally cure and even then it never 'stiffened up' and instead remained mostly rubbery, which of course, made it unusable for the intended purpose.

So, unless you're using a (liquid or gel) pigment that comes from the manufacturer of the epoxy, stick with the dry, pure artist's pigment as it contains nothing but pigment. (No binder, no suspending medium)

YMMV,

Dan

#6

Senior Member

Join Date: Jun 2003

Location: San Diego, CA

Posts: 691

Likes: 0

Received 0 Likes

on

0 Posts

Dan, you're 100% correct. Even with gel pigments from the epoxy manyfacturer you must be careful to follow the instructions. It's tempting to add a lot of pigment to get good opacity but, add too much pigment and your epoxy doesn't cure properly. Dry powders are safest.

The gel colorants I got at Home Depot say they are compatible with both epoxy and polyester (sold primarily for polyester). I'm not sure exactly what they are made of. They work fine, but are not very opaque (limited to <10% by weight). The stuff I got from an epoxy company said it had an epoxy resin base.

The gel colorants I got at Home Depot say they are compatible with both epoxy and polyester (sold primarily for polyester). I'm not sure exactly what they are made of. They work fine, but are not very opaque (limited to <10% by weight). The stuff I got from an epoxy company said it had an epoxy resin base.

#7

My Feedback: (2)

Join Date: Jul 2002

Location: Calgary, AB, CANADA

Posts: 401

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: DanSavage

As I'm sure you're already aware, not all pigments are created equal. If you're using pure artist's pigment in dry form, you're pretty safe. But, if you're using anything else you have to be sure that the medium suspending the pigment is compatible with the epoxy.

Dan

As I'm sure you're already aware, not all pigments are created equal. If you're using pure artist's pigment in dry form, you're pretty safe. But, if you're using anything else you have to be sure that the medium suspending the pigment is compatible with the epoxy.

Dan

#8

My Feedback: (5)

ORIGINAL: davidfee

Dan, you're 100% correct. Even with gel pigments from the epoxy manyfacturer you must be careful to follow the instructions. It's tempting to add a lot of pigment to get good opacity but, add too much pigment and your epoxy doesn't cure properly. Dry powders are safest.

The gel colorants I got at Home Depot say they are compatible with both epoxy and polyester (sold primarily for polyester). I'm not sure exactly what they are made of. They work fine, but are not very opaque (limited to <10% by weight). The stuff I got from an epoxy company said it had an epoxy resin base.

Dan, you're 100% correct. Even with gel pigments from the epoxy manyfacturer you must be careful to follow the instructions. It's tempting to add a lot of pigment to get good opacity but, add too much pigment and your epoxy doesn't cure properly. Dry powders are safest.

The gel colorants I got at Home Depot say they are compatible with both epoxy and polyester (sold primarily for polyester). I'm not sure exactly what they are made of. They work fine, but are not very opaque (limited to <10% by weight). The stuff I got from an epoxy company said it had an epoxy resin base.

In my case, even though I was using West System tint for epoxy, it wasn't compatible with Bondo-brand of Marine epoxy, so the final mix never really cured like it should have.

But, you're right when you say that no tint, even artist pigment will make the epoxy completely opaque. I discovered this when I added dry pigment to the resin I was using to mold inlet ducts. Luckily, they're buried inside the fuselage, so having them be a little translucent doesn't affect the quality of the final product, but it does save the builder the trouble of having to paint.

Another nice thing about using artist pigment is that it is chemically inert, so other than thickening the mixed epoxy, it doesn't really matter how much or little you add. It actually goes quite a ways. My usual practice is to add a given amount of pigment to a cup of mixed epoxy. Then as I need more tinted epoxy, I simply mix up more plain epoxy and pour it into the previous tinted and keep working. (I can do this because of the super-long pot life of MGS epoxy and I wouldn't try this with any other brand that has a shorter pot life)

ORIGINAL ptxman

Anyone tried Rit (?sp?) type clothing dye powder? It seems pretty concentrated.

Anyone tried Rit (?sp?) type clothing dye powder? It seems pretty concentrated.

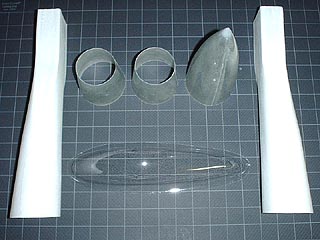

Here's a pic that shows tinted resin:

Dan

#9

Thread Starter

Join Date: Jan 2004

Location: Mt. Vernon, IL

Posts: 491

Likes: 0

Received 0 Likes

on

0 Posts

Wow lokks like I started something my reason for wanting to tint is just to make it a little easier to spread more evenly color doesn't really matter since I will have to paint anyway. I am in the process of glassing a pica fw190d9.

#10

My Feedback: (2)

Join Date: Jul 2002

Location: Calgary, AB, CANADA

Posts: 401

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL:

Here's a pic that shows tinted resin:

Dan

Here's a pic that shows tinted resin:

Dan

So if I go to an art shop & ask for pigment, is there any additional description criteria I should be conveying? What is it typically used for?

#11

My Feedback: (5)

ORIGINAL: ptxman

The white parts I assume?

So if I go to an art shop & ask for pigment, is there any additional description criteria I should be conveying? What is it typically used for?

The white parts I assume?

So if I go to an art shop & ask for pigment, is there any additional description criteria I should be conveying? What is it typically used for?

Yup, that's about it. You ask for pure dry artist pigment or you can ask for dry pigment. Same thing. It usually comes in a jar as a dry powder. There are different manufacturers such as Schmincke and Sennelier, but it's my understanding that Schmincke is considered by many to be the best pigment made.

It is usually created using natural minerals and ground into a fine powder. Titanium white pigment is made from ground-up titanium dioxide. Zinc white is ground-up zinc oxide. Van Dyke brown is ground-up brown coal, etc. Some pigments are made with toxic substances like cadmium and/or chromium, so care must be used when handling so the powder isn't inhaled.

Pigment is what gives all paints their color.

Paint consists of three components: pigment, solvent and binder. The pigment is the color, the solvent keeps the paint in liquid form and the binder is the 'glue' that keeps the pigment from 'washing' away once the solvent has evaporated.

Here's a couple more pics of the tinted inlet ducts. The second one shows what it looks like on the inside.

Dan

#12

My Feedback: (5)

If you want black, West System graphite powder works real well, and is supposed to reduce friction of the cured epoxy. It seems to me that it acts as a *wheting agent* too. Thats a chemical term for something that reduces surface tension of a liquid. Makes it penetrate the fabric more easily.

#13

Senior Member

My Feedback: (3)

Join Date: Sep 2004

Location: Bloomington,

MN

Posts: 133

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: ptxman

So if I go to an art shop & ask for pigment, is there any additional description criteria I should be conveying? What is it typically used for?

So if I go to an art shop & ask for pigment, is there any additional description criteria I should be conveying? What is it typically used for?

Second, while all you have to ask for is 'pigment', ask a few more questions. Highest quality artist pigments are extremely expensive. They are highly saturated (strongly color what they're mixed into) and don't fade for 100's of years. That means they're UV resistant which the resin isn't anyway. To give you an idea of how expensive they can be, some of the blues are actually ground up semi precious gemstone

There are 'student' and/or 'studio' grade pigments. And more modern synthetic pigments and dyes. These are cheaper. Often much cheaper. They may not stretch as far and not be as UV resistant, but you can add a whole lot more of something at $1/lb than you can of something that costs $1000/lb. Also, the colors will vary between the expensive and cheap, but sort of in name only. If you buy the more expensive 'Cadmium Red Light' it will be the same color (a spectrometer might tell the difference but you will not) from mfgr to mfgr and tube to tube, century after century. (These painters are serious about their stuff). The cheaper stuff will be different and have different names, but usually you can find a cheaper color to duplicate the more expensive ones. Real 'Cerulean Blue' vs the cheaper 'Cerulean Blue Hue' for example.

There are even dry pigments meant for making up children's paints which are really cheap. I'd use them in a New York minute if the label said they were pure pigment without vehicle (binder) and after I made a test lamination.

#14

Senior Member

My Feedback: (3)

Join Date: Sep 2004

Location: Bloomington,

MN

Posts: 133

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: TGDF

2 things to watch for in all this: First, its my understanding

(Really big Snip)

There are even dry pigments meant for making up children's paints which are really cheap. I'd use them in a New York minute if the label said they were pure pigment without vehicle (binder) and after I made a test lamination.

ORIGINAL: ptxman

So if I go to an art shop & ask for pigment, is there any additional description criteria I should be conveying? What is it typically used for?

So if I go to an art shop & ask for pigment, is there any additional description criteria I should be conveying? What is it typically used for?

(Really big Snip)

There are even dry pigments meant for making up children's paints which are really cheap. I'd use them in a New York minute if the label said they were pure pigment without vehicle (binder) and after I made a test lamination.

This last few weeks I bought some pigments. The brand was Sennelier. I bought Cadmium red light hue, Cad yellow light hue, Cerulean blue hue, Titanium white and Mars black. With those 3 primary colors you can mix almost any other color. The addition of 'hue' in the name means its not the real, old, expensive, artist formulation as explained in my post above. Its a modern, less expensive, chemical substitute. The white and black are very high quality, 'real' colors as one might say. The white is an oxide of titanium, the black is an oxide of iron. Black and white are produced in such quantities from inexpensive ingredients so they are always inexpensive. Cheap is relative here. They were all $10-16 for 100-120 grams. About 1 cup worth, ea. That's enough to color 1-10 gal depending on what color and how opaque etc.

Here's where the testing advice pays off. That is, always test new stuff. Or at least use the new stuff on small unimportant projects so a flop will not cost an arm and a leg.

The black has been working out fine. The blue also. Just add to the color saturation you want. (That's visual saturation your eye sees, not in the meaning of a saturated solution.) The jury is still out on the red and yellow. So far I made two pieces with these colors. I only used the color so I could see better where I was spreading the epoxy. As I said, test on non critical stuff.

The red started off the proper color, but when I pulled the peel ply off the finished vacuum bagged work, a light, bright red had turned to a deep violet. In fact unless its my imagination, the color has gotten even darker as the resin continued to cure these last 2-3 days. This was a very thin coat of Aeropoxy and 4.3oz e glass over foam core (the paper coated foam board product). I'm going to be putting on a tinted finish coat of micro later today/tomorrow.

The yellow almost immediately went on as yellow with an orange tint. At first I thought it was because the Aeropoxy is a light amber. But it cured to a nice halloween orange. This was a bit thicker 4.3 oz BID e glass over 6 oz UNI e glass on PVC pipe. It too was peel plyed and vacuum bagged. Both pieces were cured at about 100-110F. But I think the color change was a reaction to the epoxy.

Have not tried the white yet. And that doesn't begin to deal with mixing for secondary and tertiary colors.

Anyway, the moral of the story is, either duplicate exactly what somebody you trust has already done, or TEST!