DLE 20cc Gasser! (Data & Links 1st Post)

#6851

Member

Join Date: Mar 2013

Location: , OH

Posts: 78

Likes: 0

Received 0 Likes

on

0 Posts

FTR, the tubing and tank is new...she sat out the 2016 season so I wanted it to be fresh. She did run this year for three flights perfectly which is why I was surprised she all of a sudden developed the high idle.

Last edited by aaroncmh; 03-19-2017 at 07:00 AM.

#6852

Hi

I have a question concerning ignition systems

Can the spark plug wire be shortened on our ignition systems . Say from 15 inch to 5 inch By changing the cap ?

Thanks

Michel

I have a question concerning ignition systems

Can the spark plug wire be shortened on our ignition systems . Say from 15 inch to 5 inch By changing the cap ?

Thanks

Michel

#6856

You can shorten the length, but think about if you need the wire longer for some other installation.

#6857

My Feedback: (47)

Join Date: Apr 2009

Location: Whitestone,

NY

Posts: 1,895

Likes: 0

Received 0 Likes

on

0 Posts

CaptainJohn - exactly what I was thinking. It's not unusual to end up re-using these IE's for other engines. Shortening the plug cable length would really reduce it's transfer-ability.

On a positive note, I'm very relieved to hear that length doesn't matter.

On a positive note, I'm very relieved to hear that length doesn't matter.

#6858

Hi Thanks for youre reply

But I will most likely think along the line of keeping to basically the same scale . I,ll always have a loop in the line , or a large sag . I wouldn,t cut to measure

BTW .... It,s a DLE 20 RA in a kit built Spit-fire 60

Thanks guys

Michel

But I will most likely think along the line of keeping to basically the same scale . I,ll always have a loop in the line , or a large sag . I wouldn,t cut to measure

BTW .... It,s a DLE 20 RA in a kit built Spit-fire 60

Thanks guys

Michel

#6859

My Feedback: (10)

Join Date: May 2003

Location: Livingston,

MT

Posts: 232

Likes: 0

Received 0 Likes

on

0 Posts

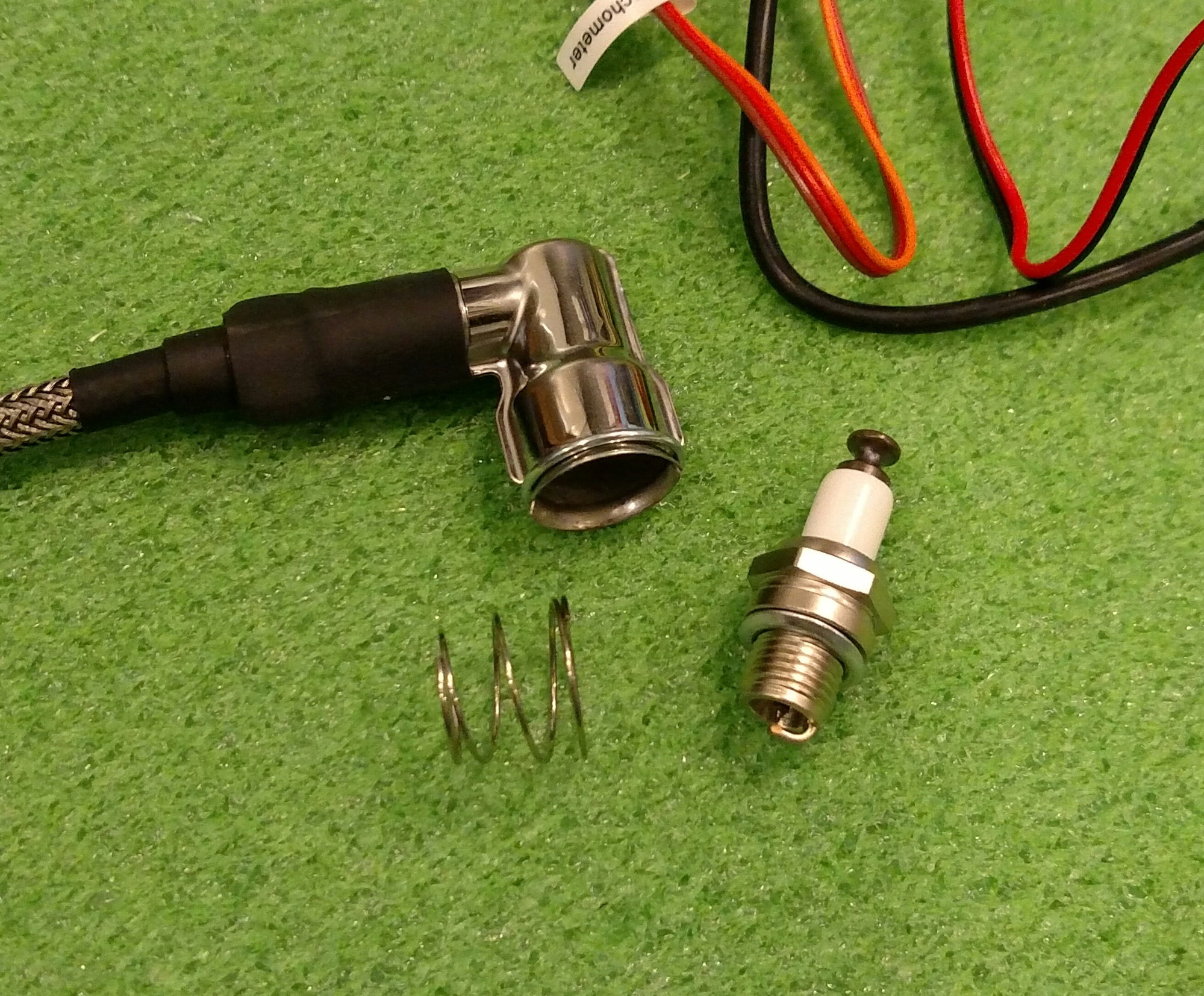

Hi guys, I just got my shiny new DLE 20 and I can't figure out how the spark plug and the spring fit into the ignition cap? Would someone be so kind to explain how this works please? Thanks

#6860

My Feedback: (11)

Spring can be optional. But narrow end into cap , then force cap down upon plug , until rubber fitting within cap is firmly seated. You may do this after the plug is screwed into the engine of course. A little motor oil on the threads will ease removal of the plug . Plug needs to be firmly pressed into cap so that electrode in cap is touching end of plug.

#6862

Join Date: Jun 2015

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

Push it in very good you shouldn’t be able to just take it out it should have a lot of resistance when pulled on. I had to use a pair of pliers before (not recommended) but just to give you an idea. Just try to push it as hard as you can.

Also do yourself a favor dump the spark plug in the garbage and get yourself NGK spark plug the size is CM6 you could order it online or you might be able to find it at your local auto parts store.

Also do yourself a favor dump the spark plug in the garbage and get yourself NGK spark plug the size is CM6 you could order it online or you might be able to find it at your local auto parts store.

#6863

My Feedback: (11)

The cap may a bit loose and you may have to crimp it a bit. Be sure that the side of the cap are as far down on the plug as it can go. There is a ring on the bottom of the cap to supply some holding tension. But if you think the cap is loose crimp it a bit . It should take some force to get it off.

#6868

#6869

Join Date: Dec 2014

Posts: 20

Likes: 0

Received 0 Likes

on

0 Posts

I am breaking in my new DLE 20, easy to start, good idle and transition but I reach full RPM using only 20 % of the servo travel. I checked the user’s manual, but nothing about what to do. This thread is too large to read it, also iam asking if I play with the high speed adjustment screw, I will be able to extend the travel?

Last edited by Volo; 02-01-2019 at 10:01 AM.

#6870

You have to set up the throttle curve on the radio. There is very little transition between idle and WOT, so you need to widen the stick to servo movement. Pretty much 0-3/4 stick should be roughly half throttle opening, anything above that is WOT on the DLE.

#6871

Join Date: Dec 2014

Posts: 20

Likes: 0

Received 0 Likes

on

0 Posts

I played already with the travel curve, but what I had to say is the travel arm on the carburetor is used only at 25% to go from idle to maximum speed. The butterfly is partially open at full speed. I want to get full speed when the air intake is fully open.

#6872

My Feedback: (19)

To a degree, what you describe is normal but not full throttle at 20% throttle. Any butterfly type throttle will reach nearly full throttle somewhere around 3/4 travel with very little RPM gain above that. Most people set up a throttle curve using mechanical differential, radio throttle curves or a combination of both to achieve the desired throttle response at the desired stick position. We can address that later. I feel your current problem is probably caused by the needles not being set yet. You need to tune that engine for idle and full throttle operation as you are probably very rich at full throttle now causing low RPM at that throttle setting. Tune the engine and it will act more normal.

#6874

Join Date: Dec 2014

Posts: 20

Likes: 0

Received 0 Likes

on

0 Posts

No idea, my RPM meter is in Canada and I am presently in Florida. I know I am near maximum speed, the engine is screaming high pitch. More over I measured the maximum trust with a scale and I read 9 1/2 pounds, which to me, seems very close to the top. This is my first gas engine, but I have a lot of experience with glow engines, turning faster than gas. I believe that if I approach max speed at 25% air flow, it is because the mixture is lean, also I will try to open the high speed needle valve.

years of making gas engines they still cant get it from the factory

years of making gas engines they still cant get it from the factory