Team Associated RC10T4.3

#76

Thread Starter

I put a 20T pinion on, now that outside temps are more normal, and all I can say is WOW!. The T4 has new life again. I worry about tire knobs/lugs/pins being tore off as power is added to my RCs. If you ever read some of my posts, you know I don't like small pins for my backyard track. Hole Shots, and even Bow Ties, are quick to have their rubber torn away from the tire in as little as one run. The T4,with Panther Step Pins on the rear, seems to be holding up with new power plant. The stock T4.1/.2/.3 RTR tires are, well...

#77

Thread Starter

After changing the oil in the shocks, I thought for sure I had grabbed the wrong bottle of oil. I had written down in my notes to go up in thickness next time that I rebuilt the shocks...from 25w to 30w shock oil. After double checking that I put in 30w oil in the shocks; checked that had #1 pistons in the rear; #2 pistons in the front shocks, and taking the truck to the track, the shocks felt like they had 20w oil in them. The truck handled terribly over the whoops. What the heck?! I did open a new bottle of shock oil.

Is it possible the bottle was mislabeled?

Is it possible the shock pistons are made incorrectly?

All my Associated 10mm shocks, that are on my other platforms, have 25w shock oil in them. Weird. I can't wait to see what happens when I put some 35w into the shocks.

Is it possible the bottle was mislabeled?

Is it possible the shock pistons are made incorrectly?

All my Associated 10mm shocks, that are on my other platforms, have 25w shock oil in them. Weird. I can't wait to see what happens when I put some 35w into the shocks.

#78

Thread Starter

I think I found the cause of rear shocks being so "bouncy". I went to open the shocks up, and it was very evident that the #1 pistons in the rear shocks were wiggling around inside. The pistons are 9mm...what the heck  ? I can only imagine how many T4.1s that are/were out there with the same issue, and using something like 60wt shock oil to compensate. I only have some 45wt as my thickest oil, and that's was not cutting it.

? I can only imagine how many T4.1s that are/were out there with the same issue, and using something like 60wt shock oil to compensate. I only have some 45wt as my thickest oil, and that's was not cutting it.

? I can only imagine how many T4.1s that are/were out there with the same issue, and using something like 60wt shock oil to compensate. I only have some 45wt as my thickest oil, and that's was not cutting it.

? I can only imagine how many T4.1s that are/were out there with the same issue, and using something like 60wt shock oil to compensate. I only have some 45wt as my thickest oil, and that's was not cutting it.

#79

Thread Starter

After digging into pit box, I put on Associated #2 pistons, and dumped in some 25wt oil. That is almost perfect now, but still too much damping. I want my #1 pistons like I have in all my other Associated rear ends  . I even went looking for some pricey delrin machined pistons, but came up with nothing. That's okay though. I have been using Associated's 10mm pistons what seems like forever. Never an issue, and never went looking for other piston replacements.

. I even went looking for some pricey delrin machined pistons, but came up with nothing. That's okay though. I have been using Associated's 10mm pistons what seems like forever. Never an issue, and never went looking for other piston replacements.

. I even went looking for some pricey delrin machined pistons, but came up with nothing. That's okay though. I have been using Associated's 10mm pistons what seems like forever. Never an issue, and never went looking for other piston replacements.

. I even went looking for some pricey delrin machined pistons, but came up with nothing. That's okay though. I have been using Associated's 10mm pistons what seems like forever. Never an issue, and never went looking for other piston replacements.

#82

Thread Starter

I normally run the #2 pistons in the front and #1 pistons in the rear ; with Associated 25wt oil in all four shocks ...on my buggy, SC10, T4 platforms that use non big bore shocks. Out of the box, the stock setup (30wt oil & #2 pistons front, #1 rear) should be good for most bashing needs. I dont over power my truck and need very plush damping for rough track. That is why I run 25wt oul.

#83

Thread Starter

It was time for the T4.3's fifteen run maintenance plan. After cleaning; re-lubing the bearings, and tranny, I rebuilt the rear shocks with proper #1 pistons. Before heading to the track, I mounted my Viper 550 4500kv motor on the rear end. Motor needed testing. No plans for permanent use of "big block" motor. The shaft was too long for gear cover to fit on so, I only ran the truck on asphalt driveway. Pretty sure slipper was locked down all the way, and after a few minutes of runtime, I think I roached the gear diff  . At least that is what it sounded like to me. Hard right turns; punching the throttle...little bit of grinding/clicking sound going on. I guess I should be okay with that. I mean, I can't expect it to last forever. The diff has over a year/at least 60+ packs of use on it.

. At least that is what it sounded like to me. Hard right turns; punching the throttle...little bit of grinding/clicking sound going on. I guess I should be okay with that. I mean, I can't expect it to last forever. The diff has over a year/at least 60+ packs of use on it.

Will stick the "small block" finned 540 motor back on, and head to track to test diff's strength left in it.

. At least that is what it sounded like to me. Hard right turns; punching the throttle...little bit of grinding/clicking sound going on. I guess I should be okay with that. I mean, I can't expect it to last forever. The diff has over a year/at least 60+ packs of use on it.

. At least that is what it sounded like to me. Hard right turns; punching the throttle...little bit of grinding/clicking sound going on. I guess I should be okay with that. I mean, I can't expect it to last forever. The diff has over a year/at least 60+ packs of use on it. Will stick the "small block" finned 540 motor back on, and head to track to test diff's strength left in it.

#84

Thread Starter

Still had a grinding noise when using the small block 540 motor. Took apart the diff (again), and found nothing out of the ordinary. The sun/planet gears looked okay. If the diff gears were worn down enough to start jumping teeth, it wouldn't matter too much which way the truck is turning. At least that's how I see it.

I'm thinking the pin and wheel were the culprits to the grinding noise. The left rear wheel nut has been loosening by itself lately, and would explain why the noise is only happening during on power hard right turns. Come to think of it, the nylon locking wheel nuts probably are the original ones I had put on during the T4.3's build. Going to throw out old wheel nuts and switch over to some serrated wheel nuts and thread locker.

I'm thinking the pin and wheel were the culprits to the grinding noise. The left rear wheel nut has been loosening by itself lately, and would explain why the noise is only happening during on power hard right turns. Come to think of it, the nylon locking wheel nuts probably are the original ones I had put on during the T4.3's build. Going to throw out old wheel nuts and switch over to some serrated wheel nuts and thread locker.

#85

Thread Starter

Given that the diff gears were worn, then pushed to their limits with the slipper clutch cranked down most of the way, and the doing WOT takeoffs... My testing the 550 motor in the T4.3 was a mistake on my part. The gears are now jumping/skipping inside the tranny with the 3100kv motor onboard. Now I'm 99% sure the loosening of wheel nut was not the cause of grinding noise. It could have been adding to the awful noise, but not the sole cause of it. According to my check-off sheet, the T4.3/diff/tranny has 63 runs on it. The last two runs with the finned 540 motor start off great, then, as everything warms up, the tranny starts to do it's thing...skip,and jump. It's not a constant grinding situation. Only during on power cornering, and full throttle takeoffs do I hear gears skipping. I'll keep on running the tranny until it's totally "toast".

#86

Thread Starter

For years, I have ran my RCs with stock rear nylon lock nuts until the nylon fails to grab the axle's threads. After a few wheel removals, they fail to keep their grip. I always had a wheel nut wrench with me at the track to check the tightness of wheel nuts every once in a while. They usually fail at a unfortunate time when I'm in the midst of pushing my platforms through the rough stuff. For me, 99.9% of the time, it's the left (drivers side) nut that loosens. My 1/8 scale buggy was notorious for having left side wheel nuts loosen in a very short time period. Once I have a hint of a nut loosening, I chuck them. When something so simple, and cost so little, it sure can ruin a great day...stripping a wheel's center drive area is such a headache; especially when you got new, or very good rubber glued on.

I would buy the serrated wheel nuts for my larger 1/8 buggy. I can normally go a full 10 minutes before having to tighten the nuts again. Buying flanged nylon insert wheel nuts, in M4 size nuts for other RC platforms, in hopes of the wider surface area would take some of stress from the nylon insert. But, they too would only last so long. I tried hunting down #8-32 flanged nylon insert locking nuts...not happening. I think JConcepts had some at one time and were way too much $$$. Now try getting some #8-32 flanged & serrated nylon insertlock nuts...forget it.

Enter thread lock saving grace: I went through many different brands of thread locking "stuff" in the past couple of years. Long story short (because of so many liquid, semi-solid, gel, plastic-safe types of thread lockers out there), I've settled on Vibra-TITE 125 Removable Medium Strength Gel Anaerobic Threadlocker to use with #8-32 flanged serrated wheel nuts. As long as the wheel is nylon base plastic, the threadlocker gel has not "attacked", or cracked the wheel. No need to goop the gel on, just enough to fill the gaps in the threads as the wheel nut is tightened. Any RC going to my track, that I have used the gel threadlocker/serrated flange nut on, I no longer have to worry about carrying a wheel nut driver with me.

I would buy the serrated wheel nuts for my larger 1/8 buggy. I can normally go a full 10 minutes before having to tighten the nuts again. Buying flanged nylon insert wheel nuts, in M4 size nuts for other RC platforms, in hopes of the wider surface area would take some of stress from the nylon insert. But, they too would only last so long. I tried hunting down #8-32 flanged nylon insert locking nuts...not happening. I think JConcepts had some at one time and were way too much $$$. Now try getting some #8-32 flanged & serrated nylon insertlock nuts...forget it.

Enter thread lock saving grace: I went through many different brands of thread locking "stuff" in the past couple of years. Long story short (because of so many liquid, semi-solid, gel, plastic-safe types of thread lockers out there), I've settled on Vibra-TITE 125 Removable Medium Strength Gel Anaerobic Threadlocker to use with #8-32 flanged serrated wheel nuts. As long as the wheel is nylon base plastic, the threadlocker gel has not "attacked", or cracked the wheel. No need to goop the gel on, just enough to fill the gaps in the threads as the wheel nut is tightened. Any RC going to my track, that I have used the gel threadlocker/serrated flange nut on, I no longer have to worry about carrying a wheel nut driver with me.

#87

Thread Starter

Just stumble across "The Edge" tires again while searching all over for ribbed ST tires. Apparently "The Edge" tires are now made for/packaged by Team Associated now. Hurray! I cant wait for em to show up and have steering in my T4 again.

#88

Thread Starter

Six runs with the F540 3100kv motor; on gimpy differential, is all it took for me to call it quits. The last run totally ruined the diff gears. It sounded like it anyway. Time for rebuild, or replacement. I won't exactly know until I open 'er up later. This is my first experience with an Associated 1/10 gear diff going out on me. Totally my fault.

#89

Thread Starter

I think I've read just about every T4.1/T4.2/SC10 thread there is. I've never seen/heard anyone use more than one shim behind each of the gears inside the gear diff. I know I used two shims behind the sun gear on my 1/8 scale buggy and, BOOM, I was back in business. The T4/SC10 gear diff has no more play/room behind the sun gear for another shim...I've tried. Oh, how I've tried.

#92

Join Date: Aug 2015

Location: Rapid City South Dakota

Posts: 27

Likes: 0

Received 0 Likes

on

0 Posts

#93

Thread Starter

It seems the T4.3 is about to take the jump onto Team Associated's discontinued page. They show the T4.3 in their current lineup, but show no current stock. If I were in a situation; looking for a ST, the T6.1 would be in my shopping cart  .

.

.

.

#94

the 6.1 can suck it! mid motor, shorty pack using POS, and it's a race car so it'll be replaced with T6.2 in about anther 20 minutes. and it looks stupid (realistically not bad by modern stadium truck terms, but it's no T, T2, T3, T4), and its WAY to damn expensive!

#95

Thread Starter

After a couple of days of "fuming" the CA glue off wheels/tires; diff rebuild kit; closed cell foams; The Edge tires, and 5k diff fluid, the T4 feels like a new truck again. New foams all around, plus new M3 Edge front tires... truck is on another level now.

I had my doubts that the old diff gears were shot. They didn't look too bad to me. After installing new rebuild kit's sun/planet gears, the grinding/gear skippin', that I had, went away. If I can get away with rebuilding the diff once a year I'll be happy. I only have 5k diff fluid laying for my 1/8 buggy so that's my starting point (once again) with the T4.3's gear diff. 5k seems to be about average from what I gathered while reading lengthy thread(s) on interwebs. So far, the 5k diff fluid allows the truck to turn great on a med traction bashing track with Edge tires leading the way. No need for me to go out and spend money on many thicknesses of diff fluid.

I had my doubts that the old diff gears were shot. They didn't look too bad to me. After installing new rebuild kit's sun/planet gears, the grinding/gear skippin', that I had, went away. If I can get away with rebuilding the diff once a year I'll be happy. I only have 5k diff fluid laying for my 1/8 buggy so that's my starting point (once again) with the T4.3's gear diff. 5k seems to be about average from what I gathered while reading lengthy thread(s) on interwebs. So far, the 5k diff fluid allows the truck to turn great on a med traction bashing track with Edge tires leading the way. No need for me to go out and spend money on many thicknesses of diff fluid.

#96

Thread Starter

the 6.1 can suck it! mid motor, shorty pack using POS, and it's a race car so it'll be replaced with T6.2 in about anther 20 minutes. and it looks stupid (realistically not bad by modern stadium truck terms, but it's no T, T2, T3, T4), and its WAY to damn expensive!

I believe you are correct in saying the T6.1 Team kit is WAY expensive for most people who just want a basher. I'd still buy one to bash if I weren't in deep with the "4" series platforms.

#97

kit choice would be nice. really the only features it would have to have are CVD's/CVA's, ball diff, and full bearings, oil shocks, but im sure most people are fine with plastic clips to adjust ride height so threaded bodies are not required. a good looking body and some halfway decent tires.

put the motor behind the shock tower where it belongs, use a stick pack, make the body look like an actual F'ing truck (think 10T - 10T3) and id be down with that for $240.

oh, and keep it on the market for several years without coming up with version 2.0 a year later. OR, offer a damn UPDATE KIT to convert it to the modern model for a decent price. WHICH THEY DID WITH THE B2 BACK IN THE DAY, THERE WAS A DAMN KIT FOR AROUND $100 TO CONVERT YOUR B2 TO A B3!!!

stop trying to make me spend money, you're not making me spend money, you're making me hate your guts!

put the motor behind the shock tower where it belongs, use a stick pack, make the body look like an actual F'ing truck (think 10T - 10T3) and id be down with that for $240.

oh, and keep it on the market for several years without coming up with version 2.0 a year later. OR, offer a damn UPDATE KIT to convert it to the modern model for a decent price. WHICH THEY DID WITH THE B2 BACK IN THE DAY, THERE WAS A DAMN KIT FOR AROUND $100 TO CONVERT YOUR B2 TO A B3!!!

stop trying to make me spend money, you're not making me spend money, you're making me hate your guts!

Last edited by suburban_hooligan; 09-30-2018 at 12:10 PM.

#98

Thread Starter

A couple of great runs today with the T4.3, and amazed by the speed/handling. I was having such a good time, I feel as though I need to get a more powerful motor for my T4.2 now. It's weird for me to have my version of the T4.3 go faster than my T4.2FT around the track. The F540 motor was pretty darn cool coming off the track @ 140°F. I could go up a tooth, or two and still be okay with temps. I think. I may have to get another F540 motor next year, and put it in the T4.2 to keep up with it's sibling. What I really want is the full size 3100kv 540 motor not the finned one. I think I've found the same motor that I originally ordered, but from different supply, and it's blue/silver instead of black/gold.

#99

Thread Starter

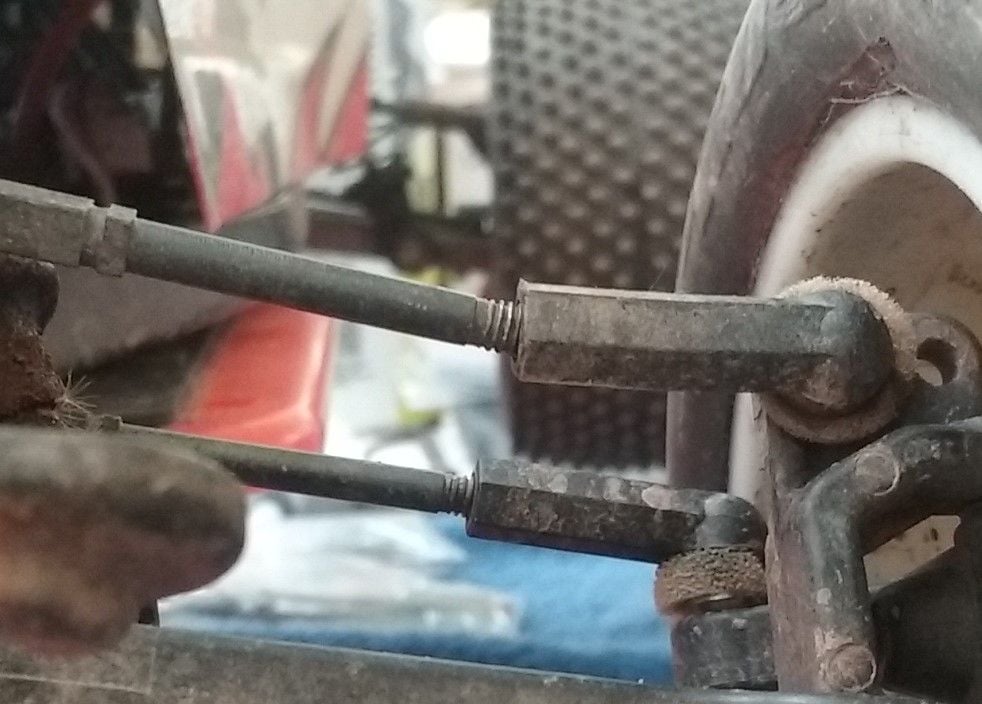

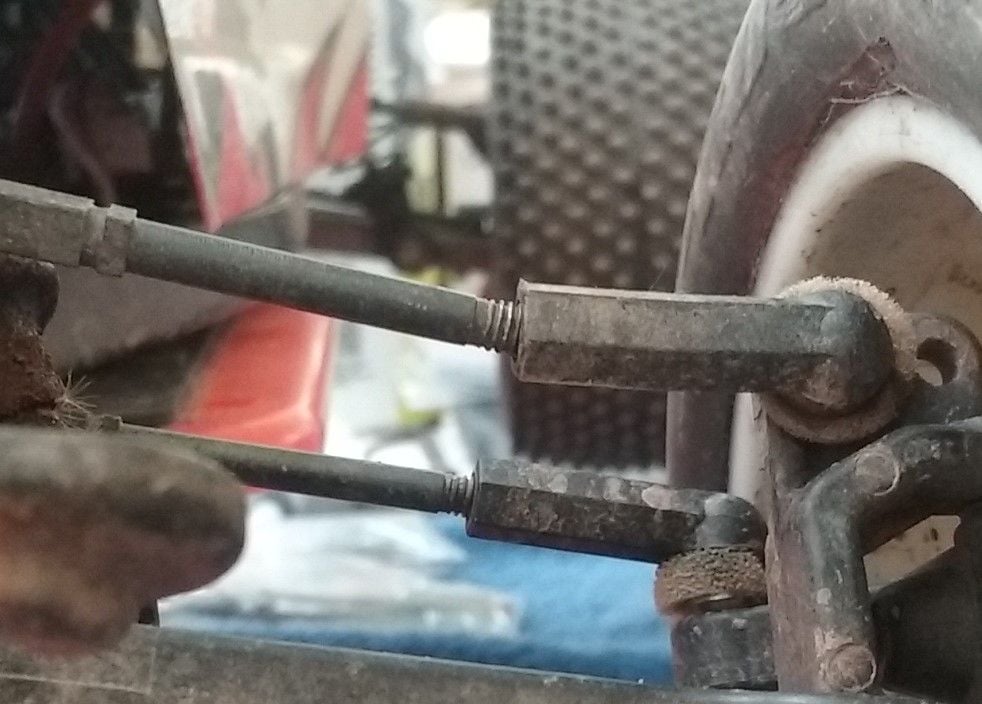

Stock B4/T4 turnbuckles are notorious for failing in all kinds of situations.

I haven't used stock turnbuckles since like 2006? on my B4 when they snapped after I tried to clear a jump. I'm really surprised Associated used these sub 3mm pieces of steel in the .1, .2, and .3 versions of the "4 " series RCs.

Waiting for a set of T6.1's turnbuckle set to show up. I'm thinking I'll have to use some long shank RPM ends to make up for difference in length on the turnbuckles.

I haven't used stock turnbuckles since like 2006? on my B4 when they snapped after I tried to clear a jump. I'm really surprised Associated used these sub 3mm pieces of steel in the .1, .2, and .3 versions of the "4 " series RCs.

Waiting for a set of T6.1's turnbuckle set to show up. I'm thinking I'll have to use some long shank RPM ends to make up for difference in length on the turnbuckles.