Poulan 33cc Chainsaw Motor

#1

Member

Thread Starter

Join Date: May 2015

Posts: 39

Likes: 0

Received 0 Likes

on

0 Posts

Hello all just wanting some advice on this poulan motor i pulled from an old 33cc chainsaw today. Runs pretty darn good and looking to use it for my airboat build. When i took it out of the chainsaw casing i had to take the cylinder off the piston to get it out of the plastic, do i need to reseal it? Also it has what is referred to as a spring carb i think, can i upgrade to a walbro carb? Does this look to be a good motor to turn a prop and has anyone used one before? Thanks guys

Pics here

http://s1383.photobucket.com/user/ju...?sort=3&page=1

Pics here

http://s1383.photobucket.com/user/ju...?sort=3&page=1

#2

Hello all just wanting some advice on this poulan motor i pulled from an old 33cc chainsaw today. Runs pretty darn good and looking to use it for my airboat build. When i took it out of the chainsaw casing i had to take the cylinder off the piston to get it out of the plastic, do i need to reseal it? Also it has what is referred to as a spring carb i think, can i upgrade to a walbro carb? Does this look to be a good motor to turn a prop and has anyone used one before? Thanks guys

Pics here

http://s1383.photobucket.com/user/ju...?sort=3&page=1

Pics here

http://s1383.photobucket.com/user/ju...?sort=3&page=1

#3

My Feedback: (6)

The Poulan 33cc is a cousin to the 42cc, and I have converted that one. If I remember right though, the magneto mounts to the saw body, so you will need to convert it to electronic ignition. That's best anyway. Yes, you can easily convert it to a Walbro carb. A carb with an 11mm venturi would work, but a 12.7mm venturi would be best, and make sure it has both high and low adjustment needles, as some of the newer carbs don't.

Where it came apart at the crankcase, carefully clean any old sealer off, then apply a new sealer such as Yamabond or Loctite case sealant. Put it back together and you're good to go. (You'll need to shorten the bolts that hold the crankcase halves together.) Try to make the crankshaft end seals seat in the same spot as they were.

It will make you a good engine for your airboat.

AV8TOR

Where it came apart at the crankcase, carefully clean any old sealer off, then apply a new sealer such as Yamabond or Loctite case sealant. Put it back together and you're good to go. (You'll need to shorten the bolts that hold the crankcase halves together.) Try to make the crankshaft end seals seat in the same spot as they were.

It will make you a good engine for your airboat.

AV8TOR

#4

Member

Thread Starter

Join Date: May 2015

Posts: 39

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the adcive gentlemen! Who do i need to talk to about prop hubs etc and also a company to check out for electronic ignition? It has a coil, what i understand it to be, mounted right beside the flywheel.

#5

My Feedback: (6)

If it has a coil mounted beside the flywheel, then it has magneto ignition and you don't need to worry about electronic ignition unless you want to do so. For a prop hub, try www.lambertsrc.com

AV8TOR

AV8TOR

#6

Member

Thread Starter

Join Date: May 2015

Posts: 39

Likes: 0

Received 0 Likes

on

0 Posts

#7

My Feedback: (6)

It appears as I said, there is nowhere to mount the coil on the engine. The coil was mounted to part of the chain saw body. You'll need to fashion a way to mount the coil, (nearly impossible), or convert it to electronic ignition. It is also one of the newer smog engines with a two barrel carburetor. You'll need to fabricate a new manifold arrangement. Block off the upper, smaller hole on the intake manifold, and use only the lower one with your new carb. It appears as though your original carb has both high and low adjustment needles. If so, you could just go ahead and use it, but when you test run it make absolutely sure it will get rich enough, as those carbs are meant to run lean. I've seen a lot of these models burnt up because they run lean and hot.

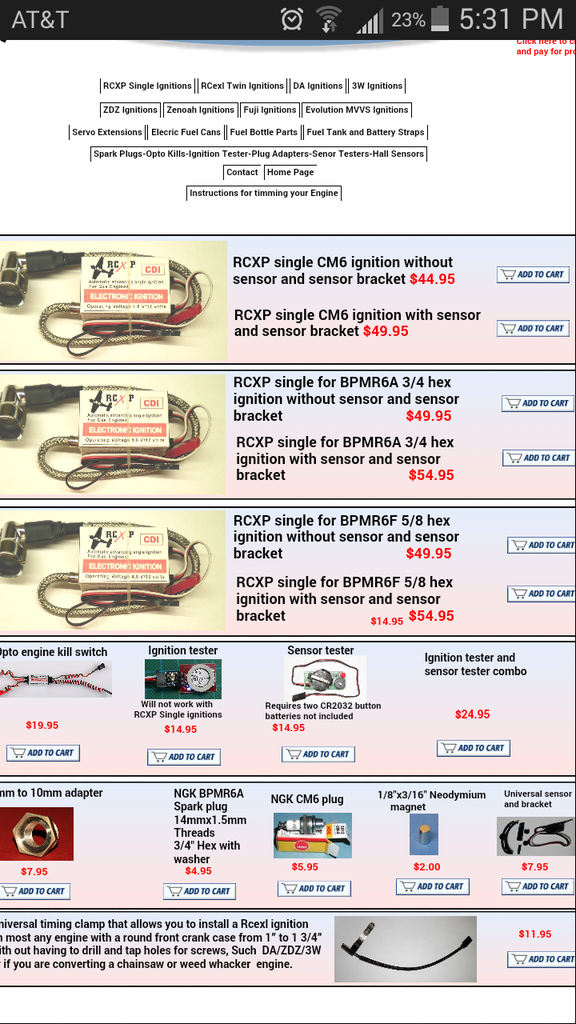

rcextremepower.net/rcxpignitions.html has good prices on electronic ignitions, and it is a worthwhile upgrade. Less weight, easier starting, better idle and often more power. I don't run magneto engines; all mine get converted to electronic. It is also something to consider before purchasing your prop hub, as a prop hub for electronic ignition is configured to hold the sensor magnet and replace the magneto flywheel, instead of just taking place of the magneto nut in front of the magneto flywheel.

Nice pictures!

Edit: For some reason that link I gave you won't work. Try just typing it into your browser. I can access the page from my computer when I do that.

AV8TOR

rcextremepower.net/rcxpignitions.html has good prices on electronic ignitions, and it is a worthwhile upgrade. Less weight, easier starting, better idle and often more power. I don't run magneto engines; all mine get converted to electronic. It is also something to consider before purchasing your prop hub, as a prop hub for electronic ignition is configured to hold the sensor magnet and replace the magneto flywheel, instead of just taking place of the magneto nut in front of the magneto flywheel.

Nice pictures!

Edit: For some reason that link I gave you won't work. Try just typing it into your browser. I can access the page from my computer when I do that.

AV8TOR

Last edited by av8tor1977; 06-20-2015 at 09:33 AM.

#8

Member

Thread Starter

Join Date: May 2015

Posts: 39

Likes: 0

Received 0 Likes

on

0 Posts

I really appreciate the info AV8TOR! When going w the electronic ignition do i need to remove the magnets from the flywheel? I did get ahold of Kenneth Lambert and he advised he could get me squared away on a hub. I suppose i need to let him know ill be running electronic ignition so he can configure a hub w a magnet. Looking forward to getting this thing to spin a prop!!

#9

My Feedback: (6)

Yes, advise Ken immediately that you are going with electronic ignition. It makes a big difference in the type of prop hub used. With electronic ignition, you do not use the magneto flywheel at all. It comes off and gets thrown away in favor of a prop hub configured for electronic ignition.

The prop hubs for electronic ignition incorporate an internal taper to mate with the crankshaft, and are a bit difficult to manufacture. If Ken can't or doesn't want to do it, check back with me. I think I have one here, and some engine mounting brackets too.

AV8TOR

The prop hubs for electronic ignition incorporate an internal taper to mate with the crankshaft, and are a bit difficult to manufacture. If Ken can't or doesn't want to do it, check back with me. I think I have one here, and some engine mounting brackets too.

AV8TOR

Last edited by av8tor1977; 06-20-2015 at 12:50 PM.

#10

Member

Thread Starter

Join Date: May 2015

Posts: 39

Likes: 0

Received 0 Likes

on

0 Posts

Ohh nice the whole flywheel comes.off! I will get back with you for sure if that falls through! As far as electronic ignition, i just need to measure the size of the hex on my spark plug and get the ignition corresponding with that size? That site is reasonably priced.

#14

Member

Thread Starter

Join Date: May 2015

Posts: 39

Likes: 0

Received 0 Likes

on

0 Posts

Not a problem i picked up some aluminum welding solder type stuff today and a good blow torch lol. Going to start mocking up the motor stand/mounts etc. I should be able to figure something with the bracket

#15

Member

Join Date: Feb 2014

Posts: 87

Likes: 0

Received 0 Likes

on

0 Posts

I recently did a serious conversion on A Wild Thing 42 CC motor. I tried using some of that Welding solder on the crankcase and it works on the crankcase but NOT ON THE TOP section. I think the top is Magnesium.

Larry Kopecky

Conyers, Georgia

Larry Kopecky

Conyers, Georgia

#17

Member

Join Date: Feb 2014

Posts: 87

Likes: 0

Received 0 Likes

on

0 Posts

There is a video on You Tube of my motor running on a test stand. look for "CONVERTED 42 CC POULAND MOTOR". My motor really sucked until I put a Frank Bowman ring in it. It picked up 1.500 RPM WOT but doesn't idle as slowly.

#18

Member

Thread Starter

Join Date: May 2015

Posts: 39

Likes: 0

Received 0 Likes

on

0 Posts

Ring as in piston ring? Im thinking of getting a new crank and piston and essentially rebuilding this one. All looks well but idk how long my dad had the chainsaw but i know it cut quite a bit of wood lol.

#19

Member

Join Date: Feb 2014

Posts: 87

Likes: 0

Received 0 Likes

on

0 Posts

The crankshaft, rod, and piston are probably ok. If it doesn't have lots of compression when you are done it will probably improve with a new piston ring. I think it cost $14.00 from Frank Bowman.

Larry Kopecky

Conyers, Georgia.

Larry Kopecky

Conyers, Georgia.

#20

Be very afraid welding around magnesium. It burns with a fury hard to believe, and is almost impossible to put out. Ask me how I know.

Happy Father's Day to all of you out there. Carpe Diem.

Best regards,

Richard

Happy Father's Day to all of you out there. Carpe Diem.

Best regards,

Richard

#21

Member

Thread Starter

Join Date: May 2015

Posts: 39

Likes: 0

Received 0 Likes

on

0 Posts

Without getting a special compression testing tool how does one get a feel of the compression of these small engines? When turning the flywheel, the little pop sound the engine makes from moving air, would this be a good judging point?

#24

An issue typical of all conversion engines is whether or not they have provision for the axial thrust of the prop on the crankshaft bearings. Chainsaw engines are designed for radial loads due to the saw chain; they do not experience axial loads. If the engine has ball bearings, then it is probably ok, balls can absorb axial loads. If roller or needle bearings are used, an additional thrust washer should be fitted. Good luck.

Best regards, Richard

Best regards, Richard

#25

My Feedback: (6)

Good point, but most modern chainsaw engines utilize ball bearings now. His Poulan 33cc has ball bearings.

JWright36 - I will try to get a pic of those mounts posted later today. I strongly advise against doing any welding on the engine at all. The aluminum welding and brazing done with a torch are difficult to do no matter what anyone tells you, and often the welds don't hold up anyway. Besides that, there is the distinct possibility that you will warp an engine component while trying to weld on it. Sorry, but the whole idea is a "recipe for disaster". I will also show you a pic of how the sensor normally mounts when converting an engine such as this to CDI.

As far as compression, the only real way to test it is with the recoil starter hooked up and using a standard compression gauge. 150 psi would be a great engine, 90 psi would be well worn, and 70 psi will barely start, if at all. When doing this, if the engine hasn't been run for a while, give it a shot of WD-40 to help the ring seal as it would with a coating of oil in it when running. Don't use thicker, regular motor or two stroke oil as that will give you a "false high" compression reading, and be sure to block the throttle open while taking the reading if the carb is still mounted.

In lieu of that, you can check the ring gap. Ideally it should be very tight; about .003". Frank Bowman's excellent rings are actually fitted with zero gap.

AV8TOR

JWright36 - I will try to get a pic of those mounts posted later today. I strongly advise against doing any welding on the engine at all. The aluminum welding and brazing done with a torch are difficult to do no matter what anyone tells you, and often the welds don't hold up anyway. Besides that, there is the distinct possibility that you will warp an engine component while trying to weld on it. Sorry, but the whole idea is a "recipe for disaster". I will also show you a pic of how the sensor normally mounts when converting an engine such as this to CDI.

As far as compression, the only real way to test it is with the recoil starter hooked up and using a standard compression gauge. 150 psi would be a great engine, 90 psi would be well worn, and 70 psi will barely start, if at all. When doing this, if the engine hasn't been run for a while, give it a shot of WD-40 to help the ring seal as it would with a coating of oil in it when running. Don't use thicker, regular motor or two stroke oil as that will give you a "false high" compression reading, and be sure to block the throttle open while taking the reading if the carb is still mounted.

In lieu of that, you can check the ring gap. Ideally it should be very tight; about .003". Frank Bowman's excellent rings are actually fitted with zero gap.

AV8TOR

Last edited by av8tor1977; 06-22-2015 at 09:52 AM.