DIY propeller?

#51

Senior Member

My Feedback: (1)

Join Date: Aug 2005

Location: Eugene, Or

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

I ordered a 1/2 gallon of 635, some 4 oz e-glass, partall wax, pva, cabosil and some other stuff to make the molds..

I'll try a few layups with the 635 and see if I need to switch to west for the layups.

I might make the first one just glass so I can make it a plug for a cuffed version.

While I wait for that to arrive I'll get started on the parting board.

I'll try a few layups with the 635 and see if I need to switch to west for the layups.

I might make the first one just glass so I can make it a plug for a cuffed version.

While I wait for that to arrive I'll get started on the parting board.

#52

I am kind of late joining this thread, but I feel I must address the safety issue. I think this has been said aleady, but I will repeat it. If you don't think you can build a safe prop, DON'T. I build racing engines for a living, and when the chasis guy asks me for advice, I usually shrug my shoulders and say I dont know. Outside my area of expertise. I have no plans to make my own prop, but I admire those who do, and I hope I can learn something from the process that I will use later in some other project.

Know your limitations and do not put others in harms way with your mistakes.

Please continue this thread, as it is very educational for those of us that havenever done it.

Scott Mooney

Scott Mooney Racing Engines

Know your limitations and do not put others in harms way with your mistakes.

Please continue this thread, as it is very educational for those of us that havenever done it.

Scott Mooney

Scott Mooney Racing Engines

#53

My Feedback: (43)

One thing to remember about this prop, the original only turned 3300ish RPM on the ground. This is not a 15000 RPM sport prop.

It also has 15" of pitch, so turning it too hard will result in a P-51 cruising along at ballistic speeds not to mention the huge horsepower it will take to turn it that hard. If I can get composite replicas of the stock blades to turn 4000 RPM on the ground, I will be ecstatic. I would worry about the stock spinner before I would would worry about a homemade blade.

It also has 15" of pitch, so turning it too hard will result in a P-51 cruising along at ballistic speeds not to mention the huge horsepower it will take to turn it that hard. If I can get composite replicas of the stock blades to turn 4000 RPM on the ground, I will be ecstatic. I would worry about the stock spinner before I would would worry about a homemade blade.

#54

Senior Member

My Feedback: (1)

Join Date: Aug 2005

Location: Eugene, Or

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

OK all supplies on hand to make molds.. time to get started..

I have 1/2 gallon of 635

Cabosil

West 404

West 423 graphite

blue dye

Partall #2 wax

Partall #10 PVA

Assorted weights of glass down to 3/4 oz.

loads of 3k and 12k carbon acquired through a friend who works in a composite shop. (off cuts and end rolls)

Just to throw a wrench in my plans I have surgery this Tuesday.. We'll see how fast I recover and get working on the molds.

Anyone see an issue with using 12k carbon in the molds? I have a lot of off cuts that were stored folded so it's not in perfect shape.

I have 1/2 gallon of 635

Cabosil

West 404

West 423 graphite

blue dye

Partall #2 wax

Partall #10 PVA

Assorted weights of glass down to 3/4 oz.

loads of 3k and 12k carbon acquired through a friend who works in a composite shop. (off cuts and end rolls)

Just to throw a wrench in my plans I have surgery this Tuesday.. We'll see how fast I recover and get working on the molds.

Anyone see an issue with using 12k carbon in the molds? I have a lot of off cuts that were stored folded so it's not in perfect shape.

#55

My Feedback: (13)

Make sure that the hub is solid enough to tighten without distortion.

Also use continuous composites that tie the blade together from tip to hub.. Avoid small pieces of composite.

I am looking at a new material that can use same glass or silicone type molds, but is a very hard reinforced urethane resin. Can eliminate the need for composites.

First test yields a prop blade way stiffer and stronger than the Byron scale Mustang blades. the material is currently used for RC boat props.

Will update in a week or two.

Steve

Also use continuous composites that tie the blade together from tip to hub.. Avoid small pieces of composite.

I am looking at a new material that can use same glass or silicone type molds, but is a very hard reinforced urethane resin. Can eliminate the need for composites.

First test yields a prop blade way stiffer and stronger than the Byron scale Mustang blades. the material is currently used for RC boat props.

Will update in a week or two.

Steve

#56

Senior Member

My Feedback: (1)

Join Date: Aug 2005

Location: Eugene, Or

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: SCALECRAFT

Make sure that the hub is solid enough to tighten without distortion.

Also use continuous composites that tie the blade together from tip to hub.. Avoid small pieces of composite.

Steve

Make sure that the hub is solid enough to tighten without distortion.

Also use continuous composites that tie the blade together from tip to hub.. Avoid small pieces of composite.

Steve

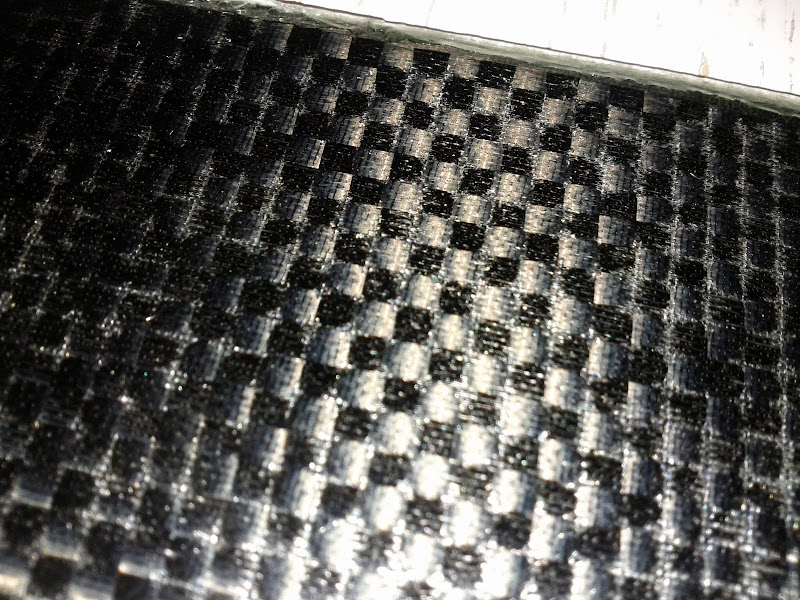

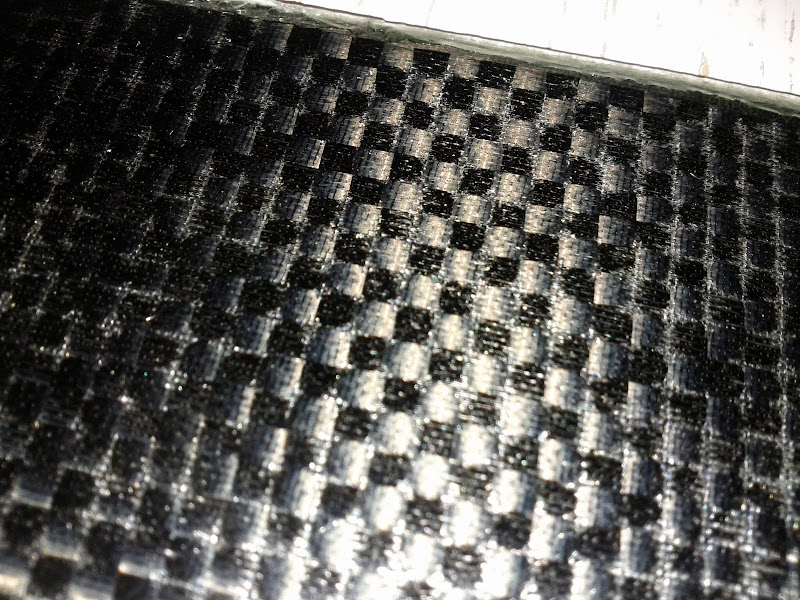

Some pieces of 12k twill were folded so I'll use some of it in the molds..

The current plan is to make a hollow mold prop..

Each half will be 3 layers of 3/4 oz glass. 3k plain weave carbon full length, 12k twill carbon full length then more layers of 12k progressively shorter back to the hub until the hub is solid.. 1 layer of 4oz glass, peel ply, blotting and then into the vac bag.. I may add in a few loops of Kevlar tow to hold it together in case of a prop strike.

after the cure they will be joined using epoxy thickened with 404 and clamped together.

The first piece I pull with be just glass and used to make a cuffed plug like the prop in the attached picture.

#57

My Feedback: (43)

ORIGINAL: SCALECRAFT

Make sure that the hub is solid enough to tighten without distortion.

Also use continuous composites that tie the blade together from tip to hub.. Avoid small pieces of composite.

I am looking at a new material that can use same glass or silicone type molds, but is a very hard reinforced urethane resin. Can eliminate the need for composites.

First test yields a prop blade way stiffer and stronger than the Byron scale Mustang blades. the material is currently used for RC boat props.

Will update in a week or two.

Steve

Make sure that the hub is solid enough to tighten without distortion.

Also use continuous composites that tie the blade together from tip to hub.. Avoid small pieces of composite.

I am looking at a new material that can use same glass or silicone type molds, but is a very hard reinforced urethane resin. Can eliminate the need for composites.

First test yields a prop blade way stiffer and stronger than the Byron scale Mustang blades. the material is currently used for RC boat props.

Will update in a week or two.

Steve

#58

Senior Member

My Feedback: (1)

Join Date: Aug 2005

Location: Eugene, Or

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

Damn.. Same day surgery turned into 5 days in the hospital, a 2nd procedure, 2 CT scans, MRI, Ultrasound, Nuclear imaging, multiple chest Xrays and 3 days whacked out of my mind on hydromorphone.

I'm still on Hydro codeine so I'm in no condition to work with power tools or make critical measurements.

I think my medical bill will far exceed my lifetime RC budget. Thank god for insurance with copay maximums.

I'm still on Hydro codeine so I'm in no condition to work with power tools or make critical measurements.

I think my medical bill will far exceed my lifetime RC budget. Thank god for insurance with copay maximums.

#60

Senior Member

My Feedback: (1)

Join Date: Aug 2005

Location: Eugene, Or

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

Feeling a little better every day! Thanks

I have a parting board plan that won't involve any dangerous tools and can handle the flex of the prop..

More info when I dig some materials out of the storage closet.

I have a parting board plan that won't involve any dangerous tools and can handle the flex of the prop..

More info when I dig some materials out of the storage closet.

#62

Senior Member

My Feedback: (1)

Join Date: Aug 2005

Location: Eugene, Or

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

I'm going with pink foam as the material for the parting board so I setup a quick vertical foam cutter using my workmate, a fiberglass kite rod, car charger and some 33g wire..

works great.

I decided the best way to make a template of the parting line from the prop was to cut out a foam copy and use a pair of dividers to scribe the parting line over to it..

I then traced paper templates and transferred them to the outer shells. then I cut along the parting line template with the hot wire..

I glued the foam to a sheet of 1/2 MDF, bolted the prop down and sanded to fit the parting line.

I'll cover it in packing tape, wax it, bolt int he prop, use clay or cabosil & epoxy to fill in the little gaps and smooth it over..

Then add some hot glue registration dots and get on with the tooling coat.

Comments and tips are always welcome..

works great.

I decided the best way to make a template of the parting line from the prop was to cut out a foam copy and use a pair of dividers to scribe the parting line over to it..

I then traced paper templates and transferred them to the outer shells. then I cut along the parting line template with the hot wire..

I glued the foam to a sheet of 1/2 MDF, bolted the prop down and sanded to fit the parting line.

I'll cover it in packing tape, wax it, bolt int he prop, use clay or cabosil & epoxy to fill in the little gaps and smooth it over..

Then add some hot glue registration dots and get on with the tooling coat.

Comments and tips are always welcome..

#63

Senior Member

My Feedback: (1)

Join Date: Aug 2005

Location: Eugene, Or

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

First tooling layer on using wyowindworks recipe of 404 and 423 graphite powder.

waiting for it to tack up then add the 2nd coat, some tow in the corners and first layers of glass.

waiting for it to tack up then add the 2nd coat, some tow in the corners and first layers of glass.

#64

Senior Member

My Feedback: (1)

Join Date: Aug 2005

Location: Eugene, Or

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

3 coats of tooling down..

the last coat of tooling has 2 layers of 1oz e glass

2 layers of 4 oz

2 more 4oz to go then sand/epoxy mix to bulk it out and then top it off with another 16oz of glass..

think I need more?

Oh yeah.. blue dye has no power over graphite even a tiny amount makes it black as night.

even a tiny amount makes it black as night.

the last coat of tooling has 2 layers of 1oz e glass

2 layers of 4 oz

2 more 4oz to go then sand/epoxy mix to bulk it out and then top it off with another 16oz of glass..

think I need more?

Oh yeah.. blue dye has no power over graphite

even a tiny amount makes it black as night.

even a tiny amount makes it black as night.

#65

Senior Member

My Feedback: (1)

Join Date: Aug 2005

Location: Eugene, Or

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

Progress so far..

I finished the glass, made a foam board box last night and packed in 3/4 lb of sand mixed with 120g of resin.

I topped that with a piece of 4oz and went to bed.. This morning I put on 3 more layers of 4oz and left it to cure.

Now all I need to do is not touch it for 24 hours... easier said then done. I'm itchin to pull the parting board off.

I finished the glass, made a foam board box last night and packed in 3/4 lb of sand mixed with 120g of resin.

I topped that with a piece of 4oz and went to bed.. This morning I put on 3 more layers of 4oz and left it to cure.

Now all I need to do is not touch it for 24 hours... easier said then done. I'm itchin to pull the parting board off.

#67

Scott

Looks good! Will be getting back into R/C again since Baseball. Now have my 4th youth Baseball Hall of Fame Ring from Cooperstown. Had a ball there!

Leroy

Looks good! Will be getting back into R/C again since Baseball. Now have my 4th youth Baseball Hall of Fame Ring from Cooperstown. Had a ball there!

Leroy

#73

Senior Member

My Feedback: (1)

Join Date: Aug 2005

Location: Eugene, Or

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

First test layup is in the bag.. Back half of the prop..

It took longer than I thought.. the resin was starting to kick just as I got the last piece of glass down..

I wasted a bit of time because I didn't have the tow pre cut.. everything else was cut and ready to roll.

I'll remember that next time..

I'll do the front half tomorrow.

It took longer than I thought.. the resin was starting to kick just as I got the last piece of glass down..

I wasted a bit of time because I didn't have the tow pre cut.. everything else was cut and ready to roll.

I'll remember that next time..

I'll do the front half tomorrow.

#74

Senior Member

My Feedback: (1)

Join Date: Aug 2005

Location: Eugene, Or

Posts: 1,152

Likes: 0

Received 0 Likes

on

0 Posts

OK I have some issues but I think I can do better next time..

tiny bubbles.. (and some big ones)

This is the part I was concerned about the most..

I didn't manage to get the glass and carbon down into the mounting lugs.

The are mostly resin and air bubbles.. I put it in the mounting plate and managed to shear the small lugs off without much effort.. I may do a couple hub only layups to work out a method of filling these in..

tiny bubbles.. (and some big ones)

This is the part I was concerned about the most..

I didn't manage to get the glass and carbon down into the mounting lugs.

The are mostly resin and air bubbles.. I put it in the mounting plate and managed to shear the small lugs off without much effort.. I may do a couple hub only layups to work out a method of filling these in..

#75

My Feedback: (43)

I would think that the raised ribs that fit inside the grooves on the back plate would be better off being filled with a thickened epoxy before you start laying cloth? I know on fuselages with details, that is what they do. They fill the grills, vents, and even sharp corners with some sort of thickend epoxy. I am not sure what you should use to thicken it, maybe milled fiber since those ribs need to be somewhat strong and durable.

Do they make a sprayable clear surface coat that you could apply before the cloth layup begins to eliminate the surface bubbles.

Do they make a sprayable clear surface coat that you could apply before the cloth layup begins to eliminate the surface bubbles.