engines

#1

Junior Member

Thread Starter

Join Date: Dec 2004

Location: mackay, AUSTRALIA

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

hi guys

well my engine is stuffed its a OS .15cv but its f*#ked i was just wondering if i bought this engine from ebay will it be a stright fit or will i have to buy a new exhaust manifold and what not???

cheers

bart

http://cgi.ebay.com.au/O-S-12TR-P-en...QQcmdZViewItem

well my engine is stuffed its a OS .15cv but its f*#ked i was just wondering if i bought this engine from ebay will it be a stright fit or will i have to buy a new exhaust manifold and what not???

cheers

bart

http://cgi.ebay.com.au/O-S-12TR-P-en...QQcmdZViewItem

#2

Senior Member

Join Date: Mar 2006

Location: Manheim ,

PA

Posts: 2,599

Likes: 0

Received 0 Likes

on

0 Posts

well you can buy a replacment piston and sleeve for like $16 on tower hobbies. It's cheaper then a new engine and will run like a new engine. But as for any mods that you will have to do I have no clue as i dont know what car/truck you have.

#3

Junior Member

Thread Starter

Join Date: Dec 2004

Location: mackay, AUSTRALIA

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

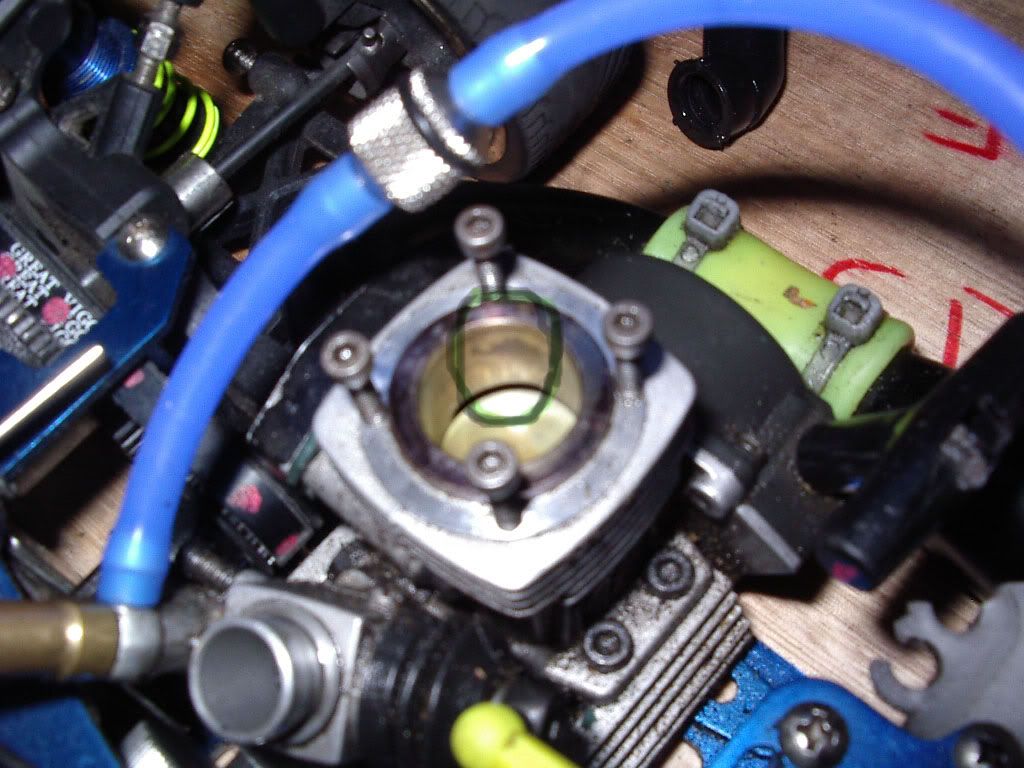

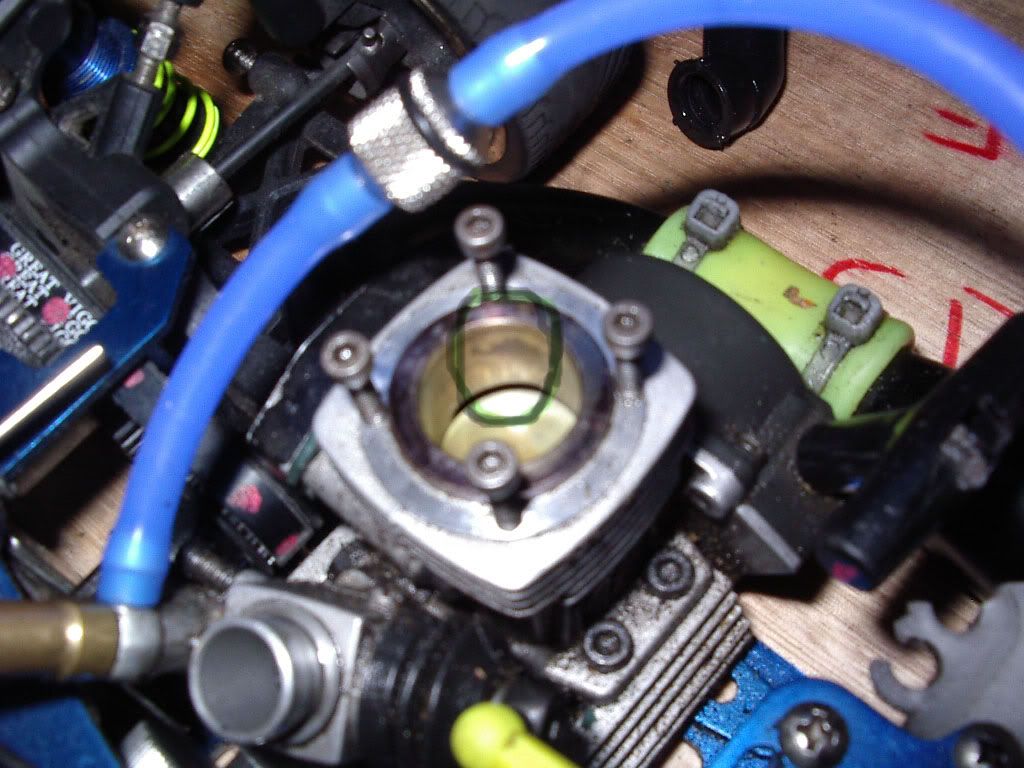

i have a gv bv2 i think it is its a v8 super car replica one. i took the car to the only hobbie store in my town but the fella there said that it wouldent b worth rebuilding and that i should jsut buy a new engine. i think hes just trying to get money out of me. heres a pic of the engine and what he pointed out to me as being wrong.  the pics a bit dodgy

the pics a bit dodgy

the pics a bit dodgy

the pics a bit dodgy

#4

Senior Member

Join Date: Oct 2005

Location: SAN DIEGO, CA CA

Posts: 1,063

Likes: 0

Received 0 Likes

on

0 Posts

Yes you will need a header specific for the TR, 3 reasons - no#1 its rear exhaust, the CV is side exhaust, no#2 it has a round exhaust port, the CV has a rectangular one, no#3 the header is mounted with springs on the TR, the header is bolted on the CV.

Edit: Can you be specific about the problem.

Edit: Can you be specific about the problem.

#5

Junior Member

Thread Starter

Join Date: Dec 2004

Location: mackay, AUSTRALIA

Posts: 14

Likes: 0

Received 0 Likes

on

0 Posts

the guy didnt realy tell me what the problem was he just pointed out that there was bits of copper sitting under the heatsink and yeah it wont fire up and if it does it pretty much stalls stright up. i can only get it going if its got the carb like fully open

#6

Senior Member

Join Date: Mar 2006

Location: Manheim ,

PA

Posts: 2,599

Likes: 0

Received 0 Likes

on

0 Posts

It can be rebuild. There is no reason why it couldnt be rebuild. I would go and try and find a replacement piston and slleve from tower's. I think there like 16 dollars and there of the new design. But the piece thats missing is not copper. The inner liner of the sleeve is made of copper but it should not have taken any copper from the sleeve. The piece that is missing is actaully the outer liner which is made of nickel.

It looks like it's near the exhasut header which may be a sign that you have ran the engine lean for a little. As this can be a cause of this sometimes but not always. The liner may have just gone bad and decided to chip off. Bt since your using a fuel filter I'm guessong no pebbles or stones got in from the fuel but may have enterd fromt he air filter. I'm not saying thatyou did anything wrong but just what might have happened.

If I where you I would just get a new piston and sleeve as if the LHS guy is prolly just wanting you to buy a new engine. But thats just me.

It looks like it's near the exhasut header which may be a sign that you have ran the engine lean for a little. As this can be a cause of this sometimes but not always. The liner may have just gone bad and decided to chip off. Bt since your using a fuel filter I'm guessong no pebbles or stones got in from the fuel but may have enterd fromt he air filter. I'm not saying thatyou did anything wrong but just what might have happened.

If I where you I would just get a new piston and sleeve as if the LHS guy is prolly just wanting you to buy a new engine. But thats just me.

#8

Senior Member

Join Date: Mar 2006

Location: Manheim ,

PA

Posts: 2,599

Likes: 0

Received 0 Likes

on

0 Posts

Your like already part of the way done. But no it's not all that hard to do it's actually simple if you think about it. You will have to take the engine off of the car. You will then have to remove the pull start, header if you want and the back plate. Wth the back plate removed you can then start the process of taking it apart. If you want to remove the header from the case I would as it makes this a lot easier to do. You can take a zip tie and put it in the exhaust port so the flat end piece is actually in the engine through the exhaust. Then with your flywheel still on rotate the piston up until you see the sleeve start to push out the top of the crank case. Then rotate the piston back down and take the sleeve out. Then with the sleeve out take off the bell gear, clutch and flywheel.

Then with the piston at BDC take a needle noes pliers and take the connecting rod out. Or if this engine has a groove in the crank case at the bottom of the piston's rotation then you will have to put the piston at TDC and slide the rod off of the crank shaft. Then put the crank down at the BDC and take out the piston. Then I would suggest taking the crank shaft out and clean it up a little and take the carb off and spray down the engine with some brake cleaner as this will give you a nice clean engine case to work with. Then I would oil the bearing with some after run oil.

Then get the piston and sleeve from tower's and I would probably suggest getting a connecting rod also. You dont have to but this is just a precaution type thing. But with the new piston and sleeve in hand then start to take the other piston and connecting rod apart. This is the hardest part of the hole ordeal and putting it back together. You will need the wrist pin and the very small c clips that are inside. Take a very small flat head screw driver and where the wrist pin is there will be a small c clip in a groove that is holding the wrist pin in there. You will need to take that out to get the wrist pin out. You will have to work at it a little maybe even getting some help from a small needle nose pliers. Once that c clip is out keep a hold of it. As you will need it later. Then just slide the wrist pin out. Or if it does not slide out you can take that same small screw driver and from the other side just gently push the wrist pin out. Then you will need to take the other c clip out.

And that is how it apart.

Then with the piston at BDC take a needle noes pliers and take the connecting rod out. Or if this engine has a groove in the crank case at the bottom of the piston's rotation then you will have to put the piston at TDC and slide the rod off of the crank shaft. Then put the crank down at the BDC and take out the piston. Then I would suggest taking the crank shaft out and clean it up a little and take the carb off and spray down the engine with some brake cleaner as this will give you a nice clean engine case to work with. Then I would oil the bearing with some after run oil.

Then get the piston and sleeve from tower's and I would probably suggest getting a connecting rod also. You dont have to but this is just a precaution type thing. But with the new piston and sleeve in hand then start to take the other piston and connecting rod apart. This is the hardest part of the hole ordeal and putting it back together. You will need the wrist pin and the very small c clips that are inside. Take a very small flat head screw driver and where the wrist pin is there will be a small c clip in a groove that is holding the wrist pin in there. You will need to take that out to get the wrist pin out. You will have to work at it a little maybe even getting some help from a small needle nose pliers. Once that c clip is out keep a hold of it. As you will need it later. Then just slide the wrist pin out. Or if it does not slide out you can take that same small screw driver and from the other side just gently push the wrist pin out. Then you will need to take the other c clip out.

And that is how it apart.

#9

Senior Member

Join Date: Mar 2006

Location: Manheim ,

PA

Posts: 2,599

Likes: 0

Received 0 Likes

on

0 Posts

Sorry I tried to post the way to put it back together but for some reason would not let me. Ohh well I guess I will have to retype all the stuff again. But I have to go soon so I will not get to it now. But when taking the engine apart make sure you take pictures with your camera. Take plenty of pics and how the sleeve goes in and how the piston is on the connecting rod and everything like that.

Just take plenty of pics as it is better to have them and not need them then to need them and not have them. RIGHT I will retype everything later on tonight if I can. hope this helped

Just take plenty of pics as it is better to have them and not need them then to need them and not have them. RIGHT I will retype everything later on tonight if I can. hope this helped