Tomahawk-Design Bae Hawk 1: 3.5

#1303

My Feedback: (1)

Join Date: Jun 2005

Location: Europe

Posts: 164

Likes: 0

Received 0 Likes

on

0 Posts

Hello to everybody.

I need some information about painting codes for MK66 SWISS AIRFORCE (U-1252 for example). Information need to prepare documentation for championship. Confirmed official information. Can somebody help me?

Thanks

I need some information about painting codes for MK66 SWISS AIRFORCE (U-1252 for example). Information need to prepare documentation for championship. Confirmed official information. Can somebody help me?

Thanks

The following users liked this post:

sewbusy (09-04-2020)

#1306

Join Date: Sep 2008

Location: KerbachMoselle, FRANCE

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

Hi all the Builder and Tomahawk Hawk Fan,

I've a problem and I need Your help.

I search a set of landing Struts cover for the Tomahawk Hawk, at this time this set is not available from manufacturer. if somebody has one for sale,

Best Regards

I've a problem and I need Your help.

I search a set of landing Struts cover for the Tomahawk Hawk, at this time this set is not available from manufacturer. if somebody has one for sale,

Best Regards

#1307

Hello, someone has information of emergency Ram Air Turbine of Hawks ???

I´m looking for info but i only find a few pictures, but poor quality.

Thanks in advance.

Carlos

www.cmjets.com

I´m looking for info but i only find a few pictures, but poor quality.

Thanks in advance.

Carlos

www.cmjets.com

#1311

#1313

#1314

My Feedback: (6)

Although the added thrust if any is questionable, some say one benefit would make the effort of installing the bypass worthwhile and that is the added safety margin it gives in case of a hot start or fire during startup or while in close proximity of the model to the operator … I’d say a distance that can be run to in three to five seconds with an extinguisher..

that’s the time a fully ducted bypass with heatshield painted surface would give you before catching on fire …

that’s the time a fully ducted bypass with heatshield painted surface would give you before catching on fire …

#1315

My Feedback: (52)

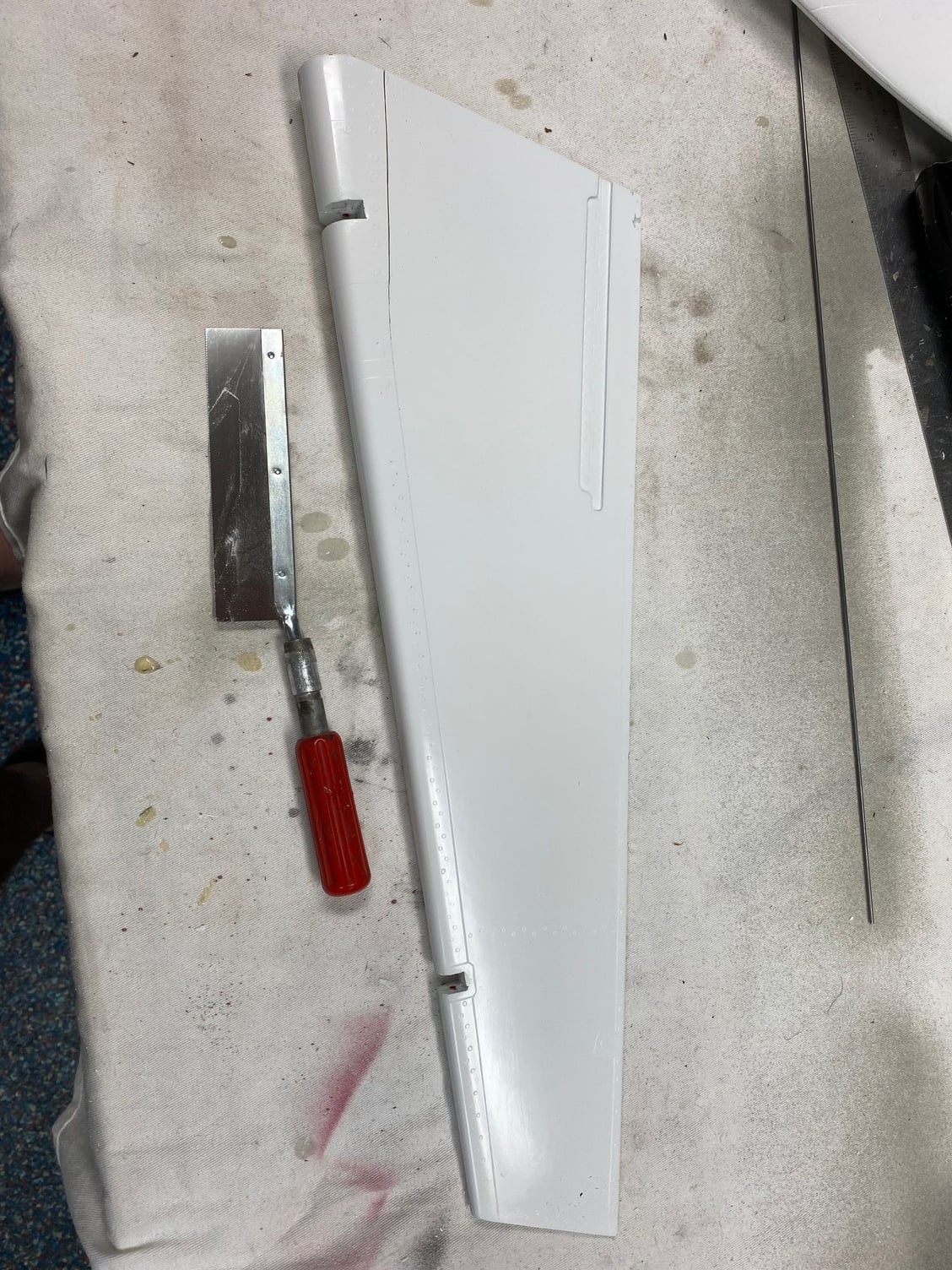

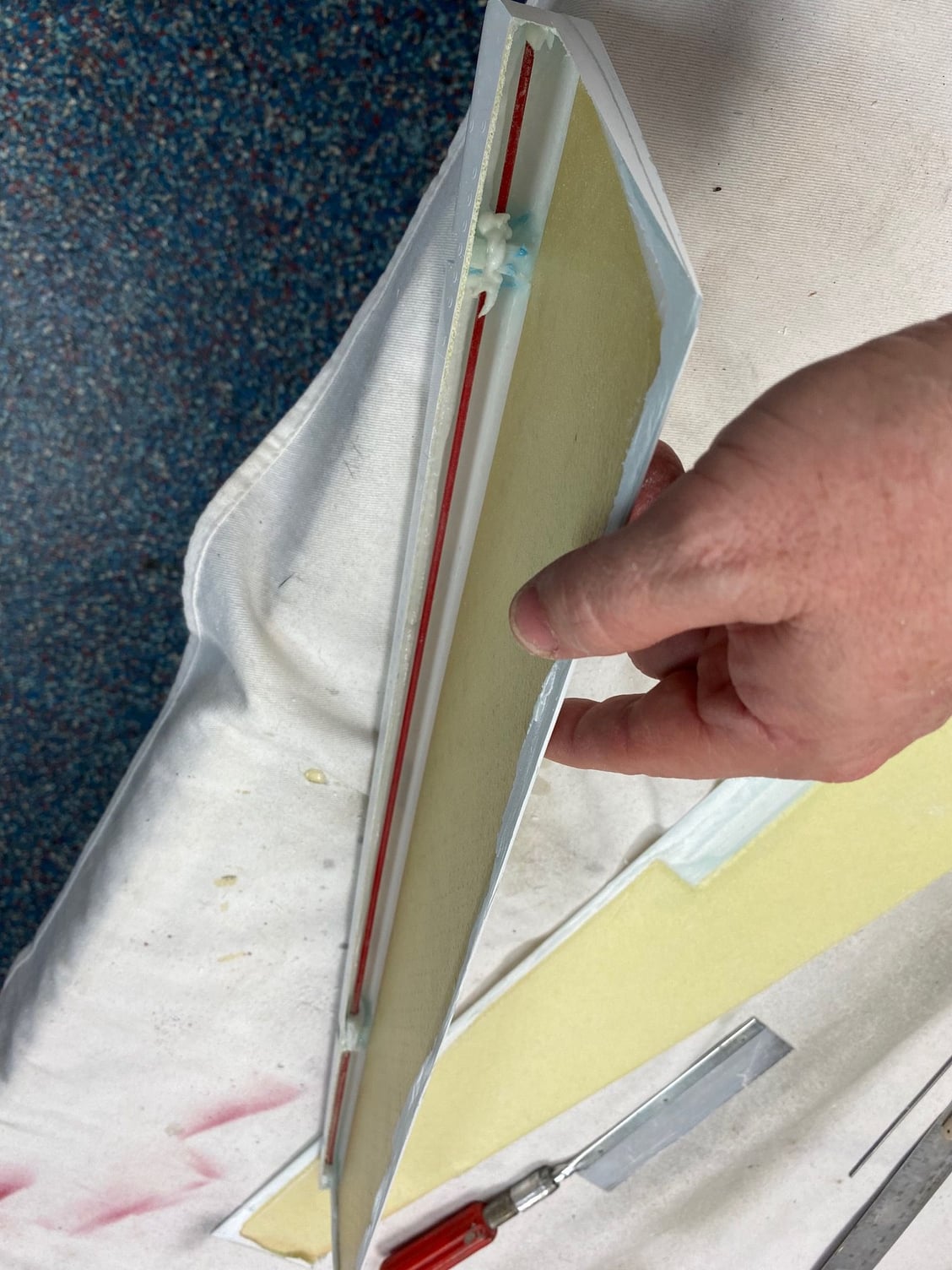

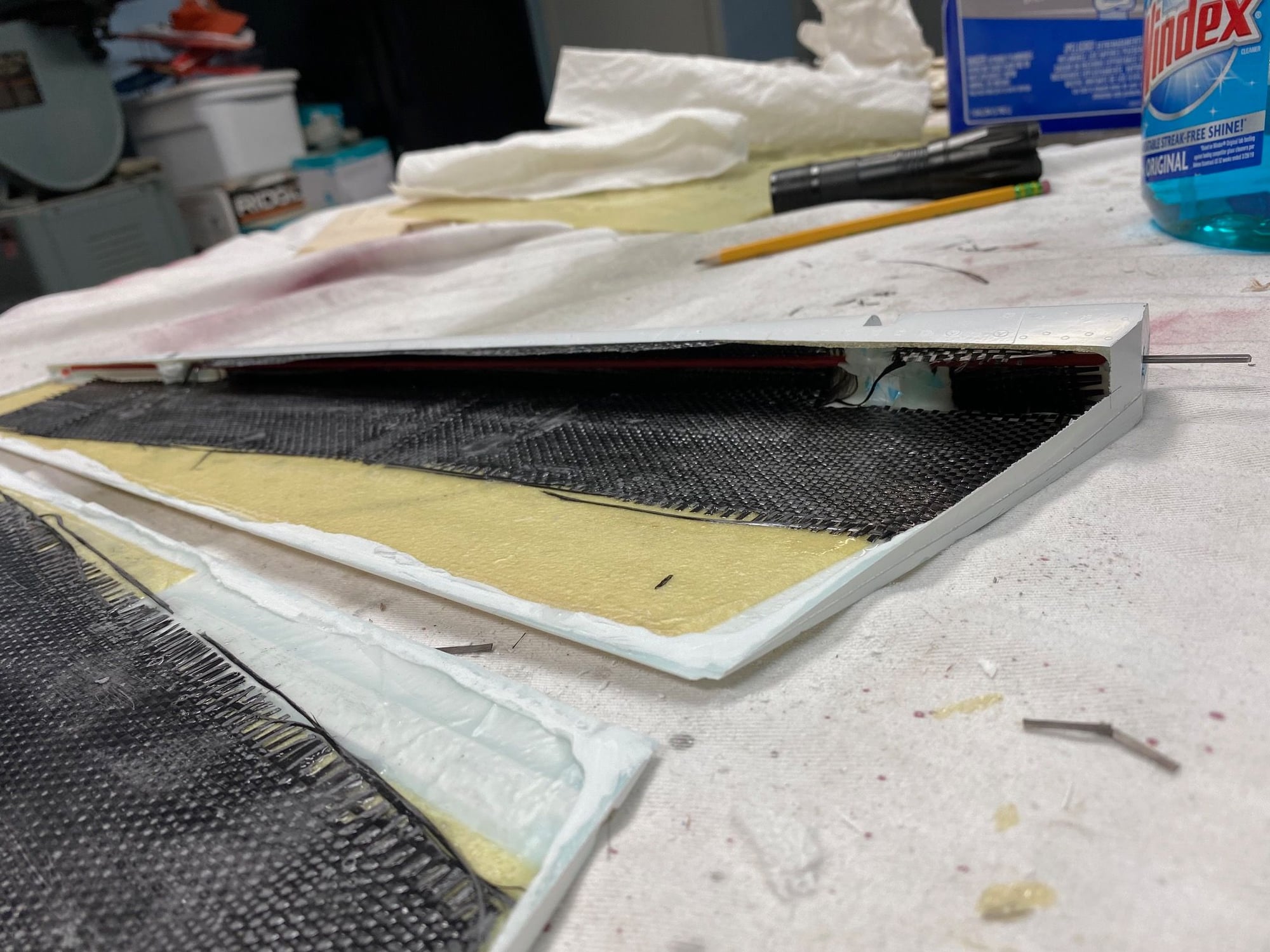

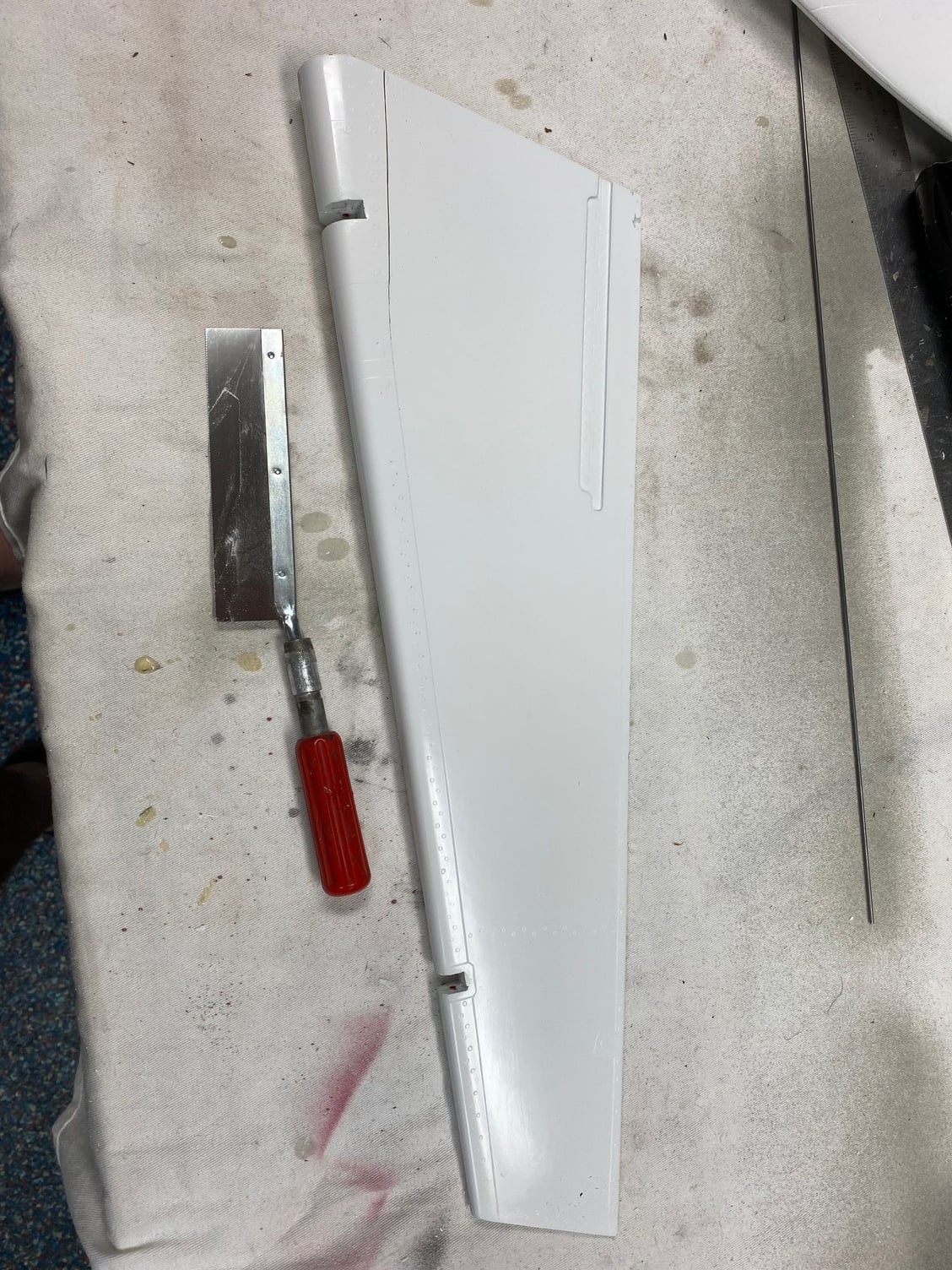

I just received my new Hawk 100 a few weeks ago and have begun building. I have to say, while the surface details of the molds on this Hawk are probably the best I've ever seen, I am pretty disappointed with the internal structure. For instance, the plywood provided to construct the engine mount and other fuselage assemblies is, in my opinion, too thin, too soft and sub-standard for a model of this size and anticipated aerodynamic stresses that will be applied. I need to replace and refabricate virtually all of it. The fuselage formers that came pre-installed seem a bit better in quality, but in some cases have been glued only along the seem of one side. Also, very sparse use of carbon fiber in the areas I would expect. For instance, there is no carbon under the long wing stringers of the trailing edges. The fiberglass in this area is paper-thin and is very concerning. Same is true for the vertical stabilizer. Very thin fiberglass skin and zero carbon under the entire length of the center spar. The leading edge of the rudder is so thin and weak as to be utterly unusable. I haven't yet decided how to remedy this, but I see significant "surgery" ahead in order to make it usable. Shameful it left the factory this way. I bought a new Futura 2.5 about two years ago and was very happy with the materials and construction. I assumed that Tomahawk would have provided the same level of quality in their much larger and far more expensive Hawk 100. Unless you are prepared to do a whole lot of remedial work on this kit, even before the first step of construction can take place, I would not recommend this kit to anyone.

#1316

My Feedback: (47)

I just received my new Hawk 100 a few weeks ago and have begun building. I have to say, while the surface details of the molds on this Hawk are probably the best I've ever seen, I am pretty disappointed with the internal structure. For instance, the plywood provided to construct the engine mount and other fuselage assemblies is, in my opinion, too thin, too soft and sub-standard for a model of this size and anticipated aerodynamic stresses that will be applied. I need to replace and refabricate virtually all of it. The fuselage formers that came pre-installed seem a bit better in quality, but in some cases have been glued only along the seem of one side. Also, very sparse use of carbon fiber in the areas I would expect. For instance, there is no carbon under the long wing stringers of the trailing edges. The fiberglass in this area is paper-thin and is very concerning. Same is true for the vertical stabilizer. Very thin fiberglass skin and zero carbon under the entire length of the center spar. The leading edge of the rudder is so thin and weak as to be utterly unusable. I haven't yet decided how to remedy this, but I see significant "surgery" ahead in order to make it usable. Shameful it left the factory this way. I bought a new Futura 2.5 about two years ago and was very happy with the materials and construction. I assumed that Tomahawk would have provided the same level of quality in their much larger and far more expensive Hawk 100. Unless you are prepared to do a whole lot of remedial work on this kit, even before the first step of construction can take place, I would not recommend this kit to anyone.

Jason

#1317

Hi Mark, I had bought a Futura from Tomahawk Germany that was one of the best quality that I have seen. But, I have heard that since then, the manufacturing has changed and is being done other places so that could explain the differences.

The following users liked this post:

MarkShapiro (10-14-2021)

#1318

So duct or no duct. The Hawk is less affected by no duct than some designs-because the inlets are small. Given the choice I would be with Ali and have the duct more for the drag reduction than the obvious fire protection, I test flew an early one of these a few years back with 220N turbine and you needed to ‘muscle’ it around the sky keeping power on longer to fly constant speed. Once you are used to this the only down side is shorter flights from using power longer.

Tomahawk move production of many of their kits to China, we have a couple of the new Futura (1.8 & 2.5) in my local club and they are much heavier than the old German produced kits, but the main issue is the paint comes off if you chip the surface. All the edges around the hatch area come off with your finger nail as the paint is not keyed (& very thick)

Tomahawk move production of many of their kits to China, we have a couple of the new Futura (1.8 & 2.5) in my local club and they are much heavier than the old German produced kits, but the main issue is the paint comes off if you chip the surface. All the edges around the hatch area come off with your finger nail as the paint is not keyed (& very thick)

#1320

My Feedback: (52)

Hello Dave. Thanks for your feedback. I love my Futura and agree with everything you've said about it. The paint is a bit odd and its characteristics are such that when I've repairs a chip, I've wondered if the paint is actually paint or some type of other covering because of its characteristics. It is definitely paint however and notwithstanding its shortcomings, it looks really good. I've actually painted over the factor paint in order to add detail or make small repairs with no issues. So that is a good thing.

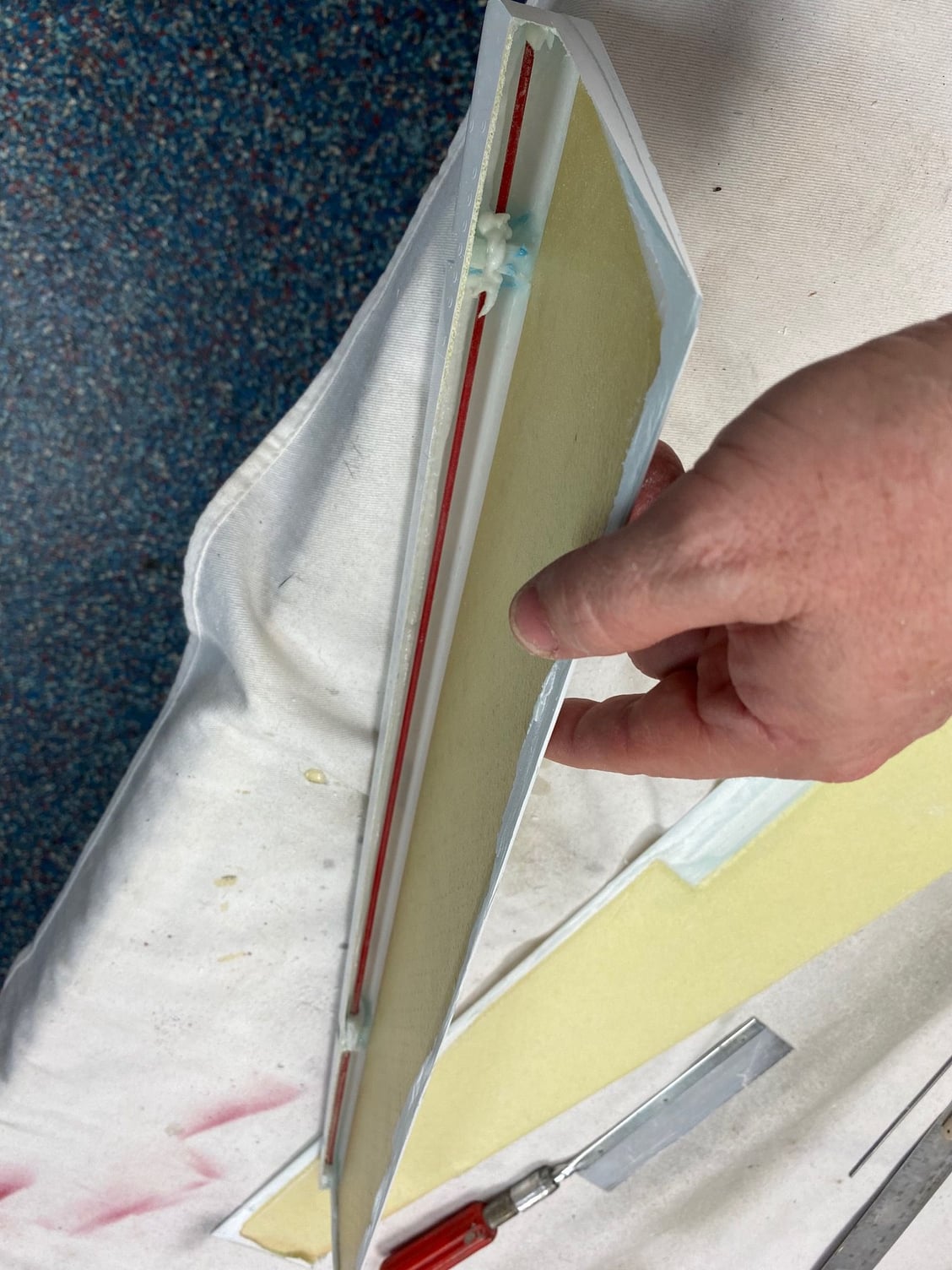

On the Hawk, this one came from Germany. I suspect that weight restrictions in Europe are a driving factor is using such light materials, but it is frustrating to have to perform so much remedial work. Maybe I am over-reacting, but I am not going to chance disaster with such a large investment. I've added carbon to both fuselage halves and did the same with the vertical stab. I also fabricated an additional full-length stringer for the stab, as the foam stock one allowed the the stab to bend. Definitely adds weight to the tail, but worth the trade off and this jet can definitely use some beefing up.

On the Hawk, this one came from Germany. I suspect that weight restrictions in Europe are a driving factor is using such light materials, but it is frustrating to have to perform so much remedial work. Maybe I am over-reacting, but I am not going to chance disaster with such a large investment. I've added carbon to both fuselage halves and did the same with the vertical stab. I also fabricated an additional full-length stringer for the stab, as the foam stock one allowed the the stab to bend. Definitely adds weight to the tail, but worth the trade off and this jet can definitely use some beefing up.

Last edited by MarkShapiro; 10-09-2021 at 03:05 AM.

#1321

Thread Starter

[...]

On the Hawk, this one came from Germany. I suspect that weight restrictions in Europe are a driving factor is using such light materials, but it is frustrating to have to perform so much remedial work. Maybe I am over-reacting, but I am not going to chance disaster with such a large investment. I've added carbon to both fuselage halves and did the same with the vertical stab. I also fabricated an additional full-length stringer for the stab, as the foam stock one allowed the the stab to bend. Definitely adds weight to the tail, but worth the trade off and this jet can definitely use some beefing up.

On the Hawk, this one came from Germany. I suspect that weight restrictions in Europe are a driving factor is using such light materials, but it is frustrating to have to perform so much remedial work. Maybe I am over-reacting, but I am not going to chance disaster with such a large investment. I've added carbon to both fuselage halves and did the same with the vertical stab. I also fabricated an additional full-length stringer for the stab, as the foam stock one allowed the the stab to bend. Definitely adds weight to the tail, but worth the trade off and this jet can definitely use some beefing up.

As the topic starter, I've bought the first production model.

I've stated from the beginning that an AMT Olympus (235N) would be fitted and that it should be strong enough.

However, several parts such as the intake outer parts were ridiculously weak and felt like paper.

Took me a lot of time to strengthen these parts.

Then we had the gear door problems despite correct linkage which was solved by partly blocking the intakes (about 40% blocked, but top intakes on the aft fuselage were opened for air).

After a lot of trouble with the pneumatic landing gear decided to have it converted to electric.

So it wasn't until the 9th flight that the gear went up and the doors closed correctly.

Unfortunately, the fuselage was too weak and it just disintegrated the 9th flight in the first horizontal full throttle pass (no dive).

Recently, in the German forum there were complaints regarding the differences in build quality of the same model (Futura 2.5), perhaps due to outsourcing and insufficient quality control.

Shows that careful inspection and remedial work should not be neglected.

The following users liked this post:

MarkShapiro (10-14-2021)

#1322

My Feedback: (52)

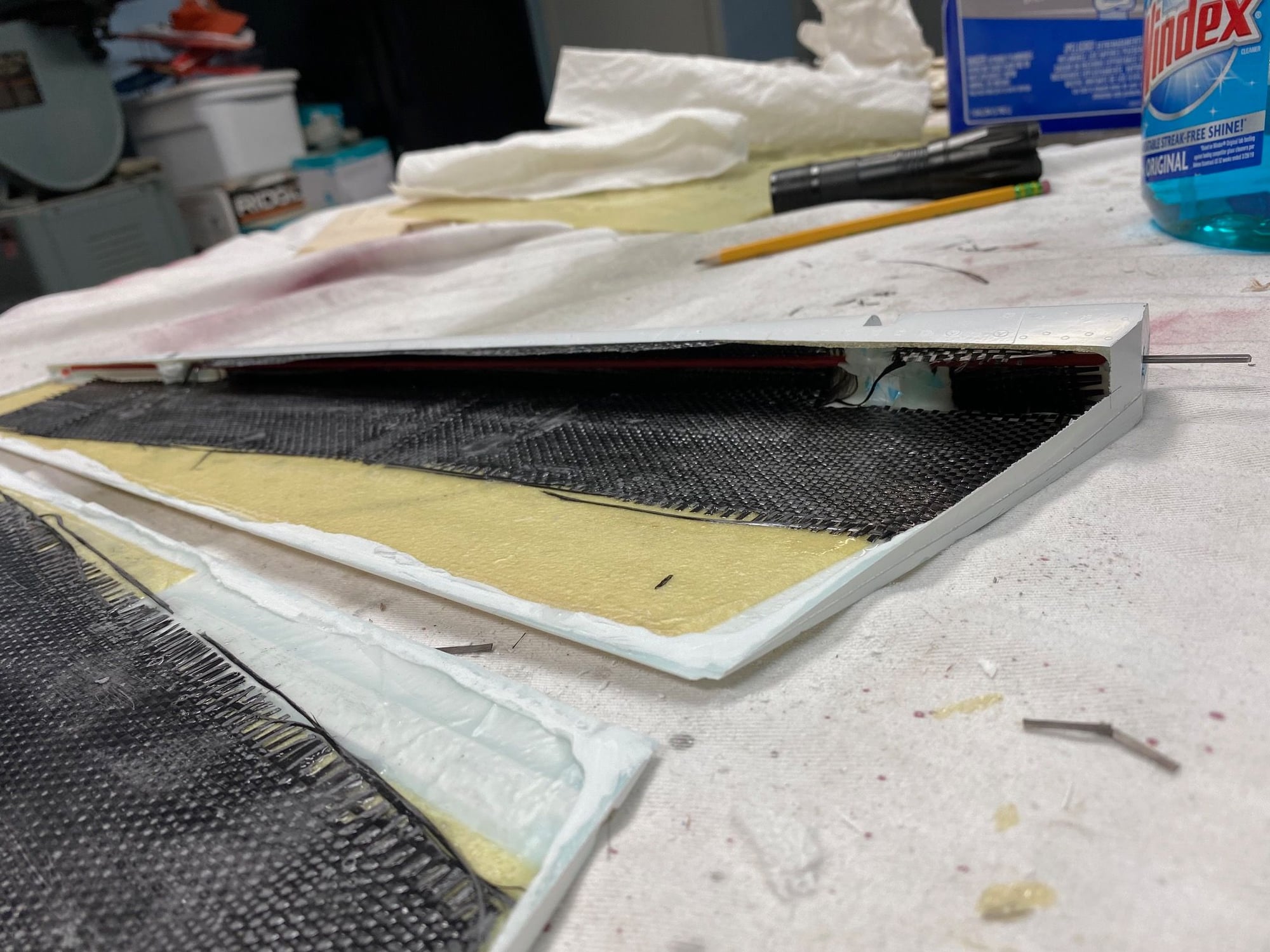

I tackled the rudder next. Again, fiberglass so thin, particularly at the leading edge, that it was absolutely unusable, and unsafe, to leave it alone. Fiberglass was onion skin thin! I sliced the rudder along its perimeter with a razor saw. Hollow inside. Next I laid in some carbon fiber into the leading edge space and out onto the skin. I did the same on the other half of the skin. I then built some ribs out of balsa and sealed back together with some hysol. 1000% improved. I'm afraid of what I may find in the ailerons and flaps. Good grief.

The following users liked this post:

Halcyon66 (12-27-2021)

#1323

My Feedback: (4)

You are doing a completely useless job, ruining and giving weight to a kit that does not need any reinforcementOn what basis did he decide to reinforce?what experience do you have for deciding such a thingI am building the second Tomahawk kit and there was never any need for reinforcement

The following users liked this post:

Tuggs (12-27-2021)