Ripmax Xcalibur Sports jet

#1151

Thread Starter

4.8v is an ancient designation from 4 cell Nicad cell batteries where the nominal voltage is used. 1.2v per cell x 4 = 4.8v...when the pack is all but flat!! In aeromodelling 4.8v does not exist as a voltage and it confuses just about everyone and even stops sales for JR. The 1.2v cell fully charged is 1.5v...little more sometimes, so 4 x 1.5 is 6.0v. In operation Ni cells collapse a little so JR test their "4.8v" servos around 5.7v. Powerbox said OK, best cells and only 2-3 servos in a delta or wing and a 4 cell Ni pack can give 5.8-5.9v, hence all PB switches and units are 5.9v output.

So your 6.6v packs dropped to 5.9v on a Powerbox Sensor switch is perfect for all JR servos. I have the 8421, 3401, 579 and 331 in my 100+ flight Xcalibur with 2 x 2s Li-Po packs supplying a PB Sensor switch

Dave

#1152

Junior Member

Join Date: Jan 2007

Location: Brunswick West, AUSTRALIA

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

Dom

4.8v is an ancient designation from 4 cell Nicad cell batteries where the nominal voltage is used. 1.2v per cell x 4 = 4.8v...when the pack is all but flat!! In aeromodelling 4.8v does not exist as a voltage and it confuses just about everyone and even stops sales for JR. The 1.2v cell fully charged is 1.5v...little more sometimes, so 4 x 1.5 is 6.0v. In operation Ni cells collapse a little so JR test their "4.8v" servos around 5.7v. Powerbox said OK, best cells and only 2-3 servos in a delta or wing and a 4 cell Ni pack can give 5.8-5.9v, hence all PB switches and units are 5.9v output.

So your 6.6v packs dropped to 5.9v on a Powerbox Sensor switch is perfect for all JR servos. I have the 8421, 3401, 579 and 331 in my 100+ flight Xcalibur with 2 x 2s Li-Po packs supplying a PB Sensor switch

Dave

4.8v is an ancient designation from 4 cell Nicad cell batteries where the nominal voltage is used. 1.2v per cell x 4 = 4.8v...when the pack is all but flat!! In aeromodelling 4.8v does not exist as a voltage and it confuses just about everyone and even stops sales for JR. The 1.2v cell fully charged is 1.5v...little more sometimes, so 4 x 1.5 is 6.0v. In operation Ni cells collapse a little so JR test their "4.8v" servos around 5.7v. Powerbox said OK, best cells and only 2-3 servos in a delta or wing and a 4 cell Ni pack can give 5.8-5.9v, hence all PB switches and units are 5.9v output.

So your 6.6v packs dropped to 5.9v on a Powerbox Sensor switch is perfect for all JR servos. I have the 8421, 3401, 579 and 331 in my 100+ flight Xcalibur with 2 x 2s Li-Po packs supplying a PB Sensor switch

Dave

Much appreciated.

Dom

#1154

What smoke pump are you using and size tank

thx izzy

#1157

Junior Member

Join Date: Jan 2007

Location: Brunswick West, AUSTRALIA

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

Hi Dave,

I am about to plumb my tank and need some advice.

Is the black bung that you used the one provided by Ripmax ? Mine is black but I thought gas/kero bungs are normally brown.

What size tygon did you use to fit to the 4mm brass tubing ?

My tank was not provided with a felt clunk. I like yours. Do you sell those ? I can't see it on your website.

And lastly with the pick up line which is quite long, is there a chance that it might get caught forward or pinch itself leading to fuel starvation.

Thanks for your help

Dom

#1158

Thread Starter

Dom

Yes, Dubro is brown, but the bung provided is a kero bung and what I use.

I used 6/4mm clear tube (like BVM supply with their UAT) and 1/8" i/d (3.2mm) bore Tygon for the clunk and overflow. Pump voltages are good.

The clunk is under Misc Jet accessories shown without the felt, but it is included.

http://www.motorsandrotors.co/index....oducts_id=5091

With Tygon there is no chance of it pinching, never had one catch or stick. My clunk line is 170mm long

Best Regards

Dave

Yes, Dubro is brown, but the bung provided is a kero bung and what I use.

I used 6/4mm clear tube (like BVM supply with their UAT) and 1/8" i/d (3.2mm) bore Tygon for the clunk and overflow. Pump voltages are good.

The clunk is under Misc Jet accessories shown without the felt, but it is included.

http://www.motorsandrotors.co/index....oducts_id=5091

With Tygon there is no chance of it pinching, never had one catch or stick. My clunk line is 170mm long

Best Regards

Dave

#1160

Junior Member

Join Date: Jan 2007

Location: Brunswick West, AUSTRALIA

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

Hi Dave,

Thanks again for the info. It is much appreciated. It has been quite a while since I built my Falcon 120 (now sold) and like to get everything straight in my head before starting to build.

It looks like you have sweat soldered those barbs on ? Very nice job. I also assume you have used the provided 4 mm tubing which comes with the bung.

How many mm of tube do you normally leave at the front of the bung ?

One last question (promise I'll stop annoying you), what adhesive do you use or recommend for the hinging ?

Regards

Dom

Thanks again for the info. It is much appreciated. It has been quite a while since I built my Falcon 120 (now sold) and like to get everything straight in my head before starting to build.

It looks like you have sweat soldered those barbs on ? Very nice job. I also assume you have used the provided 4 mm tubing which comes with the bung.

How many mm of tube do you normally leave at the front of the bung ?

One last question (promise I'll stop annoying you), what adhesive do you use or recommend for the hinging ?

Regards

Dom

#1161

Junior Member

Join Date: Jan 2007

Location: Brunswick West, AUSTRALIA

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

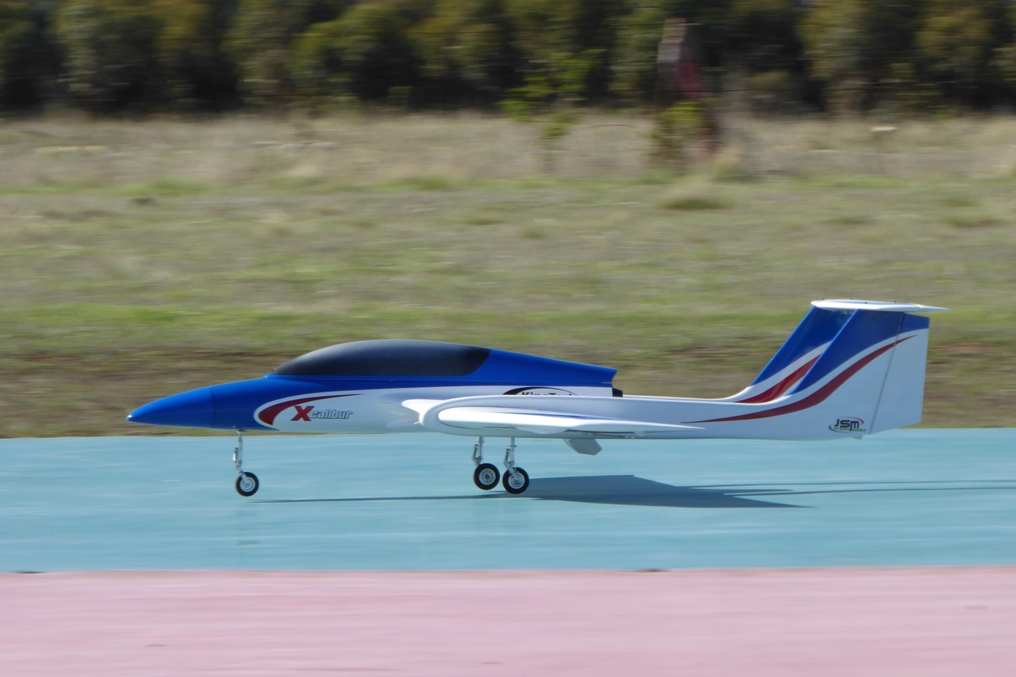

Had a great maiden today, running K80G and Trim Air Electric Retracts with Hitec 5645mg Servos all around.

Predictable and smooth with only a few clicks of elevator trim.

Landing was just perfect but she decided to take off again with a rise in our runway, plus i should have cut the nose strut a fraction shorter. I was warned!. All good, added a little bit of thrust and touched down nicely a second time but didn't have much runway left as you can see in the pic. Perhaps 10 meters. I've done a few minor tweaks and we're ready to go again..

I don't know what you guys think but the flap seems a little more like an air brake to me

Looking forward to having many weekends of good flying with this bird.

Anyone thinking this might be a good weekend flyer at your club or just a good sports jet.... just do it

Predictable and smooth with only a few clicks of elevator trim.

Landing was just perfect but she decided to take off again with a rise in our runway, plus i should have cut the nose strut a fraction shorter. I was warned!. All good, added a little bit of thrust and touched down nicely a second time but didn't have much runway left as you can see in the pic. Perhaps 10 meters. I've done a few minor tweaks and we're ready to go again..

I don't know what you guys think but the flap seems a little more like an air brake to me

Looking forward to having many weekends of good flying with this bird.

Anyone thinking this might be a good weekend flyer at your club or just a good sports jet.... just do it

How much did you shorten the noseleg ?

Did you get Tony at Trimaircraft to do it for you ?

Looks like you are flying at the Keilor club looking at that matting. I am a member there too.

Cheers

Dom

#1162

Thread Starter

Hi Dave,

Thanks again for the info. It is much appreciated. It has been quite a while since I built my Falcon 120 (now sold) and like to get everything straight in my head before starting to build.

It looks like you have sweat soldered those barbs on ? Very nice job. I also assume you have used the provided 4 mm tubing which comes with the bung.

How many mm of tube do you normally leave at the front of the bung ?

One last question (promise I'll stop annoying you), what adhesive do you use or recommend for the hinging ?

Regards

Dom

Thanks again for the info. It is much appreciated. It has been quite a while since I built my Falcon 120 (now sold) and like to get everything straight in my head before starting to build.

It looks like you have sweat soldered those barbs on ? Very nice job. I also assume you have used the provided 4 mm tubing which comes with the bung.

How many mm of tube do you normally leave at the front of the bung ?

One last question (promise I'll stop annoying you), what adhesive do you use or recommend for the hinging ?

Regards

Dom

Can never ask too many questions, its really no problem answering.

No, they are just soft soldered with a small blow torch, what you see is I cleaned these up on the lathe as the solder did not flow as I'd have liked.

Around 15mm, these are a little more installed.

I use Hysol 9462. It does not run away into the structure like ZAP 30 minute would.

(The nose leg does not need shortening...its perfect on grass or tarmac. Never had a skipped landing) I know some turbines like the KT have higher idle thrust, but you just need to come off the power earlier and add more drag. The flap will become an airbrake over 80 degrees, that's good too, the Xcalibur is lightly loaded, some people like a lot of CROW, that adds drag and dumps lift.

#1164

Hi Guys

This is my experience with the iGyro 3e. I fitted this to my Xcalibur (Not that it needs one) just to see if it would make a difference to the flying. I fitted this back in December however I just got round to trying it today so no winds blue skies and -1c. I set this up as instructions on a slider set to 0 % gain middle and 100% either side . Flying level, started toincrease gyro rate I can’t tell you the percentage as the XG 11 does not give you the percentage on the slider or if it does I can’t find it so I just went with notches. 4 notches about 10% and half throttle the Xcalibur started to porpoise quite badly two more notches and it got very bad and the same thing happened each time I tried it. Ailerons did not seem to be affected I don’t know if I got thegain high enough to bring the ailerons in. OK if I am doing some wrong let me know. This is my first gyro in a jet so as far as the Xcalibur goes don’t bother with one it flies better without. Gyrois coming out and going in my Harpoon.

This is my experience with the iGyro 3e. I fitted this to my Xcalibur (Not that it needs one) just to see if it would make a difference to the flying. I fitted this back in December however I just got round to trying it today so no winds blue skies and -1c. I set this up as instructions on a slider set to 0 % gain middle and 100% either side . Flying level, started toincrease gyro rate I can’t tell you the percentage as the XG 11 does not give you the percentage on the slider or if it does I can’t find it so I just went with notches. 4 notches about 10% and half throttle the Xcalibur started to porpoise quite badly two more notches and it got very bad and the same thing happened each time I tried it. Ailerons did not seem to be affected I don’t know if I got thegain high enough to bring the ailerons in. OK if I am doing some wrong let me know. This is my first gyro in a jet so as far as the Xcalibur goes don’t bother with one it flies better without. Gyrois coming out and going in my Harpoon.

Last edited by r 3; 01-29-2015 at 09:18 AM.

#1165

Thread Starter

The silicon holds the closed loop wire inline and does not affect the steering.

Dave

Billy will ask PB when I see them in Germany this weekend if they have an idea on that set up. You have the same speed servos on aileron and elevator?

#1168

Junior Member

Join Date: Jan 2015

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

Hi Everyone,

Just started building my Xcalibur this week and I've come up against a potential problem. When hinging the rudders and elevator I've noticed that some of the hinge holes are off centre - unfortunately I noticed this after I'd epoxied them! I've built several ARTFs in the past but this is my first jet. I've since come across some remarks about off centre hinge holes on this thread and I wondered if the off-centre control surfaces will cause any problems with the performance or handling of the model. I don't want the grief of having to re-hinge the surfaces if it's not going to affect the flight characteristics of the model. The right end of the elevator is flush but the left side is out by 1mm, the right rudder is flush at the bottom but out by 1.5mm at the top and the left rudder is flush at the top but out by 1.5mm at the bottom. I've attached some photos.

Cheers,

Pete

Just started building my Xcalibur this week and I've come up against a potential problem. When hinging the rudders and elevator I've noticed that some of the hinge holes are off centre - unfortunately I noticed this after I'd epoxied them! I've built several ARTFs in the past but this is my first jet. I've since come across some remarks about off centre hinge holes on this thread and I wondered if the off-centre control surfaces will cause any problems with the performance or handling of the model. I don't want the grief of having to re-hinge the surfaces if it's not going to affect the flight characteristics of the model. The right end of the elevator is flush but the left side is out by 1mm, the right rudder is flush at the bottom but out by 1.5mm at the top and the left rudder is flush at the top but out by 1.5mm at the bottom. I've attached some photos.

Cheers,

Pete

#1170

Junior Member

Join Date: Jan 2015

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

Hi there,

I bought the model last July and I've finally got round to starting it! I think it's from the first batch of RAF colour scheme kits. I've also seen notes on here about dodgy metal clevises where the riveted pin comes loose but I've checked mine and they seem to be fine.

Cheers,

Pete

I bought the model last July and I've finally got round to starting it! I think it's from the first batch of RAF colour scheme kits. I've also seen notes on here about dodgy metal clevises where the riveted pin comes loose but I've checked mine and they seem to be fine.

Cheers,

Pete

#1171

My Feedback: (13)

The site is great. It's very nice. The only downside to it is, in the event that you have an issue with your model there is nothing but bush around the site.

There is apparently an F16, with a turbine and all the gear sitting somewhere in the bush. People saw it go in, but no one has found it. It's very, very dense.

The wind effects can get quite intense there too.

#1172

Join Date: Mar 2006

Location: Hensley,

AR

Posts: 390

Likes: 0

Received 0 Likes

on

0 Posts

Pete,

i have an earlier kit an several of my hinge lines were mis-aligned. It doesnt affect the flight performance and if you dont point it out, few people will notice it.

Something else to check for if its not too late and really my only complaint on the model. Check to see if you can get the recommended travel both direction on the ailerons before the servo starts to bind. I can not, but I had already glued the hinges and was setting up the ailerons when i realized this. This results is a pathetic roll rate for a sport jet and im getting ready to cut my ailerons off and re-bevel them.

i have an earlier kit an several of my hinge lines were mis-aligned. It doesnt affect the flight performance and if you dont point it out, few people will notice it.

Something else to check for if its not too late and really my only complaint on the model. Check to see if you can get the recommended travel both direction on the ailerons before the servo starts to bind. I can not, but I had already glued the hinges and was setting up the ailerons when i realized this. This results is a pathetic roll rate for a sport jet and im getting ready to cut my ailerons off and re-bevel them.

#1173

Junior Member

Join Date: Jan 2015

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the advice Grodus, just epoxied my aileron hinges this afternoon and found that the hole alignment was pretty good. They were within 0.5mm, I'd say. I had to set the trailing edge of the aileron slightly proud of the wing to get the suggested movement of 23mm up and down.

Pete,

i have an earlier kit an several of my hinge lines were mis-aligned. It doesnt affect the flight performance and if you dont point it out, few people will notice it.

Something else to check for if its not too late and really my only complaint on the model. Check to see if you can get the recommended travel both direction on the ailerons before the servo starts to bind. I can not, but I had already glued the hinges and was setting up the ailerons when i realized this. This results is a pathetic roll rate for a sport jet and im getting ready to cut my ailerons off and re-bevel them.

i have an earlier kit an several of my hinge lines were mis-aligned. It doesnt affect the flight performance and if you dont point it out, few people will notice it.

Something else to check for if its not too late and really my only complaint on the model. Check to see if you can get the recommended travel both direction on the ailerons before the servo starts to bind. I can not, but I had already glued the hinges and was setting up the ailerons when i realized this. This results is a pathetic roll rate for a sport jet and im getting ready to cut my ailerons off and re-bevel them.

#1174

Thread Starter

Flight wise it won't make a big affect, but if the hinge pins are all out there might be some resistance in movement.

Even with full movement the Xcalibur roll rate is not "blink" although its a sports jet, its also many people's introduction and aileron power is still good and spins and snaps still fine.

Personally I think its worth the effort to razor saw them off and re hinge the elevator which seen, it would just annoy me all the time. What country you in?

Dave

Even with full movement the Xcalibur roll rate is not "blink" although its a sports jet, its also many people's introduction and aileron power is still good and spins and snaps still fine.

Personally I think its worth the effort to razor saw them off and re hinge the elevator which seen, it would just annoy me all the time. What country you in?

Dave

#1175

Junior Member

Join Date: Jan 2015

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

Hi Dave, thanks for your reply. I'm in good old Blighty, Bedford to be precise.

I've checked the movement on the elevator and it's fine and not stalling the servo at any point through it's travel. If it's not going to affect the flying of the model I think I'll leave it as it is - it doesn't look bad as it's only high by 1mm at one end, and 2/3rds of the length of the elevator it's flush. My concern was that it might cause flutter etc.

As I said before, my clevises seem to be fine (gripping the pin and twisting gently there's no play or sign of the riveted end failing), but what is your expert opinion on the mounting of the control horn? I've seen various modifications that people have made and I wondered what you've found in your numerous flights with the model. I've just used the standard two screws for mounting them but I see that others have used a different horn with a backing plate etc. I've pilot drilled the holes and then hardened the thread with thin CA. The holes were in the hardwood half moon but I noticed that the hardwood is only a few mm thick and then you're through to balsa?

Cheers,

Pete

I've checked the movement on the elevator and it's fine and not stalling the servo at any point through it's travel. If it's not going to affect the flying of the model I think I'll leave it as it is - it doesn't look bad as it's only high by 1mm at one end, and 2/3rds of the length of the elevator it's flush. My concern was that it might cause flutter etc.

As I said before, my clevises seem to be fine (gripping the pin and twisting gently there's no play or sign of the riveted end failing), but what is your expert opinion on the mounting of the control horn? I've seen various modifications that people have made and I wondered what you've found in your numerous flights with the model. I've just used the standard two screws for mounting them but I see that others have used a different horn with a backing plate etc. I've pilot drilled the holes and then hardened the thread with thin CA. The holes were in the hardwood half moon but I noticed that the hardwood is only a few mm thick and then you're through to balsa?

Cheers,

Pete

Flight wise it won't make a big affect, but if the hinge pins are all out there might be some resistance in movement.

Even with full movement the Xcalibur roll rate is not "blink" although its a sports jet, its also many people's introduction and aileron power is still good and spins and snaps still fine.

Personally I think its worth the effort to razor saw them off and re hinge the elevator which seen, it would just annoy me all the time. What country you in?

Dave

Even with full movement the Xcalibur roll rate is not "blink" although its a sports jet, its also many people's introduction and aileron power is still good and spins and snaps still fine.

Personally I think its worth the effort to razor saw them off and re hinge the elevator which seen, it would just annoy me all the time. What country you in?

Dave