YS DZ200cdi

#128

Join Date: Dec 2006

Location: ToowoombaQLD, AUSTRALIA

Posts: 1,026

Likes: 0

Received 17 Likes

on

15 Posts

Just a quick question.

Is there a trick to preventing an aluminium spinner backplate from slipping on the prop driver, or do I just need to add an extra weetbix to my cereal bowl for breakfast before bolting on the prop?? It's not coming loose as such, just slightly changing position every now and then, and slowing mangling the prop driver...

Is there a trick to preventing an aluminium spinner backplate from slipping on the prop driver, or do I just need to add an extra weetbix to my cereal bowl for breakfast before bolting on the prop?? It's not coming loose as such, just slightly changing position every now and then, and slowing mangling the prop driver...

Last edited by bjr_93tz; 07-23-2018 at 02:46 PM.

#129

Just a quick question.

Is there a trick to preventing an aluminium spinner backplate from slipping on the prop driver, or do I just need to add an extra weetbix to my cereal bowl for breakfast before bolting on the prop?? It's not coming loose as such, just slightly changing position every now and then, and slowing mangling the prop driver...

Is there a trick to preventing an aluminium spinner backplate from slipping on the prop driver, or do I just need to add an extra weetbix to my cereal bowl for breakfast before bolting on the prop?? It's not coming loose as such, just slightly changing position every now and then, and slowing mangling the prop driver...

Only one secret Brett. FT

Don't be afraid to reef on the spanner. Use a combo spanner with the ring end on the nut, hold the prop and pull, then pull some more. Even with a huge lean run, mine doesn't move at all.

#130

The trick is to use a plastic/nylon washer between the prop driver and spinner. A friend turned up some for me from delrin. About 1.5mm thick. You could try a round servo output wheel drilled out to suit or cut some from some thin nylon sheet. The prop driver and spinner will bight into the nylon and it will never slip again. You may need a new driver if it has worn excessively. Tate’s should have these.

Cheers

Cheers

#131

The trick is to use a plastic/nylon washer between the prop driver and spinner. A friend turned up some for me from delrin. About 1.5mm thick. You could try a round servo output wheel drilled out to suit or cut some from some thin nylon sheet. The prop driver and spinner will bight into the nylon and it will never slip again. You may need a new driver if it has worn excessively. Tate’s should have these.

Cheers

Cheers

FT will never move. Or if it does, you have a bigger problem to worry about.

What size engine are you using?

Last edited by drac1; 07-23-2018 at 03:32 PM.

#132

Join Date: Dec 2006

Location: ToowoombaQLD, AUSTRALIA

Posts: 1,026

Likes: 0

Received 17 Likes

on

15 Posts

Thanks Gents,

Still the 170cdi for now Scott, but I'm think a new prop driver/spinner back plate combo and FT might be in order. It's slowly chewed up a few drives over the years.

I was half thinking about either pinning the new set or maybe an annealed aluminium (or copper) washer to give the fresh surfaces something to bite into. I do have some delrin stock I could turn up bit I thought that might be a bit slippery?

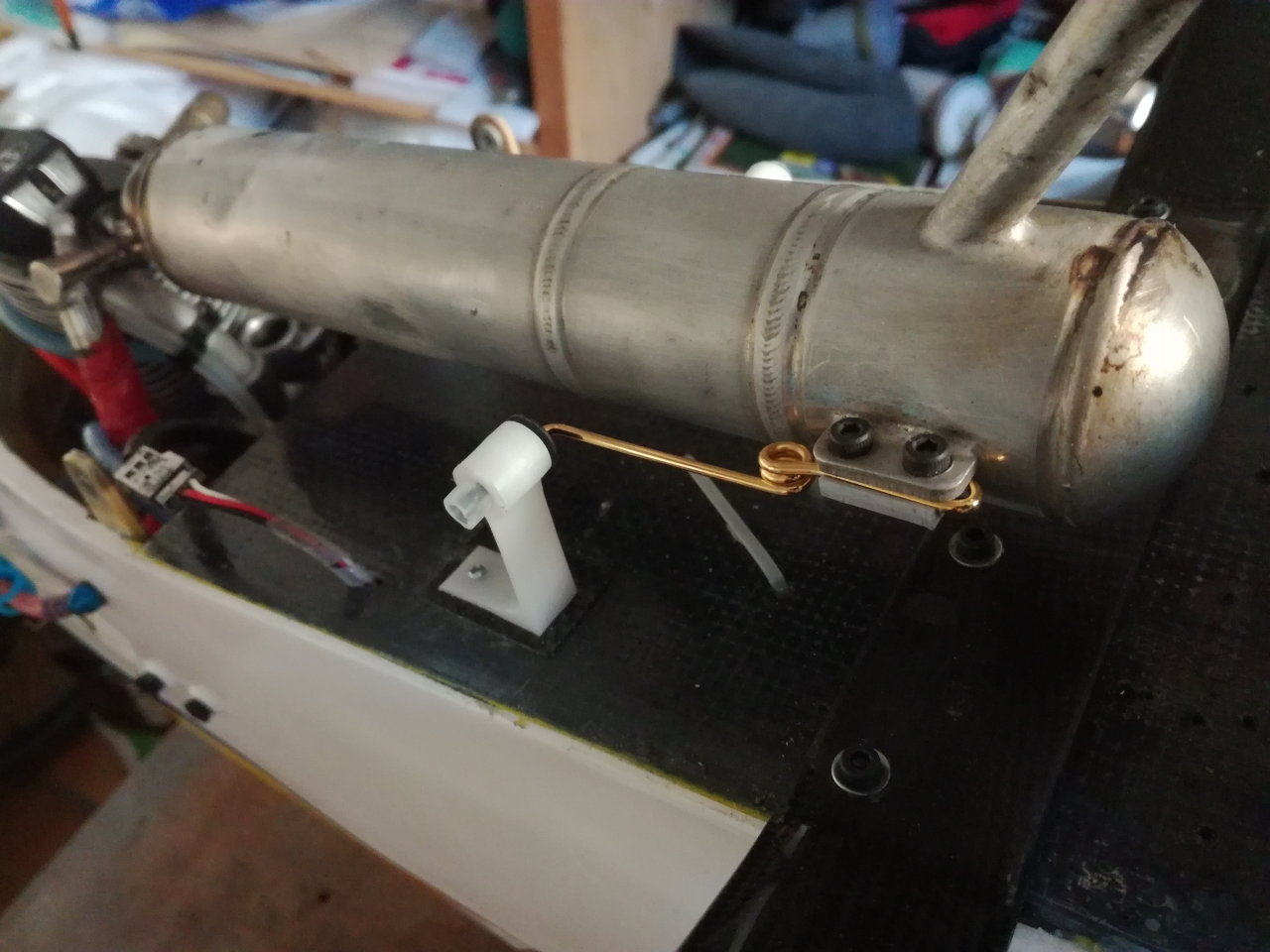

Just picked up a new Hatori 822 header from Dave. Couldn't leave it there for $60 bucks...

Still the 170cdi for now Scott, but I'm think a new prop driver/spinner back plate combo and FT might be in order. It's slowly chewed up a few drives over the years.

I was half thinking about either pinning the new set or maybe an annealed aluminium (or copper) washer to give the fresh surfaces something to bite into. I do have some delrin stock I could turn up bit I thought that might be a bit slippery?

Just picked up a new Hatori 822 header from Dave. Couldn't leave it there for $60 bucks...

Last edited by bjr_93tz; 07-23-2018 at 04:09 PM.

#133

Thanks Gents,

Still the 170cdi for now Scott, but I'm think a new prop driver/spinner back plate combo and FT might be in order. It's slowly chewed up a few drives over the years.

I was half thinking about either pinning the new set or maybe an annealed aluminium (or copper) washer to give the fresh surfaces something to bite into. I do have some delrin stock I could turn up bit I thought that might be a bit slippery?

Just picked up a new Hatori 822 header from Dave. Couldn't leave it there for $60 bucks...

Still the 170cdi for now Scott, but I'm think a new prop driver/spinner back plate combo and FT might be in order. It's slowly chewed up a few drives over the years.

I was half thinking about either pinning the new set or maybe an annealed aluminium (or copper) washer to give the fresh surfaces something to bite into. I do have some delrin stock I could turn up bit I thought that might be a bit slippery?

Just picked up a new Hatori 822 header from Dave. Couldn't leave it there for $60 bucks...

Can't go wrong for 60 bucks.

Might see you at Coolum and Tin Can Bay next March for the Masters and Trans Tasman.

#134

I had problems with slippage and the advice was to use a nylon spacer. Maybe I didn’t have the prop nut tight enough in the first place. The delrin washer has worked well so far on my DZ 185 CDI but I have only bench run the motor. The spinner back plate material will probably also affect slippage. A good back plate made of 7075-T6 would be better than one made from 3003. So a Falcon would be less likely to slip compared to a TY1/Pilot/etc.

#135

I had problems with slippage and the advice was to use a nylon spacer. Maybe I didnít have the prop nut tight enough in the first place. The delrin washer has worked well so far on my DZ 185 CDI but I have only bench run the motor. The spinner back plate material will probably also affect slippage. A good back plate made of 7075-T6 would be better than one made from 3003. So a Falcon would be less likely to slip compared to a TY1/Pilot/etc.

The problem is, the driver diameter is still the same as the 140's using 16" props. We are now swinging 21 1/2", so there is a lot of extra force on the driver.

I would try tighter, I reckon it will stop the slippage.

#138

Join Date: Dec 2006

Location: ToowoombaQLD, AUSTRALIA

Posts: 1,026

Likes: 0

Received 17 Likes

on

15 Posts

yeah mine too.....

yeah mine too.....Seriously though, It'd be nice to know what we could torque it up to. There's a couple of nuts/bolts on my motorbikes that make me cringe when torquing to spec, and others where I think "is that all?" I've never managed to strip any threads on model engines yet so maybe I'm a bit light handed...Off the top of my head it's an M8 or thereabouts thread isn't it?

Edit: looks like a grade 8.8 M8x1 is good for about 25-28Nm, or about 18Kg at 6". Not sure if I'm lifting a 20L tin of methanol when yanking on my spanner..

Last edited by bjr_93tz; 07-23-2018 at 07:35 PM.

#139

yeah mine too.....

yeah mine too.....Seriously though, It'd be nice to know what we could torque it up to. There's a couple of nuts/bolts on my motorbikes that make me cringe when torquing to spec, and others where I think "is that all?" I've never managed to strip any threads on model engines yet so maybe I'm a bit light handed...Off the top of my head it's an M8 or thereabouts thread isn't it?

I'm the opposite, I usually over tighten stuff. I have 2mm, 2.5mm and 3mm Helicoil sets on hand

I use Titanium prop nuts and washer.

Last edited by drac1; 07-23-2018 at 07:37 PM.

#140

Join Date: Dec 2007

Location: HobartTasmania, AUSTRALIA

Posts: 16

Received 0 Likes

on

0 Posts

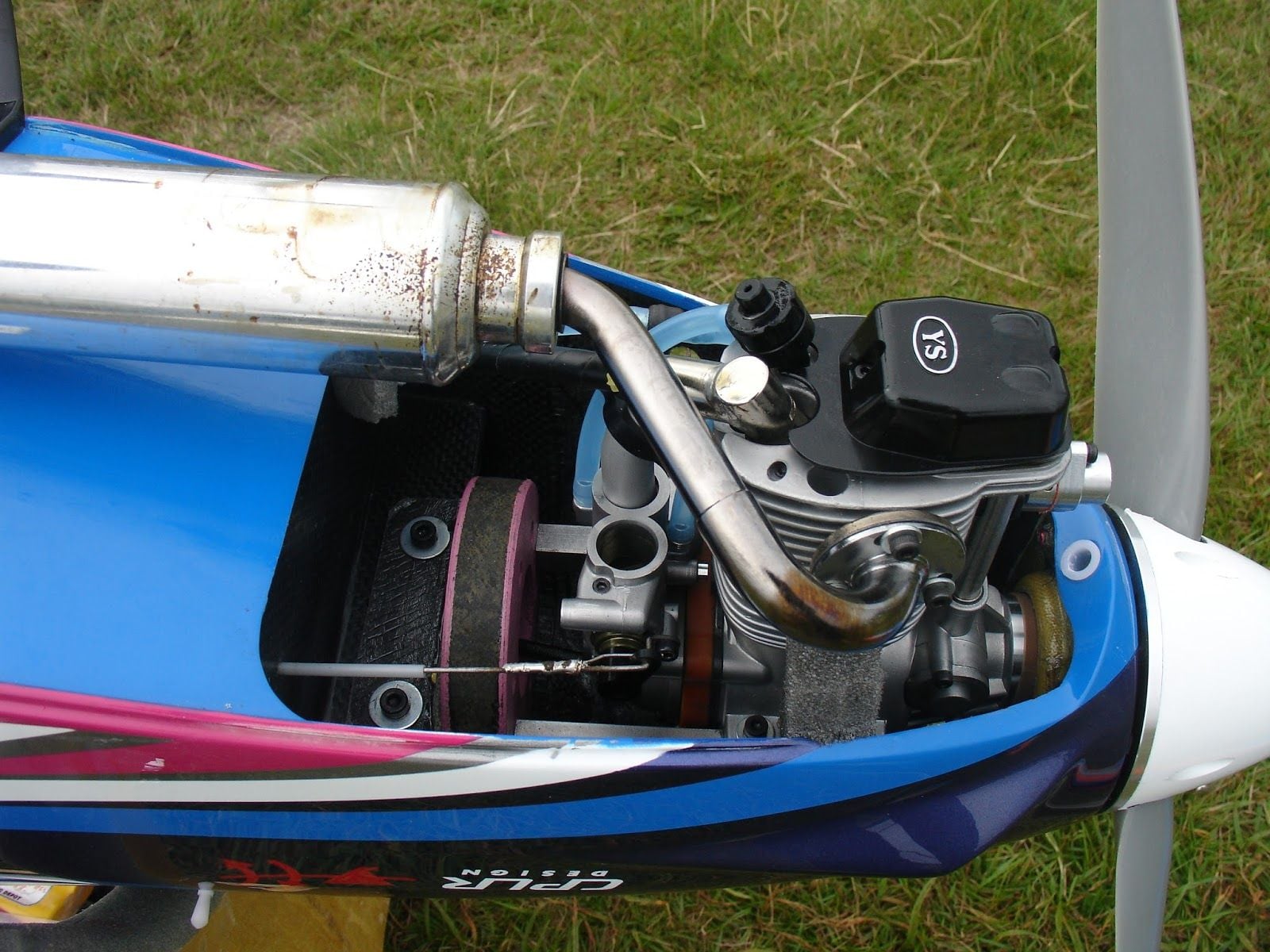

Hi Claude, I'm interested in the way the mount is attached to the airframe. Looks like a "T" bracket bolted to the mount and then bolted to a horizontal plate glued to firewall - correct? This means undo two bolts and motor/mount come out together? If so that's neat! Do you have any more detailed pics of the setup?

Regards, allenpl

My questions relate to message 114.

Regards, allenpl

My questions relate to message 114.

Last edited by allenpl; 08-02-2018 at 03:23 AM. Reason: linking to appropriate message

#144

Join Date: Dec 2007

Location: HobartTasmania, AUSTRALIA

Posts: 16

Received 0 Likes

on

0 Posts

#146

[email protected]

Hiroyuki Mouri. Great fast service. Send him an email with what you want with description and item number as per his site. He will reply with an invoice.

https://translate.google.com.au/tran...ml&prev=search

Hiroyuki Mouri. Great fast service. Send him an email with what you want with description and item number as per his site. He will reply with an invoice.

https://translate.google.com.au/tran...ml&prev=search

#148

Join Date: Feb 2007

Location: RESHON LEZIYYON, ISRAEL

Posts: 109

Likes: 0

Received 0 Likes

on

0 Posts

Hello

Engine 200 cdi

Is it necessary to lubricate the engine before the first operation ?

I read an article at the time, it is worth lubricating the engine before the first operation , for example in the cam gear area,or in the bearings

Thanks

Kobi

Engine 200 cdi

Is it necessary to lubricate the engine before the first operation ?

I read an article at the time, it is worth lubricating the engine before the first operation , for example in the cam gear area,or in the bearings

Thanks

Kobi