Saito FG-60R3

#1877

Join Date: Jan 2007

Location: Dubai, UNITED ARAB EMIRATES

Posts: 500

Likes: 0

Received 2 Likes

on

2 Posts

Adrien, your effort is VERY MUCH APPRECIATED, so thank you for taking the time and effort to go to the trouble you have to make this video.

From what I understand you basically rotated the prop hub in order to realign the magnets so that its firing static at 30deg BTDC. Obvioulsy then, you cannot use the locating pin. I will try this, because from what I can see, that engine is running VERY NICELY! I I will just use some threadlock on the collet and the prop drive. If ever there is a prop strike of any sort, it will probably mean that timing will need to be checked again, but if it is marked like you have done, then it wont be a problem.

I had suggested 3 different ways to change the timing point (redrill the sensor mounting holes, redesign the prop hub or redesign the hall sensro mount). It seems you have found a 4th way to do it! Well done!

It is a bit of a mystery as to WHY Saito have done this, and only wish that someone would be in a position to get an answer from them. My suspicion is that between RCxel, and Saito designers/engineers, they didnt go over the criteria properly, and Saito just designed it the same way they would a single cylinder. Maybe you should ask the RCxel guys to have a little 'chat' with Saito. As I mentioned before, if it IS the case that they have designed this wrong, then NOBODY would ever admit to it, the design would simply be changed (like they did with the Ray English brass bushing and now the piston redesign) and not a single thought would be spare for the users that have engines already...

Adrien, I see an opportunity for you to design and build a prop driver for the FG radials, and sell them to all of us! I would buy one, because I would be prepared to bet that THIS is the reason that people are blowing their engines to bits. I may lose that bet, but from your video, that engine is running pretty well.

The last time I ran my engine I pushed the hall sensor as close to TDC as I could, and got the timing as close to 30Deg as I could, and it ran better, and started easier.

Thank you once again for putting the time and effort in, and dont worry about the translation, you speak better english, than I could speak your home language!

From what I understand you basically rotated the prop hub in order to realign the magnets so that its firing static at 30deg BTDC. Obvioulsy then, you cannot use the locating pin. I will try this, because from what I can see, that engine is running VERY NICELY! I I will just use some threadlock on the collet and the prop drive. If ever there is a prop strike of any sort, it will probably mean that timing will need to be checked again, but if it is marked like you have done, then it wont be a problem.

I had suggested 3 different ways to change the timing point (redrill the sensor mounting holes, redesign the prop hub or redesign the hall sensro mount). It seems you have found a 4th way to do it! Well done!

It is a bit of a mystery as to WHY Saito have done this, and only wish that someone would be in a position to get an answer from them. My suspicion is that between RCxel, and Saito designers/engineers, they didnt go over the criteria properly, and Saito just designed it the same way they would a single cylinder. Maybe you should ask the RCxel guys to have a little 'chat' with Saito. As I mentioned before, if it IS the case that they have designed this wrong, then NOBODY would ever admit to it, the design would simply be changed (like they did with the Ray English brass bushing and now the piston redesign) and not a single thought would be spare for the users that have engines already...

Adrien, I see an opportunity for you to design and build a prop driver for the FG radials, and sell them to all of us! I would buy one, because I would be prepared to bet that THIS is the reason that people are blowing their engines to bits. I may lose that bet, but from your video, that engine is running pretty well.

The last time I ran my engine I pushed the hall sensor as close to TDC as I could, and got the timing as close to 30Deg as I could, and it ran better, and started easier.

Thank you once again for putting the time and effort in, and dont worry about the translation, you speak better english, than I could speak your home language!

#1878

Senior Member

Hello Adrian,

Very much appreciated you took the effort to explain and make a video of the issue.

One question, did you noticed yourself that your engine now is running better, smoother, less heat, more powerful than before you modified the timing?

Best regards Didier

Very much appreciated you took the effort to explain and make a video of the issue.

One question, did you noticed yourself that your engine now is running better, smoother, less heat, more powerful than before you modified the timing?

Best regards Didier

#1879

Join Date: Nov 2003

Location: LinkŲping, SWEDEN

Posts: 47

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for your video Adrian and for Quick and easy solution to change timing to 30 degree.

Now i understand how the ignition box is designed to work on this engine.

I have your timing kit with piston stop and it is no hard work to do this mod and no new part

needed.

One of two problem can be solved with this fix but due to Rod design not same timing each cylinder. It is now 10 degree split.

Thanks again

Now i understand how the ignition box is designed to work on this engine.

I have your timing kit with piston stop and it is no hard work to do this mod and no new part

needed.

One of two problem can be solved with this fix but due to Rod design not same timing each cylinder. It is now 10 degree split.

Thanks again

Last edited by F3A Nordic; 11-12-2018 at 09:58 AM.

#1880

Join Date: Jan 2007

Location: Dubai, UNITED ARAB EMIRATES

Posts: 500

Likes: 0

Received 2 Likes

on

2 Posts

I doubt you would notice to much difference on the bench with regards to power, but maybe with temps. It certainly starts easy, and idles pretty well. It just sounds better, although not easy to tell.

#1883

Senior Member

It is your engine, but why not make a great running engine to run even better and more important run healthier.

Very nice Adrian comes with a solution and Morris is developing a prophub for the 60 with the magnets on the correct position.

#1884

Join Date: Jan 2007

Location: Dubai, UNITED ARAB EMIRATES

Posts: 500

Likes: 0

Received 2 Likes

on

2 Posts

Sparky,

i have to to admit that I am also reluctant to believe that they would make such mistakes, but when the people that make the ignition system for them, says that that is where they need to be timed, then thatís where they should be timed. Unless the ignition manufacturer is unsure of their product. Saitoís foray into gas engines hasnít been without problems. The FG 20 had huge problems with the carbs, i know someone at our field who gave up and converted his to glow, and it runs beautifully. Just after heíd received his replacement motor after sending it back (they fixed nothing, HH just sent a new one) he had the same problem. Not long after that, a new carb was revealed in the FG21.

FG84ís were also grenading, and not long after that the FG90 appears.

Now all of a sudden we have new piston designs in the FG60, clearly to stop cylinders cracking by reducing the compression ratio. Original FG60ís had no brass bushing, now they do...

I have also noted that the exhaust valve gear doesnít get nearly enough lube to help with longevity, not an easy problem to solve but after 3-4 flights, remove the tappet cover and see how dry everything is up there. They have some issues and would never ever admit to them as it would mean a lot of angry customers....

just my opinion. I am going to adjust the timing as Adrien and Morris have done, and then slap it in the plane and see what results I get....

i have to to admit that I am also reluctant to believe that they would make such mistakes, but when the people that make the ignition system for them, says that that is where they need to be timed, then thatís where they should be timed. Unless the ignition manufacturer is unsure of their product. Saitoís foray into gas engines hasnít been without problems. The FG 20 had huge problems with the carbs, i know someone at our field who gave up and converted his to glow, and it runs beautifully. Just after heíd received his replacement motor after sending it back (they fixed nothing, HH just sent a new one) he had the same problem. Not long after that, a new carb was revealed in the FG21.

FG84ís were also grenading, and not long after that the FG90 appears.

Now all of a sudden we have new piston designs in the FG60, clearly to stop cylinders cracking by reducing the compression ratio. Original FG60ís had no brass bushing, now they do...

I have also noted that the exhaust valve gear doesnít get nearly enough lube to help with longevity, not an easy problem to solve but after 3-4 flights, remove the tappet cover and see how dry everything is up there. They have some issues and would never ever admit to them as it would mean a lot of angry customers....

just my opinion. I am going to adjust the timing as Adrien and Morris have done, and then slap it in the plane and see what results I get....

#1885

Good to see some interest has been given to the timing and prop hub. I mentioned early on that it might be the cause of the cracking cylinders.

Adrien, I wonder if you could check the timing of the other cylinders? I think no.2 is too advanced and no.3 is retarded.

As was mentioned the geometry of the master rod changes the TDC of no.2 & 3 cylinders however the magnets on the hub are 120* apart.

thanks to everybodyís input!!!!

Adrien, I wonder if you could check the timing of the other cylinders? I think no.2 is too advanced and no.3 is retarded.

As was mentioned the geometry of the master rod changes the TDC of no.2 & 3 cylinders however the magnets on the hub are 120* apart.

thanks to everybodyís input!!!!

#1886

Join Date: Jan 2007

Location: Dubai, UNITED ARAB EMIRATES

Posts: 500

Likes: 0

Received 2 Likes

on

2 Posts

Yeah, I really do think there is a problem here, and I am not trying to preach rubbish. If I am wrong, I would happily concede my argument, and the result of that will be that I get rid of both my engines, and look for something more suitable for my purpose. I wouldnt dare say they are rubbish engines, its just that mine APPEAR to run ok, but in practice, they do not. I have seen video's of planes that seem to fly a lot better than mine, and generate a lot more power. The original plane I had mine in was a 50cc sized, PilotRC Yak55M, it flew, but without any guts. It always seemed a little underpowered. The tuning was right (according to settings that others have reported around 1.2-1.5 turns out on the top end and around 4.5-5 turns out on the low). It idled nicely, transitioned well, but just would NOT tow the plane around, and was always overheating too much for my liking. There is a video on youtube with the EXACT same plane, albeit a different colour, and the guy hauls it around much better than mine. There is a video of a 2.3m wingspan, Blackhorse Corsair which sounds and flies like an absolute BEAST...it 'screams' as it fly's by. I have put mine in a Blackhorse Sea Fury that is smaller in size and weight than the Corsair....and it is marginal at best. To get it to rev out like the one in the corsair, I need to climb slowly, and then once high enough, hammer it into a dive...only then, maybe....it goes like it should. I have two engines, they are pretty much set up in an identical manner, and one behaves slightly better than the other... I have replaced rings, cleaned carbon off valves, set the tappets and double-checked everything. I even resigned myself to the fact that these engines cannot be run in the UAE heat of summer, so only run them in winter.

On the 'other forum' there is a guy who runs one in a VQ Bearcat, and he never gets temps over 115 Deg C......my temps, on the same prop, during flight....mainly 150Deg with peaks at 175! Its too high for sure.....especially when its not got the power it should... I agree that temps without baffled vs no baffles vs no cowl should be different.....but still, having tried all thre options.....doesnt make much difference in my case.

F3ANordic posted his readings with timing set when the magnet approaches the sensor, as follows:

Cyl 1 45,5. Cyl 2. 51. Cyl 3. 39,5. all in Deg BTDC.

If you move the prophub by 15Deg, to get Cyl 1 at 30 Deg, the rest will advance by the same amount giving the following:

Cyl 1 - 30Deg, Cyl 2 - 36, Cyl 3 - 24.5

This would still NOT be optimal, but I would venture it is a LOT closer to where it should be, and I am happily going to expriment on doing this. I will take the prophub off, move it by 15 Deg and then just tighten it down like Adrien has done. Get Cyl 1 at 30Deg BTDC and run it. If it is better in a flight situation, I will take the prop hub to a machine shop and have them drill and tap a new guide pin hole, 15 Deg to the LEFT of the existing one (facing the engine from the front).

If it is running better, and someone like Adrien or Morris design a hub that addresses the correct timing accordign to the crank dimensions, I will buy it in a heartbeat.

I have nothing left to lose now.... and I am quite happy to be the guinea pig on this. lol!

I have my eye on the UMS 90, 7-cyl radial.....I will move the FG60's to new owners....and reveal all honesty about the engines, hopefully someone else fares better than I have.

On the 'other forum' there is a guy who runs one in a VQ Bearcat, and he never gets temps over 115 Deg C......my temps, on the same prop, during flight....mainly 150Deg with peaks at 175! Its too high for sure.....especially when its not got the power it should... I agree that temps without baffled vs no baffles vs no cowl should be different.....but still, having tried all thre options.....doesnt make much difference in my case.

F3ANordic posted his readings with timing set when the magnet approaches the sensor, as follows:

Cyl 1 45,5. Cyl 2. 51. Cyl 3. 39,5. all in Deg BTDC.

If you move the prophub by 15Deg, to get Cyl 1 at 30 Deg, the rest will advance by the same amount giving the following:

Cyl 1 - 30Deg, Cyl 2 - 36, Cyl 3 - 24.5

This would still NOT be optimal, but I would venture it is a LOT closer to where it should be, and I am happily going to expriment on doing this. I will take the prophub off, move it by 15 Deg and then just tighten it down like Adrien has done. Get Cyl 1 at 30Deg BTDC and run it. If it is better in a flight situation, I will take the prop hub to a machine shop and have them drill and tap a new guide pin hole, 15 Deg to the LEFT of the existing one (facing the engine from the front).

If it is running better, and someone like Adrien or Morris design a hub that addresses the correct timing accordign to the crank dimensions, I will buy it in a heartbeat.

I have nothing left to lose now.... and I am quite happy to be the guinea pig on this. lol!

I have my eye on the UMS 90, 7-cyl radial.....I will move the FG60's to new owners....and reveal all honesty about the engines, hopefully someone else fares better than I have.

Last edited by cathurga; 11-14-2018 at 11:26 PM.

#1888

Join Date: Jan 2007

Location: Dubai, UNITED ARAB EMIRATES

Posts: 500

Likes: 0

Received 2 Likes

on

2 Posts

Hey guys and gals,

here is is a video of my engine and how I have moved the prop hub. Pretty much the same as what Adrien did.

Runs nicely now, will get a video of it running later.

video of start...

video of running

here is is a video of my engine and how I have moved the prop hub. Pretty much the same as what Adrien did.

Runs nicely now, will get a video of it running later.

video of start...

video of running

Last edited by cathurga; 11-17-2018 at 05:20 AM.

#1890

Join Date: Jan 2007

Location: Dubai, UNITED ARAB EMIRATES

Posts: 500

Likes: 0

Received 2 Likes

on

2 Posts

Sparky,

i couldnt get the high rpm, the Rev counter kept blanking out everytime it went over 6200rpm, but it did climb higher than that. I also need to fiddle more with the needles more. I had to lean the LS about a 1/4 turn as it was Ďrichí on idle and transition. I also leaned the HS a little but didnít want to do too much with that until have reliable rev counter. Running pump gas with 20:1 redline oil, prop is a 6-star 22x10

Before I did this mod, I was getting an idle that would only stabilise around 1300, and high end was getting around 6500.

Iíve installed that particular engine back in the sea fury after that run, and have mounted the other engine, which Iíve done the mod to as well. I have a Jeti rev counter that I will install so that I can get accurate readings on my tx. Iíll also mount the Jeti temp loops on Cylís 1 & 3 for temps.

sorry about the rubbish video quality but I had to try start, film and operate the tx all at once.

that tired old bench of min has some flex in it so itís difficult to get a stable idle with the servo connected, but didnít have anyone to help...

just by my ear, it runs better and transitions well. Previously it had a Ďburbleí when going up the rev range at about 3500 rpm. Thatís gone and it just seems to be running Ďfree-erí. I know thatís not a word...but you get the gist of it.

i couldnt get the high rpm, the Rev counter kept blanking out everytime it went over 6200rpm, but it did climb higher than that. I also need to fiddle more with the needles more. I had to lean the LS about a 1/4 turn as it was Ďrichí on idle and transition. I also leaned the HS a little but didnít want to do too much with that until have reliable rev counter. Running pump gas with 20:1 redline oil, prop is a 6-star 22x10

Before I did this mod, I was getting an idle that would only stabilise around 1300, and high end was getting around 6500.

Iíve installed that particular engine back in the sea fury after that run, and have mounted the other engine, which Iíve done the mod to as well. I have a Jeti rev counter that I will install so that I can get accurate readings on my tx. Iíll also mount the Jeti temp loops on Cylís 1 & 3 for temps.

sorry about the rubbish video quality but I had to try start, film and operate the tx all at once.

that tired old bench of min has some flex in it so itís difficult to get a stable idle with the servo connected, but didnít have anyone to help...

just by my ear, it runs better and transitions well. Previously it had a Ďburbleí when going up the rev range at about 3500 rpm. Thatís gone and it just seems to be running Ďfree-erí. I know thatís not a word...but you get the gist of it.

Last edited by cathurga; 11-17-2018 at 06:44 AM.

#1891

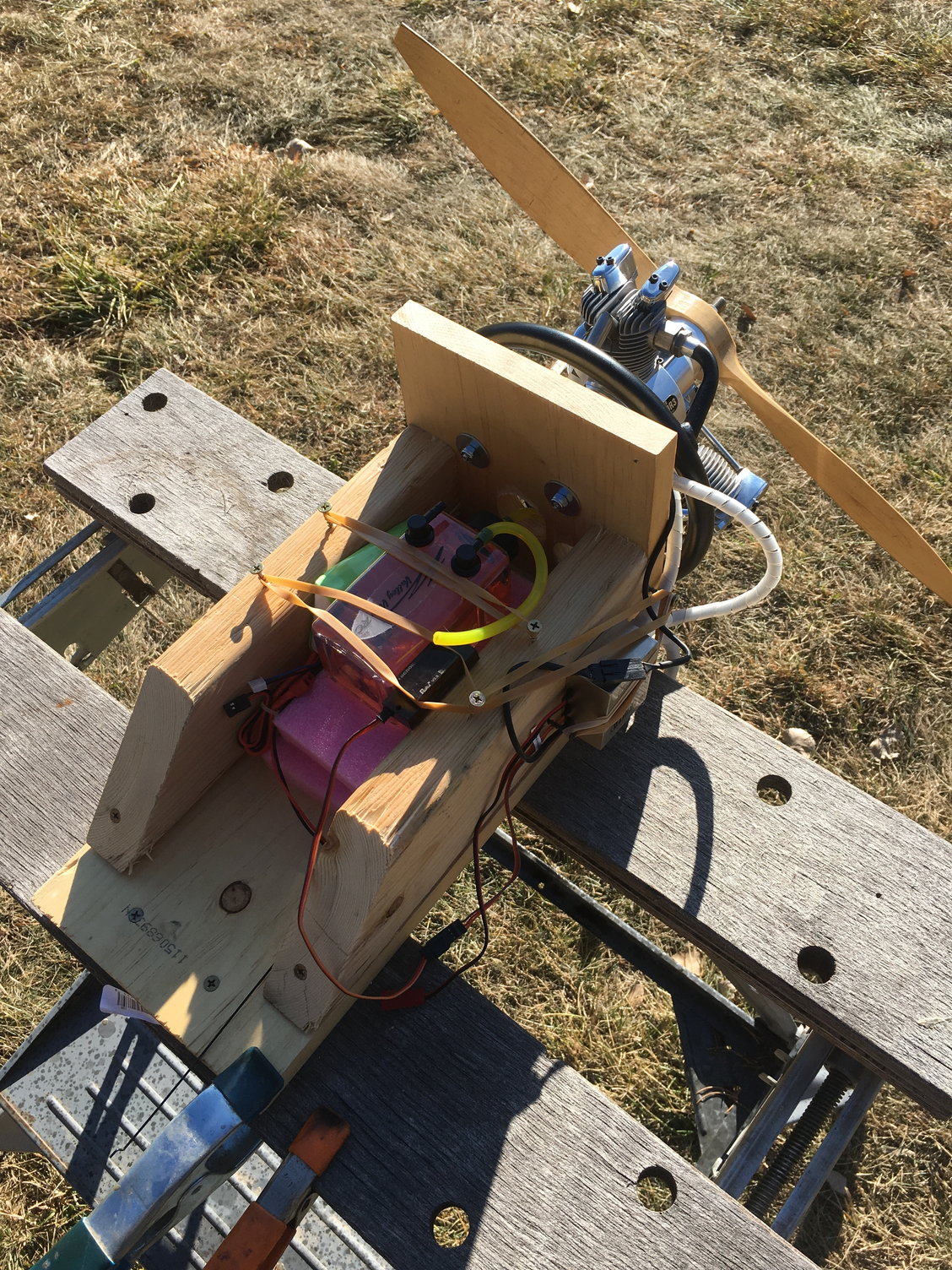

Saito 60r3 on the test stand

I just bought a 60r3 from Horizon, it basically brand new but itís been run by them. They sold it as a used engine which I saved several hundred dollars. So I mounted a Keleo ring and got it on the test stand. Iím treating it as a brand new engine, so Iím running 15:1, a 22x8 prop. The engine primes well, and hand starts well. I started out at 8 on the low and 4 on the high. Iíve ran about 10oz of fuel through it today below 4000rpm. One thing is itís not firing on cylinder #3. The temps on 1 and and 2 have been low. Could the timing be off?

Last edited by Denfly31; 11-17-2018 at 02:51 PM. Reason: Add info

#1892

I ran my 60r3 a little bit today, 15:1 8 turns out on the L and 4 on the H. So I'm running richer that it states in the manual to make sure it has proper lube to everything. I noticed a squeaking sound when turning the prop. First through it was in the carb, sucking air, but sounds like maybe the front bearing. I may just be paranoid, not sure.

#1893

Here is my second run were the engine had the sound that I'm concerned with. Again this is running at 15:1 Red Line oil, 8 turns out on the low setting and 4 on the high. Running at 6700' ASL.

#1895

Horizons Quote from there page:

- Horizon Hobby recommends the use of Red Line or Power Model synthetic oil only, at a mix ratio of 16:1 Ė 20:1

#1898

My Feedback: (6)

The engine throws a lot of Black oil what i see in the picture is something I consider normal. I would not consider that something to return the engine to Horizon for.

The squeak is another thing,. You could squirt some oil in the breather and see if it goes away, if you can isolate the squeak to the front end I would call Horizon concerning the issue.

Sparky

The squeak is another thing,. You could squirt some oil in the breather and see if it goes away, if you can isolate the squeak to the front end I would call Horizon concerning the issue.

Sparky

#1899

Here are some videos I made about my FG-60

the squeak did go away on its own and oil seems to get there better now. However the cylinder did crack and was replaced. Still no squeak.

I was was about to switch to Redline oil as HH highly suggests it. But still have about a quart of fuel left. Itís old so I was going to use it in a bonfire. I donít fly as much as I use to. But I do realize fresh gas is better for the engine. Ethanol free of course.

More thoughts on redline?.?.

I was was about to switch to Redline oil as HH highly suggests it. But still have about a quart of fuel left. Itís old so I was going to use it in a bonfire. I donít fly as much as I use to. But I do realize fresh gas is better for the engine. Ethanol free of course.

More thoughts on redline?.?.

#1900

Join Date: Jan 2007

Location: Dubai, UNITED ARAB EMIRATES

Posts: 500

Likes: 0

Received 2 Likes

on

2 Posts

The oil discussion could rage on, as it always does. I really dont want to comment, but will raise some points over the time I have run my engine.

Redline apparently 'burns off' a lot of its contents, which is what makes it (according to them, not me) a cleaner oil. The problem is it was designed for 2-stroke engines, which lubircate the crank through the fuel mix passing through the crankcase. This does not happen in an 4T engine like this. The oil that makes it through to the crankcase and valvetrain is residual that gets past the rings. I have gone back to Redline after trying Techniplate with the Benol in it. I had to dismantle the engine, remove all the valves and clean off the carbon from the valves. Wont be using that again.

With redline, everytime I have dismantled the engine, there has always been enough oil running around in the crankcase and lower cylinder valvetrain, its doing its job of lubing EXCEPT in cyl 1, where those two tappets, especially the exhaust valve, are very dry. After every third or fourth run, I remove the tappet covers and oil them manually...with more redline. I think MDavis experience above, confirms that there is not enough lube there. I would expect yours is the same.

Stihl makes a special oil for hybrid 2T/4T engines (these engines have valves like a 4T, but the mix still goes through the crankcase) I wanted to try it, but cannot get it in the UAE. So just going to stick with redline. Originally HH said to use Morgan Cool Power 2T oil, but seems that they have changed their minds. Just for the record, all my 2T engines run Redline and they all perform well, no problems. If I had to change it would be to Stihl, just because I can get the normal one here.

If you are in the break-in period still, here is what I would do/did (emphasis on I because each to their own, and its what I did after seeing many posts on here).

Only when you start leaning it out on the needles, will all of them start firing properly, but before you run it again....lube it up, it seems to be a valvetrain squeak you have there....

Oh, and by the way, your timing IS out, lol! If your prop hub and magnet are where mine are in the video's, you have the same problem. The fix that I have done is completely reversible, and if you have a puller and a protractor/timing kit, you can do it in about 20mins. Failing that, just move your hall sensor as far up towards TDC that you can, it will put the timing closer to where it should be, but you will still be out by 10 Deg as you will be at 40 deg and not 30 on cyl 1.

Good luck!

Redline apparently 'burns off' a lot of its contents, which is what makes it (according to them, not me) a cleaner oil. The problem is it was designed for 2-stroke engines, which lubircate the crank through the fuel mix passing through the crankcase. This does not happen in an 4T engine like this. The oil that makes it through to the crankcase and valvetrain is residual that gets past the rings. I have gone back to Redline after trying Techniplate with the Benol in it. I had to dismantle the engine, remove all the valves and clean off the carbon from the valves. Wont be using that again.

With redline, everytime I have dismantled the engine, there has always been enough oil running around in the crankcase and lower cylinder valvetrain, its doing its job of lubing EXCEPT in cyl 1, where those two tappets, especially the exhaust valve, are very dry. After every third or fourth run, I remove the tappet covers and oil them manually...with more redline. I think MDavis experience above, confirms that there is not enough lube there. I would expect yours is the same.

Stihl makes a special oil for hybrid 2T/4T engines (these engines have valves like a 4T, but the mix still goes through the crankcase) I wanted to try it, but cannot get it in the UAE. So just going to stick with redline. Originally HH said to use Morgan Cool Power 2T oil, but seems that they have changed their minds. Just for the record, all my 2T engines run Redline and they all perform well, no problems. If I had to change it would be to Stihl, just because I can get the normal one here.

If you are in the break-in period still, here is what I would do/did (emphasis on I because each to their own, and its what I did after seeing many posts on here).

- Before I start the engine, squirt 15-20mm raw redline (or preferred) into the crankcase breather, and let it slop around in there by turning the engine upside down and around. Removed the plugs and turned the engine over to get the oil slopping around.

- Removed all the rocker covers and lubed all the tappets, also dropped oil down the pushrod tubes

- Mounted and started it with factory needle settings. No 2 and No 3 cyls battled to heat up because it is so rich and gravity is helping the fuel down into those two. You can see unburnt oil coming out with intermittent firing. (I could see which ones weren't firing because I had the stock exhausts on, so you can see which ones are firing properly, and which arent. You can also tell by the temps of the jugs by just touching them)

- Ran 1 tank like that, and then removed the engine, and mounted it upside-down (Cyl 1 at the bottom, again, easier with the stock exhausts as you can turn them to face down mostly, you cannot do that with the collector ring and will make a mess, lol)

- Started in this orientation and VERY CLEARLY you can tell that No 1 is now not firing properly.

- Ran another tank through in upright and inverted positions (actually, what I also did was, with the help of a friend, just tilted the stand through 90 deg while it was running) you can hear/see as you tilt it, the cylinders that were too rich, start running properly)

Only when you start leaning it out on the needles, will all of them start firing properly, but before you run it again....lube it up, it seems to be a valvetrain squeak you have there....

Oh, and by the way, your timing IS out, lol! If your prop hub and magnet are where mine are in the video's, you have the same problem. The fix that I have done is completely reversible, and if you have a puller and a protractor/timing kit, you can do it in about 20mins. Failing that, just move your hall sensor as far up towards TDC that you can, it will put the timing closer to where it should be, but you will still be out by 10 Deg as you will be at 40 deg and not 30 on cyl 1.

Good luck!