FINDING THE RIGHT PAD MATERIAL FOR CARBON DISC

#1

Banned

Thread Starter

Join Date: Apr 2009

Location: Cheshire, , UNITED KINGDOM

Posts: 240

Likes: 0

Received 0 Likes

on

0 Posts

After 2hrs normal running around a grass field:

(Note the crack/seperation between the carbon layers in the rotor, thats how itcame.I didn't thinkit would really effect it though andI can't see how it might have caused theexcessive wearing).

These brakes fade so quickly! they were completely gone after an hour and needed adjusting. I tired flipping the alloy pads over to get a bit more life out of them but it didn't help for long and now the rotor is worn out.

I actually switched from Vertigo tripple CF pads (use stock rotors)and they work very well, no brake fade at all after a year but I wanted to ditch the steel rotors as I'm trying to save some weight/rotating massand the CF rotor looked like the ticket. And before anyone askes, no, they were adjusted just fine and there was not drag or binding, they just didn't seemlast.

My Baja runs with a stock CY26 and has a dry weight of 23.8lbs, I don't think it should be a strain for such an aftermarket setup.

Here's the Vertigo pads after a one year, practically no wear at all just a polished area where therotors contactand they bite just as hard as the TGNsetup.

#3

Senior Member

My Feedback: (6)

Join Date: Oct 2005

Location: sheboygan,

WI

Posts: 2,242

Likes: 0

Received 0 Likes

on

0 Posts

I also have the Vertigo setup I was one of the first people to buy them on the market, it is till going strong...the triple system is the best idea out there for the money

#4

Senior Member

Join Date: Aug 2006

Location: somewhere

Posts: 3,237

Likes: 0

Received 0 Likes

on

0 Posts

what i do is get the stock metal brake pads remove off the stock brake pad material and superglue on car brakes then sand it down to shape and it lasts forever . when applying these brakes on the feel is awsome it stops on a dime ,no need to buy tgn brake pads or carbon fibre rotors lol . ive done the same mod to both my 5B's and my FG MT

after thats done all you gotta do is drill the two holes in for assembly like i still have to do

after thats done all you gotta do is drill the two holes in for assembly like i still have to do

#5

Senior Member

Join Date: Mar 2005

Location: Kingston UK, but living in Athens, GREECE

Posts: 18,082

Likes: 0

Received 3 Likes

on

3 Posts

To be fair, you can get unlucky with individual pieces of carbon fiber, some just don't get laminated quite as well as others. It's not an excuse, just an observation, and of course that has nothing to do with the fade you describe. I never did try these brakes when I had a 5b to have any meaningful input to this, seems a shame cos I had heard this was a good product.

Anyway, brakes are for <insert your word of choice here>

#7

Banned

Thread Starter

Join Date: Apr 2009

Location: Cheshire, , UNITED KINGDOM

Posts: 240

Likes: 0

Received 0 Likes

on

0 Posts

"Brakes are for cowards!" Maybe I need 'Party Poppers' like in The Chronicles of Riddick or just a big drag chute.

IfI was up for wasting a little money right now I'd tryCF pads on a CF rotor like a Formula 1.

I've emailed TGN to see if they have any input onit, it could simply be that's what we should expect for useful life from their brakes and they expect you to change them every race...

Until then I might as well have a little play with what I have left of this TGN kit. I got thinking about CF &AL as brake materials and realised I'd had this problem along time ago with Crazy Nut brakes for the HPI savage. Those were 2 CF pads and an AL rotor, they were insanely strong brakes, way too uncontrollable and like the TGN set they suffered a lot of brake fade. The rotor didn't seem to wear so bad, it was the CF pads - most of us blamed it on poor quality CF but in hind sight I think the problem was AL is a very abrasive material and not particularly hard wearing either. At least when its the rotor there's more of it to wear away since the braking surface is spread over a larger area on the rotor then the pads. When was the last time we saw AL used as a material used in brakes anyway?

I don't know of any 1:1 vehicle that uses it AL as a contact material, I doknow that CF is used a lot in racing. Also if the Vertigo setup proves anything its that CF can be hard wearing when used with steel, and a little googling also shows that its a common setup. So maybe the CF rotor can be salvaged. I figure maybe I should file down the AL brake blocks and mount a thin strip of steel to them and give that a shot. The downside compared to the triple pad system is that I'll only be using one rotor and 2 pads so that's only half the surface area, I guess I can expect half the braking? but to be honest I don't like locking up the brakes anyway as it just means losing the rear end when cornering and its really really bad for the driveline.

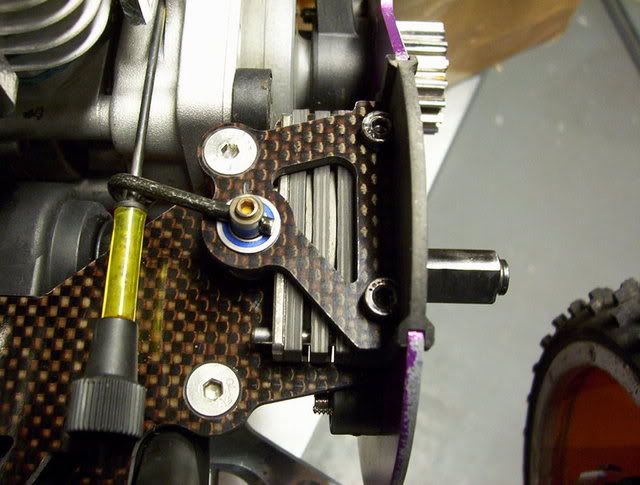

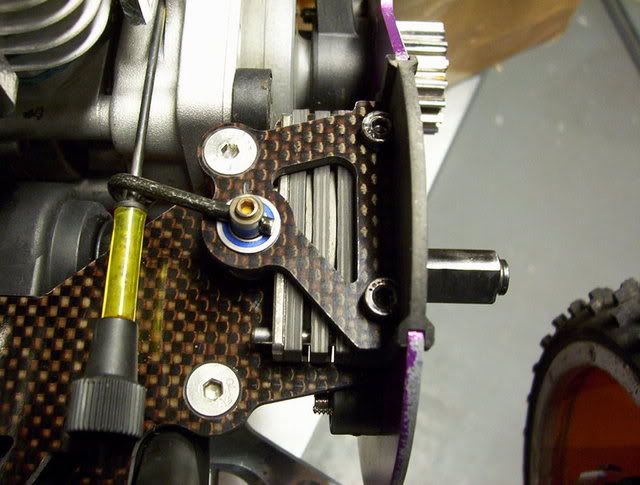

So this is what I've been up to:

I tidied up the CF rotor, pumped lots of CA glue into that crack/separation between the CF layers and sealed the edges. I'm still not thrilled about the condition of it, but it should suffice for a little testing. My goal is still to ditch the two stock steel rotors and still have a reliable durable setup.

#8

Banned

Thread Starter

Join Date: Apr 2009

Location: Cheshire, , UNITED KINGDOM

Posts: 240

Likes: 0

Received 0 Likes

on

0 Posts

Next I filed down & cleaned up the al pads. I wanted to be able to use the al pads as they are nice and light and just line the contact surface with a little steel.Looking for suitable donor steel first I tried the top of an old hard drive case, but cutting that didn't go right with it buckling and warping the surface - for this to work they need to be nice and flat.

Scratching my head asfor what to use... I didn't want to go thick on thesteel as although it would be easier to cut it would addmore weight, it hit me, right under my nose were perfectly shaped 0.4mm steelbrake shims - Thanks HPI!These like e-clips and other stamped pieces of steel have a sharpedge on one side anda smooth edge on the other soI figured it best to mount them on the al pads with the sharpside towards theAL pad and the smooth edge towards the rotor,so as not to cause it to wear anymore then it already has and just to be sure I took a little 1200grit wet'n'dry paper to the edges just to make sure there were smooth.

After a few hours work on the pads:

Digging around in my PC gear (from my overclocking days) I found some Arctic Silver thermal epoxy. This stuff was always great for permanently bonding a chip to a heatsink, insanely strong you'd sooner tear the chip from the PCB before you ever came close to getting whatever you'd glued to it off. It has great thermal transfer qualities, the trick is a thin layer and then lots of pressurein a vice until the epoxy sets (5-10mins). Since the steel pads are going to heat up a lot with the friction with the CF rotor it makes sense that they be able to off load some of that thermal energy into the alum pads behind them so this stuff should do the trick.

Shameless plug for Arctic Silver:

#9

Banned

Thread Starter

Join Date: Apr 2009

Location: Cheshire, , UNITED KINGDOM

Posts: 240

Likes: 0

Received 0 Likes

on

0 Posts

And here we go, all ready for testing, I gave the Baja a quick boot down the hallway and hit the brakes,it came to a reasonably quick stop before it hit the front door so that's a good sign at least, I had fears that it would be like watching a train trying to do an emergency stop - engineer hits the brakes, train stops a mile further down the track...

I was going to use the alum spacer to take up the slack in the setup (pictured above) but it was a little too wide so had to ditch it and use my one remaining brake shim along with a couple of washers, its still a bit sloppy for my tastes (i like to be able to lightly touch the brakes on the TX and get a responce) but until I get some more shims or a new rotor (If this all works out)It should do for now. Still it does look purdy, that should be worth something atleast.

#10

Banned

Thread Starter

Join Date: Apr 2009

Location: Cheshire, , UNITED KINGDOM

Posts: 240

Likes: 0

Received 0 Likes

on

0 Posts

Well just got back from a test run, works. The braking won't be for everyone, it comes in very soft but i'm still able to brake late and pull a sharp turn without losing the rear end so for now i'm a fairly happy bunny. Might give the CF pads a try on the CF rotor next, seems to work fine in F1 and for aircraft with an acceptable wear rate, seems CF actually has to become fairly hot before its most effective for braking and dosn't excessivly wear until it gets to 600c - should be fun.

#11

Banned

Thread Starter

Join Date: Apr 2009

Location: Cheshire, , UNITED KINGDOM

Posts: 240

Likes: 0

Received 0 Likes

on

0 Posts

Well I've decided I want to give CF pads on CF rotor a whirl, but not wanting to destroy my CF pads I decided to dig out an off cut I had knocking around and fab up a padI won't mind sacrificing. The off cut was a little short to mount properly so I mounted it on the stock HPI caliper and as luck would have it it turned out to be the exact same thickness as the alum/steel pad I just removed - which BTW was looking completely fine after the little session I had earlier.

Bite level has already jumped up quite a lot, hopefully I'll be able to report something good, and maybe in a years time I can say the wear level is acceptable...

#12

Banned

Thread Starter

Join Date: Apr 2009

Location: Cheshire, , UNITED KINGDOM

Posts: 240

Likes: 0

Received 0 Likes

on

0 Posts

Well carbon on carbon... FAIL!

Thats after less then one tank. I was running it hard to simulate race conditions, short fast staight, brake hard, quick turn and repeat. In contrast the steel lined pad that was on the other side of the disc is in fine condition. I was a bit disappointed as the braking feel that the single CF pad gave was great but there we go it wasn't ment to be. An F1 carbon brake system takes 6 months tomake, little much to try and do it in 30mins.

Whats next, Ceramic pads? I hear that works well with carbon discs, anyone know the best way to cut up a ceramic kitchen hob?

#13

Senior Member

Join Date: Jul 2005

Location: Torchy the Fiery Fast RC Turtl

Posts: 10,544

Likes: 0

Received 0 Likes

on

0 Posts

That is some serious fade, unlucky or not with the CF treatment.

I would dare say you have a bit of an urge to do alot of speed runs and hard braking. I do the same and my RC has 4disc brakes with semi-metallic brake pads. And even with 4 discs, I can make it brake so hard that you can smell the semi-metallic pads cooking just like you would on a full sized car after doing some serious jack-rabbit starts and very hard stops.

To help the braking load, you can cut the work that disc must do by one-third by installing also front brake discs. That way, three discs are doig the work to convert your KE into heat and thus the fade would only be 1/3 that of what you see now.

As for your Vertigo disc, do you brake hard on that one too?

I would dare say you have a bit of an urge to do alot of speed runs and hard braking. I do the same and my RC has 4disc brakes with semi-metallic brake pads. And even with 4 discs, I can make it brake so hard that you can smell the semi-metallic pads cooking just like you would on a full sized car after doing some serious jack-rabbit starts and very hard stops.

To help the braking load, you can cut the work that disc must do by one-third by installing also front brake discs. That way, three discs are doig the work to convert your KE into heat and thus the fade would only be 1/3 that of what you see now.

As for your Vertigo disc, do you brake hard on that one too?