OS33gt Cadence

#1

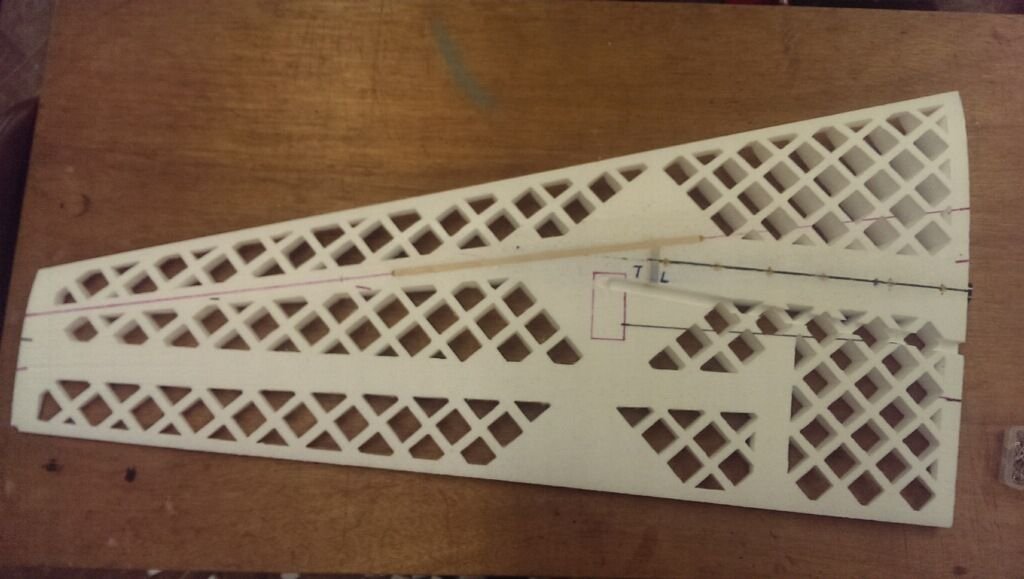

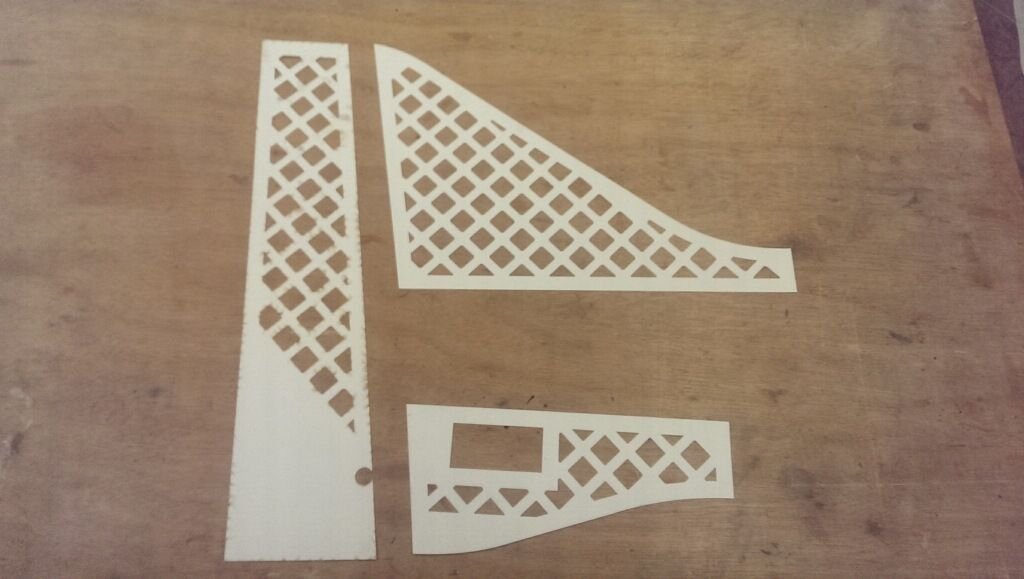

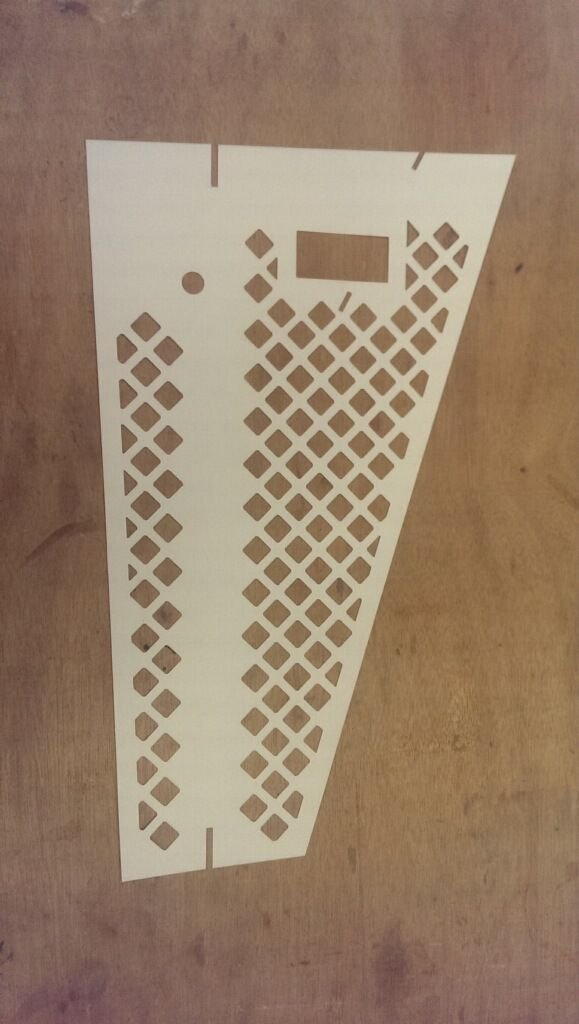

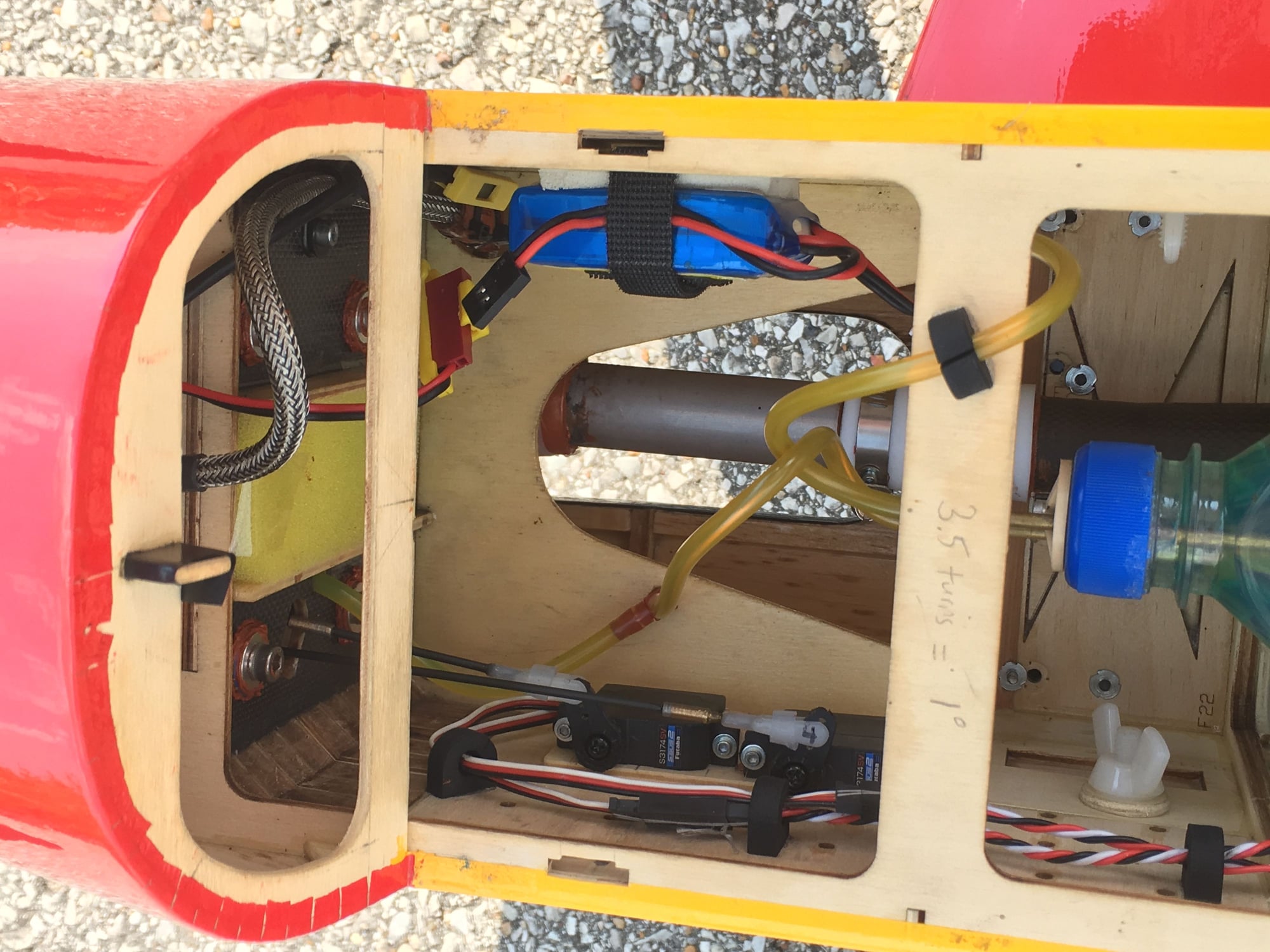

Just thought I would post the rough details of a nicely completed gas powered Cadence by Ryan Gonsoulin. Ryan did a masterful job on the build. He flys pretty well too

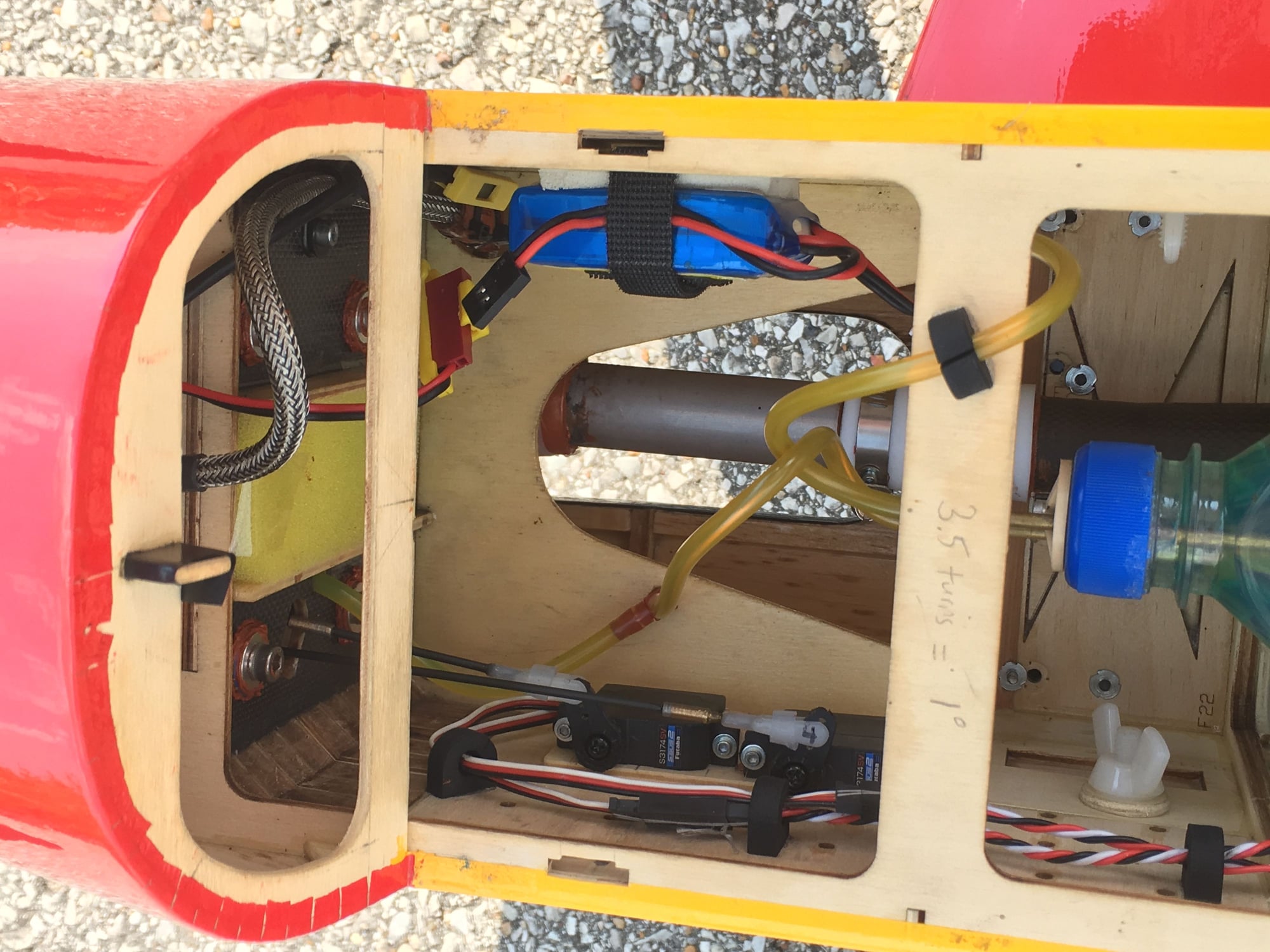

. He had to move the landing gear plate down to allow the pipe assembly to go over the plate and stay inside the belly of the fuse. He cored all the foam and finished with monokote. The finish weight is 4620g. He found a hatori header and made a MTK style coupler from the header to his header extension pipe. So far, this has held up really well. He added an air inlet at the front of the canopy to make sure heat from the pipe was encouraged to go out the rear exit. That has worked very well. Prop is a falcon 20x10 but he plans to do some experimenting with APCs. Performance is excellent and noise is acceptable now that some cushion has been added to the chin cowl and canopy rails. Weight is 10lbs7oz (incl. 2oz of lead on the tail).

. He had to move the landing gear plate down to allow the pipe assembly to go over the plate and stay inside the belly of the fuse. He cored all the foam and finished with monokote. The finish weight is 4620g. He found a hatori header and made a MTK style coupler from the header to his header extension pipe. So far, this has held up really well. He added an air inlet at the front of the canopy to make sure heat from the pipe was encouraged to go out the rear exit. That has worked very well. Prop is a falcon 20x10 but he plans to do some experimenting with APCs. Performance is excellent and noise is acceptable now that some cushion has been added to the chin cowl and canopy rails. Weight is 10lbs7oz (incl. 2oz of lead on the tail).-Mark

#3

Motor is semi soft mounted..bolts from standoffs go thru rubber grommets designed to swell when tightened through the firewall. Plane is using 125mah per masters on rx pack so control surfaces are not seeing terrible vibration really. With 20x10 falcon and break in 1st gallon we saw 7250rpm. Getting on pipe is only needed in uplines and then its still not wide open. This prop is a little noisy so apc tests will be interesting. Ryan is planning to go to the US Nats so we are trying to hide noise as much as possible to make it as appealing as possible to the judges. Ryan is a very talented pilot and quickly learning all the nuances of pattern via help of D6 guys like Don Ramsey and Bryan Hebert. The plane is extremely close in trim and yes, it has the same ke horsepower that my own electric Cadence does. Im really pleased that someone local to me built a gas version as I drew the plans to allow gas, glow, and electric.

BTW, a full cadence kit will be raffled or auctioned at the US Nats.

-Mark

BTW, a full cadence kit will be raffled or auctioned at the US Nats.

-Mark

#5

My Feedback: (121)

Hi Mark,

Thanks for reporting and good luck to Ryan!

Matt started having some mechanical breakdowns in his engine(s) and was a bit discouraged as he had fully committed to gas power (I bought all his remaining glow stuff a few months before he passed away). I recently read, this year, (Flying Giants, maybe) that the OS 33 and maybe other of their gas engine series had some early quality control issues since they were actually being manufactured in China. Those issues have been resolved (this is third hand reporting; so accuracy may be questionable) which may mean previous mechanical problems will no longer be encountered. Otherwise Matt was very happy with the design engineering of the OS.

Pretty likely the APC prop will improve the noise issues. I still fly 2-stroke glow and found that a Falcon CF 19x8 was much noisier than an APC 19x8, but the APC has a lot more blade area. I think the Falcon just unloads more in the air, at least enough to get some noticeable prop noise.

Has Ryan tried the OS gas 'glow-plug' (no ignition required)? I know their 15GT is set up for it and have wondered if it was useable throughout their gas engine line. I am still intrigued by the OS 33 GT for pattern and will continue looking for your reports.

-Will

Thanks for reporting and good luck to Ryan!

Matt started having some mechanical breakdowns in his engine(s) and was a bit discouraged as he had fully committed to gas power (I bought all his remaining glow stuff a few months before he passed away). I recently read, this year, (Flying Giants, maybe) that the OS 33 and maybe other of their gas engine series had some early quality control issues since they were actually being manufactured in China. Those issues have been resolved (this is third hand reporting; so accuracy may be questionable) which may mean previous mechanical problems will no longer be encountered. Otherwise Matt was very happy with the design engineering of the OS.

Pretty likely the APC prop will improve the noise issues. I still fly 2-stroke glow and found that a Falcon CF 19x8 was much noisier than an APC 19x8, but the APC has a lot more blade area. I think the Falcon just unloads more in the air, at least enough to get some noticeable prop noise.

Has Ryan tried the OS gas 'glow-plug' (no ignition required)? I know their 15GT is set up for it and have wondered if it was useable throughout their gas engine line. I am still intrigued by the OS 33 GT for pattern and will continue looking for your reports.

-Will

#6

Update: Apc prop has tested very well for reduced noise. Also Ryan confirmed this OS was a new batch run and I think perhaps even not made in China? I thought there was a rumor of moving production of this motor??

Hopefully the motor will hold up very well for him.

Mark

Hopefully the motor will hold up very well for him.

Mark

#13

My Feedback: (121)

Hi Jeff,

Thanks for the update. Ryan must have been disappointed (and maybe a bit frustrated to have the engine fail at the Nats). I have not run one, but conversations with Matt K before he passed away were positive until they started breaking. We wondered if the engine is just not engineered for the stresses of tuned pipe use in the demanding environment of pattern. Matt was also playing with a 55cc gasser which he liked a lot. Big jump in power, but engine weight was an issue. Lots of choices in electric power, not so much in wet power any more.

-Will

Thanks for the update. Ryan must have been disappointed (and maybe a bit frustrated to have the engine fail at the Nats). I have not run one, but conversations with Matt K before he passed away were positive until they started breaking. We wondered if the engine is just not engineered for the stresses of tuned pipe use in the demanding environment of pattern. Matt was also playing with a 55cc gasser which he liked a lot. Big jump in power, but engine weight was an issue. Lots of choices in electric power, not so much in wet power any more.

-Will

#14

The engine failure was a bummer to say the least. Ryan was flying extremely well and had the plane dialed in. He borrowed my Pletty powered cadence for the finals and flew very well but obviously it was not his plane or setup.

I understand Horizon replaced the motor no questions asked. I'm not sure what his next step will be but I'm hoping he will try again with some ideas he already mentioned to me.

As a side note, and Jeff can comment as well, the setup with the cf apc was superb in both noise, power, and speed. I think he even dialed in a delay throttle cut at idle for downlines which were steady and slow.

-Mark

I understand Horizon replaced the motor no questions asked. I'm not sure what his next step will be but I'm hoping he will try again with some ideas he already mentioned to me.

As a side note, and Jeff can comment as well, the setup with the cf apc was superb in both noise, power, and speed. I think he even dialed in a delay throttle cut at idle for downlines which were steady and slow.

-Mark

#15

My Feedback: (1)

Hi,

I hope they send in the OS engine You used to OS factory to have it investigated of the root cause why Your motor failed.

Have You any ideas Yourself why the engine failed? Except the tuned pipe theory?

Can it be the egine gets overheted?

Could it be that the engine gets overstressed in some manouvres in the P or F schedule that over time breaks the engine?

/Bo

I hope they send in the OS engine You used to OS factory to have it investigated of the root cause why Your motor failed.

Have You any ideas Yourself why the engine failed? Except the tuned pipe theory?

Can it be the egine gets overheted?

Could it be that the engine gets overstressed in some manouvres in the P or F schedule that over time breaks the engine?

/Bo

#16

Bo,

I don't know if OS will investigate the failed engine.

Overheating was not a problem at all. Ryan did an excellent job of ducting air over the engine and through the inside of the fuselage. After a flight the engine was very reasonable temperature and the ES pipe could be held by hand easily.

Ryan flew this plane in the AMA Masters class, not FAI. I did fly it through the F19 pattern as a test, and the plane did it with ease....no bad noises or vibrations from the engine or front end of the fuselage.

I only wonder if the weight of the large APC carbon prop (21x10.5) was some sort of an issue for the motor bearings. I'm only guessing.

-mark

I don't know if OS will investigate the failed engine.

Overheating was not a problem at all. Ryan did an excellent job of ducting air over the engine and through the inside of the fuselage. After a flight the engine was very reasonable temperature and the ES pipe could be held by hand easily.

Ryan flew this plane in the AMA Masters class, not FAI. I did fly it through the F19 pattern as a test, and the plane did it with ease....no bad noises or vibrations from the engine or front end of the fuselage.

I only wonder if the weight of the large APC carbon prop (21x10.5) was some sort of an issue for the motor bearings. I'm only guessing.

-mark

#17

Are these engines failing in a similar manner when used in other types of planes? That might give a clue???

Ken

#18

Matt had a problem with piston circlips. That is strange as it should be something pretty straightforward to design and fabricate. Quality assurance problem I guess.

One thing that comes to mind is large prop and increased forces. Other engines of similar size are not capable of spinning a prop of this size (21x10.5).

I have a GT33 but it has run only very little. With an ES pipe it can run APC or Falcon 20x10 but it does not sound as happy as with e.g. 18x10 or 19x11 narrow blade (Super Silence) prop.

For me electric drive seems to work so well that I doubt I would put much effort to this engine. However it has its benefits.

One thing that comes to mind is large prop and increased forces. Other engines of similar size are not capable of spinning a prop of this size (21x10.5).

I have a GT33 but it has run only very little. With an ES pipe it can run APC or Falcon 20x10 but it does not sound as happy as with e.g. 18x10 or 19x11 narrow blade (Super Silence) prop.

For me electric drive seems to work so well that I doubt I would put much effort to this engine. However it has its benefits.

#20

GT33 is a too small for IMAC, big is beautiful you know. Most IMAC guys fly DA80-100 or similar.

I know some IMAC style planes though.

There are some differences:

- No pipe but standard muffler is used. Generally noise reduction is not considered that important.

- Prop is smaller and with less pitch, quite common is 18x8 or 19x8 or even 19x6

I know some IMAC style planes though.

There are some differences:

- No pipe but standard muffler is used. Generally noise reduction is not considered that important.

- Prop is smaller and with less pitch, quite common is 18x8 or 19x8 or even 19x6

#21

Ryan's engine failure, as I recall, was due to piston damage caused by the piston ring rotating past the anti rotation pin. This allowed the ring end to get caught in the side port of the sleeve/liner and distorting the piston top ring land and thus low compression.

#22

My Feedback: (121)

Thanks Gary for the specific cause of the failure.

I don't think OS will do anything about the failures. The majority of the GT33s are probably running on mufflers with smaller props and sport flying. The failures reported here are not the typical catastrophic failure like crank or rod breakage or bearing failure. I would image that the piston ring getting caught in the port probably did a lot of damage at least to the piston and sleeve. I'm a bit puzzled as to how the ring could have rotated past the anti-rotation pin unless the pin failed, especially since the engine seems to have been operating at reasonable temperatures.

How many flights did Ryan have on the engine prior to the failure (or gallons of fuel)? I am wondering if there might be some preventative maintenance that could be performed (maybe every 100 or 200 flights) that could significantly reduce failures.

The engine seems to be a very good alternative power source for pattern, but replacing the engine every 200 flights is not especially cost effective.

-Will

I don't think OS will do anything about the failures. The majority of the GT33s are probably running on mufflers with smaller props and sport flying. The failures reported here are not the typical catastrophic failure like crank or rod breakage or bearing failure. I would image that the piston ring getting caught in the port probably did a lot of damage at least to the piston and sleeve. I'm a bit puzzled as to how the ring could have rotated past the anti-rotation pin unless the pin failed, especially since the engine seems to have been operating at reasonable temperatures.

How many flights did Ryan have on the engine prior to the failure (or gallons of fuel)? I am wondering if there might be some preventative maintenance that could be performed (maybe every 100 or 200 flights) that could significantly reduce failures.

The engine seems to be a very good alternative power source for pattern, but replacing the engine every 200 flights is not especially cost effective.

-Will

#24

My Feedback: (28)

Ryan's power setup was quiet and powerful. Certainly wasn't lacking. And no mid-range burble you often hear with gas engines. Cooling air exit to inlet ratio appeared to be 2 or maybe even 3 to 1. Also, know that Ryan comes from Louisiana, where it's hotter than blazes had been flying this setup all summer. In fact, as warm as it was, temps for the Nats in Blytheville were reletively cool this year due to hurricane Barry which had just moved through prior to first rounds. Just remembered I had taken some pictures of his setup so will include them here.

#25

My Feedback: (90)

I too have been looking at the OS 33GT for pattern use in a Black Magic 2.2.

Currently, I'm using Redline 32:1 turning a APC 19x11 or a APC 20x10. A few times that I've run the engine ran very well and was comparable to a YS DZ170.

While researching I too was concern about the piston clip failure MattK had. I knew the OS production had moved to China and maybe not as good as quality control as Japan had. I sent an email to OS directly. Here is the response.

OSエンジンインフォメーション

Jan 25, 2019, 12:06 AM

to me

We think we use 50:1 mixture with Redline 2-stroke oil.

So you do not have to increase oil ratio as long as carburetor adjustment is not harsh to the engine and you do not fly full throttle all the time.

Best regards,

Junichi

From: me

Sent: Thursday, January 24, 2019 9:31 PM

To: OSエンジンインフォメーション

Subject: Re: OS GT33 engine

Thank you for you time.

I am looking at this engine for putting into a 2 meter pattern plane. I have read an article on RCUniverse about a person doing this with great success. Not really wanting to push the engine hard. Looking at being able to turn a APC 19x11 prop in matching the YS DZ170 or 175 engine. My concern is longevity. Should I run the oil contact 40:1 instead of 50:1? Or 32:1? Would this help? I use Red line two stroke racing oil.

After reading the forum thread I really think this is one of the best engines out there for this.

Best Regards,

On Tue, Jan 22, 2019 at 5:58 PM OSエンジンインフォメーション <[email protected]> wrote:

About 5 years ago, we took back our production from China and resume making it in Japan.

From: me

Sent: Wednesday, January 23, 2019 8:55 AM

To: OSエンジンインフォメーション

Subject: Re: OS GT33 engine

Sir I greatly appreciate your reply and putting the rumor I heard that they were made in China to rest.

Best regards,

On Tue, Jan 22, 2019 at 5:23 PM OSエンジンインフォメーション <[email protected]> wrote:

Hello Sir,

Yes, it is made in Japan.

Best regards,

Junichi Shimazaki

From: me

Sent: Wednesday, January 23, 2019 4:26 AM

To: OSエンジンインフォメーション

Subject: OS GT33 engine

Hi,

Is the OS GT33 engine made in Japan as of this email?

Best regards,

Along with the engine I missed around a little making a soft mount and think I've match technique, glues and materials used in the Hyde mount.

Appreciate the thread.

Currently, I'm using Redline 32:1 turning a APC 19x11 or a APC 20x10. A few times that I've run the engine ran very well and was comparable to a YS DZ170.

While researching I too was concern about the piston clip failure MattK had. I knew the OS production had moved to China and maybe not as good as quality control as Japan had. I sent an email to OS directly. Here is the response.

OSエンジンインフォメーション

Jan 25, 2019, 12:06 AM

to me

We think we use 50:1 mixture with Redline 2-stroke oil.

So you do not have to increase oil ratio as long as carburetor adjustment is not harsh to the engine and you do not fly full throttle all the time.

Best regards,

Junichi

From: me

Sent: Thursday, January 24, 2019 9:31 PM

To: OSエンジンインフォメーション

Subject: Re: OS GT33 engine

Thank you for you time.

I am looking at this engine for putting into a 2 meter pattern plane. I have read an article on RCUniverse about a person doing this with great success. Not really wanting to push the engine hard. Looking at being able to turn a APC 19x11 prop in matching the YS DZ170 or 175 engine. My concern is longevity. Should I run the oil contact 40:1 instead of 50:1? Or 32:1? Would this help? I use Red line two stroke racing oil.

After reading the forum thread I really think this is one of the best engines out there for this.

Best Regards,

On Tue, Jan 22, 2019 at 5:58 PM OSエンジンインフォメーション <[email protected]> wrote:

About 5 years ago, we took back our production from China and resume making it in Japan.

From: me

Sent: Wednesday, January 23, 2019 8:55 AM

To: OSエンジンインフォメーション

Subject: Re: OS GT33 engine

Sir I greatly appreciate your reply and putting the rumor I heard that they were made in China to rest.

Best regards,

On Tue, Jan 22, 2019 at 5:23 PM OSエンジンインフォメーション <[email protected]> wrote:

Hello Sir,

Yes, it is made in Japan.

Best regards,

Junichi Shimazaki

From: me

Sent: Wednesday, January 23, 2019 4:26 AM

To: OSエンジンインフォメーション

Subject: OS GT33 engine

Hi,

Is the OS GT33 engine made in Japan as of this email?

Best regards,

Along with the engine I missed around a little making a soft mount and think I've match technique, glues and materials used in the Hyde mount.

Appreciate the thread.