MT Wheel Balancing

#1

Thread Starter

Join Date: Jan 2006

Location: Pleasantville,

NS, CANADA

Posts: 2,358

Likes: 0

Received 4 Likes

on

4 Posts

The wheels on my Savage wobble a lot. It isn't so noticeable while driving it, but if I pick it up by the roll-bar and rev the engine (which I do to make sure it is shifting gears when I make tranny adjustments) the wobble is very bad. So I decided to make a wheel balancer.

I made it out of scraps of aluminum and other old junk I had lying around and limited myself to a hacksaw, drill-press, files and a few taps. Lathe work will undoubtedly come later as I am going to try to make different mounting shafts for my buggy and on-road car wheels. All the parts are made to be adjustable to make sure the shaft in supported evenly. For example, the angle brackets have an enlarged hole for the allen-crew with the built in washer, so they can pivot on the outboard screw to line them up.

The little screw assemblies on top are double bearing mounted old aircraft parts. The split mounting shaft seems to rotate true, but a solid shaft would me better. Trimming down a fairly long piece of 1/4" rod to 5mm isn't exactly fun. I had the shaft you see in my junk box. A piece already necked down and threaded at each end, so I just cut it in two. I use the piece of plastic tubing to keep some force on the wheel.

It's crudely made, but seems to work well. Here's some pics:

I havn't tried to find golf lead weights yet, so I decided to glue lead to the inside of the rims. On-line help suggested using hot-glue to stick to nylon rims and it does work very well.

1/ I cut some bits of lead into 1 larger piece, two smaller pieces, and a couple more even smaller pieces. I did this for coarse and fine tuning of the weight.

2/ I taped various combinations of lead to the inside of the wheel using electrical tape until I had a pretty good balance.

3/ I then opened a can of smoked kippers and ate them as I needed a can with about the same curvature of the inside of the wheel rim. I cut the can and made cut two slits in part of it so I could fold a flange back and put it in my vice.

4/ I put in the lead, plus a very small additional amount (to allow for final balancing) and heated the can gently with a propane torch to melt the lead. My garage smelled like fish. I guess I didn't wash the can out as well as I thought. The dog came sniffing around looking for food, but the complaint about the smell came from the female member of the house.

5/ I then trimmed up the lead a bit with a file and hot-glued it in place. I did use Scotch-Brite to clean the inside of the rim, and then a final wipe with alcohol.

6/ I put the wheel back on the balancer and checked it. A little heavy due to the extra lead, so I used a rotary file with my Dremel and took a little off the top of the lead until the wheel was balanced.

Note: the worst wheel required 9 grams of lead. I weighed it during the pre-test. Quite a bit more than I would have thought.

Finally I tried out my Savage with the newly balanced wheels. Somewhat dissapointing. I'd say the wobble is only about 70% gone at most. The good news is that it doesn't wobble until the tires are rotating at a much higher speed than before. Plus, the wobble is hardly noticeable during a high speed run. It's acceptable, but not great, .... a good improvement, but not excellent.

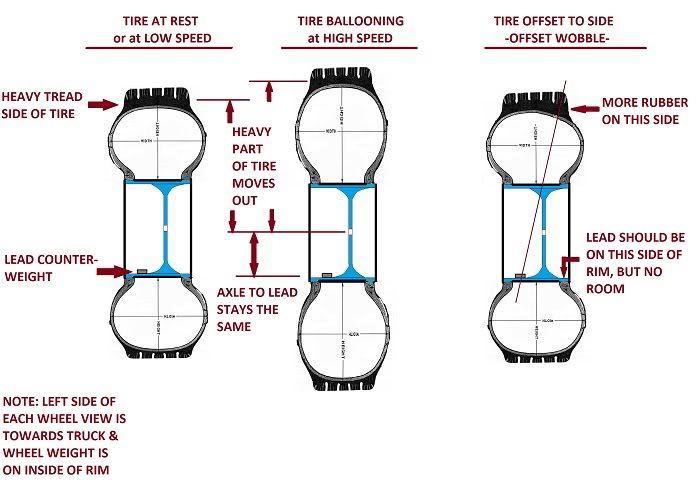

I suspect the wheel is going out of balance again as the tire balloons out (bagelizing!!!...LOL), although there might be another issue going on. I did a little sketch below. The wheel on the left is shown as it would be on the balancer, or at lower speeds. You can see the thick top part of the tire (assuming that's the main issue, and not the rim or foam) and the lead weight glued to the inside of the opposite side of the rim.

In the middle pic, the wheel is shown with the tire ballooned out. You can see that the tire center of mass is now further away from the axle than before, so the lead counter-weight won't cancel it out and the wheel is out of balance again.

In the pic on the right, you can see that no attention has been paid to where the tire may be thicker in a direction parallel to the wheel axle. If the tire is thicker on the top right and the lead weight is added to the left side, the wheel won't be in balance even though it shows OK on the balancer.

Obviously, there's more to this whole "balancing act" then I first thought. Not sure what to do next, but probably nothing unless I can come up with another way to adjust the balance. Next set of tires will be taped to help reduce the ballooning effect.

I re-checked the balancing today and found 1 wheel very out of balance again. Although I checked as best I could for water (a wet internal foam), I guess there must be some in there and it moves around. I am thinking of putting a few holes in the outside center of the tire so water will be flung out when the wheel is rotating at high speeds, but am afraid of weakenng the tire. Quite a nuiscance to deal with at the moment......

I made it out of scraps of aluminum and other old junk I had lying around and limited myself to a hacksaw, drill-press, files and a few taps. Lathe work will undoubtedly come later as I am going to try to make different mounting shafts for my buggy and on-road car wheels. All the parts are made to be adjustable to make sure the shaft in supported evenly. For example, the angle brackets have an enlarged hole for the allen-crew with the built in washer, so they can pivot on the outboard screw to line them up.

The little screw assemblies on top are double bearing mounted old aircraft parts. The split mounting shaft seems to rotate true, but a solid shaft would me better. Trimming down a fairly long piece of 1/4" rod to 5mm isn't exactly fun. I had the shaft you see in my junk box. A piece already necked down and threaded at each end, so I just cut it in two. I use the piece of plastic tubing to keep some force on the wheel.

It's crudely made, but seems to work well. Here's some pics:

I havn't tried to find golf lead weights yet, so I decided to glue lead to the inside of the rims. On-line help suggested using hot-glue to stick to nylon rims and it does work very well.

1/ I cut some bits of lead into 1 larger piece, two smaller pieces, and a couple more even smaller pieces. I did this for coarse and fine tuning of the weight.

2/ I taped various combinations of lead to the inside of the wheel using electrical tape until I had a pretty good balance.

3/ I then opened a can of smoked kippers and ate them as I needed a can with about the same curvature of the inside of the wheel rim. I cut the can and made cut two slits in part of it so I could fold a flange back and put it in my vice.

4/ I put in the lead, plus a very small additional amount (to allow for final balancing) and heated the can gently with a propane torch to melt the lead. My garage smelled like fish. I guess I didn't wash the can out as well as I thought. The dog came sniffing around looking for food, but the complaint about the smell came from the female member of the house.

5/ I then trimmed up the lead a bit with a file and hot-glued it in place. I did use Scotch-Brite to clean the inside of the rim, and then a final wipe with alcohol.

6/ I put the wheel back on the balancer and checked it. A little heavy due to the extra lead, so I used a rotary file with my Dremel and took a little off the top of the lead until the wheel was balanced.

Note: the worst wheel required 9 grams of lead. I weighed it during the pre-test. Quite a bit more than I would have thought.

Finally I tried out my Savage with the newly balanced wheels. Somewhat dissapointing. I'd say the wobble is only about 70% gone at most. The good news is that it doesn't wobble until the tires are rotating at a much higher speed than before. Plus, the wobble is hardly noticeable during a high speed run. It's acceptable, but not great, .... a good improvement, but not excellent.

I suspect the wheel is going out of balance again as the tire balloons out (bagelizing!!!...LOL), although there might be another issue going on. I did a little sketch below. The wheel on the left is shown as it would be on the balancer, or at lower speeds. You can see the thick top part of the tire (assuming that's the main issue, and not the rim or foam) and the lead weight glued to the inside of the opposite side of the rim.

In the middle pic, the wheel is shown with the tire ballooned out. You can see that the tire center of mass is now further away from the axle than before, so the lead counter-weight won't cancel it out and the wheel is out of balance again.

In the pic on the right, you can see that no attention has been paid to where the tire may be thicker in a direction parallel to the wheel axle. If the tire is thicker on the top right and the lead weight is added to the left side, the wheel won't be in balance even though it shows OK on the balancer.

Obviously, there's more to this whole "balancing act" then I first thought. Not sure what to do next, but probably nothing unless I can come up with another way to adjust the balance. Next set of tires will be taped to help reduce the ballooning effect.

I re-checked the balancing today and found 1 wheel very out of balance again. Although I checked as best I could for water (a wet internal foam), I guess there must be some in there and it moves around. I am thinking of putting a few holes in the outside center of the tire so water will be flung out when the wheel is rotating at high speeds, but am afraid of weakenng the tire. Quite a nuiscance to deal with at the moment......

#3

Thread Starter

Join Date: Jan 2006

Location: Pleasantville,

NS, CANADA

Posts: 2,358

Likes: 0

Received 4 Likes

on

4 Posts

ORIGINAL: redfisher1974

Neat. must have alot of time on your hands

Neat. must have alot of time on your hands

#4

Thread Starter

Join Date: Jan 2006

Location: Pleasantville,

NS, CANADA

Posts: 2,358

Likes: 0

Received 4 Likes

on

4 Posts

Back again with the latest efforts and news.

The day after my last run, I decided to re-check the wheel balance. Three were the same as before, but # 4 was way out. Although I had checked some tires (not all) for water and didn’t find any, plus couldn’t remember driving through water, it occurred to me I had driven a fair bit in snow and waited for it to melt a bit before I cleaned it off. At that time, water may have entered the wheel through the rim vent hole, but I really don’t’ think very much could have gotten in.

None the less, I decided to take that tire apart. Not wanting to boil it (I wanted to see if the foam was wet once it was apart) I tired CA de-bonder. So slow….after 3 days I only had one side unstuck. Soaking it in a bowl of acetone may have been faster, but again, I wanted to see if the foam was wet, plus not ruin the foam with acetone.

Becoming impatient, I went for the boiling method. 5 to 10 minutes?….oh sure……more like an hour, but it did work. Maybe I’ll try the oven method next time, but I can see problems…..stinky kitchen, worse burns than boiling water, melting plastic, brown chrome, etc.

So overall, I will never know if the foam was wet or not, but no water came out the rim vent holes when I squeezed the tire (before I boiled it).

Once everything became dry, I decided to try to balance everything again. First I put only the rim on the balancer and although it was pretty good, it did have a slightly heavy spot, so I marked the spot.

Next I put the foam on the rim and kept adjusting the foam around the rim until the heavy side of the foam lined up with the heavy part of the rim. I put a mark on the foam.

Finally I put the tire on the rim, without the foam (I can see why you need foam in tires now!), lined up the heavy part of the tire with the heavy part of the rim and marked the tire.

Interestingly the foam was the most out of balance part. You can tell by the speed and power of the rocking on the balancer how badly out of balance an item is. The rim was out of balance too, but not much, and the tire wasn’t terribly bad either.

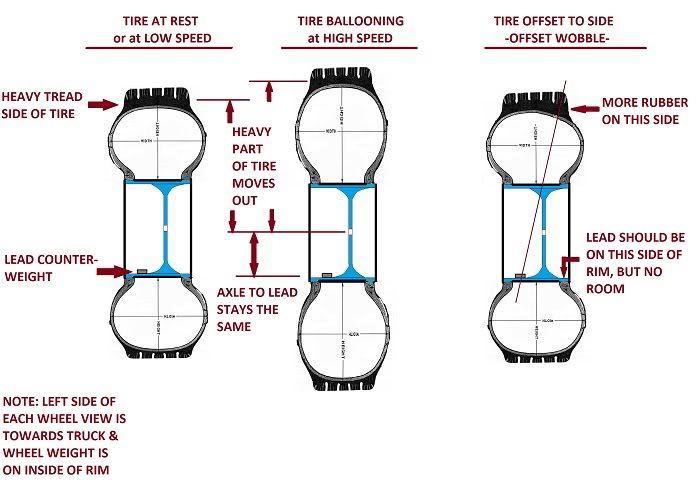

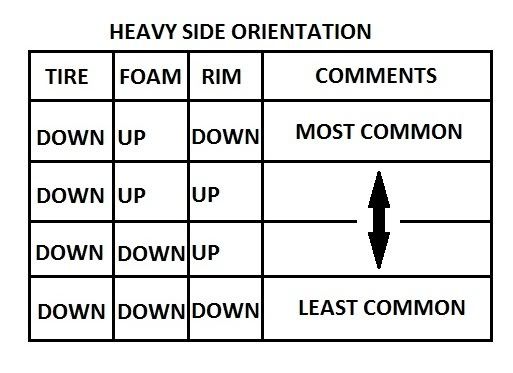

The next thing was to assemble the 3 parts for the best natural balance. It’s most likely the tire and foam will require their heaviest sides to be 180 degrees apart and the rim heavy side can be chosen to help counteract which ever side of the tire/foam is heaviest. I found the top scenario in the table below worked best for me:

Not sure why I added the last scenario….it would be darned odd to have to align all the heavy sides of all the parts together…..so probably best to ignore that one. I guess I was trying to cover all the possible combinations.

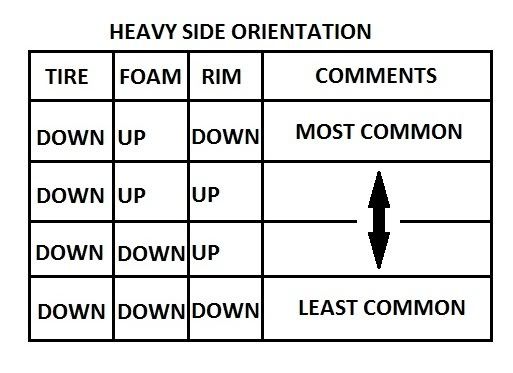

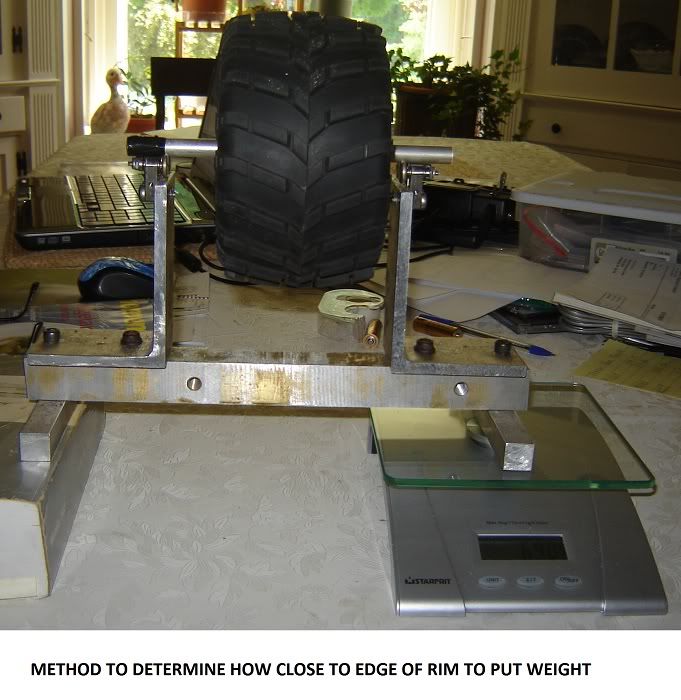

Having everything assembled, I found the amount of lead weight that would balance the tire and stuck it on with electrical tape. Next I wanted to investigate how far the weight should be from the edge of the rim, so I put one end of the balancer on a digital scale. The theory should be that if the weight is lined up with the center mass of the heavy side, the scale will read constant if the wheel is rotated with the heavy part on top, or the weight on top.

In put some tape on the balance shaft to keep it the same distance right and left during the 180 deg rotation, Results weren’t great as there‘s not much range to work with. With the weight on the outer most edge of the rim, the two readings were only one gram apart, but with the weight centered on the rim, the readings were the same. So it makes sense, glue the weight about center of the rim….close to the webbing. Besides, gluing it too far out and it would probably interfere and hit the wheel knuckle.

I still need to re-glue the tire to the rim and do a final balance. I did manage to get my new high speed 3rd gear, 19T CB and new clutch shoes installed during the CA debonder waiting.

I guess, with all said and done, that:

1/ Trying to balance a MT wheel isn’t going to be that effective as the tire balloons, and presumably the foam as well, at least to some extent

2/ The foam seems to be the worst offender when it comes to balancing, possibly due to it getting wet, but perhaps due to inconsistencies in its density as well. Even dry, mine were still out of balance pretty badly.

3/ Naturally balancing the 3 wheel components, the rim, foam and tire helps reduce the imbalance quite a bit and results in much less required wheel weight mass to be added.

4/ Separating tires from rims is a real pain.

The day after my last run, I decided to re-check the wheel balance. Three were the same as before, but # 4 was way out. Although I had checked some tires (not all) for water and didn’t find any, plus couldn’t remember driving through water, it occurred to me I had driven a fair bit in snow and waited for it to melt a bit before I cleaned it off. At that time, water may have entered the wheel through the rim vent hole, but I really don’t’ think very much could have gotten in.

None the less, I decided to take that tire apart. Not wanting to boil it (I wanted to see if the foam was wet once it was apart) I tired CA de-bonder. So slow….after 3 days I only had one side unstuck. Soaking it in a bowl of acetone may have been faster, but again, I wanted to see if the foam was wet, plus not ruin the foam with acetone.

Becoming impatient, I went for the boiling method. 5 to 10 minutes?….oh sure……more like an hour, but it did work. Maybe I’ll try the oven method next time, but I can see problems…..stinky kitchen, worse burns than boiling water, melting plastic, brown chrome, etc.

So overall, I will never know if the foam was wet or not, but no water came out the rim vent holes when I squeezed the tire (before I boiled it).

Once everything became dry, I decided to try to balance everything again. First I put only the rim on the balancer and although it was pretty good, it did have a slightly heavy spot, so I marked the spot.

Next I put the foam on the rim and kept adjusting the foam around the rim until the heavy side of the foam lined up with the heavy part of the rim. I put a mark on the foam.

Finally I put the tire on the rim, without the foam (I can see why you need foam in tires now!), lined up the heavy part of the tire with the heavy part of the rim and marked the tire.

Interestingly the foam was the most out of balance part. You can tell by the speed and power of the rocking on the balancer how badly out of balance an item is. The rim was out of balance too, but not much, and the tire wasn’t terribly bad either.

The next thing was to assemble the 3 parts for the best natural balance. It’s most likely the tire and foam will require their heaviest sides to be 180 degrees apart and the rim heavy side can be chosen to help counteract which ever side of the tire/foam is heaviest. I found the top scenario in the table below worked best for me:

Not sure why I added the last scenario….it would be darned odd to have to align all the heavy sides of all the parts together…..so probably best to ignore that one. I guess I was trying to cover all the possible combinations.

Having everything assembled, I found the amount of lead weight that would balance the tire and stuck it on with electrical tape. Next I wanted to investigate how far the weight should be from the edge of the rim, so I put one end of the balancer on a digital scale. The theory should be that if the weight is lined up with the center mass of the heavy side, the scale will read constant if the wheel is rotated with the heavy part on top, or the weight on top.

In put some tape on the balance shaft to keep it the same distance right and left during the 180 deg rotation, Results weren’t great as there‘s not much range to work with. With the weight on the outer most edge of the rim, the two readings were only one gram apart, but with the weight centered on the rim, the readings were the same. So it makes sense, glue the weight about center of the rim….close to the webbing. Besides, gluing it too far out and it would probably interfere and hit the wheel knuckle.

I still need to re-glue the tire to the rim and do a final balance. I did manage to get my new high speed 3rd gear, 19T CB and new clutch shoes installed during the CA debonder waiting.

I guess, with all said and done, that:

1/ Trying to balance a MT wheel isn’t going to be that effective as the tire balloons, and presumably the foam as well, at least to some extent

2/ The foam seems to be the worst offender when it comes to balancing, possibly due to it getting wet, but perhaps due to inconsistencies in its density as well. Even dry, mine were still out of balance pretty badly.

3/ Naturally balancing the 3 wheel components, the rim, foam and tire helps reduce the imbalance quite a bit and results in much less required wheel weight mass to be added.

4/ Separating tires from rims is a real pain.