Lanier 94" Yak help

#402

Junior Member

Join Date: Apr 2006

Location: Wonder Lake, IL

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

Bosshossv8

How much larger is the carb hole in the fire wall? With the DA 85 it looks like I will have to enlarge the hole, and am worried about the strength of the fire wall.

How much larger is the carb hole in the fire wall? With the DA 85 it looks like I will have to enlarge the hole, and am worried about the strength of the fire wall.

#403

Member

Join Date: Jul 2007

Location: , WI

Posts: 65

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: Bosshossv8

I Don;t know how you guys with the twins are going to get enough air through the cowl to cool them. I know I will be gutting the bottom of mine, for sure. It may have to be braced with cf and overlayed glass , just for support. The only way I can see getting enough air through is opening the bottom completely, or fabbing a rear facing scoop.

Some very delicate dremeling of the louvres may help , too...[:-][:-]

Even baffled , where would the air go in a twin install? And have a larger exit than entrance is near impossible.

I really think a healthy motor is going to need this cowl to be swiss cheese....um, Russian style

I am just going attack mine with the dremel and Sharpie marker and see how it turns out. If the bottom, after being gutted, makes the cowl flimsy, I can lay cf rod around the perimeter of the hole and glass over it. Pain in the butt, but I can;t see another way....

Anyone?

ORIGINAL: matfree

Does anyone have a picture of the da-100 or dl-100 mounted on the firewall with the Cowl on. Trying to deside on 100cc or 85cc dont want to cut the cowl but would like to see what the 100cc's would look like and how they fly????? THanks Matt

Does anyone have a picture of the da-100 or dl-100 mounted on the firewall with the Cowl on. Trying to deside on 100cc or 85cc dont want to cut the cowl but would like to see what the 100cc's would look like and how they fly????? THanks Matt

Some very delicate dremeling of the louvres may help , too...[:-][:-]

Even baffled , where would the air go in a twin install? And have a larger exit than entrance is near impossible.

I really think a healthy motor is going to need this cowl to be swiss cheese....um, Russian style

I am just going attack mine with the dremel and Sharpie marker and see how it turns out. If the bottom, after being gutted, makes the cowl flimsy, I can lay cf rod around the perimeter of the hole and glass over it. Pain in the butt, but I can;t see another way....

Anyone?

#404

Member

Join Date: Jul 2007

Location: , WI

Posts: 65

Likes: 0

Received 0 Likes

on

0 Posts

This is the kind of thing I was talking about...........

http://www.hangar-9.com/Products/Def...ProdID=HAN4468

Anybody have any idea who makes something like that in different sizes?????

http://www.hangar-9.com/Products/Def...ProdID=HAN4468

Anybody have any idea who makes something like that in different sizes?????

#405

My Feedback: (13)

Join Date: Nov 2002

Location: Maumelle,

AR

Posts: 655

Likes: 0

Received 0 Likes

on

0 Posts

Probably the best thing to do for cooling is make a baffle that covers the entire opening of the cowl, and just cut out openings in it for the cylinder head, fins, and crankcase of the engine that you're using. That cuts the inlet area way down, forces cooling air to only go through the fins, and reduces the size of the cutout you'll need for the air outlet. Finding a cosmetically appealing way of doing that is the challenge. I thought there was a company out there that made dummy radial engine plates for that purpose, but don't remember who...............................

#406

Senior Member

Join Date: Dec 2006

Location: Orange,

CA

Posts: 194

Likes: 0

Received 0 Likes

on

0 Posts

I glassed up the Opening on my 50cc WH Sukhoi and did just what your talking about Mitsu but I just made a duct out of the same light glass cloth and extended it to the cylinder. will do the same with this bird but will have to wait until I see what engine I am getting First. I am going to Glass the Cowl closed Tomorrow though as I am doing everything I can that Doesn't require any money till I get my Electronics and Engine, the Ducting will have to wait though. Temperature is a big concern here in California in the summer as normal summer days are in the high 90's to mid 100's for about 2 months.

Got my Firewall reinforcing done today. What I ended up doing was to pop rivet a 1/2 " aluminum angle to the left and right sides and added 1/2 corner stock to all the other 90 deg junctions. should be plenty strong with anything I hang there. once I am done mounting the cowl I will pretty much be at a stand still for a while.

Got my Firewall reinforcing done today. What I ended up doing was to pop rivet a 1/2 " aluminum angle to the left and right sides and added 1/2 corner stock to all the other 90 deg junctions. should be plenty strong with anything I hang there. once I am done mounting the cowl I will pretty much be at a stand still for a while.

#408

Senior Member

My Feedback: (10)

Join Date: Aug 2003

Location: Schiller park,

IL

Posts: 1,664

Likes: 0

Received 0 Likes

on

0 Posts

AFPD ...Addison Fire Protection District, or Antioch Fire protection District?

The hole is like 2 x 2 with a little slant to it , ala the slant of the carb. I alum angled mine my corners, and tri-stocked with hardwood everywhere I could. The wood that the firewall is made of seems to be very good quality. The sides of the box are very strong, the bottom is suspect. However, after I beat the snot out of mine for a few flights , the bottom seam did separate, some, not much , but the box integritiy was still solid. I am glassing it over .

You can come and see mine fly when the DA gets back next week. I don't think we are very far apart, I wil lbe at the Tri-village/Northwest R/C Fly-in next week, at the Shoe Factory Rd. flying field. There I will be flying my 1/3 Super Cub.

For sure, the baffling will take a creative approach like Mitsu's. I will fab something up for the 85 when it comes back.

The hole is like 2 x 2 with a little slant to it , ala the slant of the carb. I alum angled mine my corners, and tri-stocked with hardwood everywhere I could. The wood that the firewall is made of seems to be very good quality. The sides of the box are very strong, the bottom is suspect. However, after I beat the snot out of mine for a few flights , the bottom seam did separate, some, not much , but the box integritiy was still solid. I am glassing it over .

You can come and see mine fly when the DA gets back next week. I don't think we are very far apart, I wil lbe at the Tri-village/Northwest R/C Fly-in next week, at the Shoe Factory Rd. flying field. There I will be flying my 1/3 Super Cub.

For sure, the baffling will take a creative approach like Mitsu's. I will fab something up for the 85 when it comes back.

#409

Junior Member

Join Date: Apr 2006

Location: Wonder Lake, IL

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

Bosshossv8,

Thanks for the info. That would be Addison Fire Protection District. Instead of using aluminum I glassed the corners and applied extra epoxy to the inside of the firewall. Whats the date for the fly in? I'll see if I free.

Thanks for the info. That would be Addison Fire Protection District. Instead of using aluminum I glassed the corners and applied extra epoxy to the inside of the firewall. Whats the date for the fly in? I'll see if I free.

#410

Senior Member

Join Date: Aug 2006

Location: Egg Harbor City,

NJ

Posts: 760

Likes: 0

Received 0 Likes

on

0 Posts

OK guys,

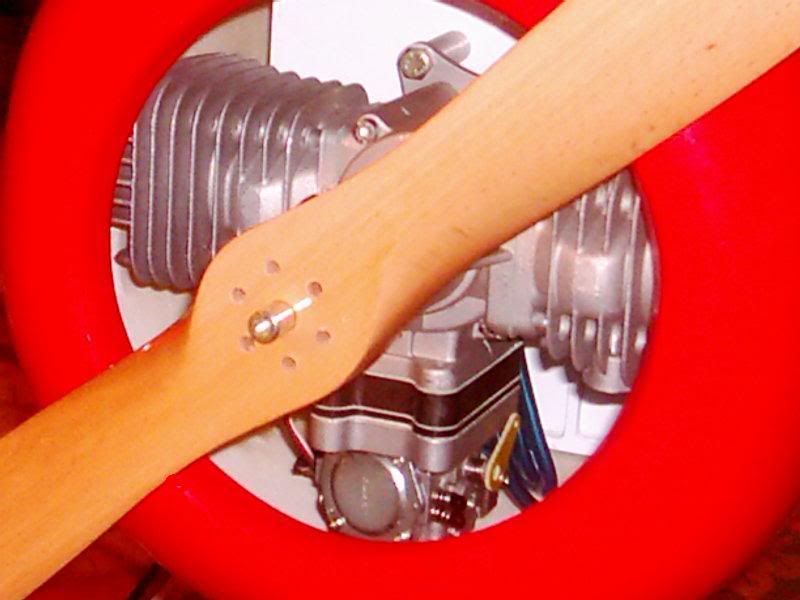

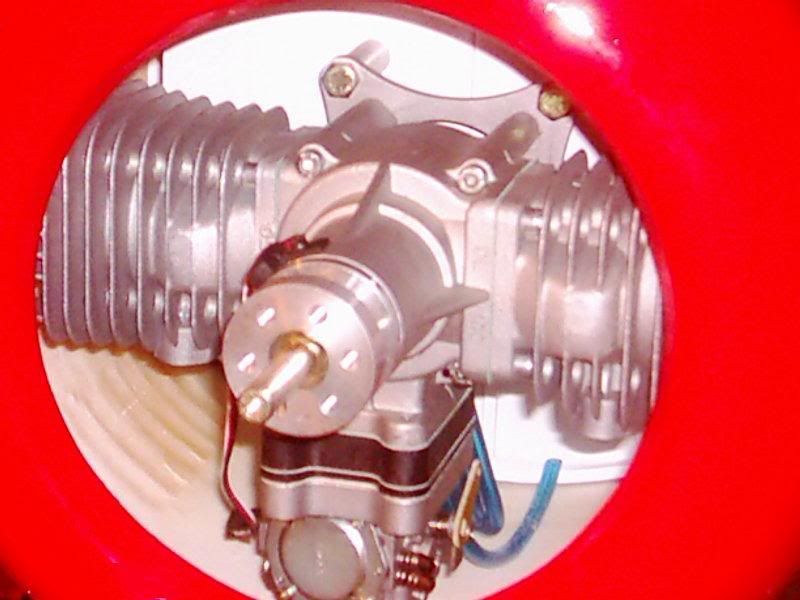

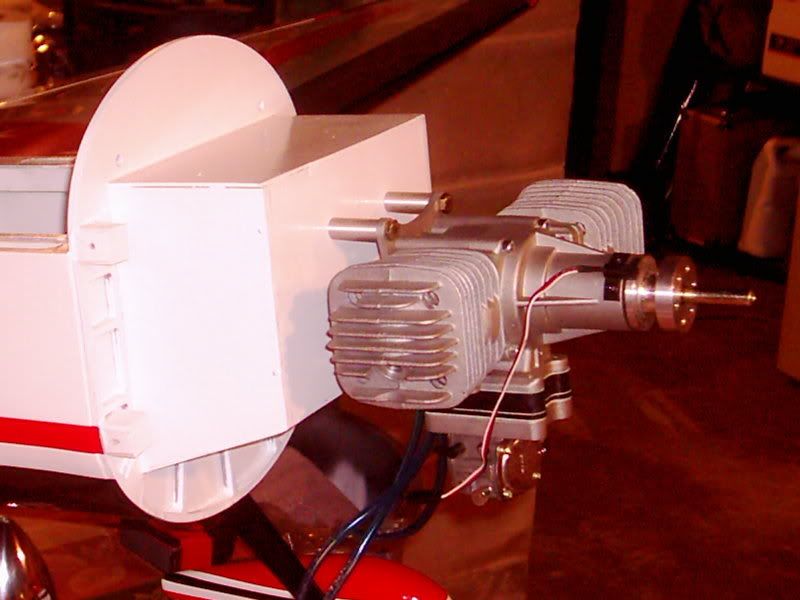

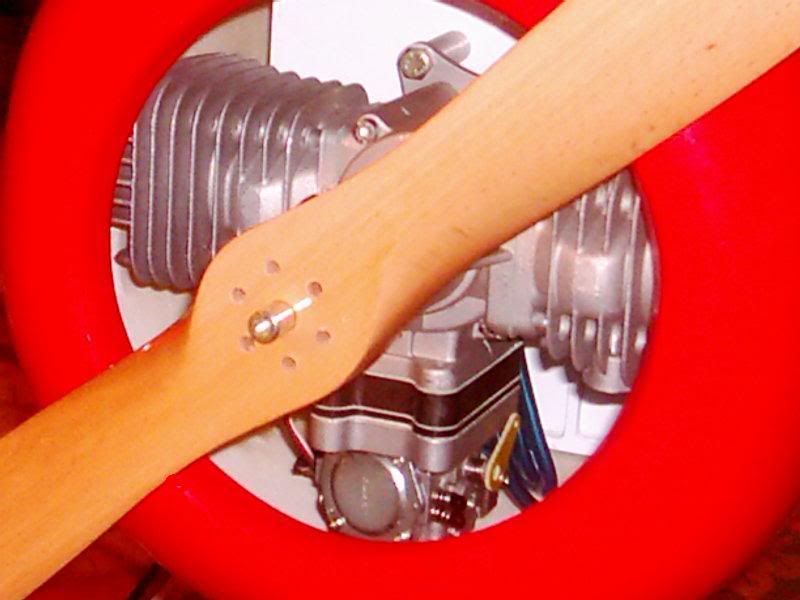

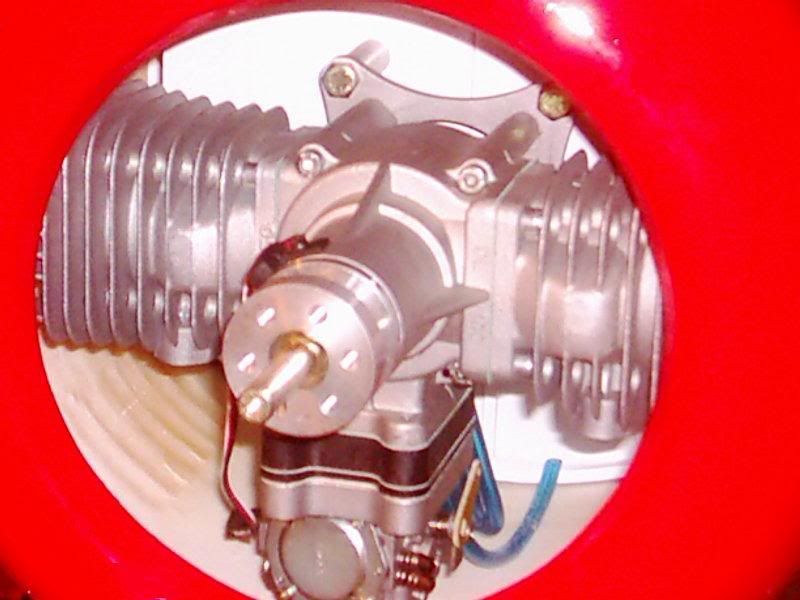

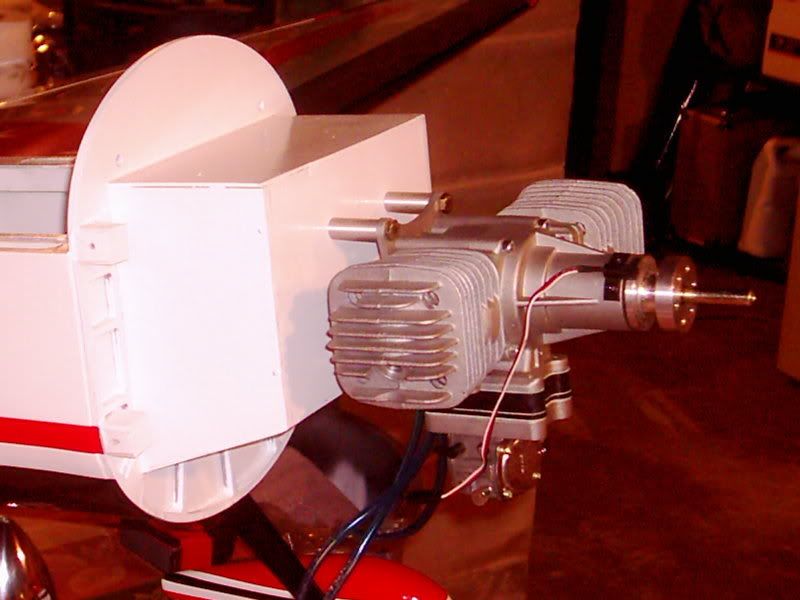

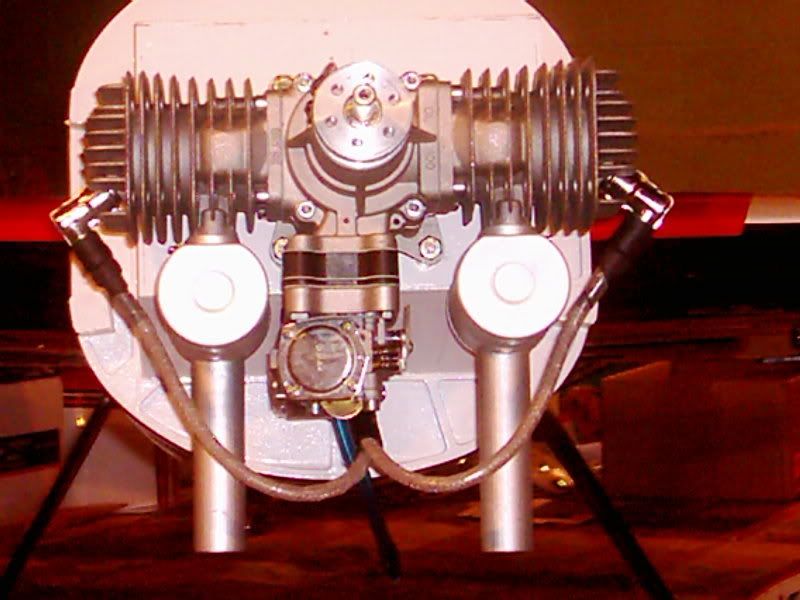

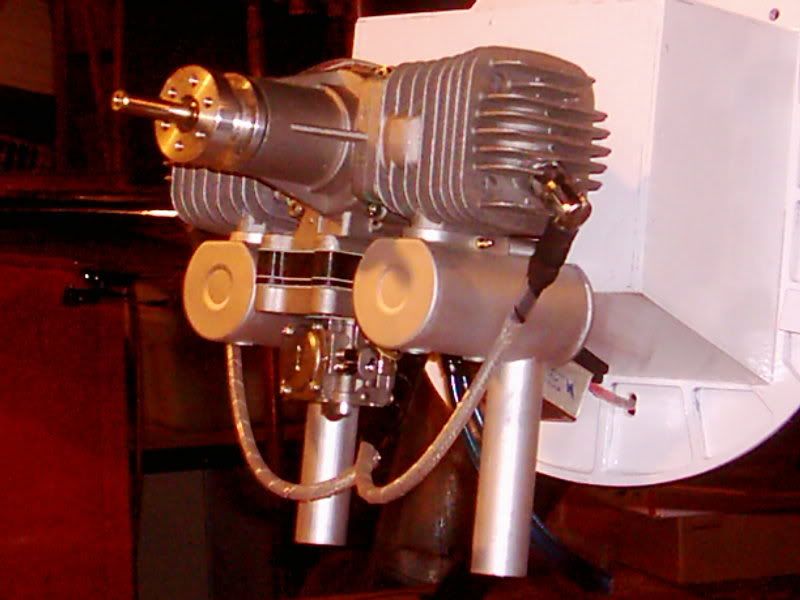

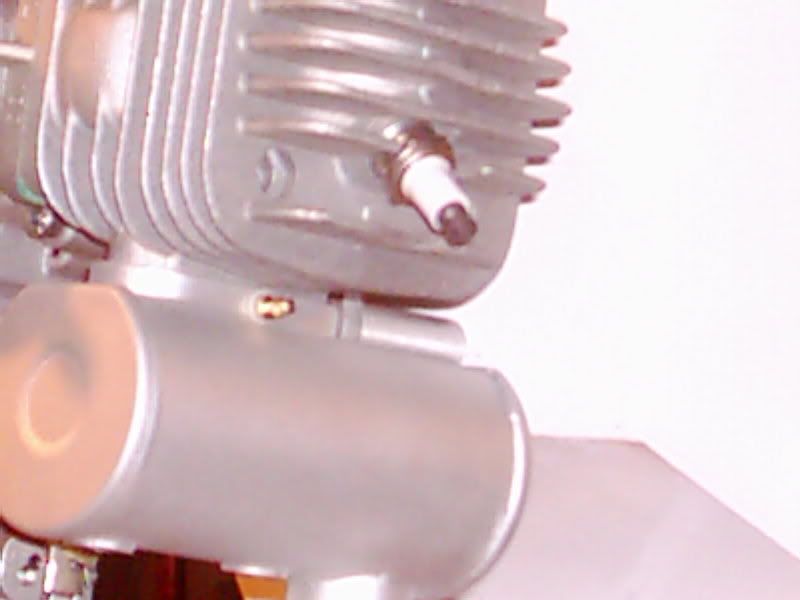

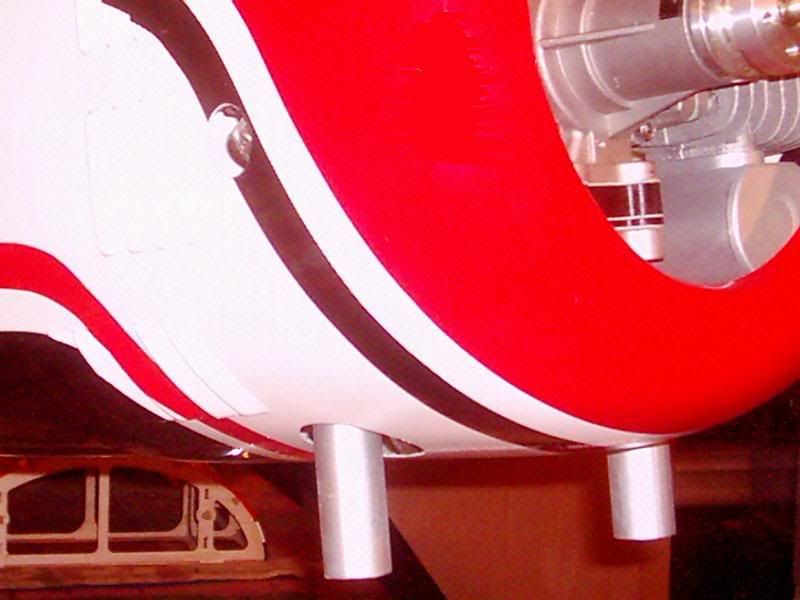

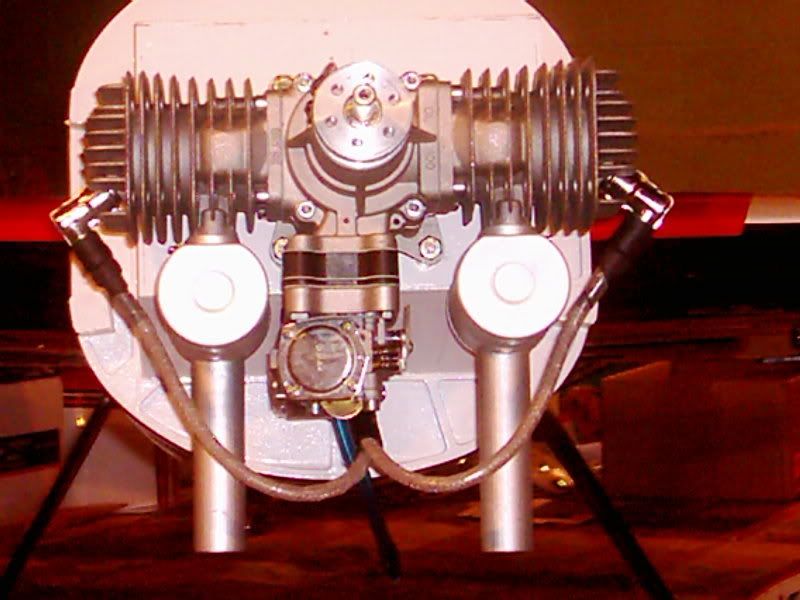

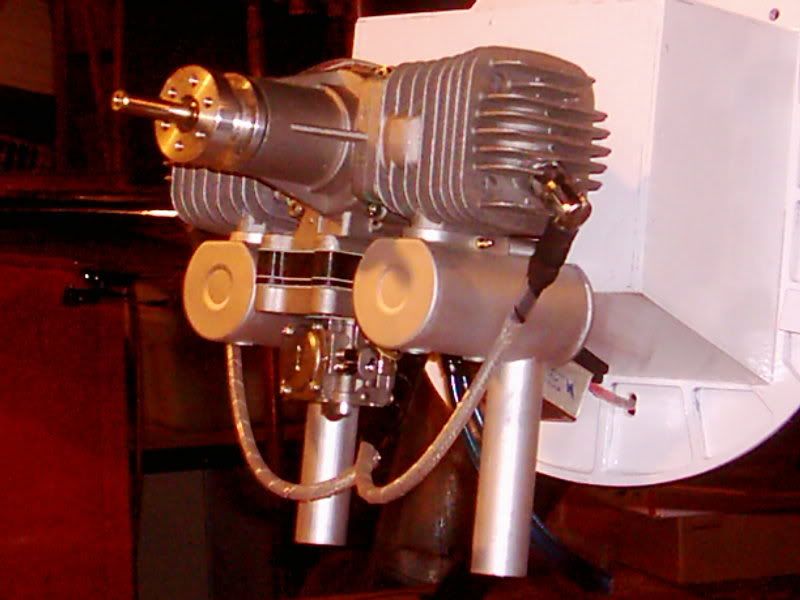

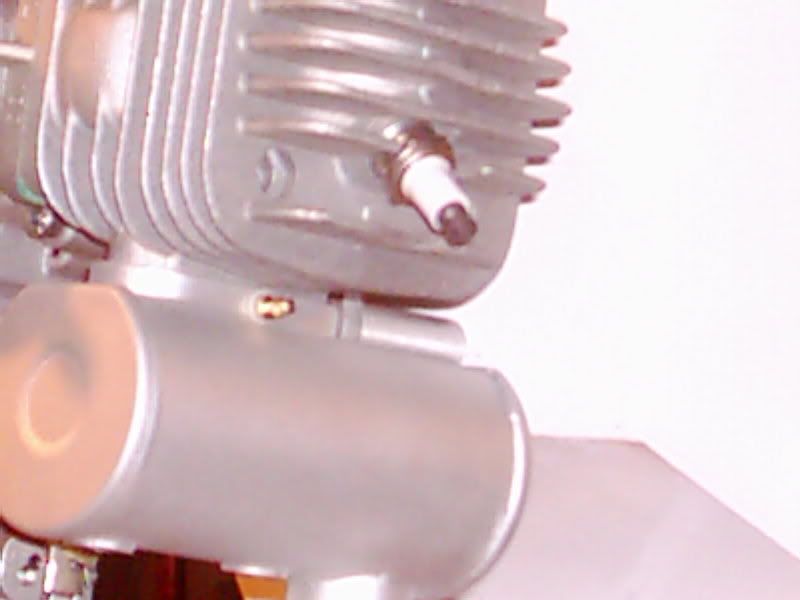

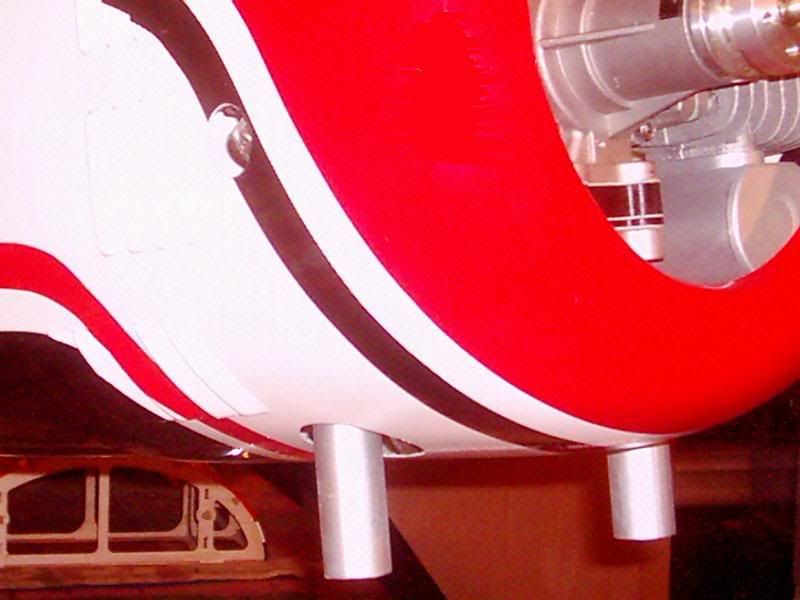

Here is the mounting of my engine.

I am working on it as I write this, but I wanted to give you guys a taste of what I am doing.

DL-100, rough cut holes for mufflers.

I mounted the prop washer 1" in front of the cowl for maximum prop efficiency.

I will post more a little later.

Here is the mounting of my engine.

I am working on it as I write this, but I wanted to give you guys a taste of what I am doing.

DL-100, rough cut holes for mufflers.

I mounted the prop washer 1" in front of the cowl for maximum prop efficiency.

I will post more a little later.

#411

Senior Member

Join Date: Aug 2006

Location: Egg Harbor City,

NJ

Posts: 760

Likes: 0

Received 0 Likes

on

0 Posts

Got all wiring and ignition mounted how I want it.

Finished cutting cowling for sparkplug rub, finished muffler holes.

I used a quarter for a pattern for sparkplug openings.

The plug caps just touched and if left they would wear holes in the cowling.

I also mounted the nipples in my mufflers for smoke.

Tomorrow night I guess i'll start on baffleing.

Finished cutting cowling for sparkplug rub, finished muffler holes.

I used a quarter for a pattern for sparkplug openings.

The plug caps just touched and if left they would wear holes in the cowling.

I also mounted the nipples in my mufflers for smoke.

Tomorrow night I guess i'll start on baffleing.

#413

Member

Join Date: Oct 2003

Location: Grapevine, TX

Posts: 51

Likes: 0

Received 0 Likes

on

0 Posts

What did you use for the engine spacers/mounts and bolts? Why do you have it 1" for prop efficient. Not sure what that is? This is my first gas engine. Thanks Matt

#414

My Feedback: (13)

Join Date: Nov 2002

Location: Maumelle,

AR

Posts: 655

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: matfree

What did you use for the engine spacers/mounts and bolts? Why do you have it 1" for prop efficient. Not sure what that is? This is my first gas engine. Thanks Matt

What did you use for the engine spacers/mounts and bolts? Why do you have it 1" for prop efficient. Not sure what that is? This is my first gas engine. Thanks Matt

#416

Senior Member

Join Date: Aug 2006

Location: Egg Harbor City,

NJ

Posts: 760

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: matfree

What did you use for the engine spacers/mounts and bolts? Why do you have it 1" for prop efficient. Not sure what that is? This is my first gas engine. Thanks Matt

What did you use for the engine spacers/mounts and bolts? Why do you have it 1" for prop efficient. Not sure what that is? This is my first gas engine. Thanks Matt

I usally make that distance as tight as possible, UNTIL I took the cowling of of a Laser 200 that I am flying and the performance almost doubled. I know that the cowl catches air, but it also robs thrust in the areas behind the prop.

My Laser 200 has 1/8" between the back of the prop and front of the cowl.

The Lanier Yak has a distance of 1" and should allow the prop to be almost to maximum efficient.

Anyway if you look at the picture of the full scale Yak that Mitsu1 poated there is plenty of distance between the prop and cowl on the real thing.

I just was always anal about keeping that distance as tight as possible.

This is my 1st time mounting an engine like this, but everything I have read it will work great.

#418

Senior Member

My Feedback: (1)

Join Date: Apr 2005

Location: Rio Rancho, NM

Posts: 267

Likes: 0

Received 0 Likes

on

0 Posts

2robinhood, any special reason why you chose a JXF prop? Is it better than others you have tried? Also, have you decided what you're going to do with the choke? The arm on my DL is at an odd angle. What about yours?

Steve

Steve

#420

Senior Member

Join Date: Aug 2006

Location: Egg Harbor City,

NJ

Posts: 760

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: Doppelganger

2robinhood, any special reason why you chose a JXF prop? Is it better than others you have tried? Also, have you decided what you're going to do with the choke? The arm on my DL is at an odd angle. What about yours?

Steve

2robinhood, any special reason why you chose a JXF prop? Is it better than others you have tried? Also, have you decided what you're going to do with the choke? The arm on my DL is at an odd angle. What about yours?

Steve

Doesn't seem like anyone really uses Vess on larger engines.

This is my 1st large engine, I have sold glow engines and have gone 100% gasoline.

My list of engines are CRRC Pro GF26I, Brillelli 36GT, CRRC Pro GF50I, DL-50, DL-100.

I have tried Xoars, Zinger Pros, Vess, APC, etc.

So, wooden is 1st choice JFX, 2nd is Vess.

The best props I ever used are Mejzliks. They are my favorites.

I only went with the JFX on the DL-100 is due to price and I wanted a wooden prop for break in.

The JFX was $32.00, the Mejzlik is $80.00

I will be running a Mejzlik on it soon enough.

#421

Senior Member

My Feedback: (1)

Join Date: Apr 2005

Location: Rio Rancho, NM

Posts: 267

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: 2robinhood

Out of wooden props I like the JFX and Vess.

Doesn't seem like anyone really uses Vess on larger engines.

This is my 1st large engine, I have sold glow engines and have gone 100% gasoline.

My list of engines are CRRC Pro GF26I, Brillelli 36GT, CRRC Pro GF50I, DL-50, DL-100.

I have tried Xoars, Zinger Pros, Vess, APC, etc.

So, wooden is 1st choice JFX, 2nd is Vess.

The best props I ever used are Mejzliks. They are my favorites.

I only went with the JFX on the DL-100 is due to price and I wanted a wooden prop for break in.

The JFX was $32.00, the Mejzlik is $80.00

I will be running a Mejzlik on it soon enough.

ORIGINAL: Doppelganger

2robinhood, any special reason why you chose a JXF prop? Is it better than others you have tried? Also, have you decided what you're going to do with the choke? The arm on my DL is at an odd angle. What about yours?

Steve

2robinhood, any special reason why you chose a JXF prop? Is it better than others you have tried? Also, have you decided what you're going to do with the choke? The arm on my DL is at an odd angle. What about yours?

Steve

Doesn't seem like anyone really uses Vess on larger engines.

This is my 1st large engine, I have sold glow engines and have gone 100% gasoline.

My list of engines are CRRC Pro GF26I, Brillelli 36GT, CRRC Pro GF50I, DL-50, DL-100.

I have tried Xoars, Zinger Pros, Vess, APC, etc.

So, wooden is 1st choice JFX, 2nd is Vess.

The best props I ever used are Mejzliks. They are my favorites.

I only went with the JFX on the DL-100 is due to price and I wanted a wooden prop for break in.

The JFX was $32.00, the Mejzlik is $80.00

I will be running a Mejzlik on it soon enough.

Steve

#422

Senior Member

Join Date: Aug 2006

Location: Egg Harbor City,

NJ

Posts: 760

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: Doppelganger

Also, have you decided what you're going to do with the choke? The arm on my DL is at an odd angle. What about yours?

Steve

Also, have you decided what you're going to do with the choke? The arm on my DL is at an odd angle. What about yours?

Steve

I took a metal clevis and bent a 90degree " L " about 2" down from the clevis in a metal pushrod.

Drilled a hole right below the choke arm in the bottom of my cowl.

I then slipped a piece of glow fuel line over the entire length or the wire push rod.

I put the clevis pushrod assy up through the hole in the cowl under the choke arm.

The fuel tubing acts as a insulator against vibration and keeps the wire rod from ever touching the cowl.

Pull it straight down for choke on, push it back up for choke off.

Net, clean, and most of all simple.

#424

Senior Member

Join Date: Dec 2006

Location: Orange,

CA

Posts: 194

Likes: 0

Received 0 Likes

on

0 Posts

Damn Mitsu, your just crankin along on that thing, kudos to you on a great and informative built so far, lookin forward to more pics ... keep em coming. I like your piant on the inside of the fuse. I may do something similar but in a different color. Im in the Processoh cutting out a CF radio tray and battery mounts atm, hope th have them mocked in tomorrow. I will be using some .090 Carbon/kevlar I had left over from a previous project. should raise the bling factor a tad. gOT MY COWL MOUNTED TODAY. GONNA GLASS IN SOME thin CF backing behind the bolt holes bor a bit of stregnth. should keep vibes from elongating the holes a bit longer. Had to put off glassing in the cowl as I ran out of 1/2 oz glass and dont want to add too much weight

#425

Senior Member

My Feedback: (10)

Join Date: Nov 2002

Location: Lake View Terrace,

CA

Posts: 407

Likes: 0

Received 0 Likes

on

0 Posts

Sorry I have been gone guys, but busy is not the word around here, swamped is.

For cooling purposes you are supposed to have at least 1.5 to 2 times the opening on the bottom as you do for the air inlet, I know it is a Yak and all opening. But we are not running a 480HP 5 cylinder radial so we do not need all of the opening. I have made the engine baffles out of everything from fiberglass to 4mil foam core, you close the opening and cut it out for your cylinders or cylinder and output shaft then make it duct back to the motor. It is rather simple to duct it this way and the Midwest foam core you can get at your LHS is very light and works just fine, then the hard part, you need to make the air hole on the bottom of the cowl that is 1.5 to 2 times the opening to let the air out. I will attach pictures of my big 260 where you can see one of the ways I do this, but on the Yak the cowl is round and if you make one opening it looks like carp. I have seen people spend hours opening all the louvers in the cowl and then still have to make more opening on the bottom that looked pretty good, but that solution is for someone with no life, LOL. On my Lanier Yak I ran a ZDZ 80 and only had a duct on the bottom of the cowl, I opened the bottom of the cowl just enough where the air would escape around the top and rear of the head and back to my Pitts style outlets which didn't look too bad, but for those running a twin you can make strips like I did here from mid way to the body of the plane on the bottom 1 on the outside of the exhaust outlets and a few in between to get the proper air flow.

For cooling purposes you are supposed to have at least 1.5 to 2 times the opening on the bottom as you do for the air inlet, I know it is a Yak and all opening. But we are not running a 480HP 5 cylinder radial so we do not need all of the opening. I have made the engine baffles out of everything from fiberglass to 4mil foam core, you close the opening and cut it out for your cylinders or cylinder and output shaft then make it duct back to the motor. It is rather simple to duct it this way and the Midwest foam core you can get at your LHS is very light and works just fine, then the hard part, you need to make the air hole on the bottom of the cowl that is 1.5 to 2 times the opening to let the air out. I will attach pictures of my big 260 where you can see one of the ways I do this, but on the Yak the cowl is round and if you make one opening it looks like carp. I have seen people spend hours opening all the louvers in the cowl and then still have to make more opening on the bottom that looked pretty good, but that solution is for someone with no life, LOL. On my Lanier Yak I ran a ZDZ 80 and only had a duct on the bottom of the cowl, I opened the bottom of the cowl just enough where the air would escape around the top and rear of the head and back to my Pitts style outlets which didn't look too bad, but for those running a twin you can make strips like I did here from mid way to the body of the plane on the bottom 1 on the outside of the exhaust outlets and a few in between to get the proper air flow.

Keep the pictures coming !

Keep the pictures coming !