Galeb G2 - new jet made in Serbia

#176

Thread Starter

Hvala Dragane...

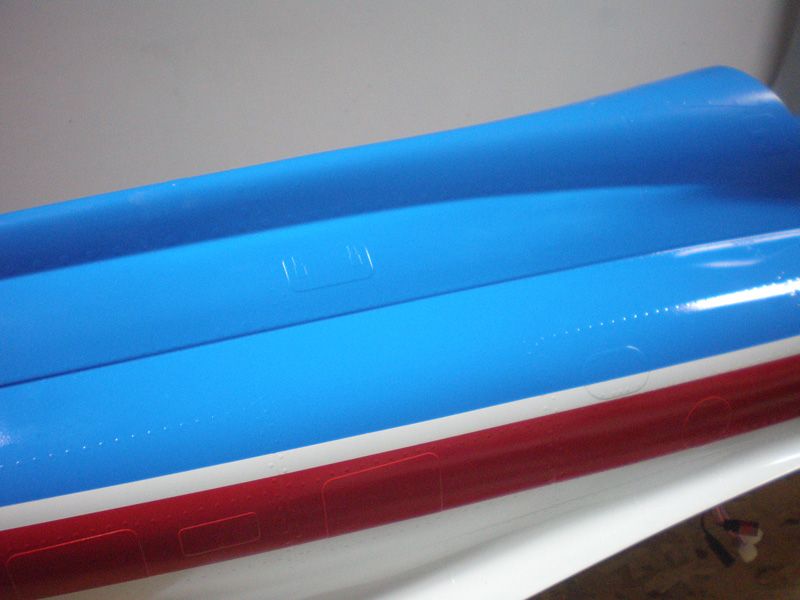

Today we made small photo session on our airfield with real and model of Galeb G2. Full size and 1/5 scale...

Here is first few photos for the beginning... Enjoy...

Regards

Mirce

Today we made small photo session on our airfield with real and model of Galeb G2. Full size and 1/5 scale...

Here is first few photos for the beginning... Enjoy...

Regards

Mirce

#178

Senior Member

Join Date: Dec 2009

Location: Belgrade, SERBIA, YUGOSLAVIA

Posts: 274

Likes: 0

Received 0 Likes

on

0 Posts

I had witnessed the build from the very first moments. Now looking at the final product I can tell you that the pictures show only a very small part from how it looks in real.

Really amazing, and on my shopping list!

Velco

#180

Join Date: Mar 2002

Location: TWICKENHAM, UNITED KINGDOM

Posts: 401

Likes: 0

Received 1 Like

on

1 Post

This is great to see some real modelling as it was before we discovered the "Far East Moulding Company".

Dont get me wrong I am victim of this as well but there is nothing quite like the real construction from start to finish.

I am older and less patient these days and I therefore give up that final feeling of satisfaction derived from cutting wood.

Well done its a great piece of work.

Having said all of the above i would certainly buy a moulded kit of this plane as it would suit my flying style and site perfectly.

How about getting it moulded ??

Regards

David

Dont get me wrong I am victim of this as well but there is nothing quite like the real construction from start to finish.

I am older and less patient these days and I therefore give up that final feeling of satisfaction derived from cutting wood.

Well done its a great piece of work.

Having said all of the above i would certainly buy a moulded kit of this plane as it would suit my flying style and site perfectly.

How about getting it moulded ??

Regards

David

#181

Thread Starter

Thank you for kind words...

David, I don't plan to moulded this model, but can offer to made it, same like I made this model on the pictures.

For now I want to made maiden flight first, and after that start "working" on "marketing".

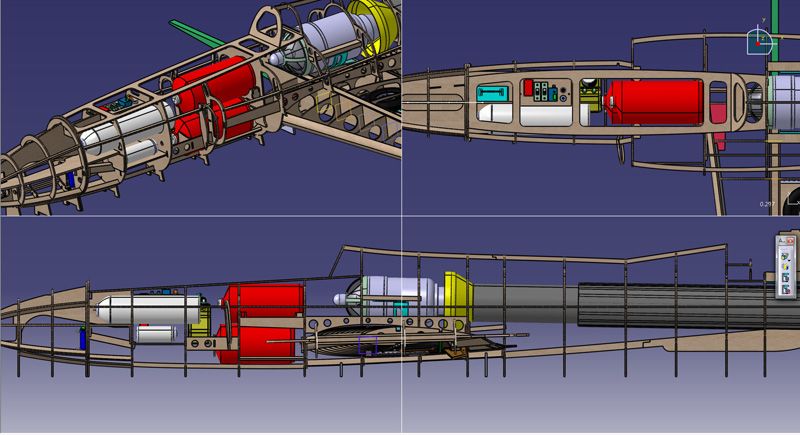

Because Galeb is in this phase, Martin and I made changes on 3D drawings and some parts. Biggest news is that all ply ribs are now from 3mm, not from 4 mm like it was on first model.

Spars will be smaller also. Wing is excessive strong.

With thinner ribs, smaller spars and some other small changes, complete model will be easier.

Yesterday I measure weight, fuselage, with three servos in the tail, is 3640 gr, complete wing with all servos, landing gear, wires... 5340 gr, all other parts which I need to instal is little less than 3500 gr, so total weight is about 12500 gr, dry.

With changes we plan to made, I think that weight can go down between 500 - 1000 gr.

If I compare Galeb with Ziroli Panther, which I have, F9F is 10500 gr dry, but it is much smaller model. So, I'm satisfied with G2 weight. Of course, if it can be lighter, that will be better and I will work on that before first kit go on the market...

For now, few more picture from yesterday and after that we will come back to G2 building...

Dragan, pilot of real G2, was flying yesterday and he made his "program"...

Low, but no slow...

Or this...

What to say, Serbia, everything is possible...

Regards

David, I don't plan to moulded this model, but can offer to made it, same like I made this model on the pictures.

For now I want to made maiden flight first, and after that start "working" on "marketing".

Because Galeb is in this phase, Martin and I made changes on 3D drawings and some parts. Biggest news is that all ply ribs are now from 3mm, not from 4 mm like it was on first model.

Spars will be smaller also. Wing is excessive strong.

With thinner ribs, smaller spars and some other small changes, complete model will be easier.

Yesterday I measure weight, fuselage, with three servos in the tail, is 3640 gr, complete wing with all servos, landing gear, wires... 5340 gr, all other parts which I need to instal is little less than 3500 gr, so total weight is about 12500 gr, dry.

With changes we plan to made, I think that weight can go down between 500 - 1000 gr.

If I compare Galeb with Ziroli Panther, which I have, F9F is 10500 gr dry, but it is much smaller model. So, I'm satisfied with G2 weight. Of course, if it can be lighter, that will be better and I will work on that before first kit go on the market...

For now, few more picture from yesterday and after that we will come back to G2 building...

Dragan, pilot of real G2, was flying yesterday and he made his "program"...

Low, but no slow...

Or this...

What to say, Serbia, everything is possible...

Regards

#182

Join Date: Apr 2006

Location: Carrollton

Posts: 1,698

Likes: 0

Received 0 Likes

on

0 Posts

Hello Mirce,

You know the saying "a picture is worth 1000 words". I can only think of one word - AWESOME ! ! ! I love the pictures of your Galeb with the real one screaming by behind it. I cannot wait to see your model in the air.

Take care,

David

You know the saying "a picture is worth 1000 words". I can only think of one word - AWESOME ! ! ! I love the pictures of your Galeb with the real one screaming by behind it. I cannot wait to see your model in the air.

Take care,

David

#184

Thread Starter

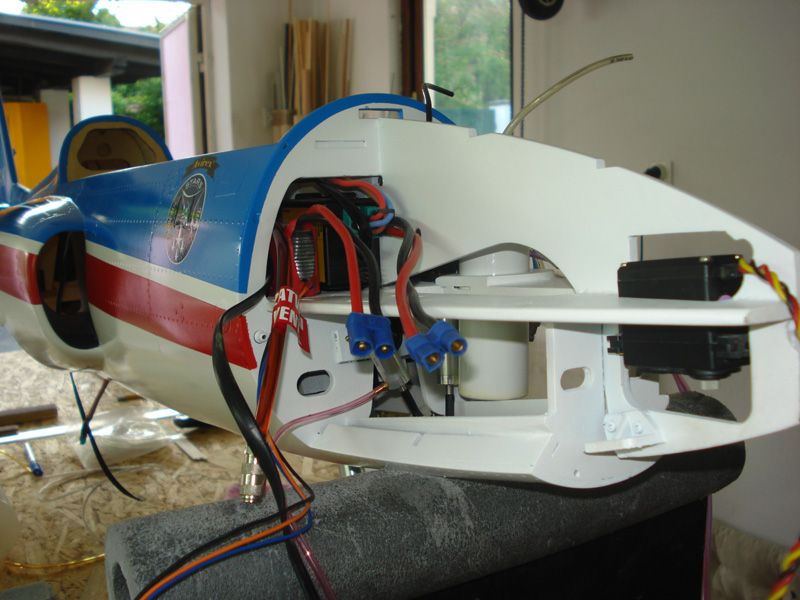

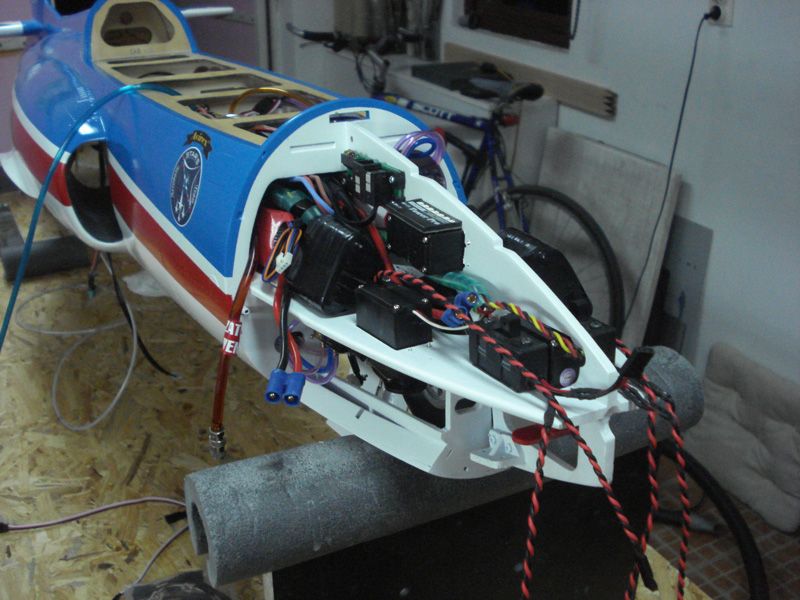

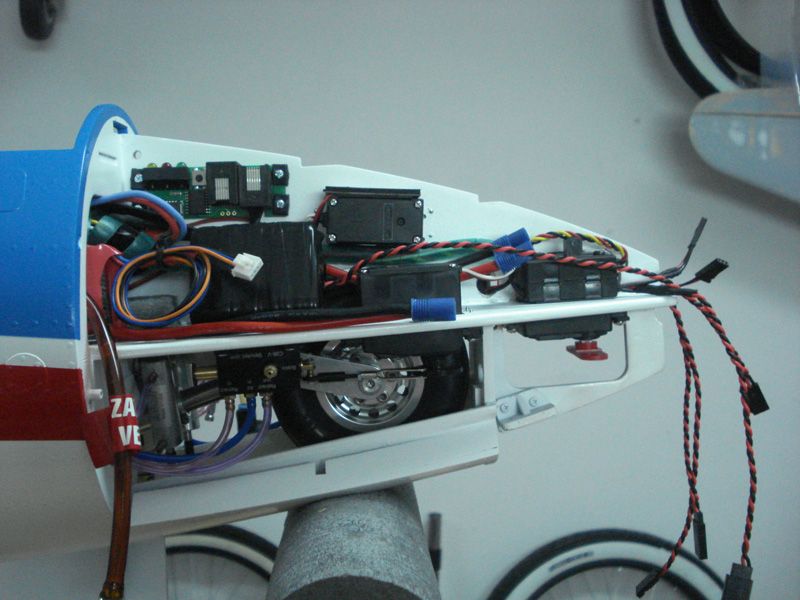

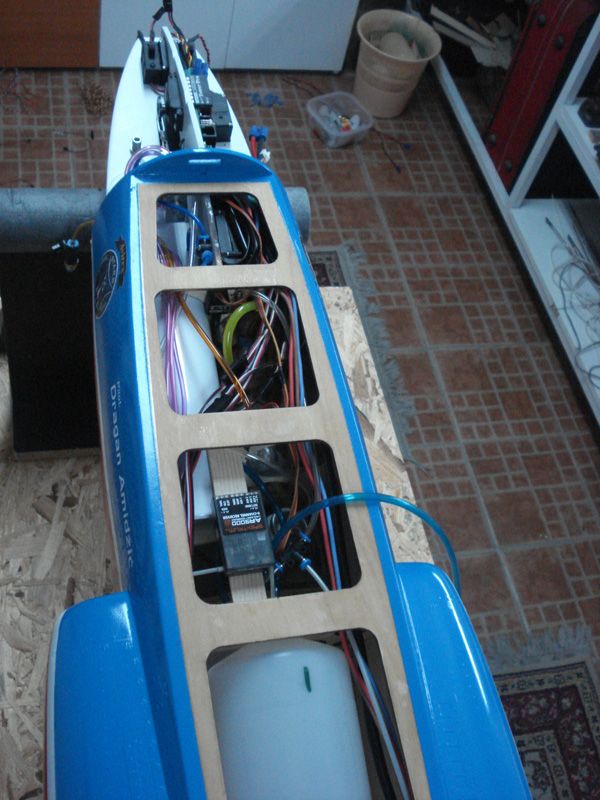

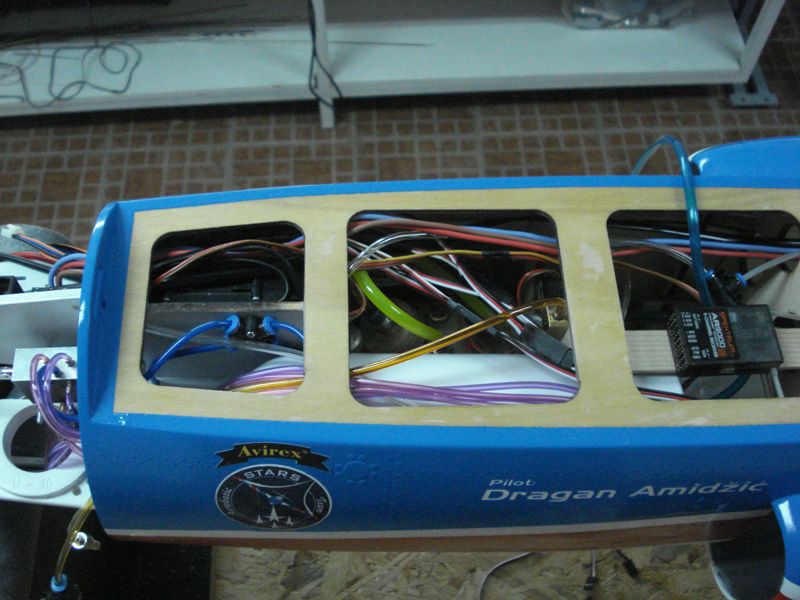

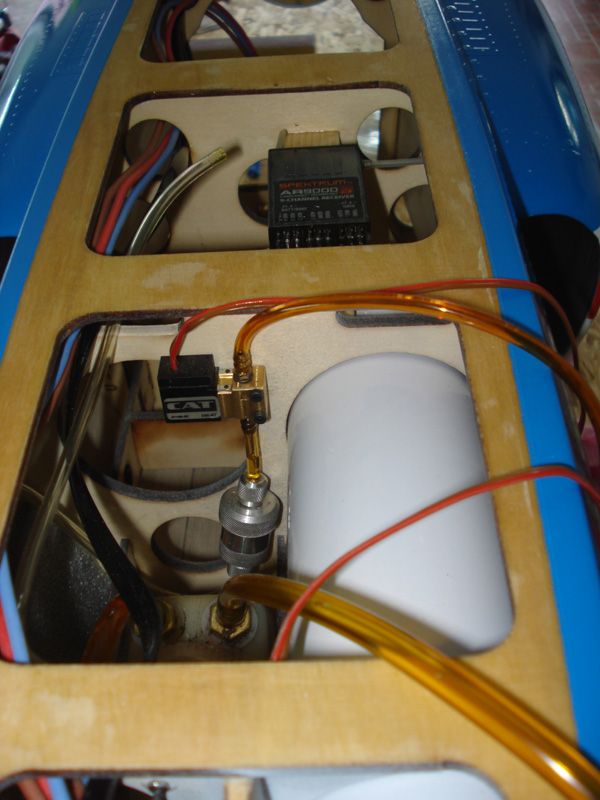

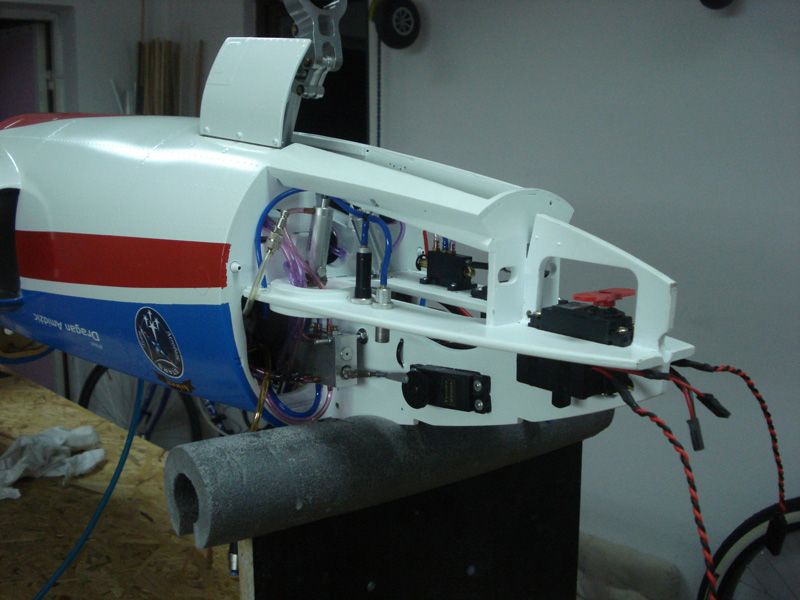

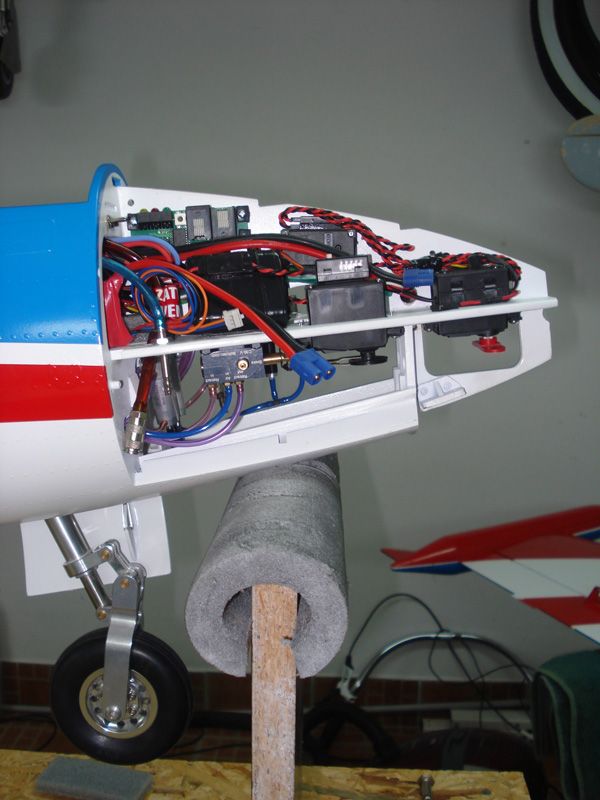

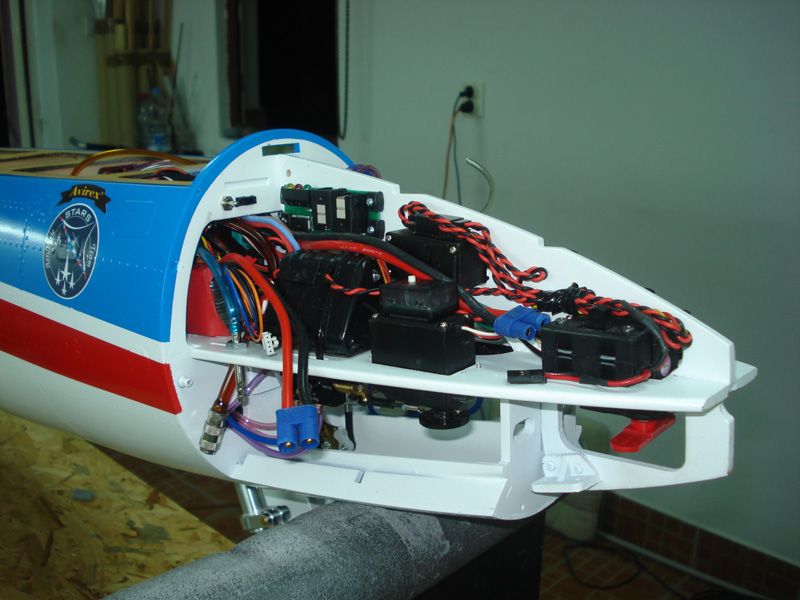

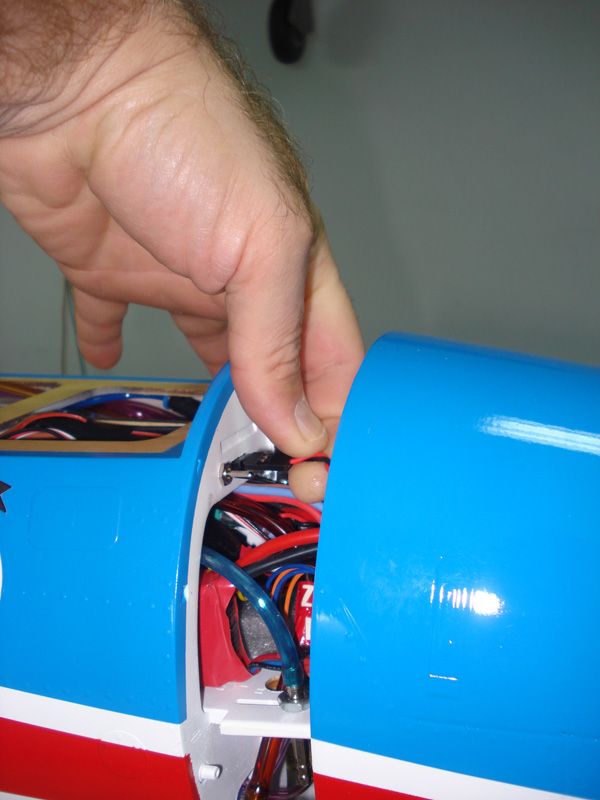

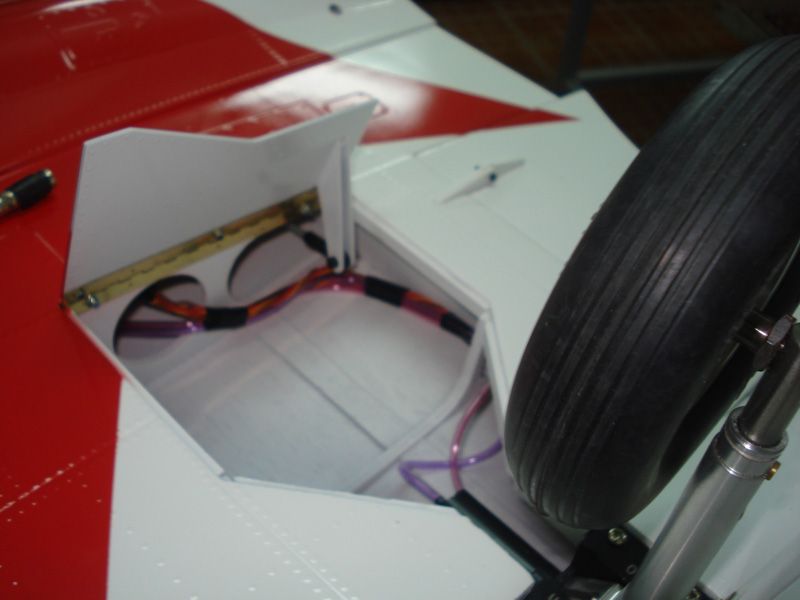

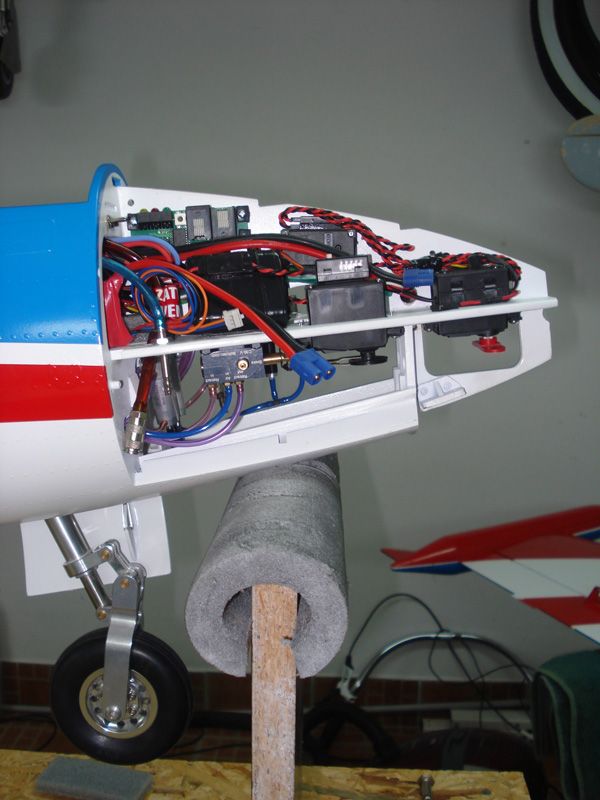

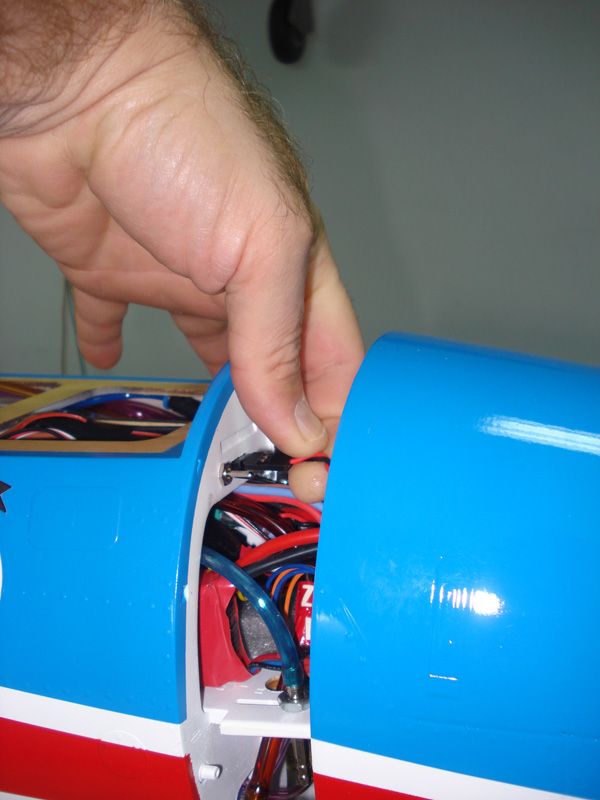

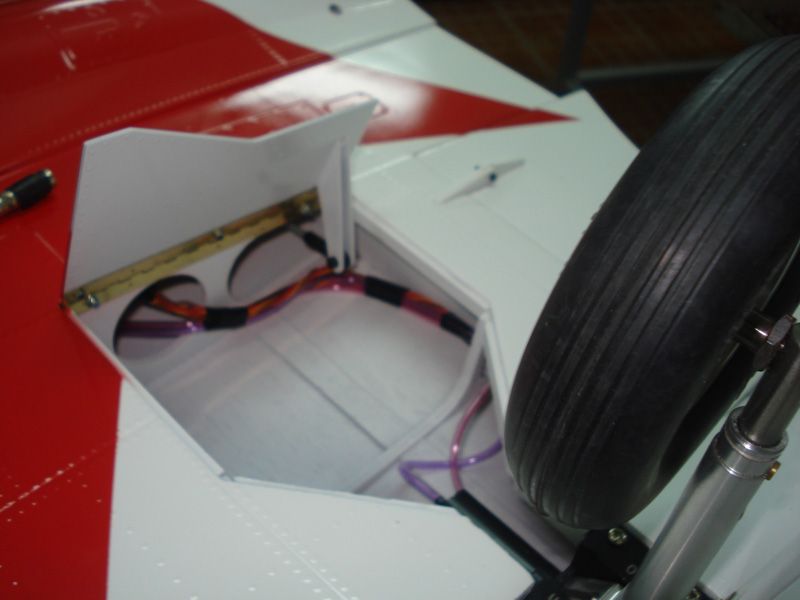

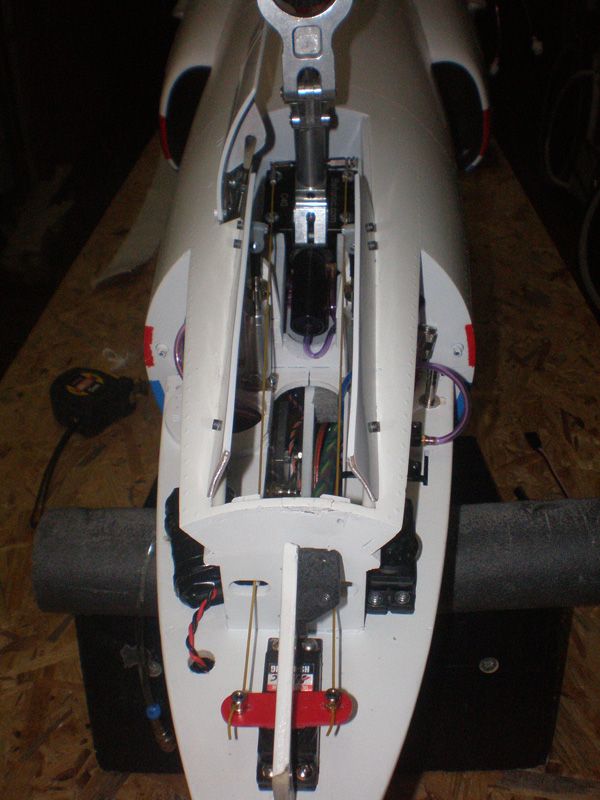

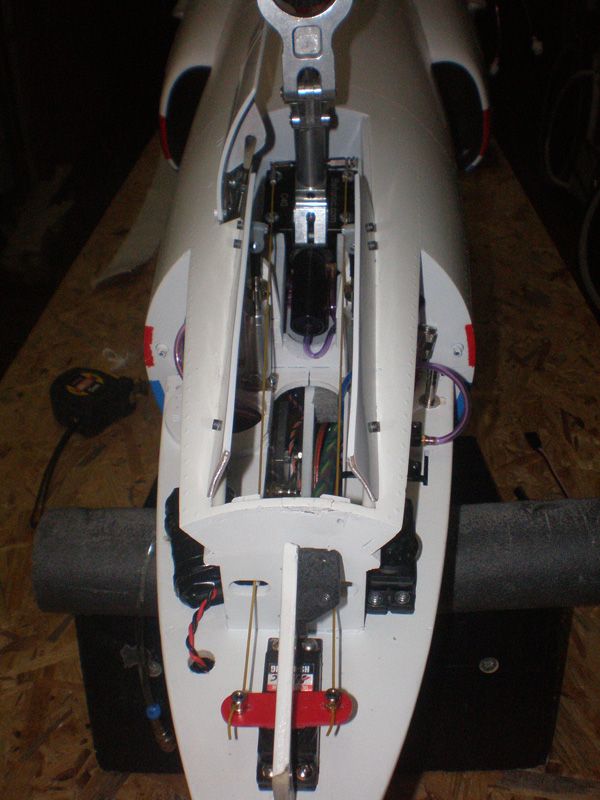

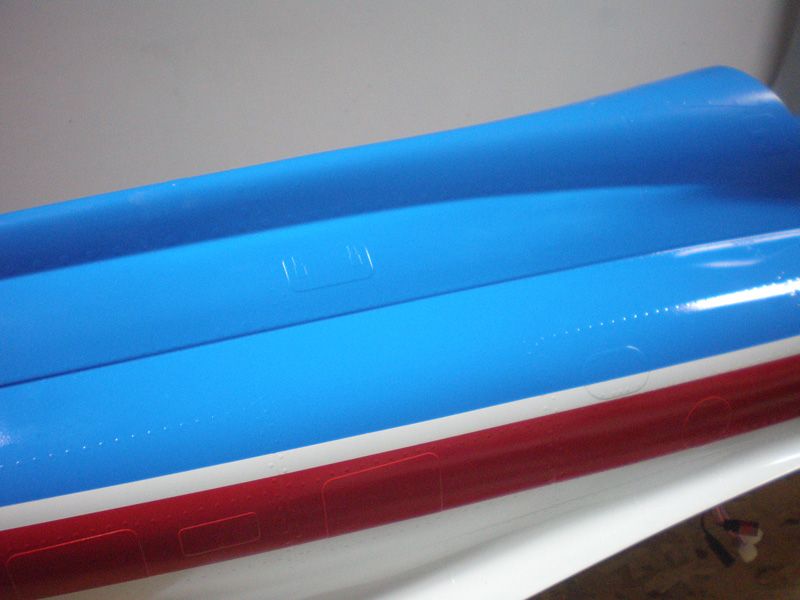

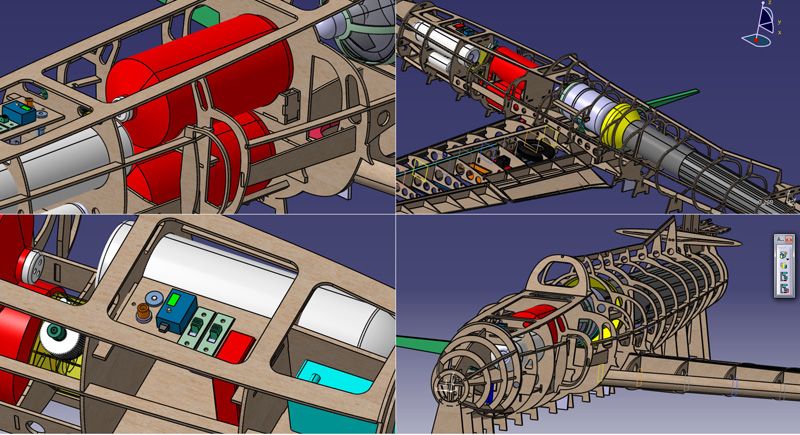

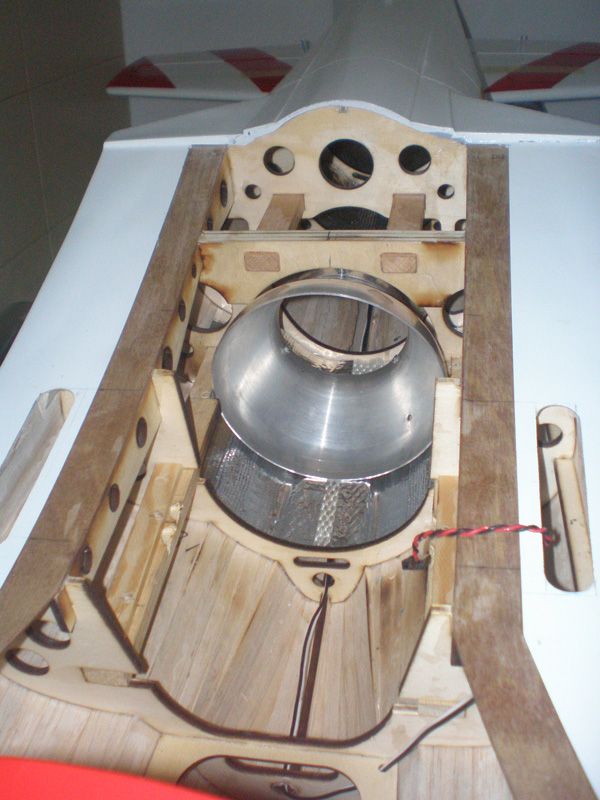

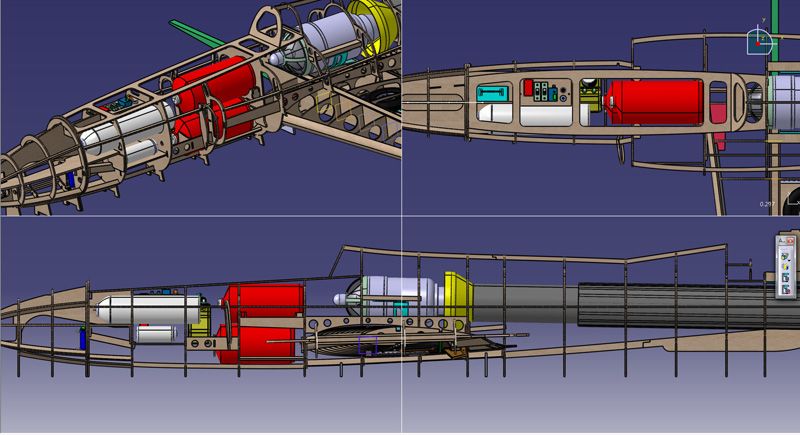

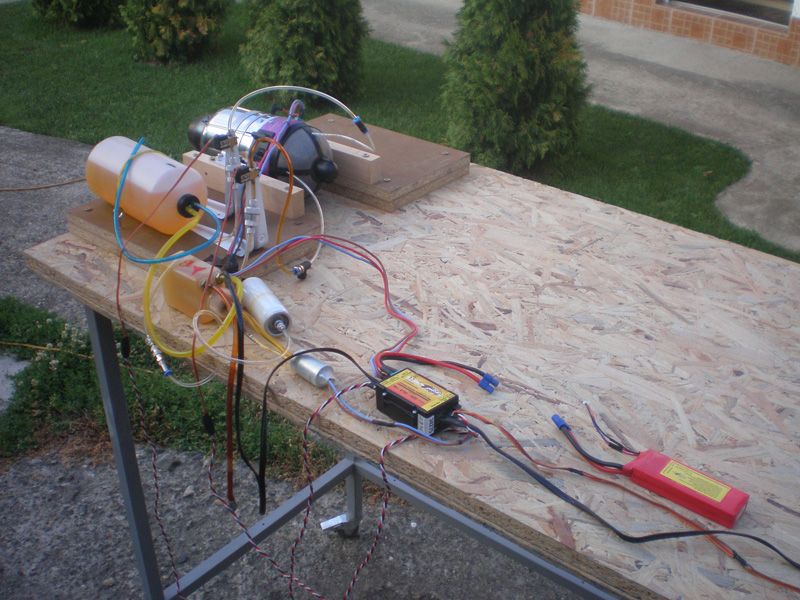

In last few days I worked on the installation of parts in Galeb. This model is 1/5 scale, but fuselage is rather narrow, small diameter, so now is quite busy with parts...

The front part of the body is "designed" for the horizontal and vertical mount bracket as many elements ...

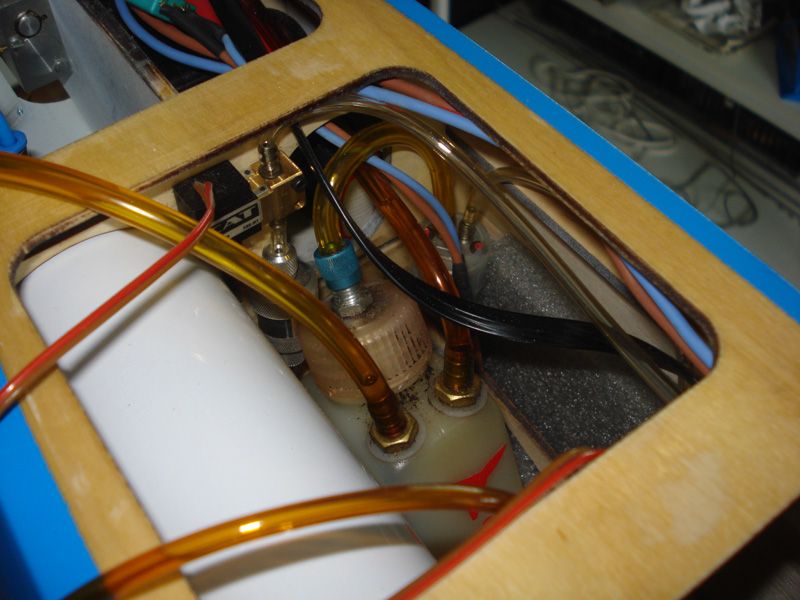

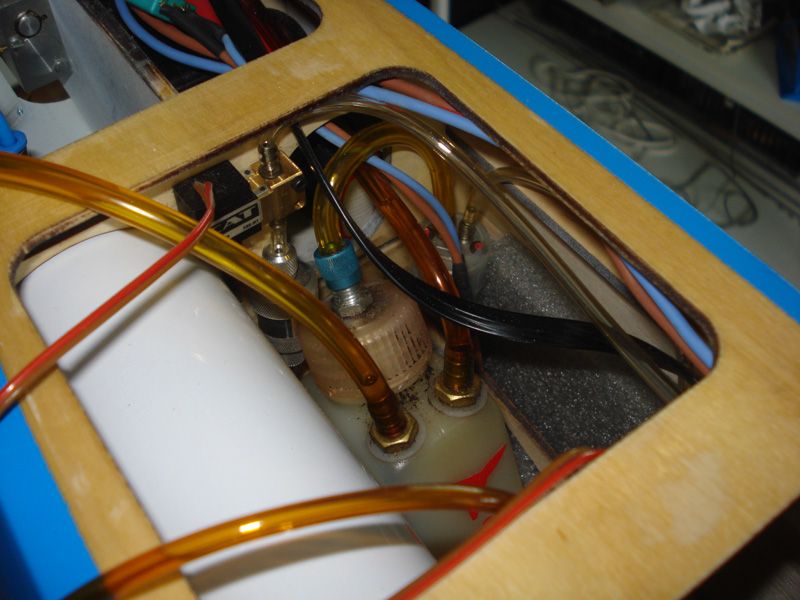

Small 0,1 liter plastic tank, serves to eliminate bubbles in the hose to supply jet fuel to the turbine. The air in the intestine that the "death" of the engine, which is immediately extinguished if an "air cap".

Tank carrier is designed to provide an angle of 45 degrees, because in that position nipples are on the top place and that allows to get almost full tank with no air in the tank ...

In front of the UAT is visible electronic valve for kerosene. The same valve is also behind this thank and used for propane - butane gas during ignition (last picture) ...

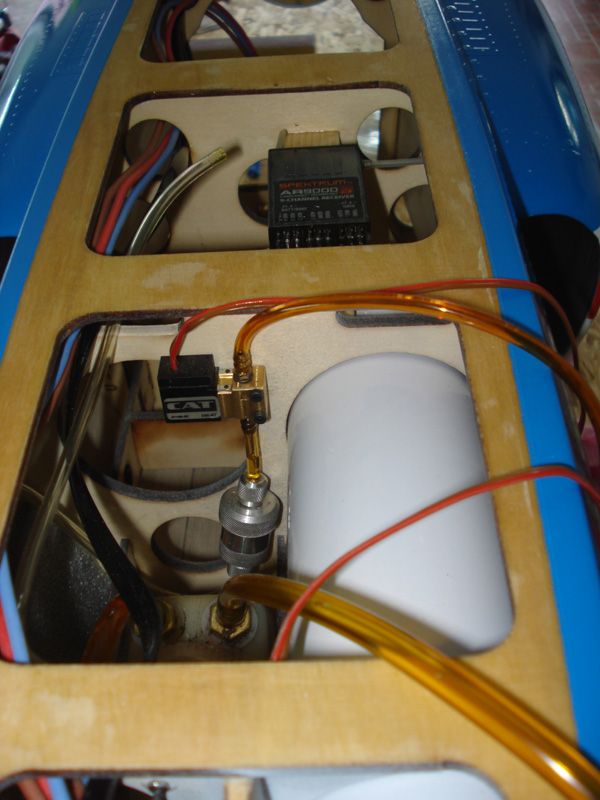

As you can see from the photos, in the "chamber" in front of the UAT, set the ECU (Electronic Control Unit) of the turbine, and next to him LiPo batteries for jet electronics.

Great white bottle is a reservoir of air for a pneumatic system ...

It was planned that the front left side set up a small tank of propane - butane. Right next to it is able to "squeeze" cylinder double door front suspension and traps ...

In the beginning, the way it was assembled, but it turned out to servo moving part and UP2 cylinder moving parts are not in line, so I change that latter...

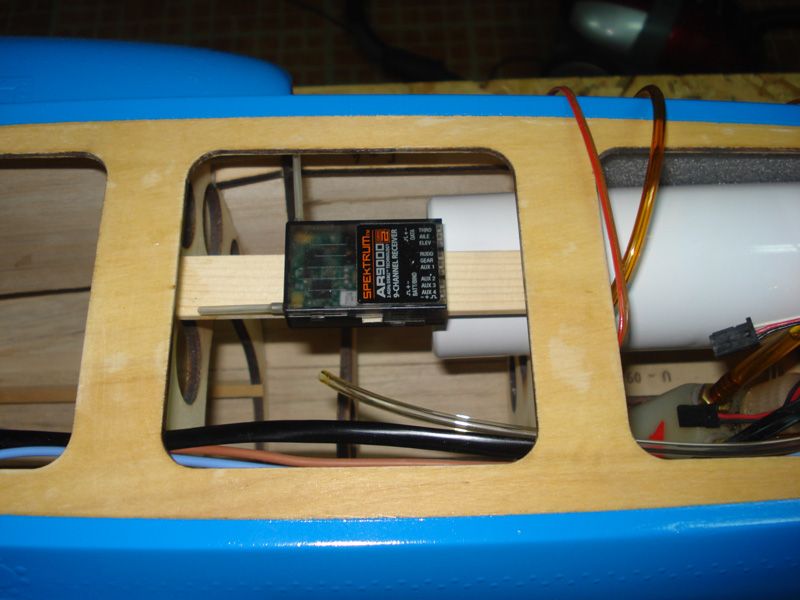

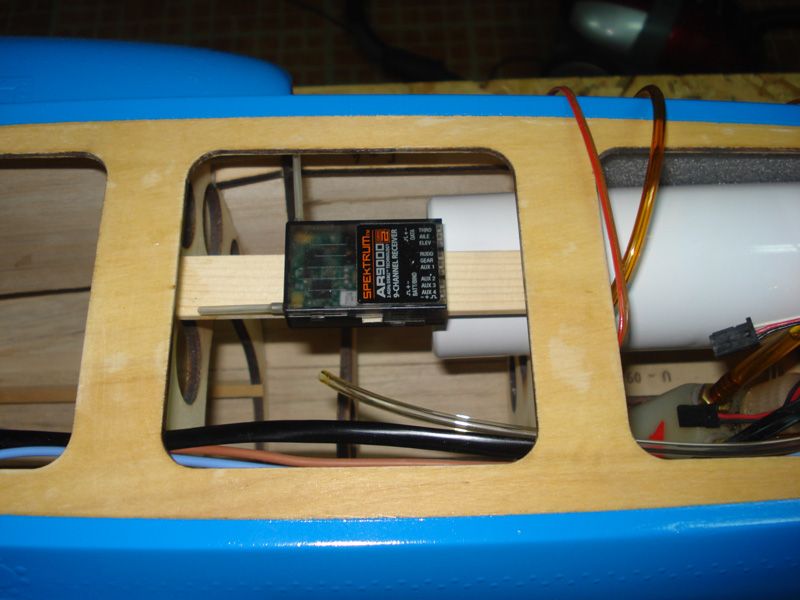

Receiver is behind air tank...

All moving parts are glued. I used R&G 5 minute epoxy glue for this operation. I add little oil on hinges shaft before gluing process...

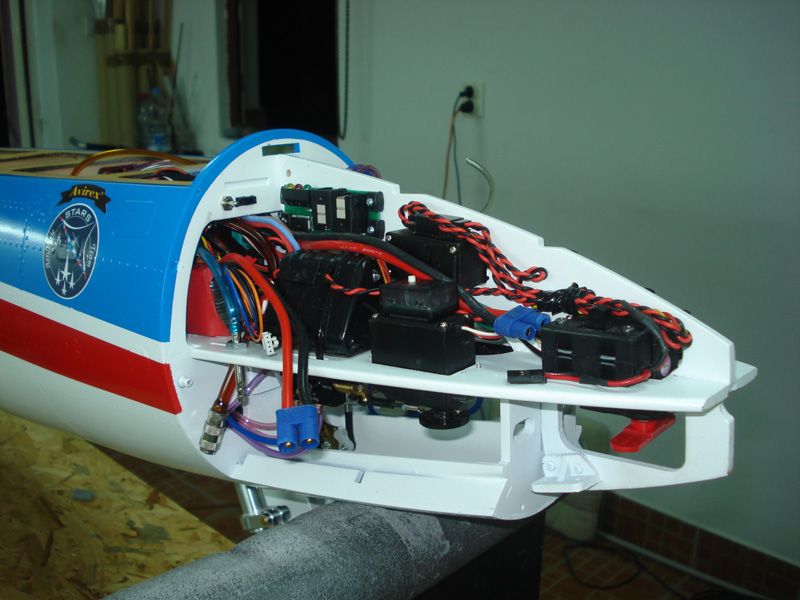

Images that look they were taken during the three days of work, so they are visible to some minor changes.

I realized that will be much better to move air cylinder away from vertical sections, but because that, I had to move a small bottle for propan - butan gas over backwards. Now standing in front of part of the fuel tank ...

Switches are set all the way forward.

I corrected the battery, ie. I soldered a new, shorter cables. Batteries will stand as shown, one on the left and one to the right side.

Servo is set all the way forward, is for the front wheel steering. This is the power of 10 kg and has a metal gear (Hitec HS 645 MG). This is important, because the front trap through cables to manage shocks transmitted to the servo motor ...

On the servo box, that runs a large air cylinder, with double adhesive tape I gluedp voltage indicator. On the right side of the vertical supports, is the electronics of the turbine with LEDs - indicators of the turbine and the board connector for an external unit for Jet Cat engines ...

Servo motor on the right side of the horizontal plate (servo stand up side down) move a second, smaller, air cylinder. This opens a big door of the front retract...

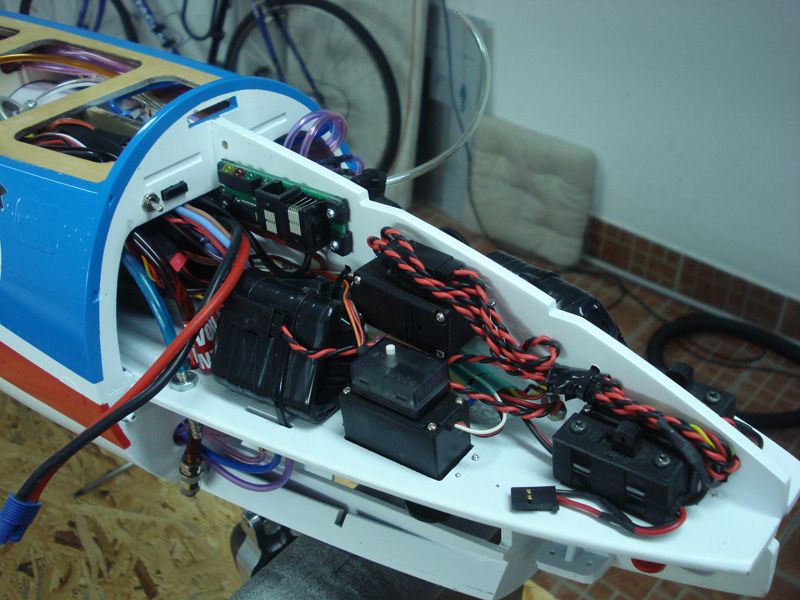

On the bottom it looks like this ...

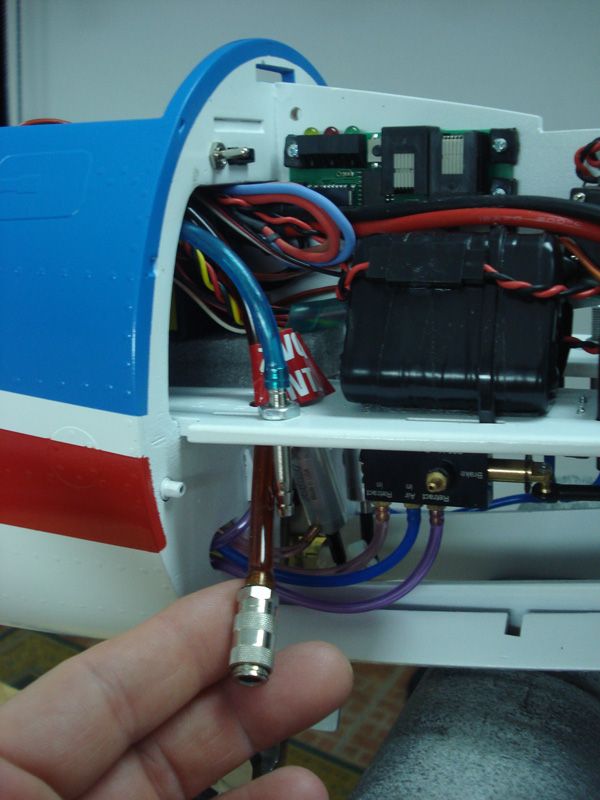

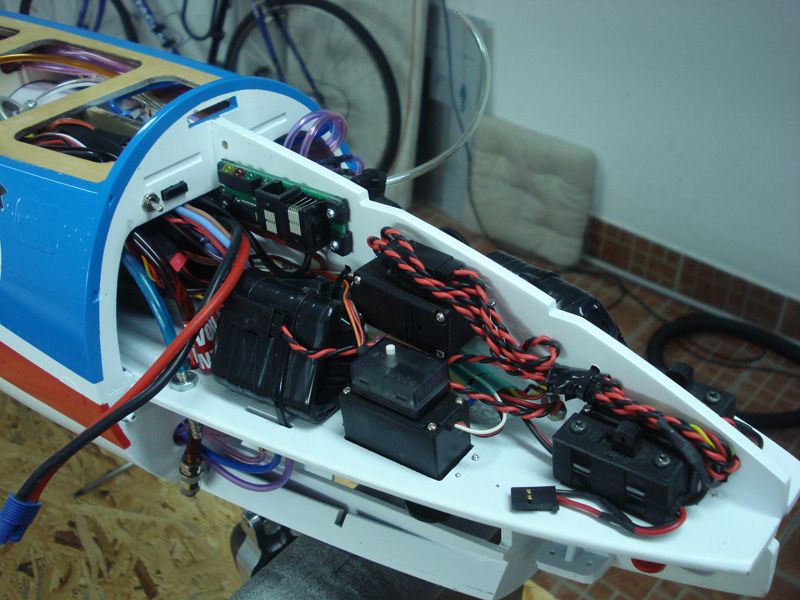

On the other below side, there are parts of the compressed air connection and pressure gauge. In front of this will come two cell battery and a switch, for LEDs - lights on the model ...

Small 1/2" stroke air cylinders for front doors are installed and connected also ...

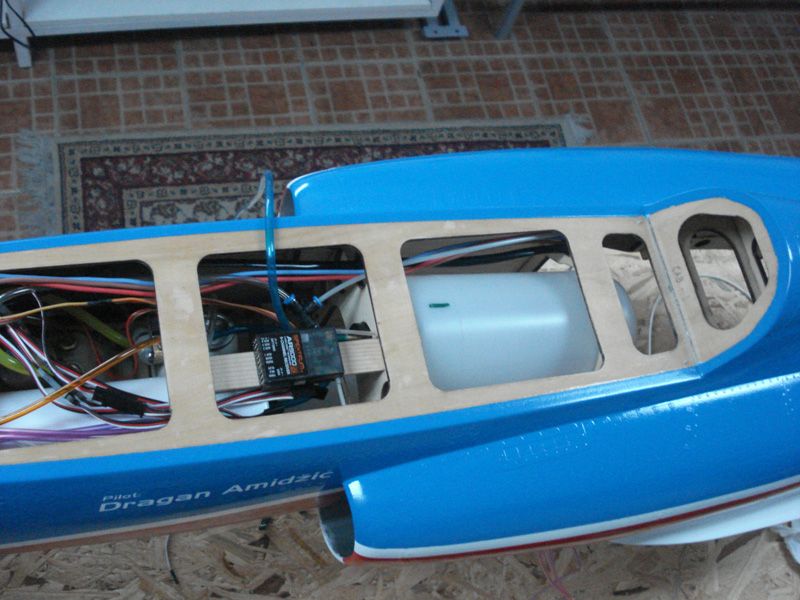

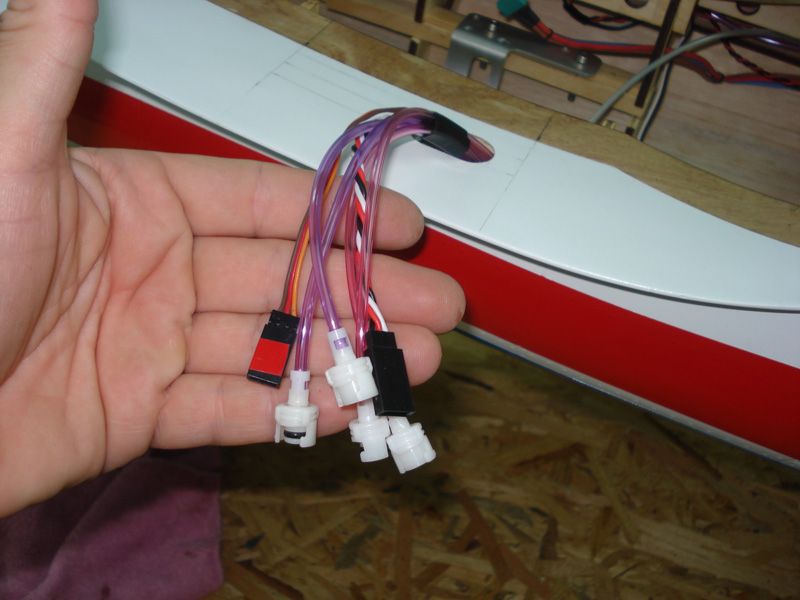

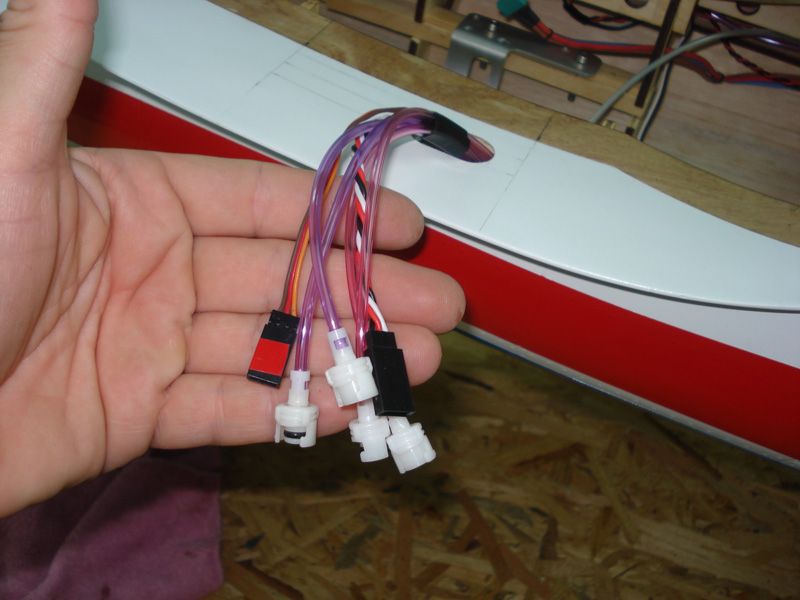

In its place and kerosene tanks. Wires and hoses on the last image are for the turbine and LG in the wings ...

The model was started to be "full" with wires. There are a variety of servos, of the voltage regulator, "crowd" goes from ECU, and there are those of a receiver that powered the entire system ...

As you can see, the idea is that when you take off the front of the fuselage, in that area, will be all the "happening". It will contain all the connections (fuel, air, propane butane), there are a voltage indicator, pressure gauge, and at home, there are wires for recharge the batteries of the receiver and turbine ...

Turbine and exhaust tube have been provisionally appointed to their seats, but about that in the "next issue".

Of course, that did not work "smooth", but pretty much everything is permitted ...

Regards

Mirce

The front part of the body is "designed" for the horizontal and vertical mount bracket as many elements ...

Small 0,1 liter plastic tank, serves to eliminate bubbles in the hose to supply jet fuel to the turbine. The air in the intestine that the "death" of the engine, which is immediately extinguished if an "air cap".

Tank carrier is designed to provide an angle of 45 degrees, because in that position nipples are on the top place and that allows to get almost full tank with no air in the tank ...

In front of the UAT is visible electronic valve for kerosene. The same valve is also behind this thank and used for propane - butane gas during ignition (last picture) ...

As you can see from the photos, in the "chamber" in front of the UAT, set the ECU (Electronic Control Unit) of the turbine, and next to him LiPo batteries for jet electronics.

Great white bottle is a reservoir of air for a pneumatic system ...

It was planned that the front left side set up a small tank of propane - butane. Right next to it is able to "squeeze" cylinder double door front suspension and traps ...

In the beginning, the way it was assembled, but it turned out to servo moving part and UP2 cylinder moving parts are not in line, so I change that latter...

Receiver is behind air tank...

All moving parts are glued. I used R&G 5 minute epoxy glue for this operation. I add little oil on hinges shaft before gluing process...

Images that look they were taken during the three days of work, so they are visible to some minor changes.

I realized that will be much better to move air cylinder away from vertical sections, but because that, I had to move a small bottle for propan - butan gas over backwards. Now standing in front of part of the fuel tank ...

Switches are set all the way forward.

I corrected the battery, ie. I soldered a new, shorter cables. Batteries will stand as shown, one on the left and one to the right side.

Servo is set all the way forward, is for the front wheel steering. This is the power of 10 kg and has a metal gear (Hitec HS 645 MG). This is important, because the front trap through cables to manage shocks transmitted to the servo motor ...

On the servo box, that runs a large air cylinder, with double adhesive tape I gluedp voltage indicator. On the right side of the vertical supports, is the electronics of the turbine with LEDs - indicators of the turbine and the board connector for an external unit for Jet Cat engines ...

Servo motor on the right side of the horizontal plate (servo stand up side down) move a second, smaller, air cylinder. This opens a big door of the front retract...

On the bottom it looks like this ...

On the other below side, there are parts of the compressed air connection and pressure gauge. In front of this will come two cell battery and a switch, for LEDs - lights on the model ...

Small 1/2" stroke air cylinders for front doors are installed and connected also ...

In its place and kerosene tanks. Wires and hoses on the last image are for the turbine and LG in the wings ...

The model was started to be "full" with wires. There are a variety of servos, of the voltage regulator, "crowd" goes from ECU, and there are those of a receiver that powered the entire system ...

As you can see, the idea is that when you take off the front of the fuselage, in that area, will be all the "happening". It will contain all the connections (fuel, air, propane butane), there are a voltage indicator, pressure gauge, and at home, there are wires for recharge the batteries of the receiver and turbine ...

Turbine and exhaust tube have been provisionally appointed to their seats, but about that in the "next issue".

Of course, that did not work "smooth", but pretty much everything is permitted ...

Regards

Mirce

#185

Join Date: Aug 2008

Location: KragujevacSerbia, YUGOSLAVIA

Posts: 202

Likes: 0

Received 0 Likes

on

0 Posts

Last weekend I was visiting Mirce in Novi Sad. Model looks fantastic.

The model is great and I have the impression that it will have less weight than Mirce plans.

Pictures can not show how the model looks in person. So many detalis and color scheme looks phenomenal.

According to what I see model will soon be ready for the first flight, so I wish all the best to Mirce and Galeb for the maiden flight

The model is great and I have the impression that it will have less weight than Mirce plans.

Pictures can not show how the model looks in person. So many detalis and color scheme looks phenomenal.

According to what I see model will soon be ready for the first flight, so I wish all the best to Mirce and Galeb for the maiden flight

#186

Join Date: Apr 2006

Location: Carrollton

Posts: 1,698

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: misha034

According to what I see model will soon be ready for the first flight, so I wish all the best to Mirce and Galeb for the maiden flight

According to what I see model will soon be ready for the first flight, so I wish all the best to Mirce and Galeb for the maiden flight

Take care,

David

#187

Thread Starter

Thanks my friends...

I have a question, on Ziroli web site, on F9F Panther page I saw that model area is 1050 sq inches. Is that with or without elevator area?

I want to made parallel between Panther and Galeb, so Panther is 67,75 sq dm and Galeb wing is 75,60. Elevator on G2 is 17,85 sq dm.

My Panther was 10,5 kilograms dry, and Galeb is 12,5 kilograms.

So, when I divide 10,5 kg with 67,75 sq dm I get 154 gr/sq dm.

On G2 math says, 12,5 kg divide with 75,60 sq dm is 165 gr/sq dm. But if I add elevator area, than load drop on 134 gr/sq dm

Galebs wing is much bigger than Panthers, so I think that information on F9F area are collect wing + elevator. Does someone know that exactly?

Regards

Mirce

I have a question, on Ziroli web site, on F9F Panther page I saw that model area is 1050 sq inches. Is that with or without elevator area?

I want to made parallel between Panther and Galeb, so Panther is 67,75 sq dm and Galeb wing is 75,60. Elevator on G2 is 17,85 sq dm.

My Panther was 10,5 kilograms dry, and Galeb is 12,5 kilograms.

So, when I divide 10,5 kg with 67,75 sq dm I get 154 gr/sq dm.

On G2 math says, 12,5 kg divide with 75,60 sq dm is 165 gr/sq dm. But if I add elevator area, than load drop on 134 gr/sq dm

Galebs wing is much bigger than Panthers, so I think that information on F9F area are collect wing + elevator. Does someone know that exactly?

Regards

Mirce

#188

Join Date: Sep 2007

Location: buenos aires, ARGENTINA

Posts: 181

Received 0 Likes

on

0 Posts

congrats,your work is superb!!!! i don´t know where you use that tower pro battery check,but you should be very carefull.because (+) and (-)terminal leads are soldered very close one to each other n the board,and theres a hi chance of short circuit.i can tell cause my friend lost a 30cc msx because of that.i would remove it .

againg i love your work,it´s state of art

againg i love your work,it´s state of art

#189

Thread Starter

Thank you Robersteam on advice...

I use it in Panther without any problem, but should be careful. After all I have Spectrum Flight Log and will install it in G2. In that case I can check other options too...

Thanks

Mirce

I use it in Panther without any problem, but should be careful. After all I have Spectrum Flight Log and will install it in G2. In that case I can check other options too...

Thanks

Mirce

#190

Thread Starter

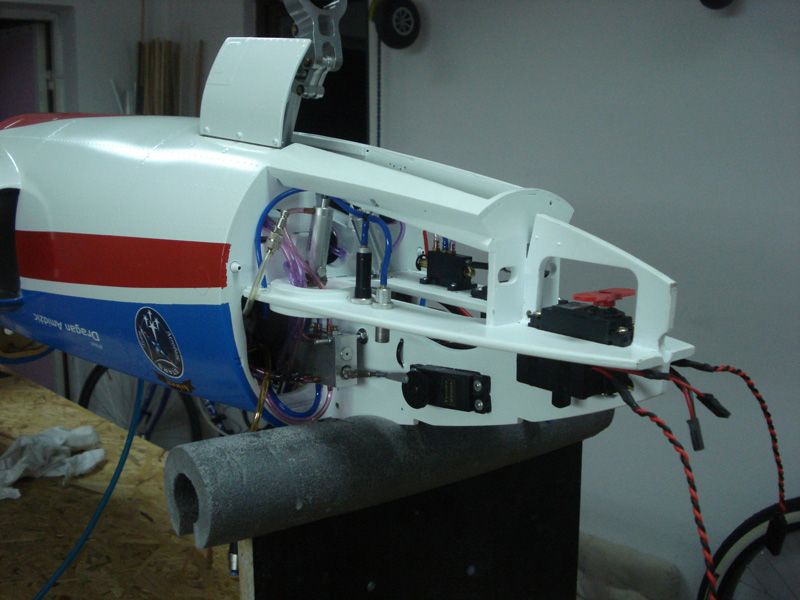

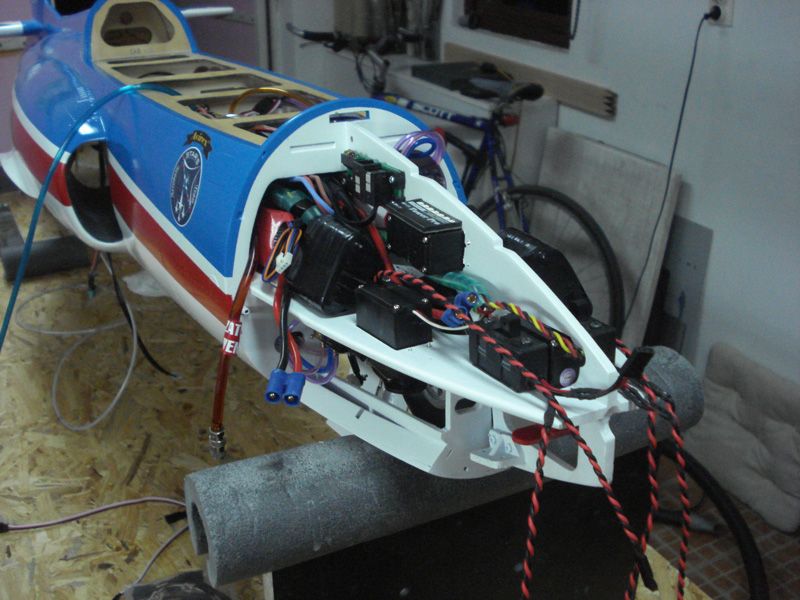

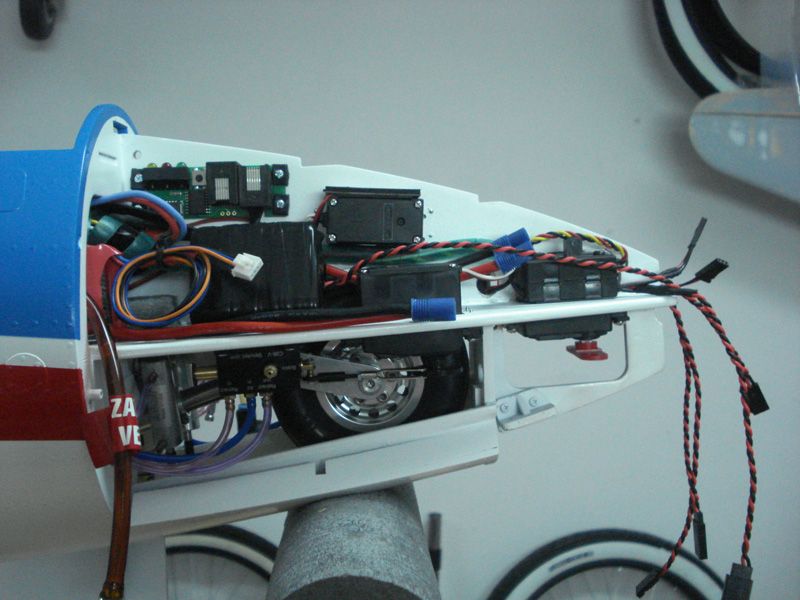

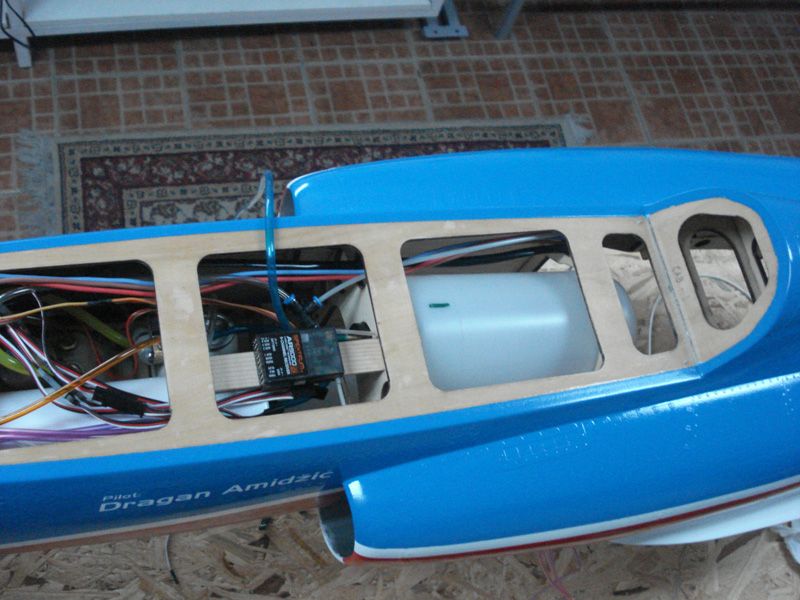

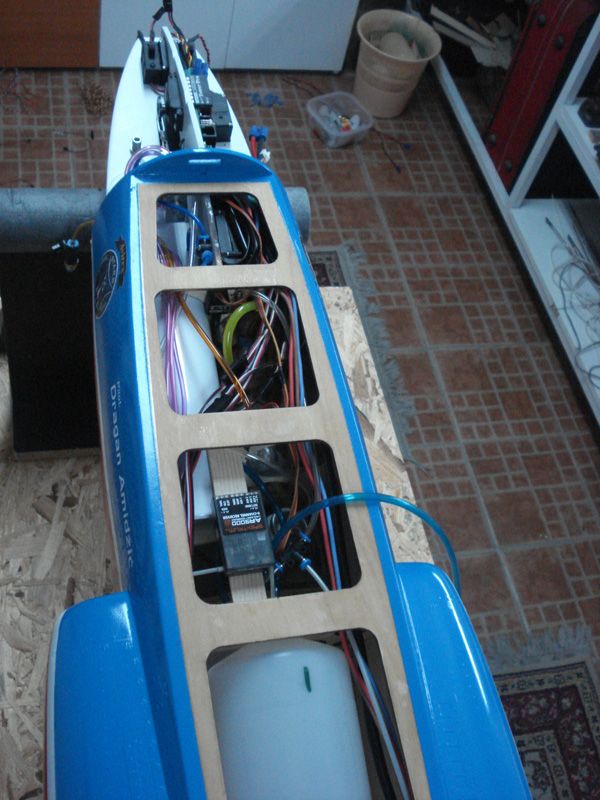

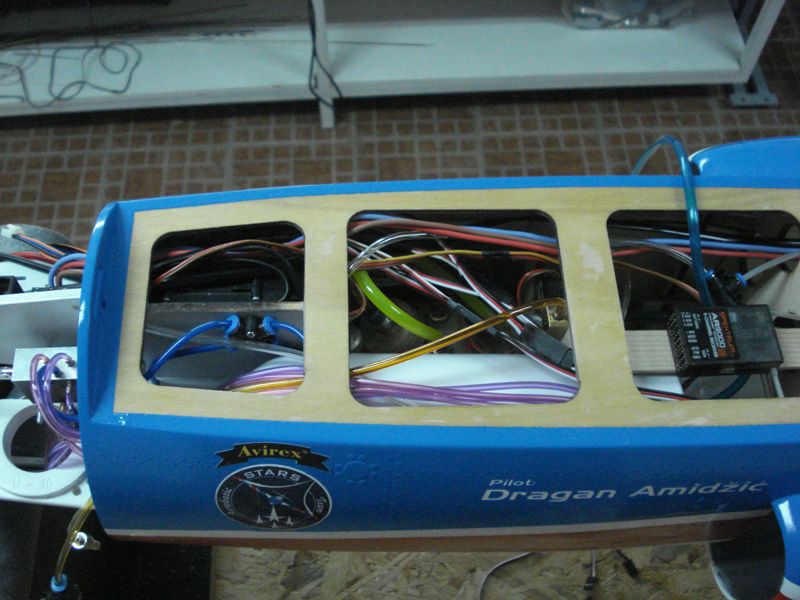

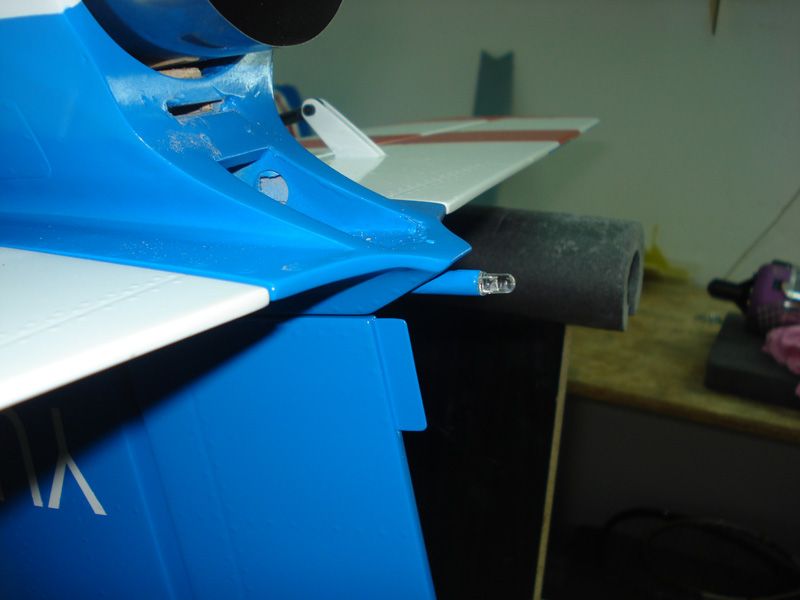

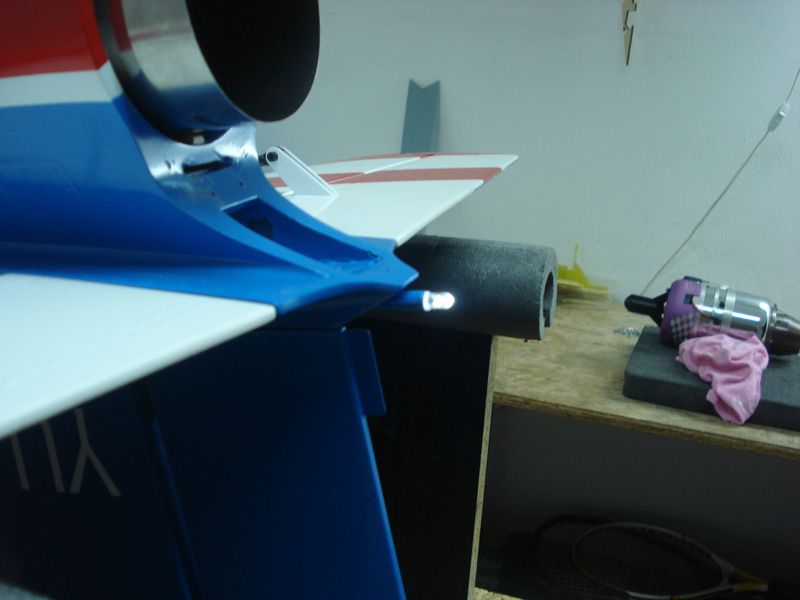

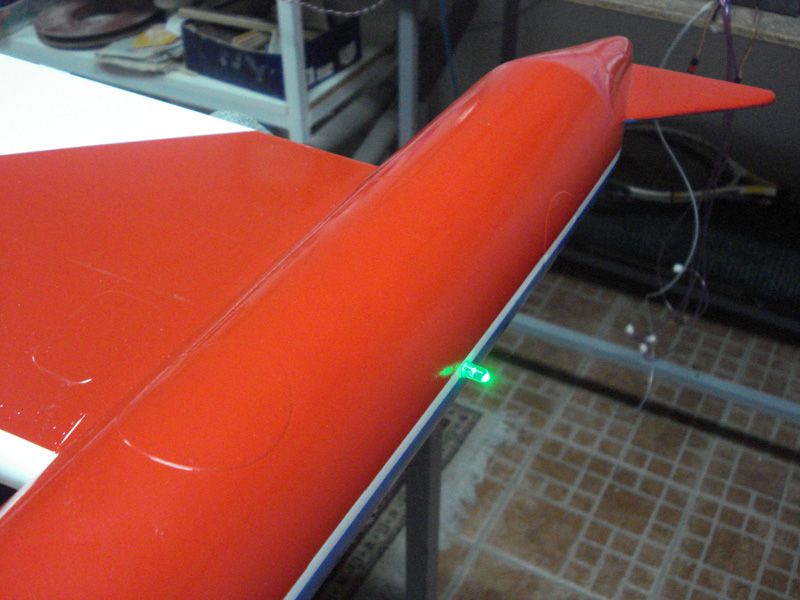

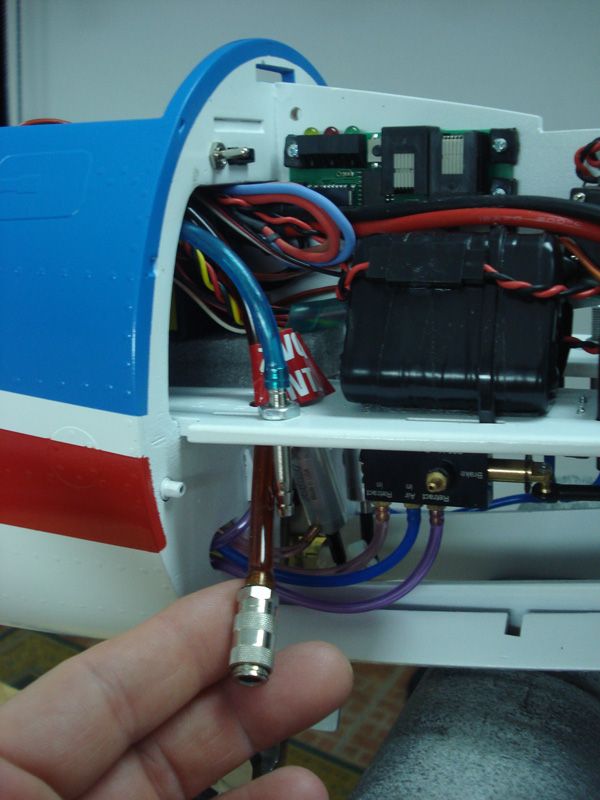

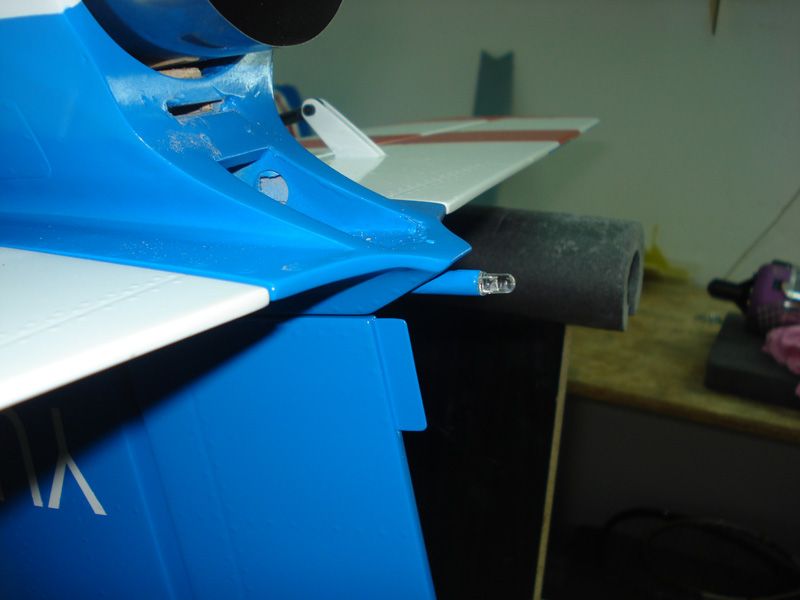

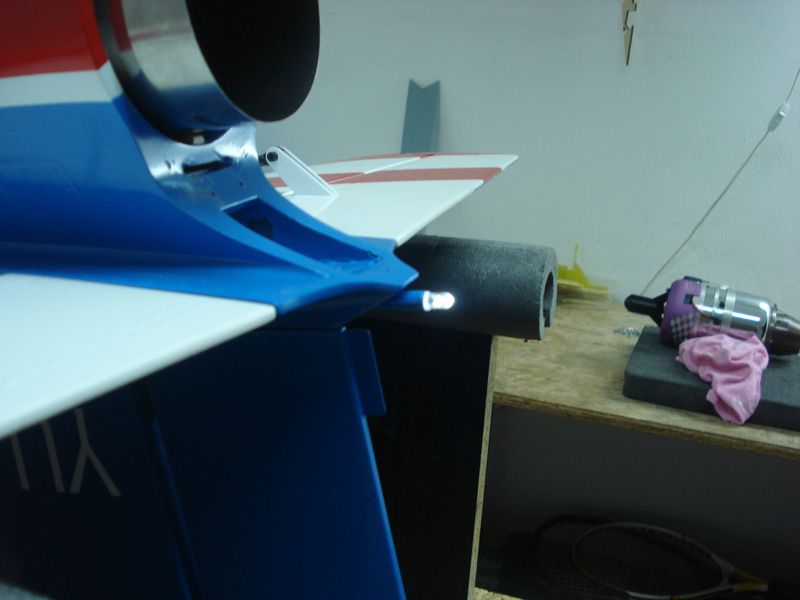

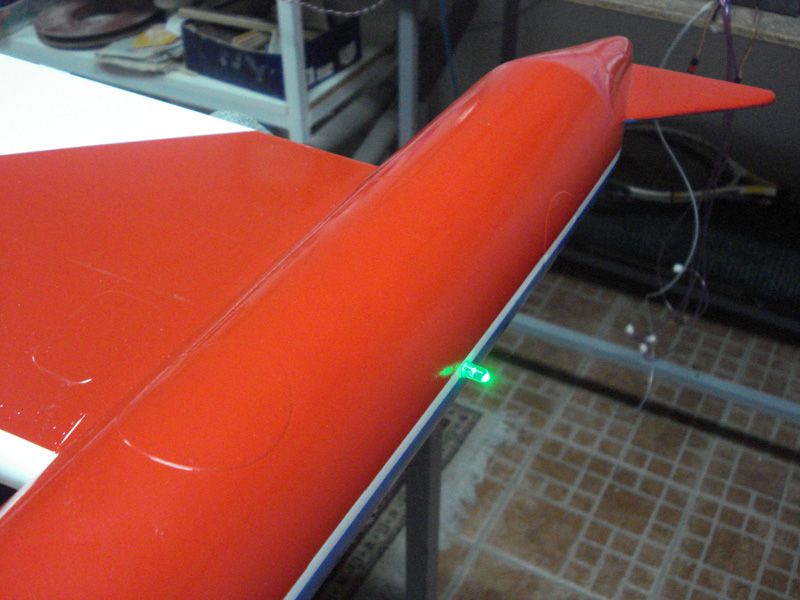

Works on G2 are almost done. Other to fit them double door at the front landing gear, and check out how the pneumatic system works. All servos are in position, everything works, light system also...

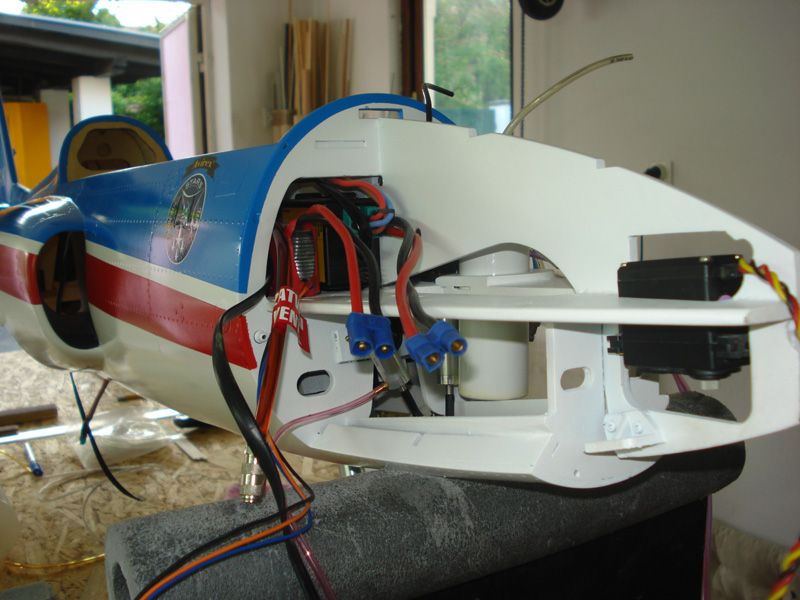

Here's a few pictures ...

At the front of the fuselage built all the necessary parts ...

Right side...

All the way forward is a switch and cable for battery charging devices. The model has two batteries and two switches ...

Behind the switch is servo of pneumatic valves. On the top of the servo box are fixed cables of the batteries, and on lower servo box the JR Flight Log. I changed Tower pro battery checker with JR Flight Log - thanks Robersteam...

Behind servos is one of the two batteries of the receiver. On it is a double adhesive tape stuck connector from the battery light. Above, on the vertical panel, there is a part of the turbine electronics.

Next, I instal on this side system for fueling and loose. Of course, both gut "more" down to "dripping" ...

The upper part is a light switch and socket head lamps as he is removed from the front of the fuselage...

On the bottom there is servo and pneumatic valve for large door of front landing gear and internal landing gears doors on the wings...

Running these doors I change from servos to the pneumatic cylinders ... Changing that I get much easier system for setting...

On the left front side, all the way from the front, set the second switch of the receiver and servos and right behind it a second receiver battery. The batteries are NiMH 2650 mAh five cells (6V). This is all take down from my Ziroli Panther, where everything worked perfectly...

Behind battery is connector for charging pneumatic system with air and the pressure gauge right behind him.

Servo runs UP2 pneumatic cylinder that opens and closes the front double door of the nose landing gear and lower and pulls LG system...

In front of the cylinder is Festo valve with which I close line to turbine when the fuel tanks filled with kerosene.

At the bottom I put the battery for LEDs, and hoses for propane - butane (some for the bottle, some for the turbine ...)

Below the light switch is a space for turbine LiPo battery... All in all, as you can see, it's pretty "crowd in the middle"...

Behind fuselage rib, there is the ECU (Electronic Control Unit) of the turbine, and behind it is a small UAT and propan - butan tank. There are electronic switches for kerosene and propane - butane.

Of course, through this fuselage part passing all cables and pneumatic tubes ...

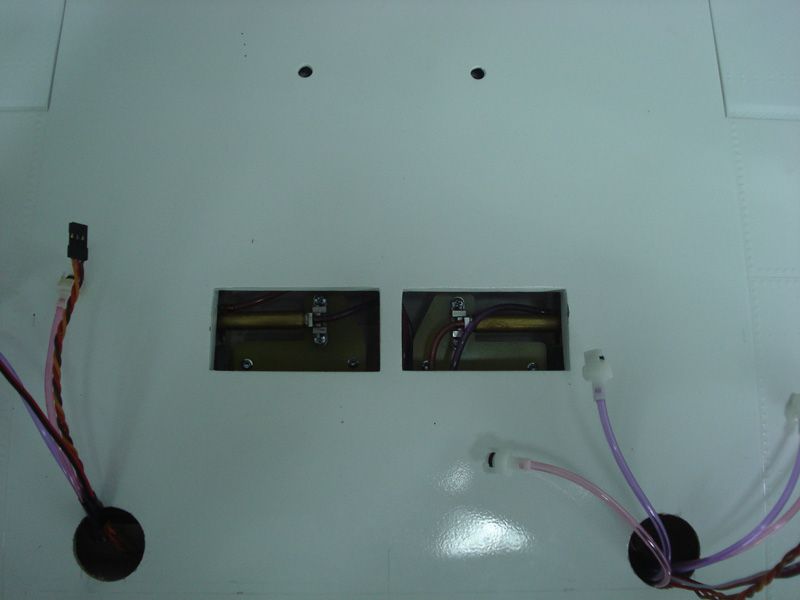

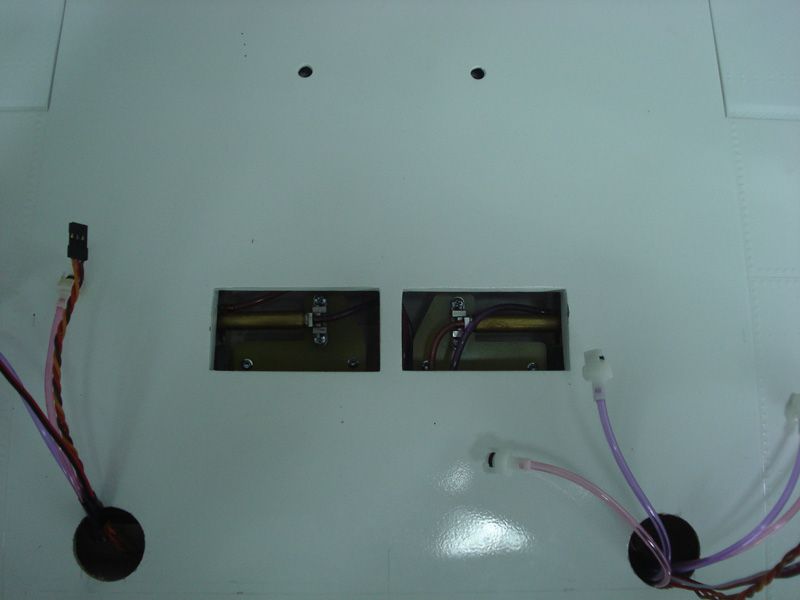

That the cables do not accidentally leaned on the turbine, on the fuselage I made openings for all connections and outputs for "electricity" and for pneumatic tubes...

Openings are made ​​on the wings too and, of course, coincide with those of the fuselage...

Cables and pneumatic hoses are placed just at the edge of the hole in the wheel that goes ...

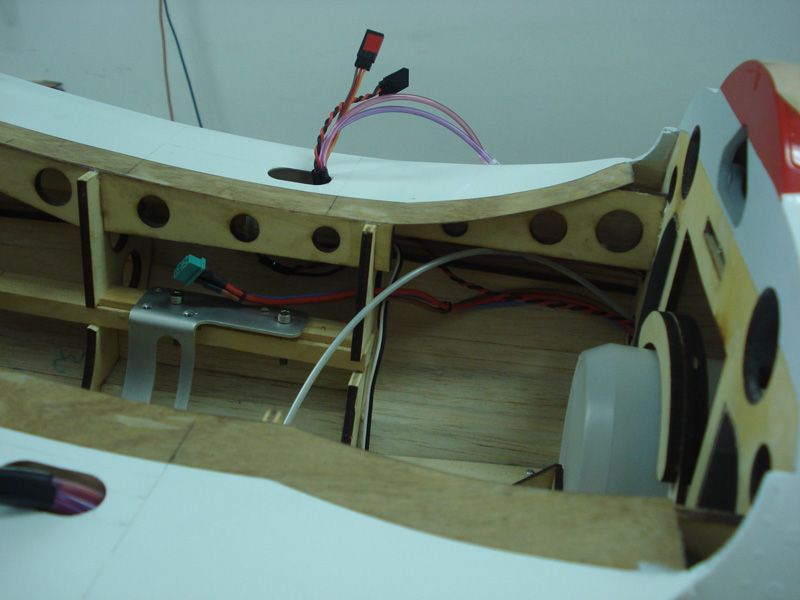

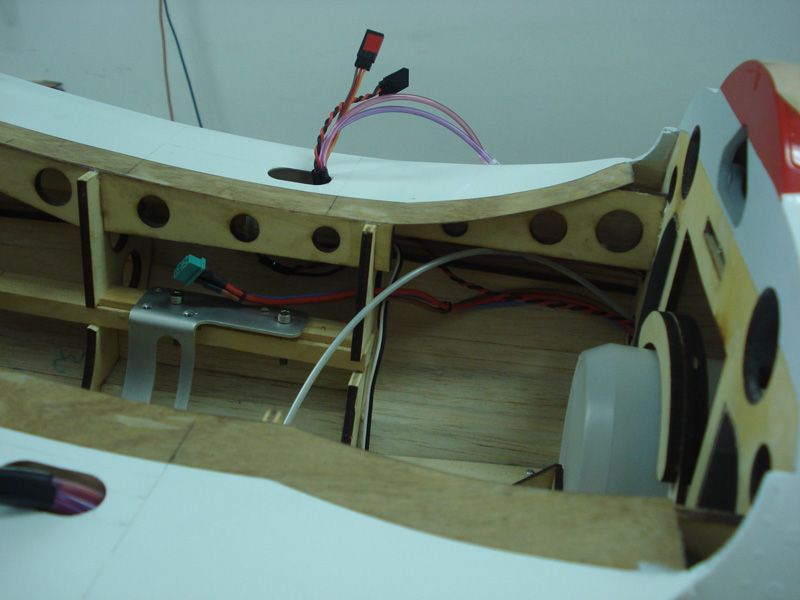

The wing is set JR Match Box for flawless stroke both flaps. Aileron connected to V cable ...

As for the elevators I used Match Box. Because that I take just one cable for Match box, not for every elevators half. To the rear part of the fuselage went two more cables, one for rudder servo and second for tail fuselage light...

Linkage are short and precise...

I instal all lights on the model. On the tail and in the front - white...

...and on the tip tanks - red and green...

Fuel tanks are on the places also. The system has three tanks, two one-liter and the third is UAT of 0.1 liter capacity ... The lower reservoir lying on the tray and top tank is fixed from back side with the small wooden part...

So much for now.

I'm waiting for some parts from Jet Cat, and when I get them, I'll start turbine and check temperature inside of the fuselage...

Until then I'll check weight and CG...

New reports soon...

Regards

Mirce

Here's a few pictures ...

At the front of the fuselage built all the necessary parts ...

Right side...

All the way forward is a switch and cable for battery charging devices. The model has two batteries and two switches ...

Behind the switch is servo of pneumatic valves. On the top of the servo box are fixed cables of the batteries, and on lower servo box the JR Flight Log. I changed Tower pro battery checker with JR Flight Log - thanks Robersteam...

Behind servos is one of the two batteries of the receiver. On it is a double adhesive tape stuck connector from the battery light. Above, on the vertical panel, there is a part of the turbine electronics.

Next, I instal on this side system for fueling and loose. Of course, both gut "more" down to "dripping" ...

The upper part is a light switch and socket head lamps as he is removed from the front of the fuselage...

On the bottom there is servo and pneumatic valve for large door of front landing gear and internal landing gears doors on the wings...

Running these doors I change from servos to the pneumatic cylinders ... Changing that I get much easier system for setting...

On the left front side, all the way from the front, set the second switch of the receiver and servos and right behind it a second receiver battery. The batteries are NiMH 2650 mAh five cells (6V). This is all take down from my Ziroli Panther, where everything worked perfectly...

Behind battery is connector for charging pneumatic system with air and the pressure gauge right behind him.

Servo runs UP2 pneumatic cylinder that opens and closes the front double door of the nose landing gear and lower and pulls LG system...

In front of the cylinder is Festo valve with which I close line to turbine when the fuel tanks filled with kerosene.

At the bottom I put the battery for LEDs, and hoses for propane - butane (some for the bottle, some for the turbine ...)

Below the light switch is a space for turbine LiPo battery... All in all, as you can see, it's pretty "crowd in the middle"...

Behind fuselage rib, there is the ECU (Electronic Control Unit) of the turbine, and behind it is a small UAT and propan - butan tank. There are electronic switches for kerosene and propane - butane.

Of course, through this fuselage part passing all cables and pneumatic tubes ...

That the cables do not accidentally leaned on the turbine, on the fuselage I made openings for all connections and outputs for "electricity" and for pneumatic tubes...

Openings are made ​​on the wings too and, of course, coincide with those of the fuselage...

Cables and pneumatic hoses are placed just at the edge of the hole in the wheel that goes ...

The wing is set JR Match Box for flawless stroke both flaps. Aileron connected to V cable ...

As for the elevators I used Match Box. Because that I take just one cable for Match box, not for every elevators half. To the rear part of the fuselage went two more cables, one for rudder servo and second for tail fuselage light...

Linkage are short and precise...

I instal all lights on the model. On the tail and in the front - white...

...and on the tip tanks - red and green...

Fuel tanks are on the places also. The system has three tanks, two one-liter and the third is UAT of 0.1 liter capacity ... The lower reservoir lying on the tray and top tank is fixed from back side with the small wooden part...

So much for now.

I'm waiting for some parts from Jet Cat, and when I get them, I'll start turbine and check temperature inside of the fuselage...

Until then I'll check weight and CG...

New reports soon...

Regards

Mirce

#191

Senior Member

Join Date: Jul 2007

Location: Wetumpka,

AL

Posts: 177

Likes: 0

Received 0 Likes

on

0 Posts

Hello Mirce,

Beautiful job on the plane, and I hate to nit pick - but the instructions for the Matchbox strongly discourages using the Matchbox further than 12 inches from the receiver. It appears you have one mounted next to an elevator servo.

Here is the quote from the instructions: "Installing the Matchbox close to the connected servo(s) with a single extension to the receiver can create a considerable current loss to the servo(s) and is not recommended."

I'm sure you know what you are doing, but I thought I should say something just in case.

Again, a beautiful model and I wish you well on the maiden.

Beautiful job on the plane, and I hate to nit pick - but the instructions for the Matchbox strongly discourages using the Matchbox further than 12 inches from the receiver. It appears you have one mounted next to an elevator servo.

Here is the quote from the instructions: "Installing the Matchbox close to the connected servo(s) with a single extension to the receiver can create a considerable current loss to the servo(s) and is not recommended."

I'm sure you know what you are doing, but I thought I should say something just in case.

Again, a beautiful model and I wish you well on the maiden.

#192

Thread Starter

Thank you JPate for comment and more for advice. To be frank, I wasn't see that in instruction. Now I read it again and, yes, that's right... I'll change that...

This is good example of great RC Universe community where modelers around the world want to help each other...

Yesterday I measure model and put it on balance machine. What to say, I'm not satisfied, but have answers.

My friend calculated CG and his "mathematics" told that I need to add 750 gr in front of the model.

For this situation CG is very forward, maybe more than it need to be. But, that is better for starting point and maiden flight.

If I move CG just 10 mm backwards situation is better...

Don't forget, on this pictures UAT is empty, and lead will come more in front of the model, so theoretical less weight will be needed for CG.

All in all, I was thinking that I will not use any lead for CG, and every gram of it is something that I'm not satisfied with...

As everybody know this is project made from drawings and now, after I made model I saw some points where I can made it better. OK, this is first prototype...

My biggest disappointment is weight.

Construction from start wasn't made to be easy, heavy duty spars, all ply ribs was from 4 mm, a lot of filler for panel lines, complete model was paint in white...

With all that model is exactly 13 kilogram, or 28,7 pounds - dry. On that weight I must add about 0,75 kg (1,65 pound) to balance G2.

My goal was to model don't be more than 12 - 12,5 kg. So with this weight, as I told, I'm not satisfied. I'm sure that Galeb will fly very nice without any problem, but, on our airfield we have grass runway which is not very smooth. My fear is that I'll need a lot of space to take off...

My friends told me that my fear is for no reason, but when I add 2 liters of kerosine, model will be almost 16 kilograms, and for my taste, it's too much.

My Ziroli Panther was 12,5 kilograms with fuel, and for take off, with Jet Cat 80, it need 25 - 30 meters. With same engine, but more weight, I'm not sure how safe is for me to try to make maiden flight.

Should not be forgotten that Galeb is bigger model, with more surface area, but as I told, I'm not sure...

So, very soon, I will start working on new Galeb G2, second version, on which will be done many modifications.

Biggest difference is that all ribs will be from 3mm ply, some spars will be smaller, some ply parts I will change with balsa parts.

Panel lines will me made on different way, so no need to add so much filler (weight).

In white will be paint just areas which need to be white...

Some parts I made from G10 now will be made from balsa... And so on...

I thing that I will take off tip tanks on this model, so with all this modifications I'm sure that can take down 1,5 - 2 kilograms. In that case that will be different story for maiden flight on conditions I have on our airfield and I will be much much relaxed...

That is all for now. Maybe some opinion of modeler around the world about size - weight - turbine size will be useful for me and this model.

Regards

Mirce

This is good example of great RC Universe community where modelers around the world want to help each other...

Yesterday I measure model and put it on balance machine. What to say, I'm not satisfied, but have answers.

My friend calculated CG and his "mathematics" told that I need to add 750 gr in front of the model.

For this situation CG is very forward, maybe more than it need to be. But, that is better for starting point and maiden flight.

If I move CG just 10 mm backwards situation is better...

Don't forget, on this pictures UAT is empty, and lead will come more in front of the model, so theoretical less weight will be needed for CG.

All in all, I was thinking that I will not use any lead for CG, and every gram of it is something that I'm not satisfied with...

As everybody know this is project made from drawings and now, after I made model I saw some points where I can made it better. OK, this is first prototype...

My biggest disappointment is weight.

Construction from start wasn't made to be easy, heavy duty spars, all ply ribs was from 4 mm, a lot of filler for panel lines, complete model was paint in white...

With all that model is exactly 13 kilogram, or 28,7 pounds - dry. On that weight I must add about 0,75 kg (1,65 pound) to balance G2.

My goal was to model don't be more than 12 - 12,5 kg. So with this weight, as I told, I'm not satisfied. I'm sure that Galeb will fly very nice without any problem, but, on our airfield we have grass runway which is not very smooth. My fear is that I'll need a lot of space to take off...

My friends told me that my fear is for no reason, but when I add 2 liters of kerosine, model will be almost 16 kilograms, and for my taste, it's too much.

My Ziroli Panther was 12,5 kilograms with fuel, and for take off, with Jet Cat 80, it need 25 - 30 meters. With same engine, but more weight, I'm not sure how safe is for me to try to make maiden flight.

Should not be forgotten that Galeb is bigger model, with more surface area, but as I told, I'm not sure...

So, very soon, I will start working on new Galeb G2, second version, on which will be done many modifications.

Biggest difference is that all ribs will be from 3mm ply, some spars will be smaller, some ply parts I will change with balsa parts.

Panel lines will me made on different way, so no need to add so much filler (weight).

In white will be paint just areas which need to be white...

Some parts I made from G10 now will be made from balsa... And so on...

I thing that I will take off tip tanks on this model, so with all this modifications I'm sure that can take down 1,5 - 2 kilograms. In that case that will be different story for maiden flight on conditions I have on our airfield and I will be much much relaxed...

That is all for now. Maybe some opinion of modeler around the world about size - weight - turbine size will be useful for me and this model.

Regards

Mirce

#193

Thread Starter

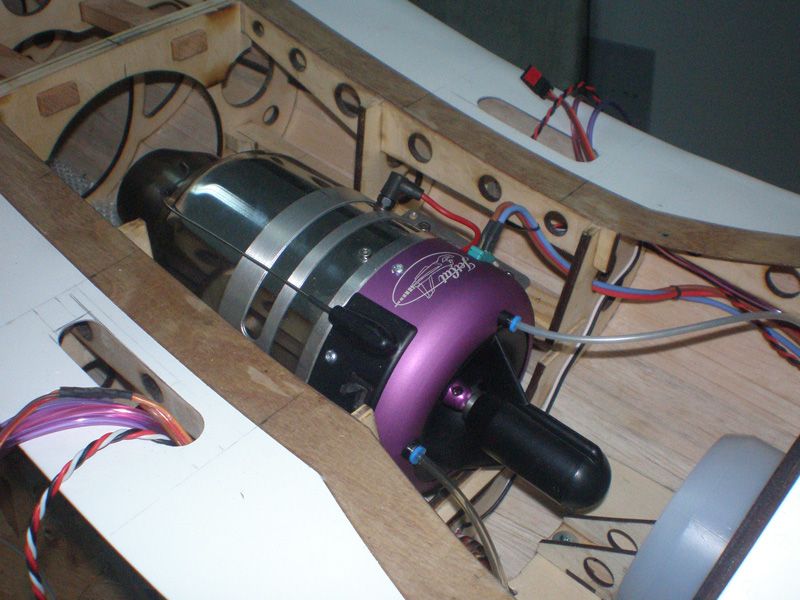

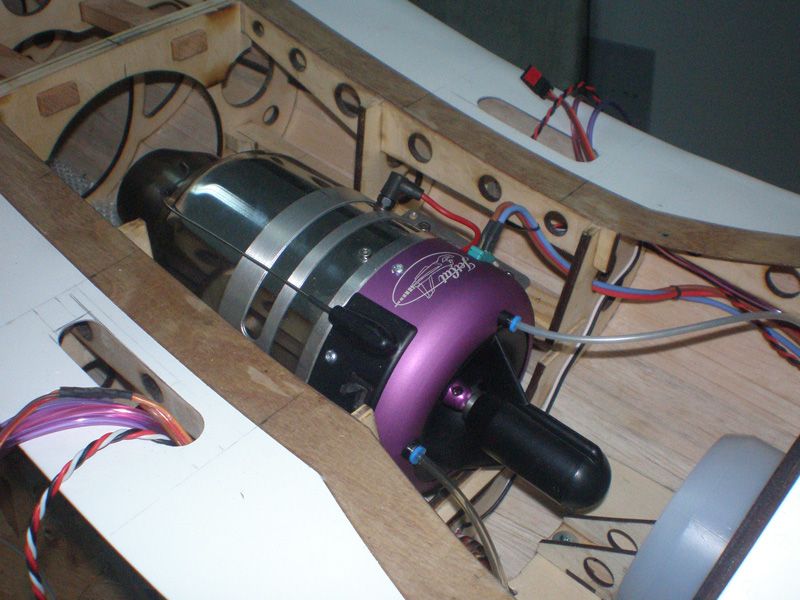

Finally in next day - two will be first start of jet Cat turbine in Galeb G2...

In meantime I made almost everything on model. All servos work perfectly, Match Box of elevator is move forward (thank's JPate ), pneumatic system also work grate...

), pneumatic system also work grate...

All retract doors are instal and front wheel is connect with servo...

From Jet Cat I received new LiPo battery and connector for propane gas...

Some concern I have about temperature in fuselage, so I decided to install heat protection material.

This, on the picture, is 3 mm thick cloth, but in next week I will get 1 mm thin ceramic cloth with thin aluminum foil on one side. Thickness is important because weight - all this protection is behind CG.

OK, this is not very heavy, 0,75 meter of 3 mm cloth is 85 gr...

...but now I need to think about every gram behind CG...

Galeb G2 fuselage is rather narrow, so on some places I want to be sure that temperature will not made problem. Maybe is this unnecessarily, I'll see after first turbine start...

Jet Cat is install also. I want to check how it lie down in fuselage.

Today thrust tube will be install, and that is last part which I need to put in model before starting turbine...

Best regards

Mirce

In meantime I made almost everything on model. All servos work perfectly, Match Box of elevator is move forward (thank's JPate

), pneumatic system also work grate...

), pneumatic system also work grate...All retract doors are instal and front wheel is connect with servo...

From Jet Cat I received new LiPo battery and connector for propane gas...

Some concern I have about temperature in fuselage, so I decided to install heat protection material.

This, on the picture, is 3 mm thick cloth, but in next week I will get 1 mm thin ceramic cloth with thin aluminum foil on one side. Thickness is important because weight - all this protection is behind CG.

OK, this is not very heavy, 0,75 meter of 3 mm cloth is 85 gr...

...but now I need to think about every gram behind CG...

Galeb G2 fuselage is rather narrow, so on some places I want to be sure that temperature will not made problem. Maybe is this unnecessarily, I'll see after first turbine start...

Jet Cat is install also. I want to check how it lie down in fuselage.

Today thrust tube will be install, and that is last part which I need to put in model before starting turbine...

Best regards

Mirce

#194

Thread Starter

As I told in last topic, I install all parts in model...

...and want to start turbine for the first time in Galeb G2...

All system was checked, everything worked well, battery are full... My friends was here also...

After few starts I saw that fuselage is hotter than it was be on my Ziroli Panther. It is not alarming, but...

Regardless of the higher temperature paint is same as it was...

Next day I bought ceramic blanket and aluminum foil, so add that inside of model...

I add one piece on the wing also...

After that, Jet Cat was working again...

...but unfortunately no big difference.

Now I decided to stop project on this point, and start work on Galeb G2 - version II.

I want to made model with which I will primarily be satisfied, and then potential buyers also. On this first prototype do not like two things - weight and fuselage heat.

Right now, Martin work and change some things on 3D project for next model, I call Jet Cat and arrange to send them thrust tube back and they will add one more wall on tube.

This thrust tube with one wall definitely is not a good option. Thrust tube is long (85 cm) and I want to made it light, so order tube with one wall. Unfortunately that was mistake... [&o]

What to say now in this moment, prototypes are made to show what can be better on product. Our Galeb show us those points.

Now I will stop working on this model, but very soon, in week or two, project will be continue on next Galeb G2 - version II.

Of course, about all details I will write here. Next model will be good example of project progress and on that model we will change all things which we saw that can be made better.

I hope that next G2 will be 1,5 - 2 kilograms lighter and with two wall thrust tube, and some other changes in fuselage design (inside and out) temperature will not be issue any more...

This weight and temperature I mention for sure will not be a problem for maiden flight, but because I know that I can made better model, I'll invest few months more and made new G2.

Regards

Mirce

...and want to start turbine for the first time in Galeb G2...

All system was checked, everything worked well, battery are full... My friends was here also...

After few starts I saw that fuselage is hotter than it was be on my Ziroli Panther. It is not alarming, but...

Regardless of the higher temperature paint is same as it was...

Next day I bought ceramic blanket and aluminum foil, so add that inside of model...

I add one piece on the wing also...

After that, Jet Cat was working again...

...but unfortunately no big difference.

Now I decided to stop project on this point, and start work on Galeb G2 - version II.

I want to made model with which I will primarily be satisfied, and then potential buyers also. On this first prototype do not like two things - weight and fuselage heat.

Right now, Martin work and change some things on 3D project for next model, I call Jet Cat and arrange to send them thrust tube back and they will add one more wall on tube.

This thrust tube with one wall definitely is not a good option. Thrust tube is long (85 cm) and I want to made it light, so order tube with one wall. Unfortunately that was mistake... [&o]

What to say now in this moment, prototypes are made to show what can be better on product. Our Galeb show us those points.

Now I will stop working on this model, but very soon, in week or two, project will be continue on next Galeb G2 - version II.

Of course, about all details I will write here. Next model will be good example of project progress and on that model we will change all things which we saw that can be made better.

I hope that next G2 will be 1,5 - 2 kilograms lighter and with two wall thrust tube, and some other changes in fuselage design (inside and out) temperature will not be issue any more...

This weight and temperature I mention for sure will not be a problem for maiden flight, but because I know that I can made better model, I'll invest few months more and made new G2.

Regards

Mirce

#195

Join Date: Apr 2006

Location: Carrollton

Posts: 1,698

Likes: 0

Received 0 Likes

on

0 Posts

Hello Mirce,

I hope you are having a great summer. I'm sorry to see your beautiful Galeb turned out a little bit heavy.......... I know with your skills, Version 2 will be much better and I will follow along as you build it. I am curious though, what are you going to do with your current jet? It would be a shame to waste such a beautiful aircraft.

I know with your skills, Version 2 will be much better and I will follow along as you build it. I am curious though, what are you going to do with your current jet? It would be a shame to waste such a beautiful aircraft.

Take care,

David

I hope you are having a great summer. I'm sorry to see your beautiful Galeb turned out a little bit heavy..........

I know with your skills, Version 2 will be much better and I will follow along as you build it. I am curious though, what are you going to do with your current jet? It would be a shame to waste such a beautiful aircraft.

I know with your skills, Version 2 will be much better and I will follow along as you build it. I am curious though, what are you going to do with your current jet? It would be a shame to waste such a beautiful aircraft.Take care,

David

#196

Thread Starter

Thanks David... Yes, version II will be much better, and for me it's not big deal to made it.

My main fear is how much space I need on my grass and bumpy airfield for G2 take off.

Turbine (Jet Cat P 80) have 10 kg of thrust and for my Ziroli Panther, with 12,5 kg wet, I need 25 - 30 meter for take off. Some time, because bumpy surface, model jump earlier, but over power engine help at that moment.

Galeb is 15,5 kg, OK it's bigger, with more wing area. I'm afraid that jumping on take off can also happen, but then I haven't those extra boost.

Other thing is to need to put two wall thrust tube. I haven't it right now...

Easier model will have better performance on take off, and two wall pipe will help with reduce heat on fuselage.

Tarmac surface, and other thrust tube are solutions but right now I haven't it... That are reasons why I don't want to force myself for maiden flight. I'll easily fix those "problems" but need just more time.

David, for this model I have two solutions, first is to sell it to my friend, pilot of real G2. His Galeb is original airplane for my model. Dragan want that model to put it in his office like model for static display...

Other solution is to take down price a little and sell it. Lower price is just because this model haven't any flight.

Regards

Mirce

My main fear is how much space I need on my grass and bumpy airfield for G2 take off.

Turbine (Jet Cat P 80) have 10 kg of thrust and for my Ziroli Panther, with 12,5 kg wet, I need 25 - 30 meter for take off. Some time, because bumpy surface, model jump earlier, but over power engine help at that moment.

Galeb is 15,5 kg, OK it's bigger, with more wing area. I'm afraid that jumping on take off can also happen, but then I haven't those extra boost.

Other thing is to need to put two wall thrust tube. I haven't it right now...

Easier model will have better performance on take off, and two wall pipe will help with reduce heat on fuselage.

Tarmac surface, and other thrust tube are solutions but right now I haven't it... That are reasons why I don't want to force myself for maiden flight. I'll easily fix those "problems" but need just more time.

David, for this model I have two solutions, first is to sell it to my friend, pilot of real G2. His Galeb is original airplane for my model. Dragan want that model to put it in his office like model for static display...

Other solution is to take down price a little and sell it. Lower price is just because this model haven't any flight.

Regards

Mirce

#197

Thread Starter

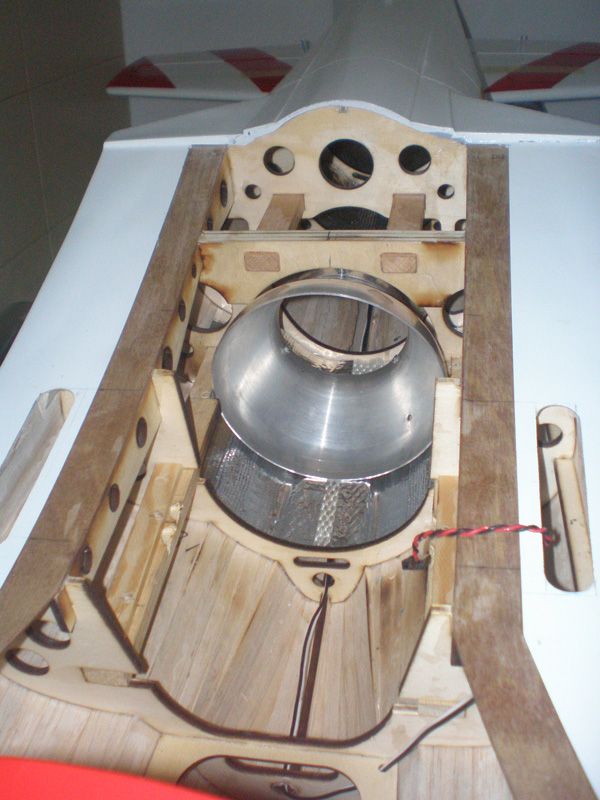

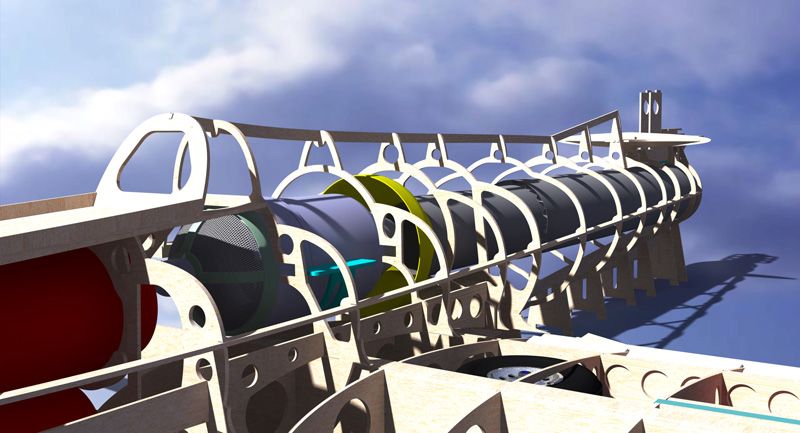

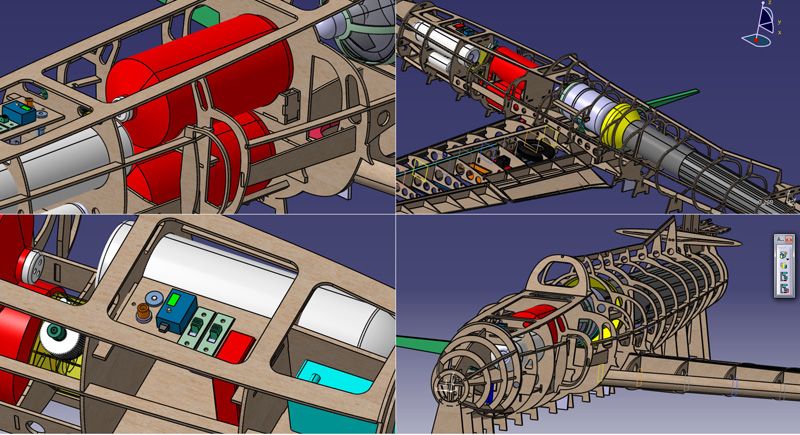

OK, lets start chapter two of this story...

In meantime Martin and I was working on changes on Galeb G2. Drawing is drawing, but when model come in full size, some points show what can be better. First model, putting parts inside, starting turbine for the first time, show that...

My two biggest objections was model weight and heat on fuselage.

Galeb in version II will be much lighter. We change all ribs, on first model they was from poplar ply 4 mm wide, now it's 3 mm.

On wing, spars will be smaller too, same like wing joiners. Parts which close boxes between spars and wing ribs, now will be from ply just in wing root and after that from balsa. Some boxes will have those parts just from one side of the spars...

Biggest weight save will be on panel lines, which I will made now on new way, without so much filler. Filler add a lot of weight and it is mostly behind of CG.

On new model I will not made tip tanks. Of course always will be option for this parts, but my next model will be without this parts...

All this will help for big weight reduction on the wing section.

On fuselage we made many changes also.

Biggest difference is on fuselage rib design, which will be much thinner in rear part.

Changes are made now on ribs near turbine and thrust tube inlet too. There ribs will be with bigger holes to allow more air flow to go in rear fuselage section.

Before:

On next model this fuselage parts will look like this...

Next big change on fuselage are section with gas tanks. On first model upper tank was direct in front of the turbine...

On new design all tanks are in one compartment. We close those fuselage part with removing holes on the ribs, so now in case that kerosine somehow come out from tanks, will not flow direct in turbine. OK, this never happened, to be honest, but I need to think in advance ...

Other big thing on fuselage is changing part which will be removed before every flight. On first model idea was to remove front of the fuselage, but in that case propane butane line is very long, so I have two big hot starts on first G2.

On Galeb's second edition, for all works before flight we will remove cabin. That give more opportunities and short all tubes, for kerosine, but what is more important, for propane - butane gas.

I never have hot starts on my Ziroli Panther, but as I told, propane - butane tubes from small tank to turbine was much shorter. In new G2 design, bottle is on new place, lie horizontal and tubes go direct to turbine.

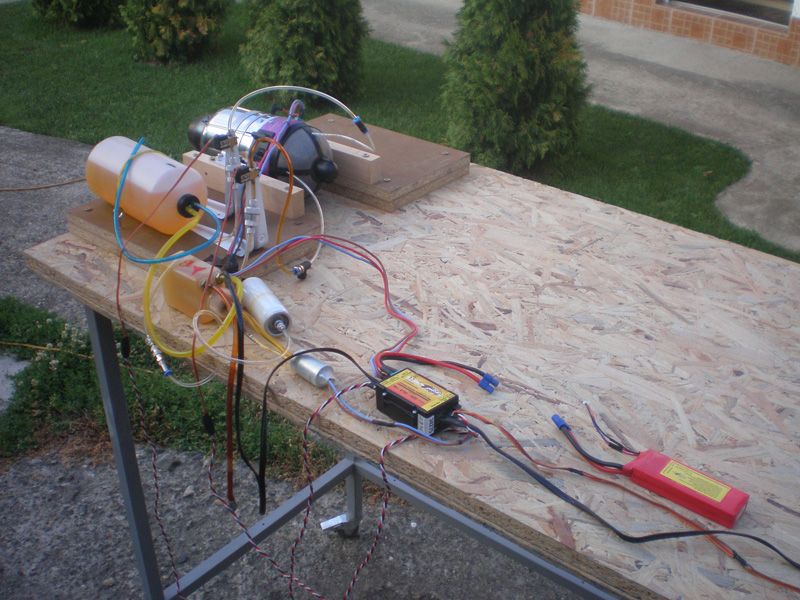

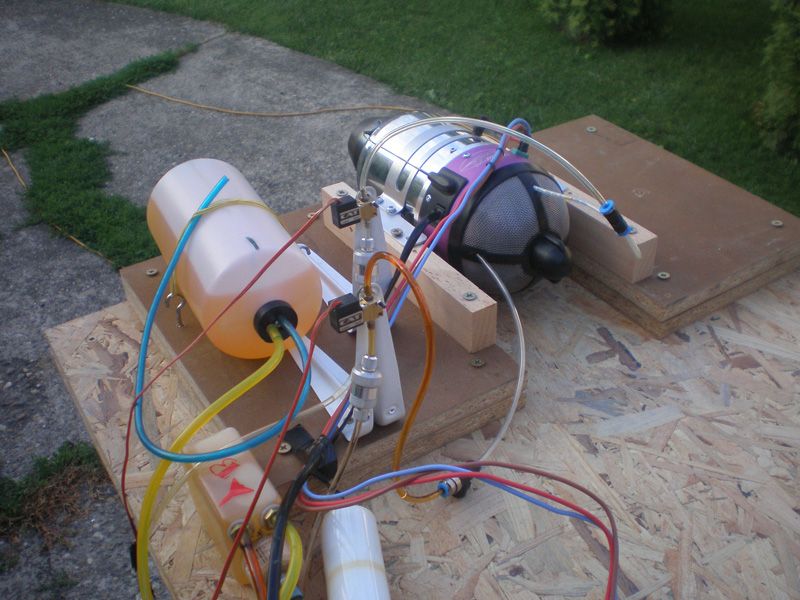

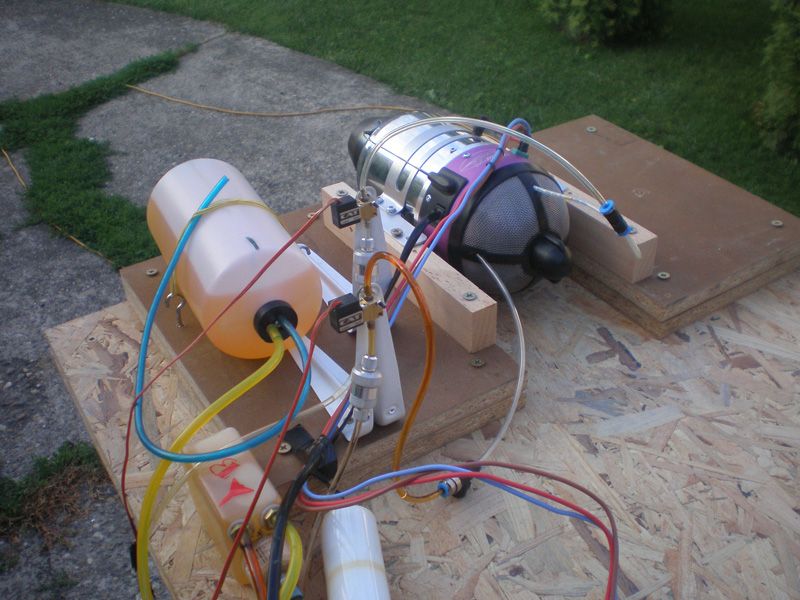

To be 100% sure that tube length was issues, I made test bench and start my Jet Cat at least 15 times, every time without hot start. That convinced me that long propane - butane tube was be main problem for this issues...

Front fuselage part will be still removable, but not be needs for take it down before every flight.

Switchers, connectors for air will be now under cabin too.

Red part on drawing is LiPo battery for ECU. Battery position is like that, because charging battery must be outside of the model and this allow easy manipulation with battery.

ECU will be on same place like before.

Working on fuselage is not finish yet. We need more time to made all changes, but this is what's changed so far.

I order balsa, new spars, wing joiners, so my hopes are that at next week working on wing will start...

Regards

Mirce

In meantime Martin and I was working on changes on Galeb G2. Drawing is drawing, but when model come in full size, some points show what can be better. First model, putting parts inside, starting turbine for the first time, show that...

My two biggest objections was model weight and heat on fuselage.

Galeb in version II will be much lighter. We change all ribs, on first model they was from poplar ply 4 mm wide, now it's 3 mm.

On wing, spars will be smaller too, same like wing joiners. Parts which close boxes between spars and wing ribs, now will be from ply just in wing root and after that from balsa. Some boxes will have those parts just from one side of the spars...

Biggest weight save will be on panel lines, which I will made now on new way, without so much filler. Filler add a lot of weight and it is mostly behind of CG.

On new model I will not made tip tanks. Of course always will be option for this parts, but my next model will be without this parts...

All this will help for big weight reduction on the wing section.

On fuselage we made many changes also.

Biggest difference is on fuselage rib design, which will be much thinner in rear part.

Changes are made now on ribs near turbine and thrust tube inlet too. There ribs will be with bigger holes to allow more air flow to go in rear fuselage section.

Before:

On next model this fuselage parts will look like this...

Next big change on fuselage are section with gas tanks. On first model upper tank was direct in front of the turbine...

On new design all tanks are in one compartment. We close those fuselage part with removing holes on the ribs, so now in case that kerosine somehow come out from tanks, will not flow direct in turbine. OK, this never happened, to be honest, but I need to think in advance ...

Other big thing on fuselage is changing part which will be removed before every flight. On first model idea was to remove front of the fuselage, but in that case propane butane line is very long, so I have two big hot starts on first G2.

On Galeb's second edition, for all works before flight we will remove cabin. That give more opportunities and short all tubes, for kerosine, but what is more important, for propane - butane gas.

I never have hot starts on my Ziroli Panther, but as I told, propane - butane tubes from small tank to turbine was much shorter. In new G2 design, bottle is on new place, lie horizontal and tubes go direct to turbine.

To be 100% sure that tube length was issues, I made test bench and start my Jet Cat at least 15 times, every time without hot start. That convinced me that long propane - butane tube was be main problem for this issues...

Front fuselage part will be still removable, but not be needs for take it down before every flight.

Switchers, connectors for air will be now under cabin too.

Red part on drawing is LiPo battery for ECU. Battery position is like that, because charging battery must be outside of the model and this allow easy manipulation with battery.

ECU will be on same place like before.

Working on fuselage is not finish yet. We need more time to made all changes, but this is what's changed so far.

I order balsa, new spars, wing joiners, so my hopes are that at next week working on wing will start...

Regards

Mirce

#199

Thread Starter

OK, back to business...

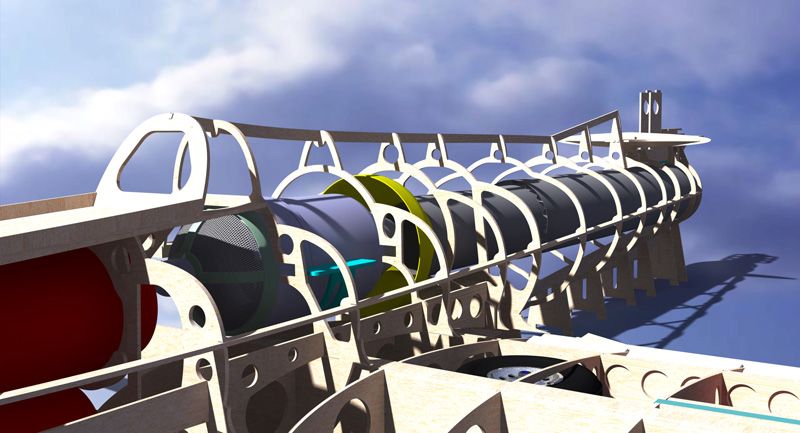

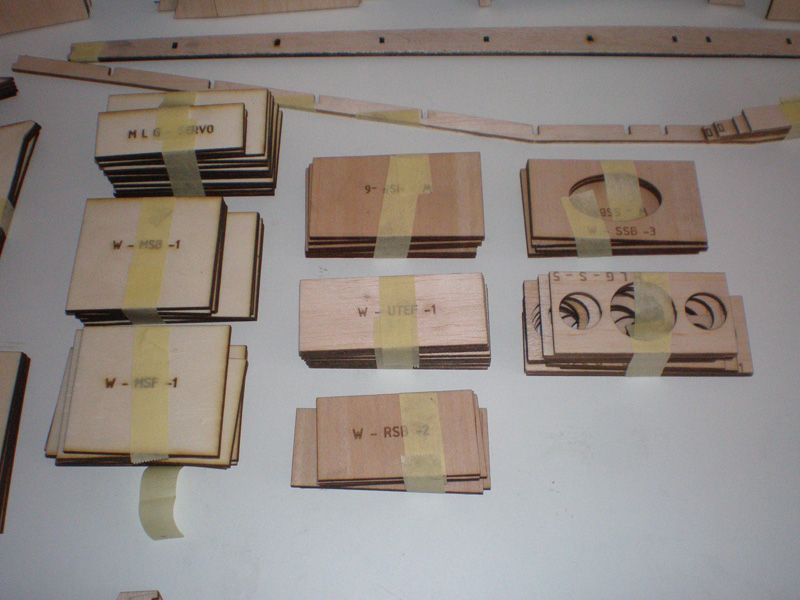

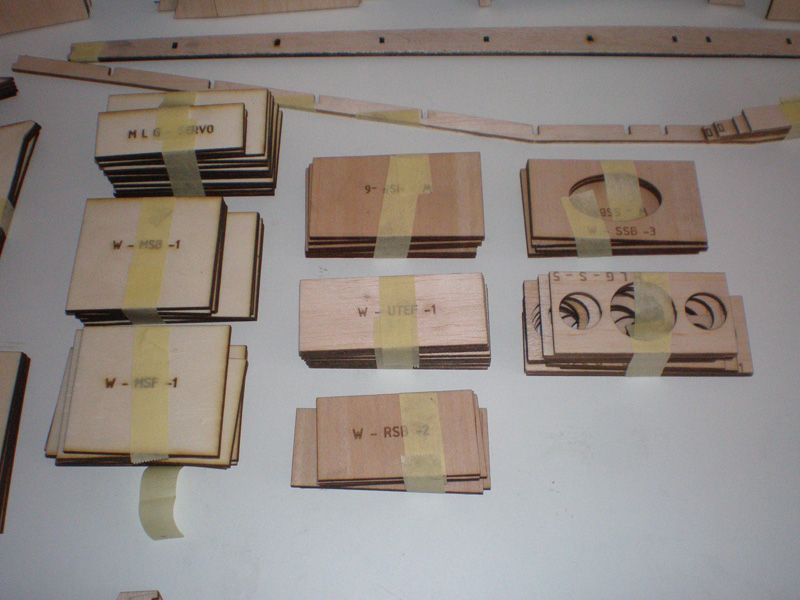

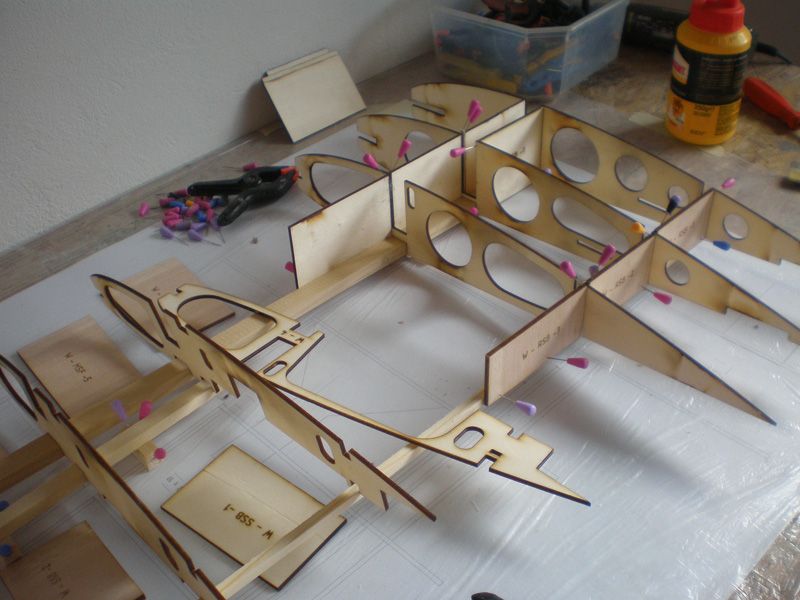

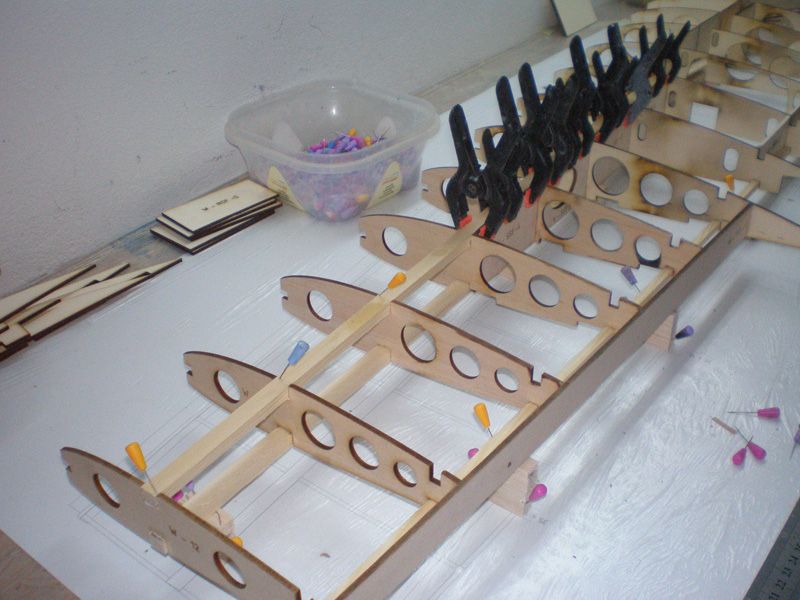

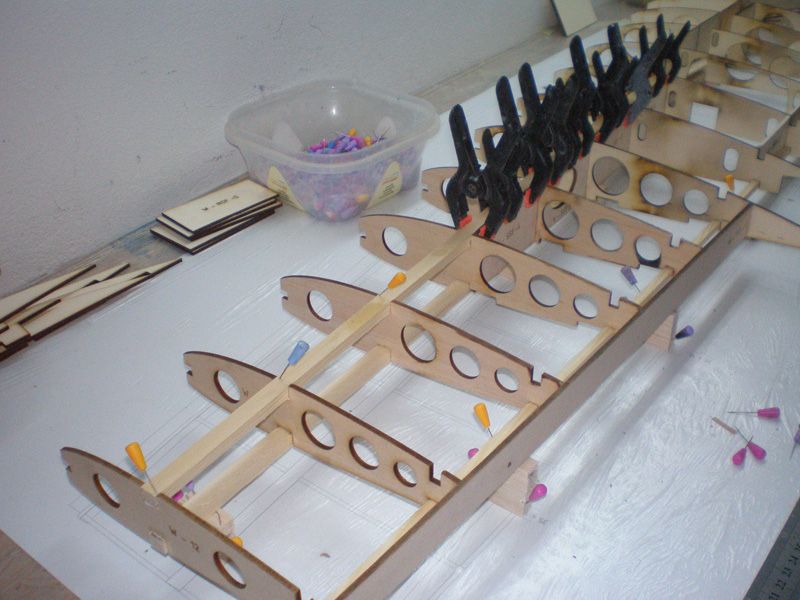

Few days ago drawings for new Galeb G2, balsa and ply plates was given to my friend Dragan. He need on his laser cut machine almost all working day to cut all parts just for wing, elevator and rudder...

It took 24 pieces 3mm balsa sheets!!! OK, on laser cur was cut all ailerons, flaps, elevator and rudder covers, but 24 sheets...

Don't forget, some parts was made from 3mm poplar ply, so for now a lot of material was needed. There aren't ribs and parts for fuselage...

Unlike the first model now we cut all parts which come between ribs, in front and behind of spars...

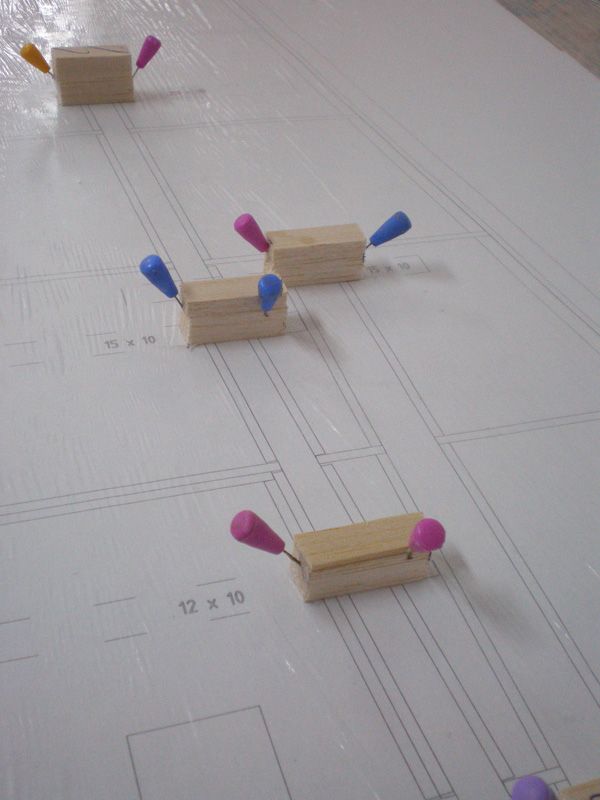

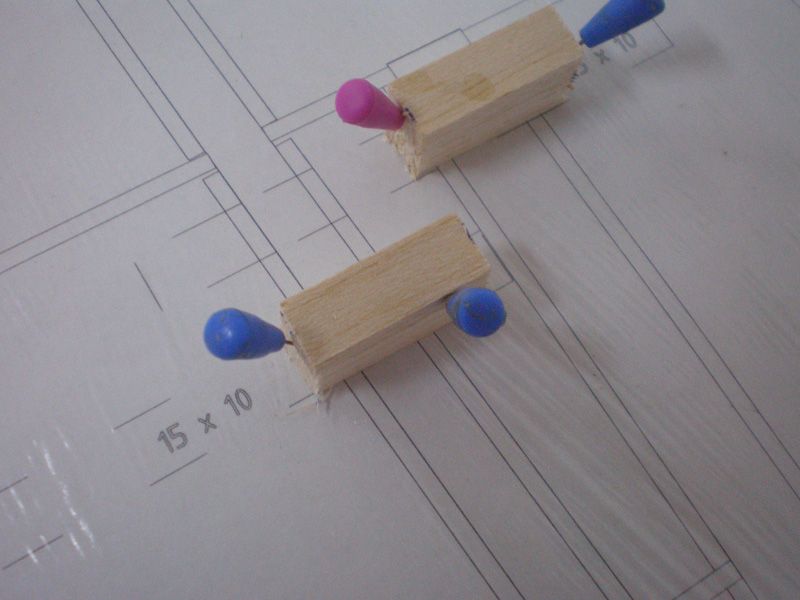

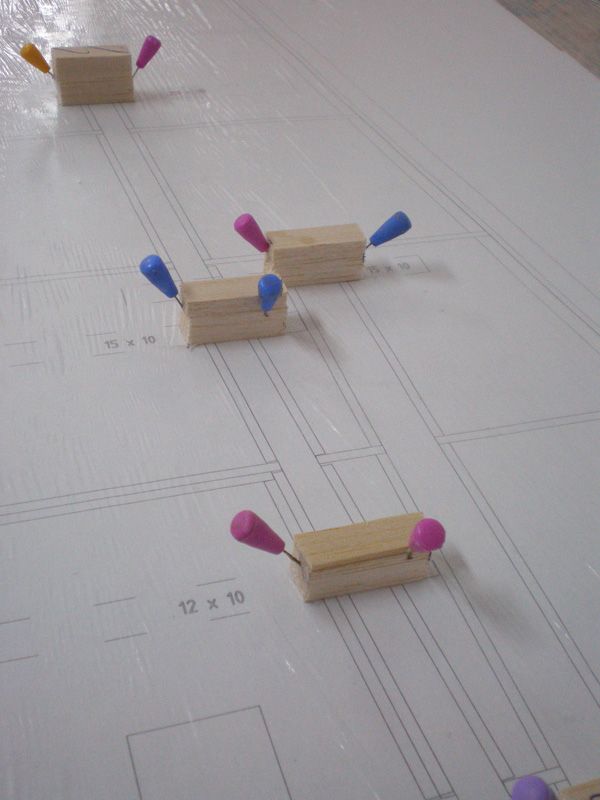

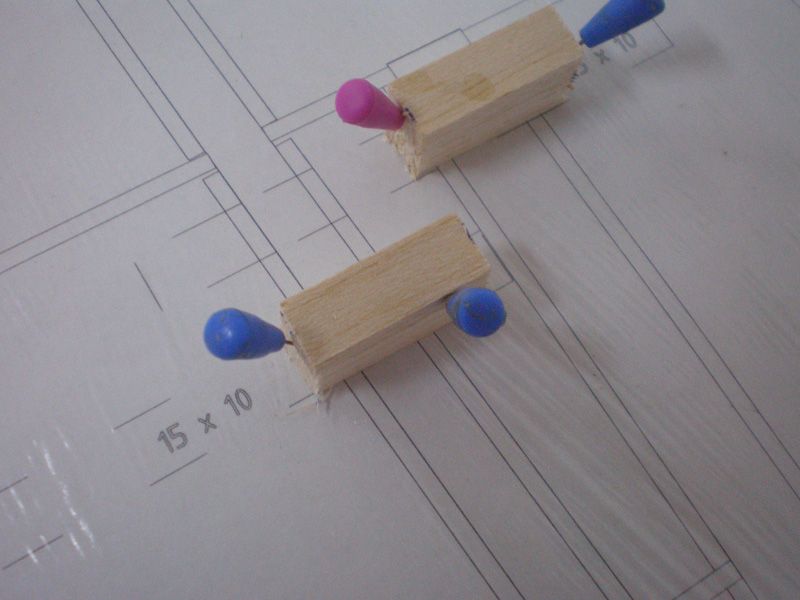

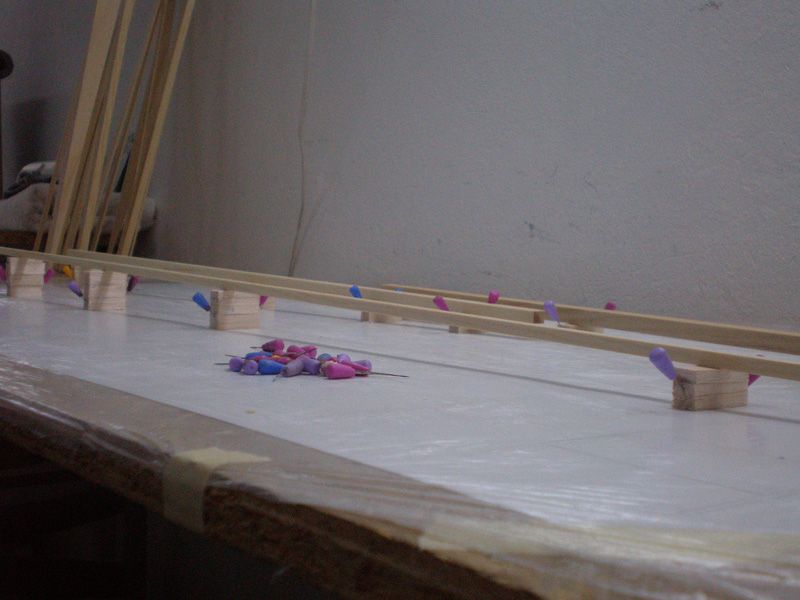

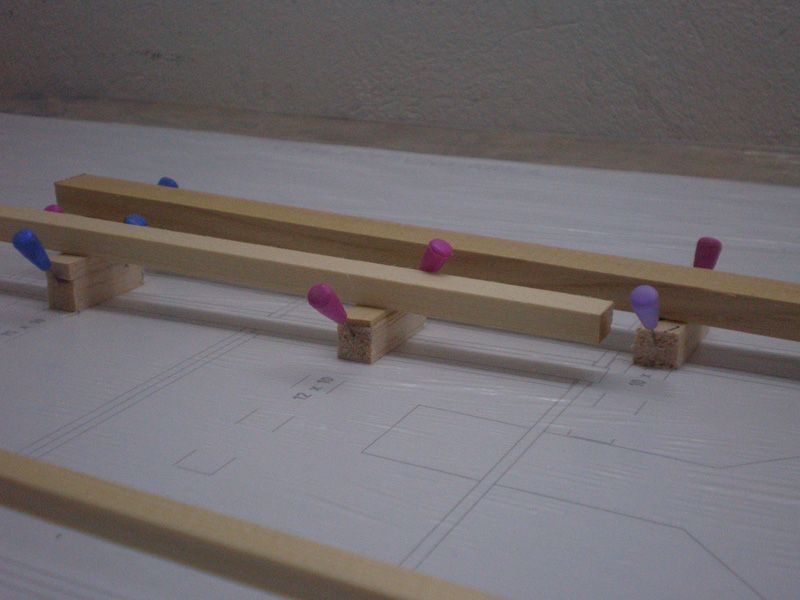

After I put plan on working board, I made parts which will come under bottom spar. Martin draw every dimension and exactly places where every part will come...

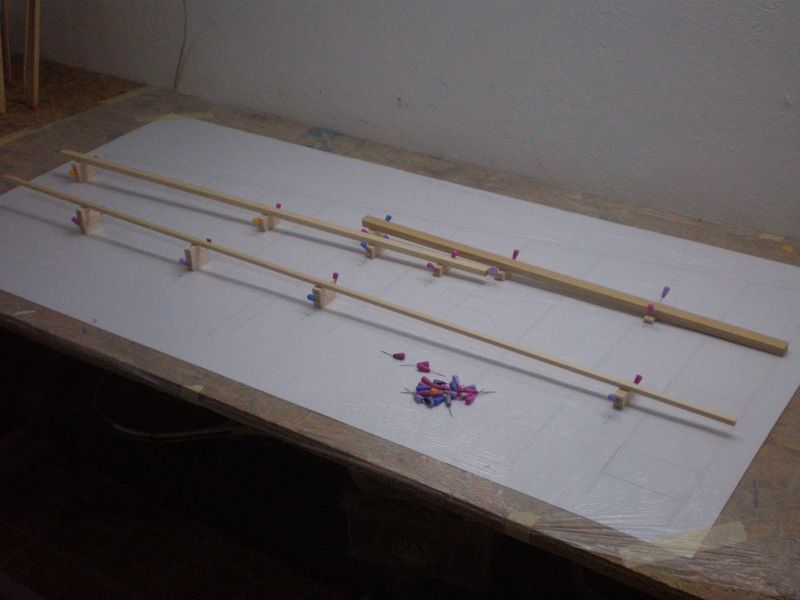

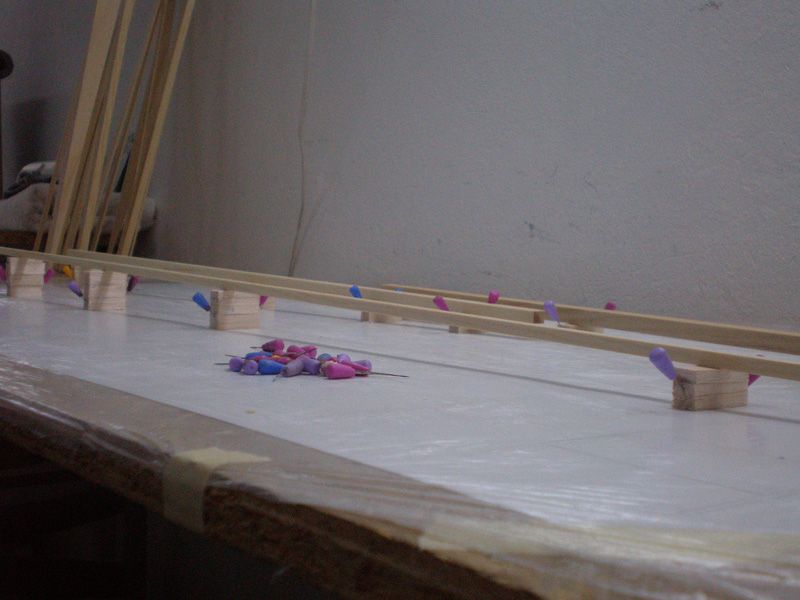

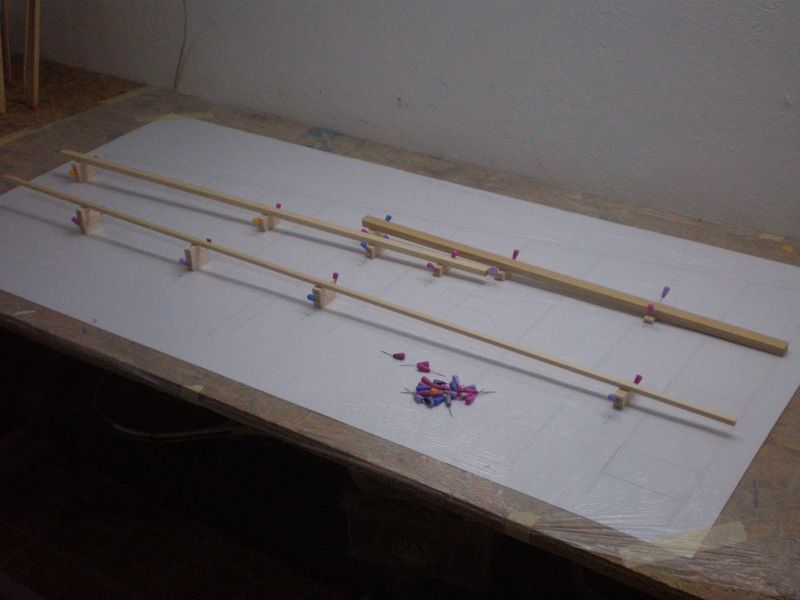

Next step was to put in place all spars...

Than I put some ribs, without glue, just to check how they will fit on spars. What to say, perfect...

To be continued...

Few days ago drawings for new Galeb G2, balsa and ply plates was given to my friend Dragan. He need on his laser cut machine almost all working day to cut all parts just for wing, elevator and rudder...

It took 24 pieces 3mm balsa sheets!!! OK, on laser cur was cut all ailerons, flaps, elevator and rudder covers, but 24 sheets...

Don't forget, some parts was made from 3mm poplar ply, so for now a lot of material was needed. There aren't ribs and parts for fuselage...

Unlike the first model now we cut all parts which come between ribs, in front and behind of spars...

After I put plan on working board, I made parts which will come under bottom spar. Martin draw every dimension and exactly places where every part will come...

Next step was to put in place all spars...

Than I put some ribs, without glue, just to check how they will fit on spars. What to say, perfect...

To be continued...

#200

Thread Starter

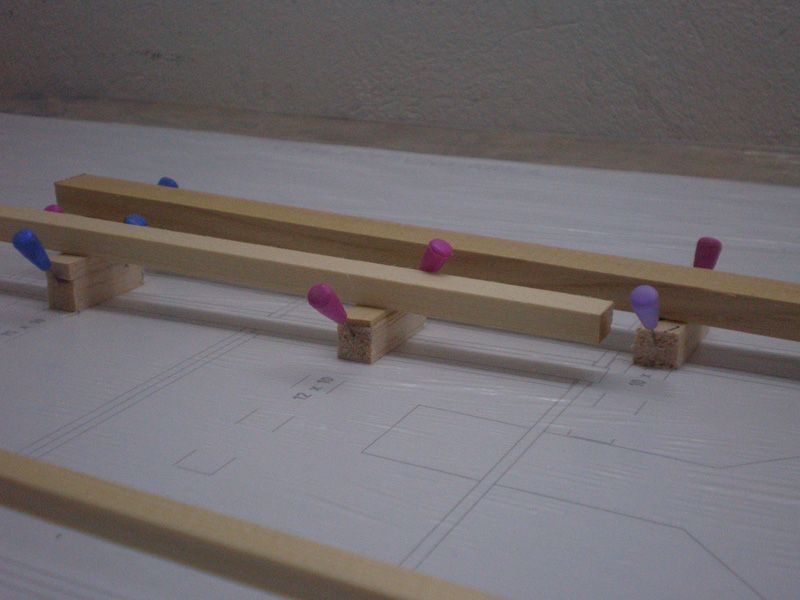

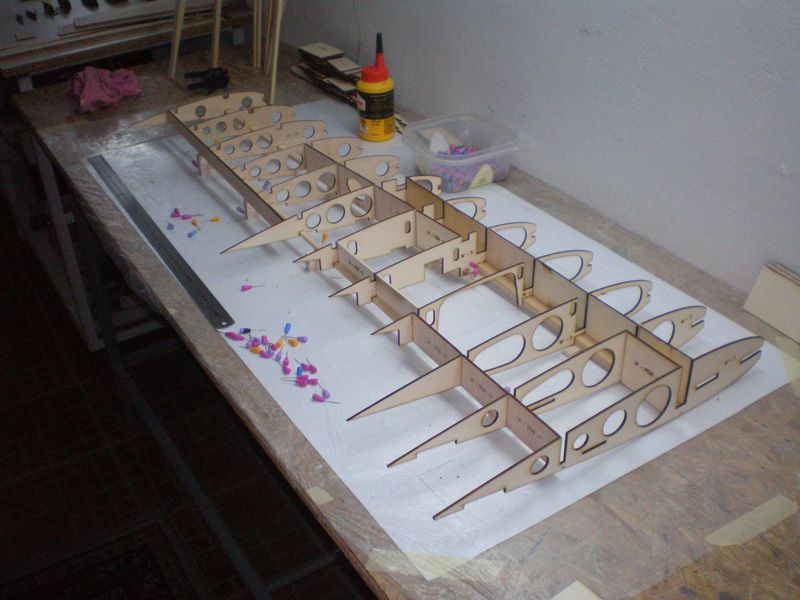

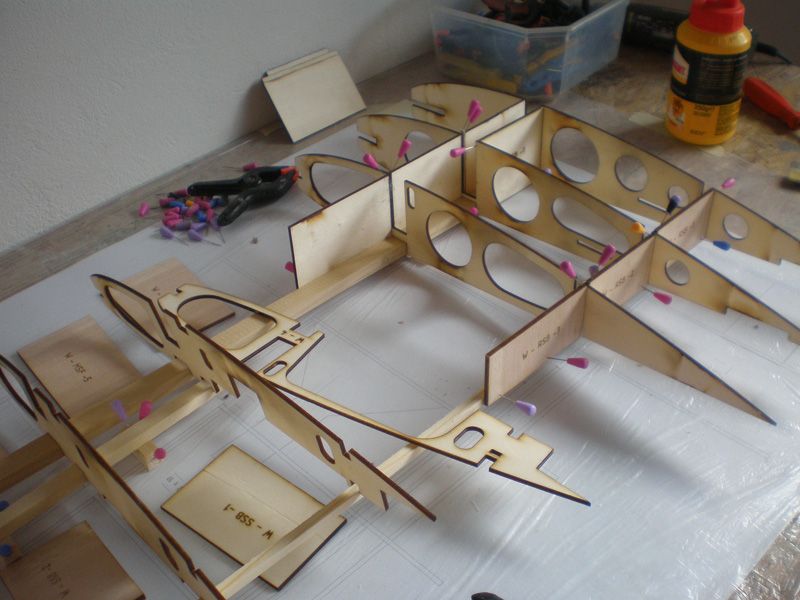

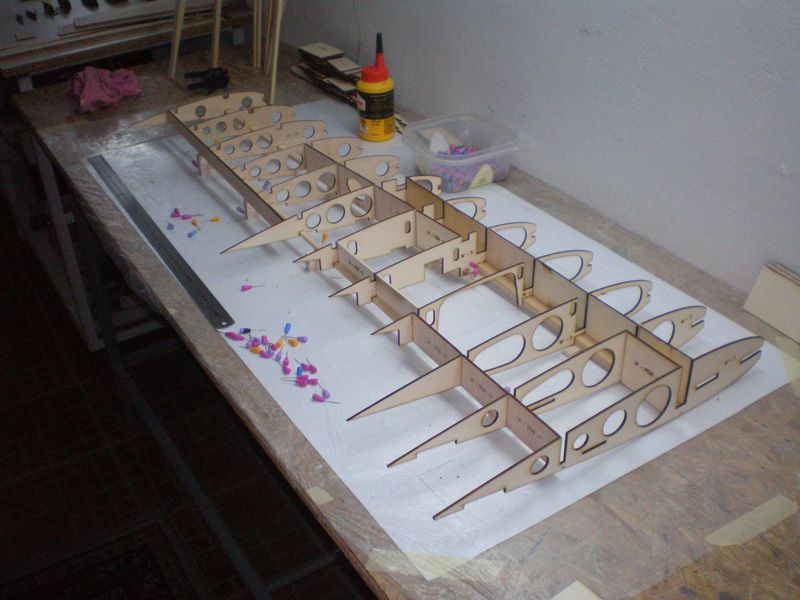

Same like on first model, I start working with rib number one, which was glued on bottom spars. To not move, I screw it with two small bolts. For gluing I used white (carpenter) glue. When I fix first rib, I set first two ply plates, in front and behind of the spar. Those plates give me right distance for next rib...

Rib after rib, panel after panel, wing shape was very fast in this condition...

...than like this...

Next, I glued first upper spar...

On this model all spars and wing joiners are smaller than on first model.

All plates between ribs and spars on first model was form ply. Now some plates, closer to wing middle are still from ply, but other are made from balsa. Closer to wing tip, those plates are just from one spar side...

For now, some plates are not install, because it's easier to put bottom wing joiner plate without them...

Same is on rear side...

When glue was dry I put spars, to check how they lies in the wing...

Rear wing joiner...

Both are absolutely parallel...

For now I wasn't glue wing joiners in the wing. I want to made right wing half and than check level and how wing joiners stay in position in both sides.

So, that's all for today...

Rib after rib, panel after panel, wing shape was very fast in this condition...

...than like this...

Next, I glued first upper spar...

On this model all spars and wing joiners are smaller than on first model.

All plates between ribs and spars on first model was form ply. Now some plates, closer to wing middle are still from ply, but other are made from balsa. Closer to wing tip, those plates are just from one spar side...

For now, some plates are not install, because it's easier to put bottom wing joiner plate without them...

Same is on rear side...

When glue was dry I put spars, to check how they lies in the wing...

Rear wing joiner...

Both are absolutely parallel...

For now I wasn't glue wing joiners in the wing. I want to made right wing half and than check level and how wing joiners stay in position in both sides.

So, that's all for today...

Last edited by mirce; 08-21-2013 at 08:19 AM.