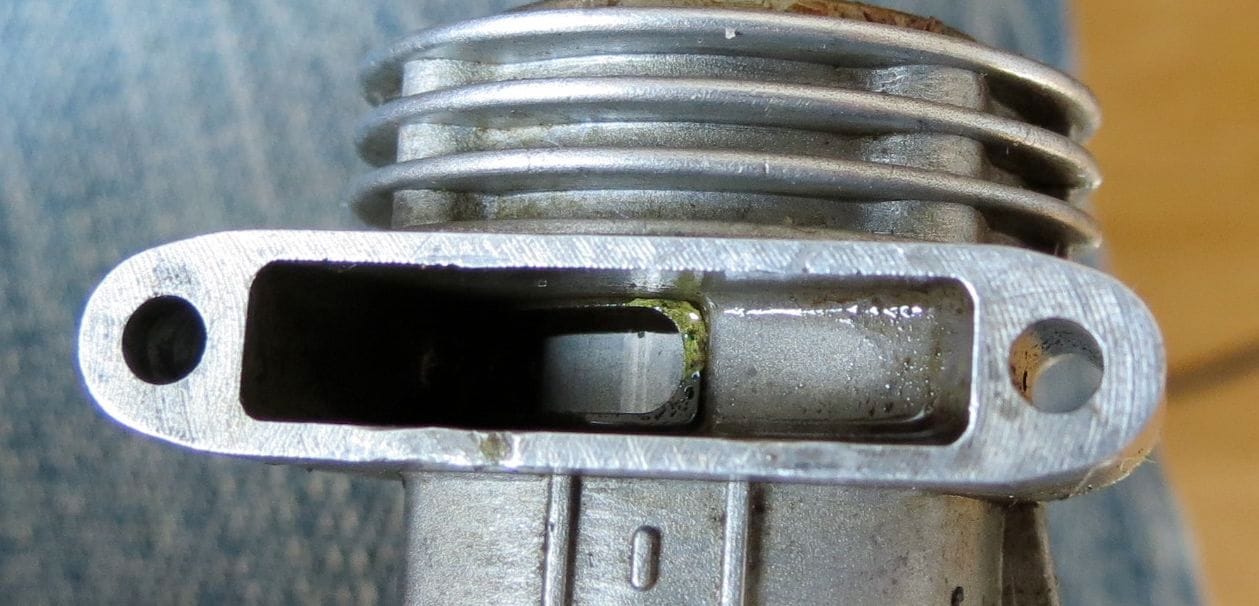

OSMax 46FXi Cylinder Rear Port Lube Channel

#1

Thread Starter

Join Date: Dec 2009

Location: Cincinnati, OH

Posts: 34

Likes: 0

Received 0 Likes

on

0 Posts

OSMax 46 FXi CYL Rear Port Lube Channel

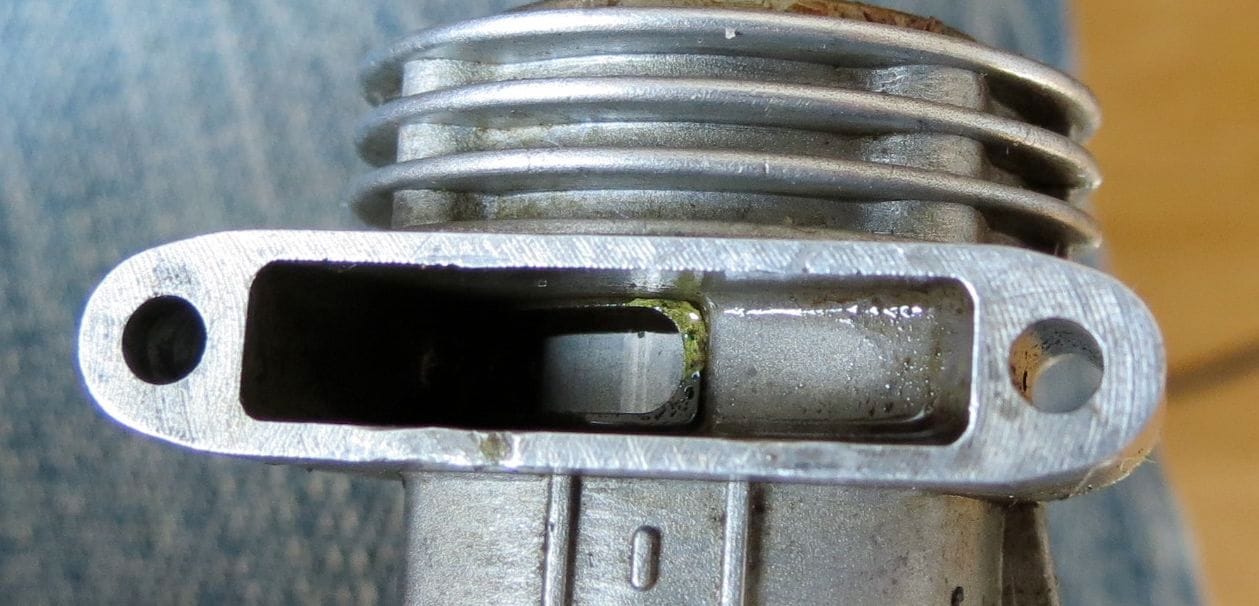

OSMax 46 FXi CYL Front Smooth Bore

Has anyone experience with such a cylinder channel feature in an OS Max engine. Please see the images attached ... comments ... what to expect from this feature??? Flypast111

#2

Thread Starter

Join Date: Dec 2009

Location: Cincinnati, OH

Posts: 34

Likes: 0

Received 0 Likes

on

0 Posts

Look at this additional view for more clear geometry ... Flypast111

OSMax 46 FXi CYL Rear Port Lube Channel View

#7

Thread Starter

Join Date: Dec 2009

Location: Cincinnati, OH

Posts: 34

Likes: 0

Received 0 Likes

on

0 Posts

There is NO flaw in the liner plating ... that condition may "appear" from poor lighting in the image. But, the channel is a real manufacturing condition. If it is a flaw, it is one of the most "straight made" machined flaws that I have ever seen ... Flypast111

#8

My Feedback: (29)

Your engine ingested something that put a gouge in the liner, it is NOT there intentionally. All machining of that liner is done prior to plating. Your engine needs a new piston and liner, the good news is Im pretty sure the ASP brand parts are a drop in fit and are roughly half the price of OS parts. Do a google search and you will find a video.

#9

Thread Starter

Join Date: Dec 2009

Location: Cincinnati, OH

Posts: 34

Likes: 0

Received 0 Likes

on

0 Posts

For the record ... this engine is essentially NEW & UNUSED ... the overall condition is EXCELLENT ... there is just this one "channel or groove" for lack of a better word ... it is clearly from the cylinder manufacturing ... is it a defect (really weird ???) ... or is it an attempt to increase and maintain cylinder wall-to-piston lubrication in an ABC type application ... this is the question ... else ... it is the most "straight machined" defect that I have encountered ... Flypast111

#10

My Feedback: (29)

I'm sorry that you are not getting the information that you WANT but you are getting the CORRECT information none the less. Your piston and liner are ruined! Regardless of how much use is on the engine a particle of debris has wedged itself between the piston and liner and created that gouge. Of course it is perfectly straight because the piston travels perfectly straight up and down. If you remove the liner and then the piston you will find damage on the piston as well. If you continue to run the engine in this condition the nickel plating will start to peel and create even more damage to the engine not to mention it is not going to run well and its performance will only deteriorate as the nickel peels.

#12

My Feedback: (1)

yes you need a new liner and piston for sure,, make sure after you remove them that you clean out the inside of the case very-very well with spry oil, and make sure you check the bearings, you may need to replace the bearings too. without a better photo it almost looks to be cut so well that it was done during manufacturing

Jim

Jim

#13

My Feedback: (125)

As these guys noted, your engine ate something and machined it's own groove. I have several 40 & 46 FX engines and none of them have a groove. No ABC engine I've ever owned has had a groove like that, regardless of make, model or manufacture.

That said, if it runs okay, then run it til it doesn't. A fuel with a good bit a castor will help fill in the groove a bit.

That said, if it runs okay, then run it til it doesn't. A fuel with a good bit a castor will help fill in the groove a bit.

#14

My Feedback: (29)

I can't suggest to continue running the engine. As of right now it can be repaired for minimal cost. If he continues to run it the nickel plating is going to flake off and damage other parts and essentially ruin the entire engine.

https://www.rcgroups.com/forums/show...liner-SUCCESS-!!!

https://www.rcgroups.com/forums/show...liner-SUCCESS-!!!

#15

Thread Starter

Join Date: Dec 2009

Location: Cincinnati, OH

Posts: 34

Likes: 0

Received 0 Likes

on

0 Posts

To ALL of YOU who have responded ... you have given me insight and clear indication of the case that this is a manufacturing defect "artifact" of some unknown machining operation ... it is far to "straight" to be a random event. Especially for a NEW engine. I only planned some BREAK-IN runs ... now to be postponed until repairs are completed.

The good news is that I have one-each of this models CLONES; Magnum XLS 46A & ASP S46AII. Both are nearly twins to the OSM 46 FX engine. I will utilze them for now and put this one on the shelf until further need arises. Thanks for ALL of your reviews and insights. Here they are with diesel head installations. - Flypast111

The good news is that I have one-each of this models CLONES; Magnum XLS 46A & ASP S46AII. Both are nearly twins to the OSM 46 FX engine. I will utilze them for now and put this one on the shelf until further need arises. Thanks for ALL of your reviews and insights. Here they are with diesel head installations. - Flypast111

#18

Thread Starter

Join Date: Dec 2009

Location: Cincinnati, OH

Posts: 34

Likes: 0

Received 0 Likes

on

0 Posts

the WASP ... thanks for the heads-up about the ASP 46 carburetor issues ... for those using variable throttle applications (i.e. RC carbs) it is good to know these things ... however, the good news is that I am primarily a CONTROL LINE flyer and I will "acquire" a special-make venturi & needle valve assembly (NVA) to operate this engine - Flypast111

#20

Thread Starter

Join Date: Dec 2009

Location: Cincinnati, OH

Posts: 34

Likes: 0

Received 0 Likes

on

0 Posts

Mr Cox ... during a routine inspection and cleaning I performed the following;

a) had real difficulty removing the original RC carb due to "VERY STUCK" M3.5 screws (recall NEW & UNUSED in a box for 10+ yrs.)

b) removed cylinder head / cyl. head gasket / rear backplate / then "boiled&cold-shocked" subassembly about 5-6 times

c) RC carb screws would still NOT loosen for removal / got out the small SKILL hand drill plus 1/16 & 3/32 drill bits

d) CAREFULLY hand drilled both M3.5 screws / first 1/16 thru ... second 3/32 thru / used magnet (repeatedly) throughout drilling operation to remove debris

e) CAREFULLY used small needle nose vise-grip pliers to "grab" M3.5 screw-head - YAHOO! ... both screws were extracted ... WHEHHH!

f) Carefully washed and cleaned remaining subassembly and fully re-lubed for re-assembly

SOO ... I then examined the piston and cylinder ... NO noticeable marks on the piston in the location of the "liner lube-channel," as I mistook

this "machined" condition of the liner inner plating condition ... piston only had some "very light" casting line marks (along the sidewall skirt) at the

rear backplate location ... that is, along the vertical skirt across the piston pin bore ... otherwise normal ABC geometry smooth condition

Clearly ... this "liner lube-channel" condition is simply some weird machining operation condition that was "missed - OR passed" at inspection - Flypast111

a) had real difficulty removing the original RC carb due to "VERY STUCK" M3.5 screws (recall NEW & UNUSED in a box for 10+ yrs.)

b) removed cylinder head / cyl. head gasket / rear backplate / then "boiled&cold-shocked" subassembly about 5-6 times

c) RC carb screws would still NOT loosen for removal / got out the small SKILL hand drill plus 1/16 & 3/32 drill bits

d) CAREFULLY hand drilled both M3.5 screws / first 1/16 thru ... second 3/32 thru / used magnet (repeatedly) throughout drilling operation to remove debris

e) CAREFULLY used small needle nose vise-grip pliers to "grab" M3.5 screw-head - YAHOO! ... both screws were extracted ... WHEHHH!

f) Carefully washed and cleaned remaining subassembly and fully re-lubed for re-assembly

SOO ... I then examined the piston and cylinder ... NO noticeable marks on the piston in the location of the "liner lube-channel," as I mistook

this "machined" condition of the liner inner plating condition ... piston only had some "very light" casting line marks (along the sidewall skirt) at the

rear backplate location ... that is, along the vertical skirt across the piston pin bore ... otherwise normal ABC geometry smooth condition

Clearly ... this "liner lube-channel" condition is simply some weird machining operation condition that was "missed - OR passed" at inspection - Flypast111

#21

Nickel plating - which is what O.S. uses in their liners, is not machined post-plating due to nickel plating very evenly. Only true chrome is ground to size post-plating due to uneven plating. That groove in the liner could have easily happened by a previous handler that turned the engine over with foreign debris that got inside the engine. Unless you bought the engine new from a retail seller, you do not know the exact provenance of that engine. Replacing the piston and liner with ASP parts will rejuvenate the engine and be much better quality and longer lasting than the OEM parts without question.

#23

Regarding the carb screws, they use some sort of locktite on them I think. A little heat from a hand held torch is usually enough, plus the right size of JIS screw driver.

It is odd that there is no damage on the piston, I would almost have bet money on some foreign material getting stuck in the exhaust port, thus scoring both the piston and liner perfectly straight.

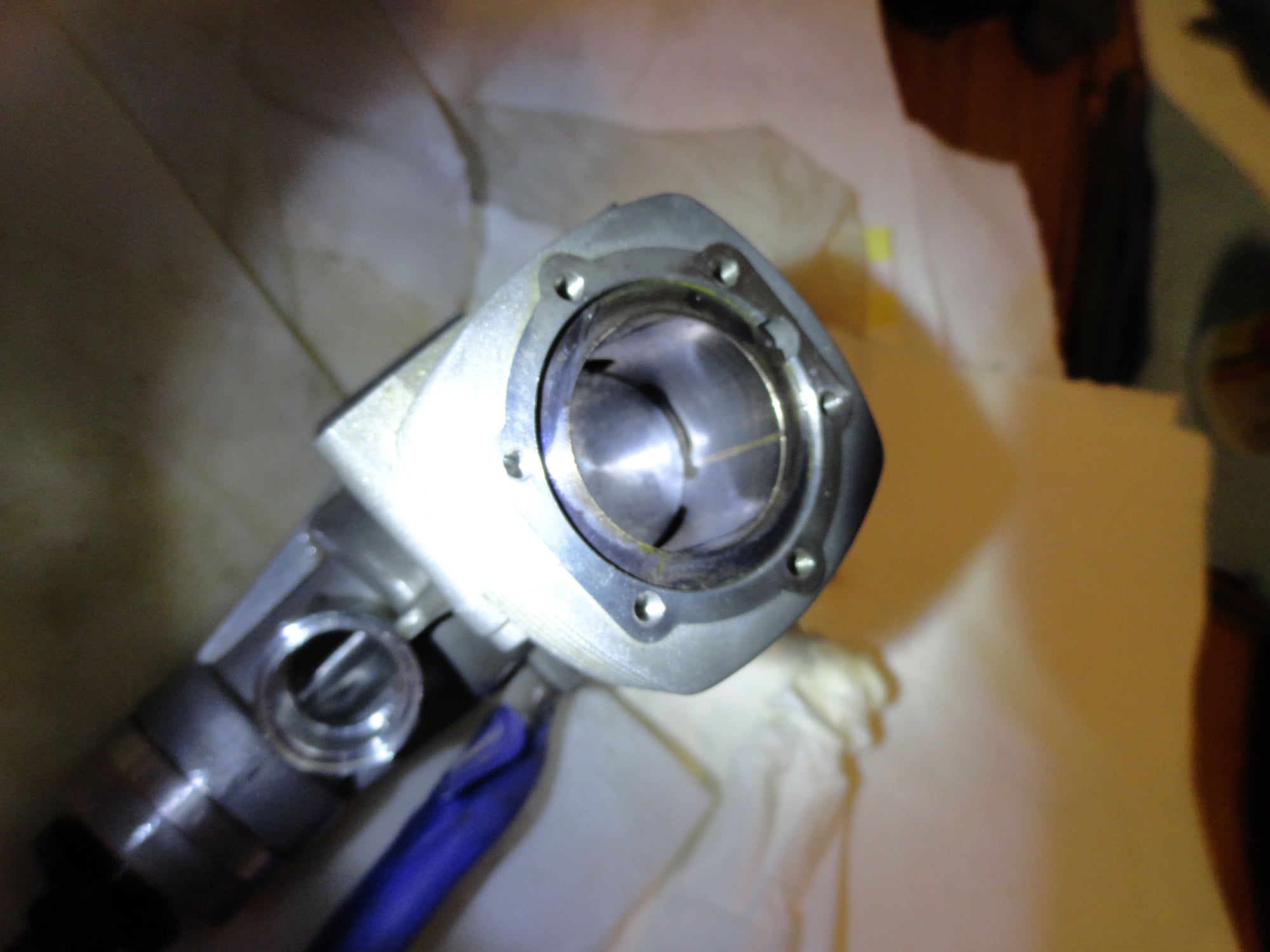

Here is what that can look like (on a second hand engine), still runs fine though to my big surprise:

It is odd that there is no damage on the piston, I would almost have bet money on some foreign material getting stuck in the exhaust port, thus scoring both the piston and liner perfectly straight.

Here is what that can look like (on a second hand engine), still runs fine though to my big surprise: