wing tube lube

#2

My Feedback: (54)

Don't use any lube. Take a long dowel that will fit into your drill chuck. 1/4 inch dowel works well. Cut a slit at the opposite end. Take about and inch wide and a couple inches long 500 sand paper. Operate the drill ON sliding in and out of the wing tube. Don't go any more course then 500. If anything, 1000 grit is even better. Then, wet sand the wing tube with 500-1000 paper.

#4

My Feedback: (54)

There's always more then one way to skin the cat. Speed usually has viable alternative methods that work for him, my experience works for me.

1). Wax only helps the male side of the tube. Doesn't help the female tube in the wing when gummed up.

2) Hopefully, you know better then to sand through the tube. You are Only supposed to sand up and down the inside of the tube but a couple times.

3) . If it is a paper or cardboard tube, my method is to soak the tube with thin CA. The tube becomes extremely rigid, and can take the sanding. Another reason that you use a fine grade of sand paper. You'll never have to worry about the tube again.

4) My method is usually good for a long time. Maybe even the life of the airplane.

5) With lube, it's a constant nuisance and continues to attract dirt. Depending upon how neat your are with the tube when it's out of the plane on clean up. Holding the tube with fingers cover in glow residue doesn't help.

6) Graphite is another dry alternative, but messy.

Stay Safe! Stay Well! Dan

1). Wax only helps the male side of the tube. Doesn't help the female tube in the wing when gummed up.

2) Hopefully, you know better then to sand through the tube. You are Only supposed to sand up and down the inside of the tube but a couple times.

3) . If it is a paper or cardboard tube, my method is to soak the tube with thin CA. The tube becomes extremely rigid, and can take the sanding. Another reason that you use a fine grade of sand paper. You'll never have to worry about the tube again.

4) My method is usually good for a long time. Maybe even the life of the airplane.

5) With lube, it's a constant nuisance and continues to attract dirt. Depending upon how neat your are with the tube when it's out of the plane on clean up. Holding the tube with fingers cover in glow residue doesn't help.

6) Graphite is another dry alternative, but messy.

Stay Safe! Stay Well! Dan

#6

My Feedback: (54)

They are on Amazon. What's neat about this kind of applicator, is that you can make a U out of the stem and glue upwards.

I had to look it up.

They are more clear. I also use them when spraying small amounts of urethane paint.

#13

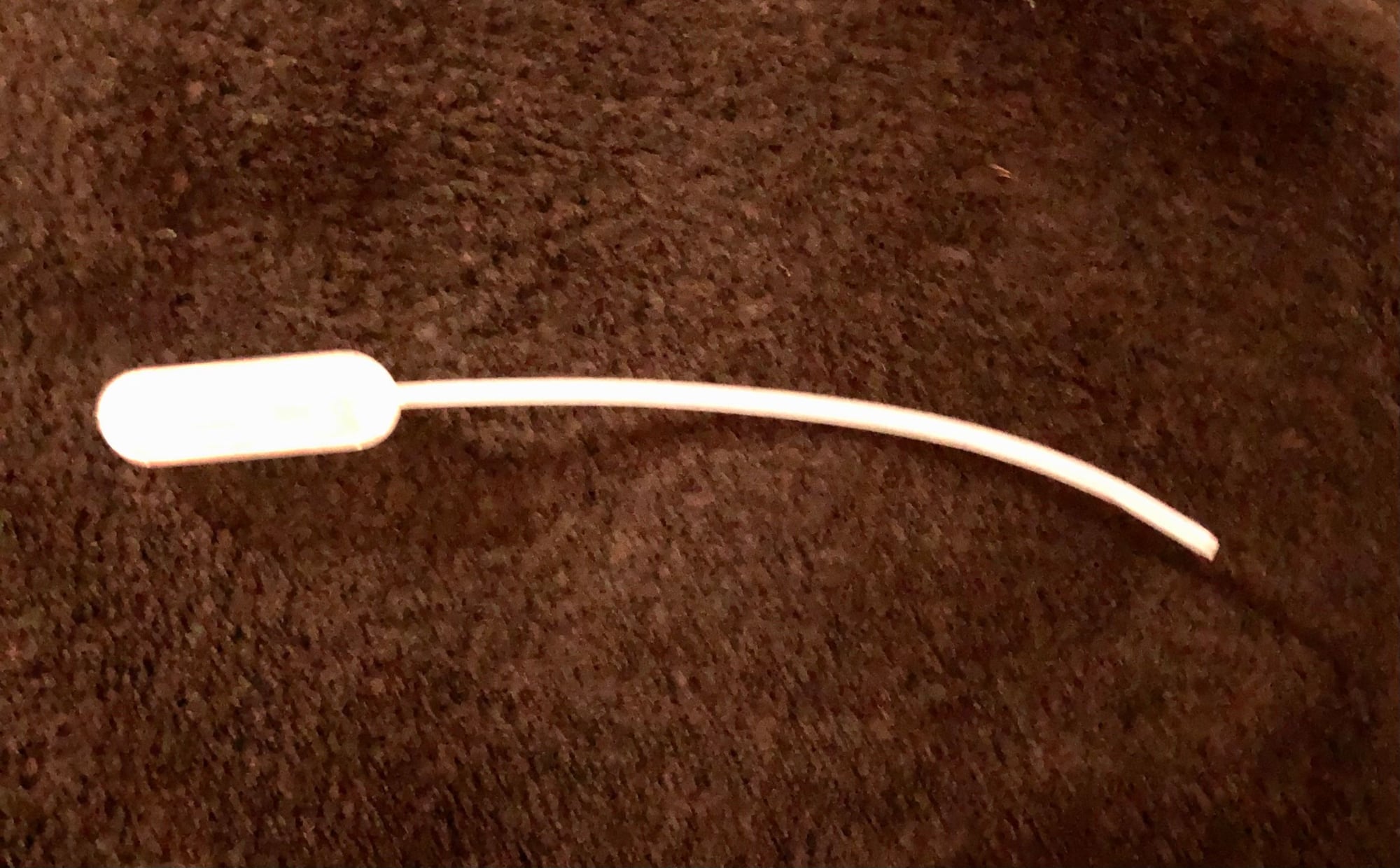

I used a band saw split dowel and 600 wet and dry (this is the finest I had on hand). The dowel was a 3/4" with pieces of sandpaper about 4" wide wrapped around to a thickness just under the phenolic tube ID. Hand rotating It in the deepest part of the tube has made an improvement in the fit that I think I can live with.

I decided against the 1/4" dowel and smaller strips of paper because I worried that I might leave a strip in the tube and have difficulty getting it out. Even the 4" came loose but I was able to retrieve it with a long needle nose.

Thanks again for the suggestions.

I decided against the 1/4" dowel and smaller strips of paper because I worried that I might leave a strip in the tube and have difficulty getting it out. Even the 4" came loose but I was able to retrieve it with a long needle nose.

Thanks again for the suggestions.