Why rebuilding turbine by jet companies cost so much $ is this monopol .

#52

Senior Member

My Feedback: (7)

Join Date: Dec 2001

Location: Gig Harbor,

WA

Posts: 524

Likes: 0

Received 0 Likes

on

0 Posts

Well.... really don't have many complains, and these usually come from customers who bought his first turbine used and received a engine older and more used than what they where told. Don't have data of this year, but average repair cost on 2013 was of 375EUR.

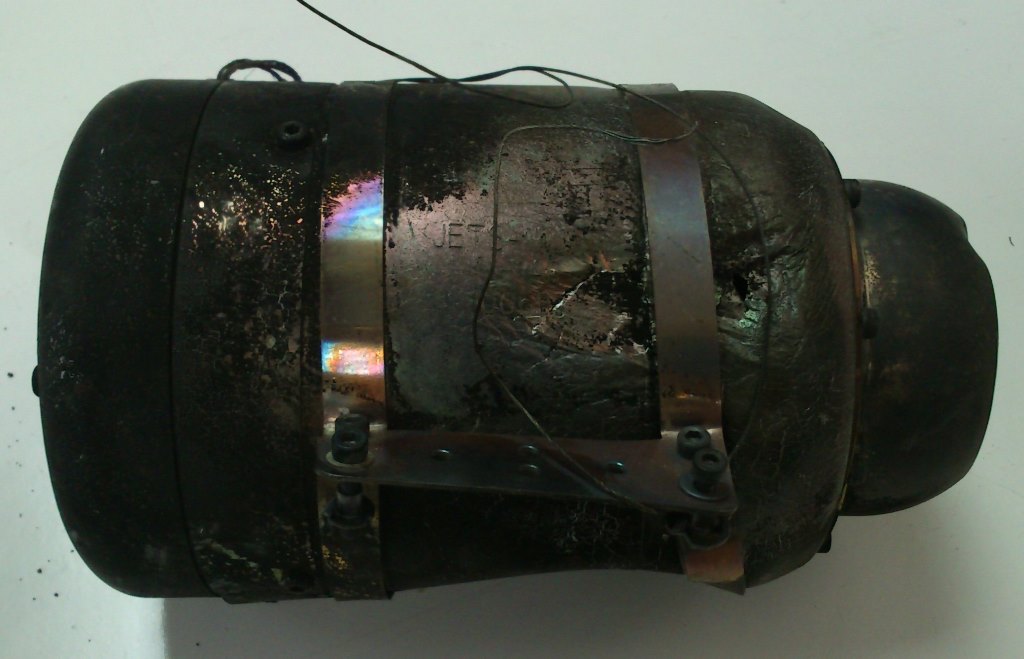

The most expensive repair we have done was on a burned engine (pictures below), where the repair was 550EUR less than a new one, so customer choose to fix it.

Gaspar

The most expensive repair we have done was on a burned engine (pictures below), where the repair was 550EUR less than a new one, so customer choose to fix it.

Gaspar

My next engine will be a JetMunts 200 ;-)

Z

#53

Join Date: Jun 2002

Location: Arenys de Munt- BARCELONA, SPAIN

Posts: 425

Likes: 0

Received 5 Likes

on

3 Posts

No, the repair cost was 550E less than the cost of a new engine. If the costumer had thrown away and had bought a new one, he would have paid 550EUR more for about the same.

Gaspar

Gaspar

Last edited by Gaspar; 10-05-2014 at 11:04 AM.

#54

Senior Member

Join Date: Feb 2011

Location: london, UNITED KINGDOM

Posts: 864

Likes: 0

Received 0 Likes

on

0 Posts

#56

My Feedback: (11)

I found the opposite. I see many guys (not all) who can afford turbines and are complete idiots. I see many that would be great turbine pilots and dont have the will nor the bank.

Do you really think a guy who makes big $$ hiring illegal Mexicans and paying them under min wage under the table to build houses, will be a responsible turbine owner? The known answer is NO.

In reality, the best turbine guy is the one who has to save up to buy one, or work overtime etc and really earn it. That is the person who will value his jet, value others, and be safe.

Nearly anyone can afford a turbine and a jet, its all about what you want to spend your money on. Nice car, bigger house, big TV, PS4, 4 or 5 foamies etc.. Or fly jets. This was discussed in another thread.

Do you really think a guy who makes big $$ hiring illegal Mexicans and paying them under min wage under the table to build houses, will be a responsible turbine owner? The known answer is NO.

In reality, the best turbine guy is the one who has to save up to buy one, or work overtime etc and really earn it. That is the person who will value his jet, value others, and be safe.

Nearly anyone can afford a turbine and a jet, its all about what you want to spend your money on. Nice car, bigger house, big TV, PS4, 4 or 5 foamies etc.. Or fly jets. This was discussed in another thread.

#57

Join Date: Nov 2005

Location: Moss Vale, NSW, AUSTRALIA

Posts: 181

Likes: 0

Received 0 Likes

on

0 Posts

Im more than happy with Kingtech, so Ill be sticking with them, I havent heard of an unhappy customer over here yet either. The Aussie distributer is fantastic. Same with their service department.

#58

Join Date: Oct 2006

Location: SAO JOSE DO RIO PRETO-SP, BRAZIL

Posts: 791

Likes: 0

Received 0 Likes

on

0 Posts

Hello Gaspar

do you have an dealer in Brazil ?

if yes the support is the same that you offereing in factory ?

let me know

jose

ps i have jetcats, the maintenance costs are very high!!! But, the dealer in Brazil is amazing!!

do you have an dealer in Brazil ?

if yes the support is the same that you offereing in factory ?

let me know

jose

ps i have jetcats, the maintenance costs are very high!!! But, the dealer in Brazil is amazing!!

#59

Actually the total point of this thread was to determine if the rc turbine company's and rc turbine mechanics shuld charge 3-4 times more than hight performance motorcycle cars jets ski mechanics ,the job it's much lighter and cleaner no heavy object to lift and no big tool box ,if I'm not wrong one turbine company charge over $100 for hour labor and usually never less than two labor hours for bearing exchange

#60

Join Date: Jul 2006

Location: Norfolk , UNITED KINGDOM

Posts: 1,409

Likes: 0

Received 0 Likes

on

0 Posts

The problem with the rotors for our small turbines is that, as explained by Dirk at Kingtech, they need balancing to a very high standard. This takes the use of a very expensive specialist balancer and a trained operative. The bearings are only available from GRW and are made in small quantities to extremely high standards and hence are expensive. Dirk was not exaggerating about the standard of balance required. I too balance engines to the same tolerances he does. This is way better than the standard for car turbo work and even gyros. As has been explained many times the engine has to be balanced as a complete engine after being assembled. I balance the rotor first as accurately as I can and then assemble and do final balance of the complete engine. I never get the engine to give low readings after the compressor position has been marked taken off and reassembled even if the compressor is a heat shrink fit on the shaft.

Having said that the cost of a bearing change including disassembly should be a standard charge unless further internal damage is found when stripping down. Wren for example have standard charges for a bearing change including stripping down reassembling and balancing and currently is £280 inc tax.

http://www.wrenturbines.co.uk/engine-services/servicing/wren-engine-service-thrust-gas-generator

I think this is a pretty reasonable charge for what will probably take 2-3 hours to do. I would always ask for a standard servicing cost before sending an engine in. There is a turbine repair service in Germany as an alternative and they hold some manufacturers parts.

I have seen posts of people that think a bearing change will solve damage from a completely failed bearing. This will often wreck the NGV, turbine wheel, compressor and intake, it can also damage the shaft. If this happens do not expect it to be economic to repair the engine even if parts are available.

I have done work on a number of early turbine engines of various makes and it always a bit of a lottery as combustion chambers of early engines were often of stainless and not Inconel and may well need replacing, it all depends on the amount of use. It amazes me though how often I take an engine apart and it looks nice and clean inside and clearly has had very little running in maybe 10 years.

The comparison with a mass produced car is not really relevant. The car has many cheap components that need replacing according following a manual. Relatively untrained staff can do the work provided they can read and measure clearances. There is no requirement to balance the components and the level of skill required is much less. Why anyone would strip a standard transmission is beyond me. It would be far cheaper to buy a reconditioned one with a guarantee. With auto work it is all about time and cost.

John

Having said that the cost of a bearing change including disassembly should be a standard charge unless further internal damage is found when stripping down. Wren for example have standard charges for a bearing change including stripping down reassembling and balancing and currently is £280 inc tax.

http://www.wrenturbines.co.uk/engine-services/servicing/wren-engine-service-thrust-gas-generator

I think this is a pretty reasonable charge for what will probably take 2-3 hours to do. I would always ask for a standard servicing cost before sending an engine in. There is a turbine repair service in Germany as an alternative and they hold some manufacturers parts.

I have seen posts of people that think a bearing change will solve damage from a completely failed bearing. This will often wreck the NGV, turbine wheel, compressor and intake, it can also damage the shaft. If this happens do not expect it to be economic to repair the engine even if parts are available.

I have done work on a number of early turbine engines of various makes and it always a bit of a lottery as combustion chambers of early engines were often of stainless and not Inconel and may well need replacing, it all depends on the amount of use. It amazes me though how often I take an engine apart and it looks nice and clean inside and clearly has had very little running in maybe 10 years.

The comparison with a mass produced car is not really relevant. The car has many cheap components that need replacing according following a manual. Relatively untrained staff can do the work provided they can read and measure clearances. There is no requirement to balance the components and the level of skill required is much less. Why anyone would strip a standard transmission is beyond me. It would be far cheaper to buy a reconditioned one with a guarantee. With auto work it is all about time and cost.

John

#61

I'm not talking about the parts cost just the labor ,and training it's relatively not expensive compared to it tech .college and a lot less to learn to fix turbine engine. And for changing the bearings you don't have to strip the turbine just the front compressor half and the exhaust about 20 screws often same size and than the compressor and press all down than 12-13 mm ranches and puller than change bearing and press the back will than balance and 20 more screws finished wow $200 labor + parts .I'm just talking about sample bearing exchange .When I did my supercharger rebuild for my racing watercraft it's a lot more than the and also require balance and clearance + the clutch tension a lot more than re turbine and the labor if done by performance shop it's a lot less for four times more labor time.

#62

I'm not talking about the parts cost just the labor ,and training it's relatively not expensive compared to it tech .college and a lot less to learn to fix turbine engine. And for changing the bearings you don't have to strip the turbine just the front compressor half and the exhaust about 20 screws often same size and than the compressor and press all down than 12-13 mm ranches and puller than change bearing and press the back will than balance and 20 more screws finished wow $200 labor + parts .I'm just talking about sample bearing exchange .When I did my supercharger rebuild for my racing watercraft it's a lot more than the and also require balance and clearance + the clutch tension a lot more than re turbine and the labor if done by performance shop it's a lot less for four times more labor time.

#63

Join Date: Nov 2005

Location: Moss Vale, NSW, AUSTRALIA

Posts: 181

Likes: 0

Received 0 Likes

on

0 Posts

I think everyone likes to see things done cheaper. At the same time, if you own a business your generally in business to make money. That being said what you seem to be saying is that Model Turbine Manufacturers or People who service them should pay the people who work for them less money per hour because its just a model turbine. Aside from the fact that the cost associated in tools and equipment per repair or turbine is a lot higher because those cost are spread over a smaller market. I cant imagine that the equipment to properly balance a shaft turning at 100,000+rpm accurately is going to be cheap. So if your only balancing a couple of thousand a month, which I would say is unlikely to be that high the cost of your equipment in order to make money back on your investment is going to be higher. Economies of Scale.

#67

Member

Join Date: Dec 2005

Location: London, UNITED KINGDOM

Posts: 36

Likes: 0

Received 0 Likes

on

0 Posts

Perhaps you could print your own.

An old doc, but gives the idea:

http://www.cdti.es/recursos/doc/even...ys2011/1D2.pdf

An old doc, but gives the idea:

http://www.cdti.es/recursos/doc/even...ys2011/1D2.pdf

For old super eagle and no warranty for the next 12months this is the treatment I received .

For old super eagle and no warranty for the next 12months this is the treatment I received .