Incompatibility with CAT air trap and Kingtech/Jetcat engines?

#26

I disagree Oli,

The none perfect clunk scenario complemented by an UAT is only a band-aid to the problem. Yes you could get away by doing some rolls, but you can not perform inverted flight in any duration without flaming out.

Further, a better band-aid to the problem would have been a center header tank rather than the UAT, still not the best setup to let the clunk issue go in my opinion.

The none perfect clunk scenario complemented by an UAT is only a band-aid to the problem. Yes you could get away by doing some rolls, but you can not perform inverted flight in any duration without flaming out.

Further, a better band-aid to the problem would have been a center header tank rather than the UAT, still not the best setup to let the clunk issue go in my opinion.

Wrong and wrong.

Modern air traps are not designed to eliminate cavitation but to reduce the likeliness of it by reducing the suction drag they create. However:

The primary function of an air trap is to work as a complement to the non perfect clunk.

As a reminder, air gets sucked into the system while performing maneuvers. No clunk system is perfect and no matter what, it will get into an empty portion of the tank at some point and pickup air.

When this happens, air is sent into the system downstream the tank and will be trapped by the air trap. The more aerobatics, the stiffer the clunk line, the more air will be sent into the system, especially towards the end of the flight. This is normal and cannot be avoided.

So it is essential to be able to back flush your air trap to refill it between each flight.

Otherwise, after a few flights, the air trap will be empty.

Also, there is a big mis-conception with the latest air trap. People believe that it is so good at trapping cavitation, that they do not need to have a big air trap volume in there. Once again, cavitation trapping is a secondary function of the air trap. The primary function is to block the air that is being sucked by the clunk and offer continuous flow to the engine. The main advantage of CATs or similar is to offer a various buffer volumes. Large volumes are important for big engines and I recommend chosing an air trap that offers 30 seconds of buffer at full thrust.

Down sizing an air trap is a big mistake and most system that I have seen getting people flame outs where either because of a drastic restriction in the system ( creating a cavitation condition ), wrong clunk line plumbing ( clunks blocking against a wall or stiff line due to hardening tygon ) and very small air trap buffer capacity.

Modern air traps are not designed to eliminate cavitation but to reduce the likeliness of it by reducing the suction drag they create. However:

The primary function of an air trap is to work as a complement to the non perfect clunk.

As a reminder, air gets sucked into the system while performing maneuvers. No clunk system is perfect and no matter what, it will get into an empty portion of the tank at some point and pickup air.

When this happens, air is sent into the system downstream the tank and will be trapped by the air trap. The more aerobatics, the stiffer the clunk line, the more air will be sent into the system, especially towards the end of the flight. This is normal and cannot be avoided.

So it is essential to be able to back flush your air trap to refill it between each flight.

Otherwise, after a few flights, the air trap will be empty.

Also, there is a big mis-conception with the latest air trap. People believe that it is so good at trapping cavitation, that they do not need to have a big air trap volume in there. Once again, cavitation trapping is a secondary function of the air trap. The primary function is to block the air that is being sucked by the clunk and offer continuous flow to the engine. The main advantage of CATs or similar is to offer a various buffer volumes. Large volumes are important for big engines and I recommend chosing an air trap that offers 30 seconds of buffer at full thrust.

Down sizing an air trap is a big mistake and most system that I have seen getting people flame outs where either because of a drastic restriction in the system ( creating a cavitation condition ), wrong clunk line plumbing ( clunks blocking against a wall or stiff line due to hardening tygon ) and very small air trap buffer capacity.

#28

Yes, I agree that the UAT needs to be filled but not necessary back flushed, perhaps using a manual valve to bleed off air from the other port during filling when necessary.

#29

#30

#31

Join Date: Jan 2007

Location: farnborough, , UNITED KINGDOM

Posts: 3,294

Likes: 0

Received 1 Like

on

1 Post

I prefer an airtrap that I can open and clean the filter inside

My focus when I designed the CAT was to make it as reliable as possible, as David suggests well filtered fuel will rarely result in problems with filters so that in turn means you don't need to open anything up.

marcs

#33

My Feedback: (9)

Oli this is a misunderstanding. Barry just recently dealt with a flame out issue on a plane that had the clunk stuck to the bottom of the tank so when inverted it would flame out. He thought thats what you where talking about with an imperfect clunk not a working clunk.

On a side note most flame outs are caused by the fuel system and more times then not it is improper use or installation of components.

#35

My Feedback: (9)

Hello Matt

The pump does not hit a voltage limit the ECU shuts it off when it gets to high as a safety measure like most other turbines do also. Even if you have your PUMP LIMIT set say to a value of around 350 the pump will go well over that to try and keep the engine running but at some point it cant keep up shuts the engine down.

The guy here on RCU that contacted me that was also seeing problems with CATs is a hard core jetcat guy but wished to remain out of this.

At kingtech we are not in the business of selling UATs and we are not trying to shed any negative light on Marcs product that appears to be a great product. We are only going by our experience helping many customers during tech support calls trouble shooting their engines. Also Barry had the issue with his own aircraft that he bought with a CAT. Its possible it has nothing to do with the CAT but we are only saying after removing the CAT and nstalling other UATs flameouts are gone.

#36

The non perfect clunk scenario I am referring to is for a working one, as you suggest.

Basically, no clunk will be good enough to pickup all the fuel of the tank without sucking some quantity of air in the process. This is what the air trap was originally designed for by BVM for his very early pylon racers and early jets. It is still the main reason why we put an air trap in the system and the reason why this must be full after each flight.

As a matter of fact, if the clunk gets sucked into a tank wall, the engine will flame out immediately. This is because the suction drag will instantly rise to cavitation level and starve the fuel injectors with air bubble while the pump voltage will rise massively as it cavitates as well. These is no way any air trap on the market would be able to help in this situation. The only way around this is a good plumbing of the clunk system as described in my fuel article. Note that I will be adding some pictures about this very case in one week from now in my blog.

#37

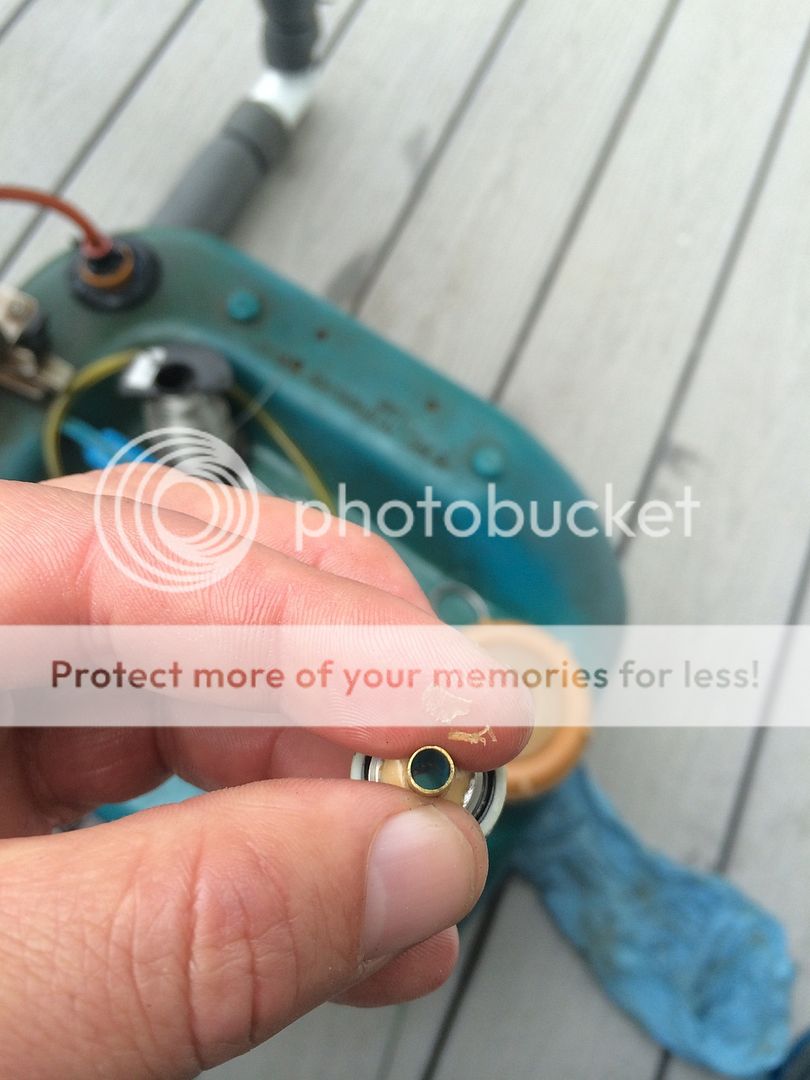

Barry, your pictures seem to show some slime aggregated around the debris as well as on the filter membrane.

It is not so easy to say from these pictures. It would require touching it ( it would feel like a jelly substance ).

However slime will certainly produce the described effect. The accumulated substance will clog the air trap after a while. Changing the unit will immediately restore original fuel system conditions, but only for a certain amount of time as the fuel system would remain contaminated and slime would accumulated again after a while no matter what type of air trap you use.

In this specific case, the best long term cure is to kill slime ( which is a type of algae that lives in kerosen and diesel ) with the proper additive. This is also explained in my blog.

It is not so easy to say from these pictures. It would require touching it ( it would feel like a jelly substance ).

However slime will certainly produce the described effect. The accumulated substance will clog the air trap after a while. Changing the unit will immediately restore original fuel system conditions, but only for a certain amount of time as the fuel system would remain contaminated and slime would accumulated again after a while no matter what type of air trap you use.

In this specific case, the best long term cure is to kill slime ( which is a type of algae that lives in kerosen and diesel ) with the proper additive. This is also explained in my blog.

#38

My Feedback: (71)

The debris people are getting inside the Cat or any other UAT come from your fuel Jug due you are refueling your plane true barb you must have filters in you fuel jug to prevent this I been using CAT for the past 1.5 years and never have any problems and I replace all my BVM ones with Cat every plane i Build I use CAT and recommend those to people who ask me yes the only problem they have is the O ring.

#39

Oli, there's no indication of slime or bio growth, and as stated in my earlier post, my fuel pressure gauge indicated low numbers when pumping fuel through the direction of fuel flow to simulate engine run, so low that it was even lower than a brand new KT UAT in comparison, probably due to the size of fittings as well as the single filter rather than the dual.

Barry

Barry

#41

My Feedback: (10)

Hello Matt

The pump does not hit a voltage limit the ECU shuts it off when it gets to high as a safety measure like most other turbines do also. Even if you have your PUMP LIMIT set say to a value of around 350 the pump will go well over that to try and keep the engine running but at some point it cant keep up shuts the engine down.

The pump does not hit a voltage limit the ECU shuts it off when it gets to high as a safety measure like most other turbines do also. Even if you have your PUMP LIMIT set say to a value of around 350 the pump will go well over that to try and keep the engine running but at some point it cant keep up shuts the engine down.

#42

Matt, it should be the case that under such sudden drastic change of conditions, that the ECU commands a shutdown. Let's say a debris is stuck into the port during filling and caused higher than normal pump voltage, during this time the ECU has learned itself to deal with the new conditions. Next, if and when the debris was suddenly flushed free (at this instance it would most likely be at full throttle with highest possible fuel pressure) then the RPM would overshoot enough for the ECU to command an immediate shutdown.

Regards,

Barry

Regards,

Barry

#43

Join Date: Jun 2002

Location: Arenys de Munt- BARCELONA, SPAIN

Posts: 425

Likes: 0

Received 5 Likes

on

3 Posts

I see that there are some misunderstandings about what the ecu does, the ecu don't shutdown the engine in the case of a clogged filter.

-If the RPM of the engine don't reach the commanded value, the ecu increases the pump power up to the "pump limit" value, not more. It doesn't shutdown the engine, just sits there so that the engine continue running at reduced power, issuing the alarm "Pump Limit reached" that you can see after the flight.

-Sometimes the engine flame out because when returning to idle, the calibrated power for the pump at idle (calibrated at each startup) is not in aft to keep the engine running. Other reason is that the fine bubbles caused by the cavitation in the aspiration line colapse to big bubbles when the power is retarded, due to the less fuel demand, causing the combustion to cease.

-In the case of overspeed the ecu don't shut down the pump, it just reduces the fuel flow very fast to fet the speed back to the safe zone. Some engines flame out due at too fast fuel reduction, but this case is not usual in the engines I have tested.

Gaspar

#44

My Feedback: (9)

Hi,

I see that there are some misunderstandings about what the ecu does, the ecu don't shutdown the engine in the case of a clogged filter.

-If the RPM of the engine don't reach the commanded value, the ecu increases the pump power up to the "pump limit" value, not more. It doesn't shutdown the engine, just sits there so that the engine continue running at reduced power, issuing the alarm "Pump Limit reached" that you can see after the flight.

-Sometimes the engine flame out because when returning to idle, the calibrated power for the pump at idle (calibrated at each startup) is not in aft to keep the engine running. Other reason is that the fine bubbles caused by the cavitation in the aspiration line colapse to big bubbles when the power is retarded, due to the less fuel demand, causing the combustion to cease.

-In the case of overspeed the ecu don't shut down the pump, it just reduces the fuel flow very fast to fet the speed back to the safe zone. Some engines flame out due at too fast fuel reduction, but this case is not usual in the engines I have tested.

Gaspar

I see that there are some misunderstandings about what the ecu does, the ecu don't shutdown the engine in the case of a clogged filter.

-If the RPM of the engine don't reach the commanded value, the ecu increases the pump power up to the "pump limit" value, not more. It doesn't shutdown the engine, just sits there so that the engine continue running at reduced power, issuing the alarm "Pump Limit reached" that you can see after the flight.

-Sometimes the engine flame out because when returning to idle, the calibrated power for the pump at idle (calibrated at each startup) is not in aft to keep the engine running. Other reason is that the fine bubbles caused by the cavitation in the aspiration line colapse to big bubbles when the power is retarded, due to the less fuel demand, causing the combustion to cease.

-In the case of overspeed the ecu don't shut down the pump, it just reduces the fuel flow very fast to fet the speed back to the safe zone. Some engines flame out due at too fast fuel reduction, but this case is not usual in the engines I have tested.

Gaspar

I have also seen problems in the fuel system and the engine will do exactly like you say reach the pump limit and sit their then give you PUMP LIMIT REACHED on the data terminal. Sometimes I have seen this caused by the pump other times it was other fuel system problems.

#45

My Feedback: (11)

This.

And I'd go even farther to say, that if you have a flame out, it likely points out to a "new" problem in your fuel system.

I have 3 CATS all getting worked and non babied. I had some debris in 5 year old tanks that were clogging up my PICK UP line IN MY TANK!! And it was very intermittant. I was lucky I found the debris. I could not find it before.

And by the look of the debris, it was from building/configuring the stopper/vent lines when it was being built. I was unable to pick up this debris even with vigorous flushing.

I have been very happy with my CAT's. The O-rings that come with them have been replaced with rubber bands. I don't even think about that any more.

So, is it possible the debris seen in the CAT came from the tanks?

Oh, and it's kinda funny that Barry's pic clearly show the filters in the CAT's being "Made in China" when Marc gets them from the US. Go figure.

Anyways, here is some debris that was causing my flameouts.

Last edited by ravill; 01-25-2016 at 09:33 AM.

#46

My Feedback: (8)

I have been using both BVM and TamJets UAT's with no issues over the years. I have also use the CAT with no issues as well.

JetCat has no issue with the use of either unit. The CAT does come in different sizes and should be used accordingly for the engine size. Don't use the small unit with a large engine, etc.

Always filter your fuel into your fuel jug and as it goes into your aircraft. I change the filter on my Jersey Modeler every season.

JetCat has no issue with the use of either unit. The CAT does come in different sizes and should be used accordingly for the engine size. Don't use the small unit with a large engine, etc.

Always filter your fuel into your fuel jug and as it goes into your aircraft. I change the filter on my Jersey Modeler every season.

#48

Because when the pump cavitates, its RPM will jump up all of a sudden ( driving air instead of liquid ). This will will drive its power up temporarily. Just like when you lose the propeller on an electric prop plane or go full dive/ high speed on an electric propeller/ impeller motor.

#49

Because when the pump cavitates, its RPM will jump up all of a sudden ( driving air instead of liquid ). This will will drive its power up temporarily. Just like when you lose the propeller on an electric prop plane or go full dive/ high speed on an electric propeller/ impeller motor.

#50

My Feedback: (24)

Join Date: Dec 2001

Location: Daytona Beach

Posts: 6,102

Likes: 0

Received 0 Likes

on

0 Posts

Seems to be some lack of logic being applied here by Kingtech?! If your pump PW has changed drastically from one flight to the next or is steadily climbing, this is a clear sign of a fuel system issue. If the airtrap is found to be the source of restriction but was functioning nominally on previous runs, something has clearly changed to induce the restriction. In Barry's case, you can clearly see the filter is dirty and appears to have some sort of microbial slime on the surface. How this can be attributed to a fault in the CAT, I fail to comprehend? Throw enough toilet paper in the toilet and its going to plug...... Of course replacing the trap will alleviate the restriction, till you plug the filters again....

PRE-FILTER your fuel going into your jugs using a MR Funnel and use an inline filter on your fill line and you wont have these issues.....

PRE-FILTER your fuel going into your jugs using a MR Funnel and use an inline filter on your fill line and you wont have these issues.....