Vortex F3A build thread

#53

Thread Starter

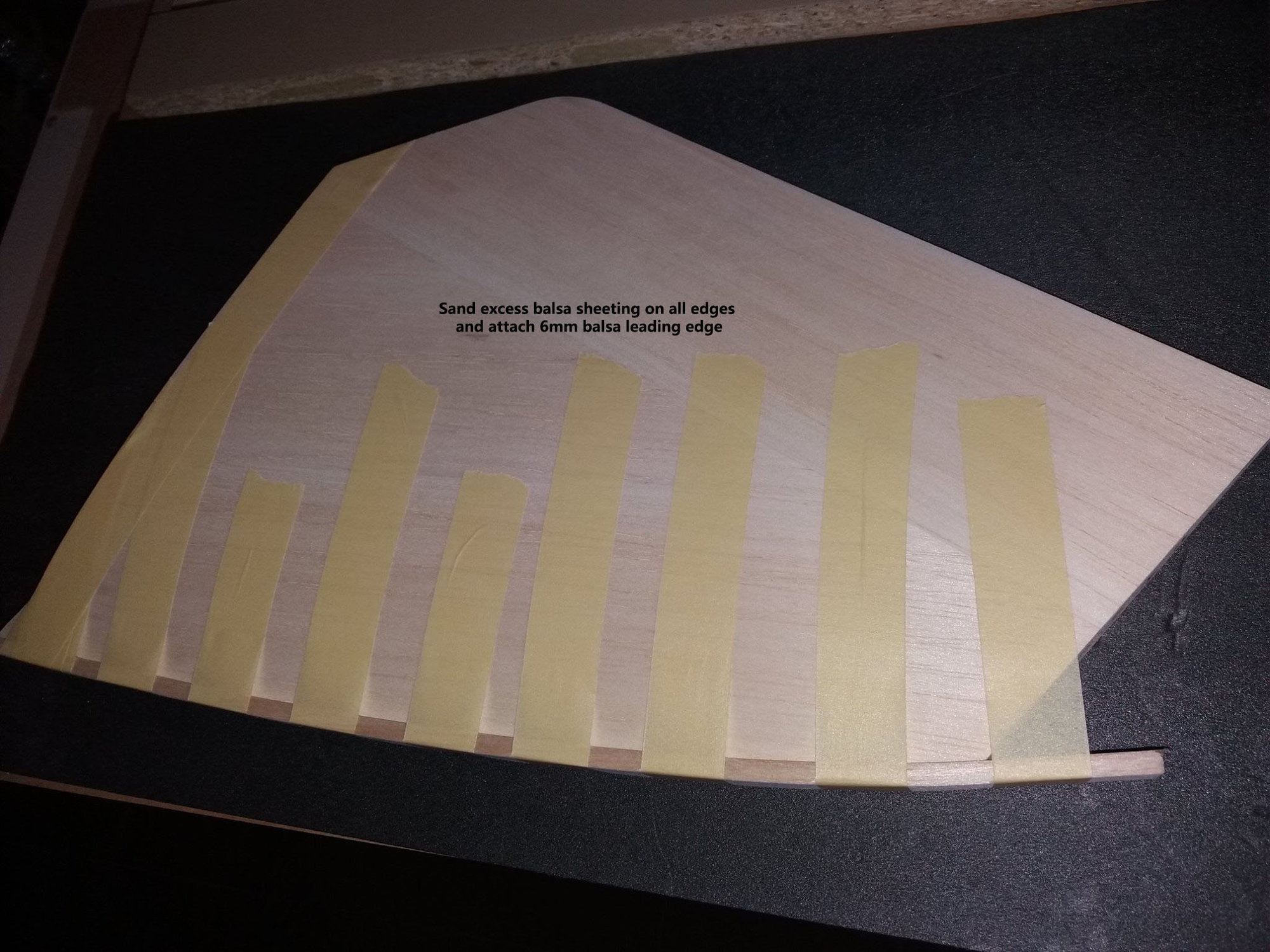

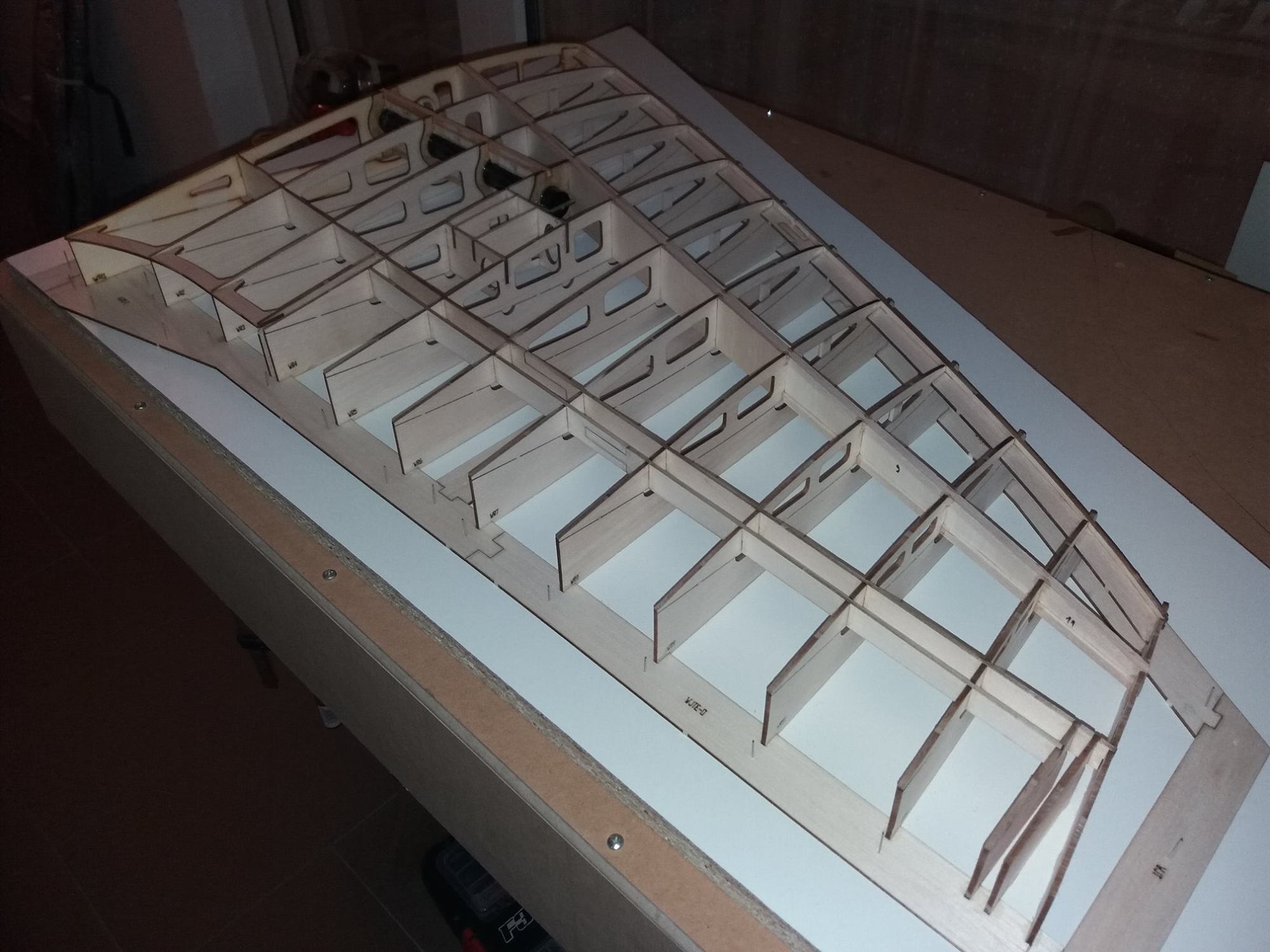

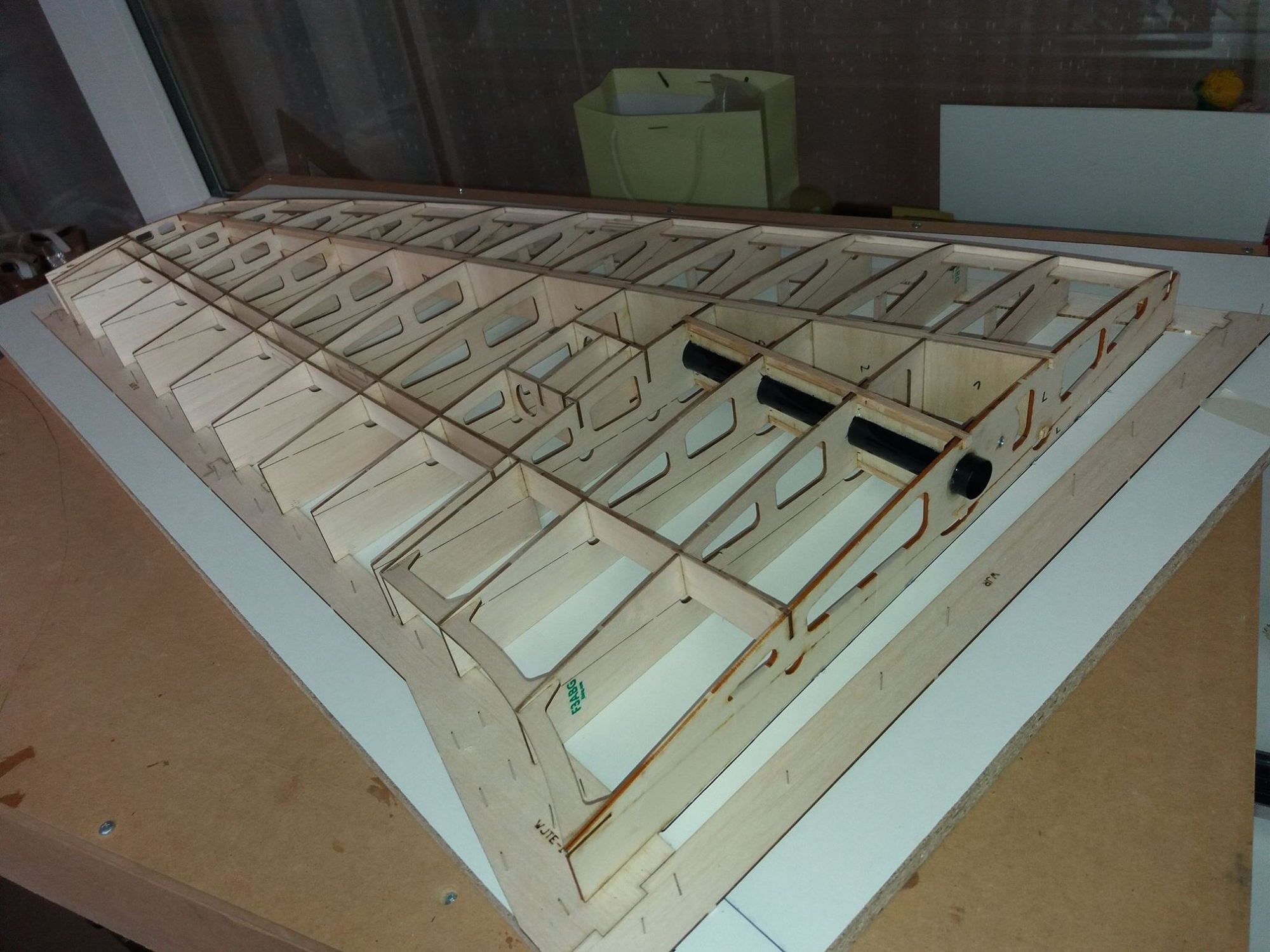

I'm not aiming for a specific weight, as long as it will be under 5kg i'll be happy. It's a very large plane and i built it entirely with 100kg/m3 (or 6.25 lb/ ft3) balsa. I've seen other builders using significantly lighter balsa sheets, so it is possible to achieve better weights for all parts.

Weights of the finished parts are as follows:

fuselage (without canopy, cowl, paint or film covering): 900g

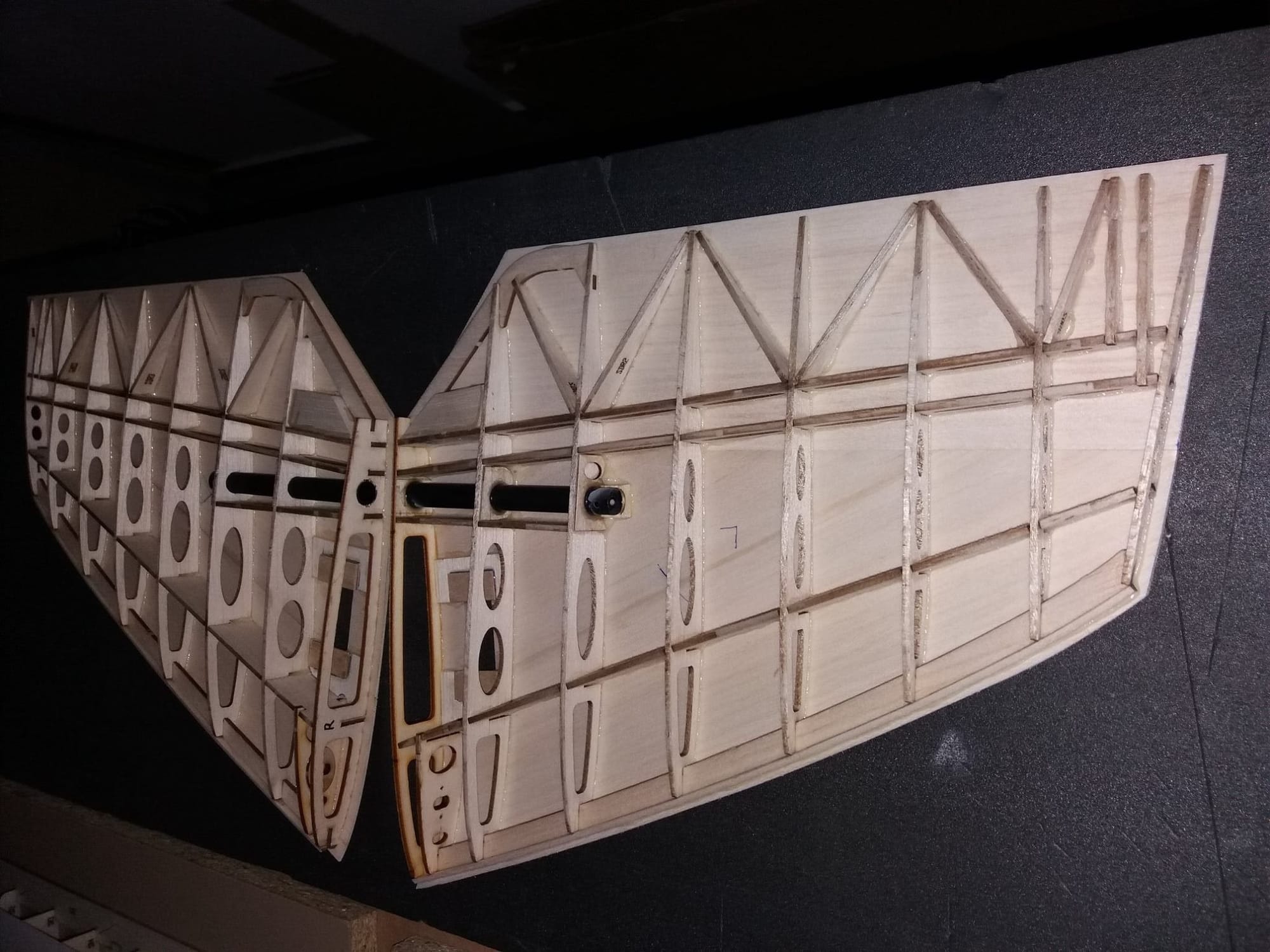

wings (without film covering, servo, control horn, linkage): 265g each

stabs (without film covering, servo, control horn, linkage): 70g each

rudder (without film covering, control horns): 62g

More weight reduction can be achieved by hollowing the balsa tips of the wings, stabs and the large balsa block at the bottom of the rudder. I was too lazy to do that

#59

My Feedback: (1)

Hi,

I saw that frequent_flyer posted on the other main "Classic RC Pattern Flying" forum this:

"Vortex molds for the cowl and canopy are in progress and will be finished soon."

http://www.rcuniverse.com/forum/12547127-post802.html

It will be interesting to see these parts added to a Vortex build soon.

/Bo

I saw that frequent_flyer posted on the other main "Classic RC Pattern Flying" forum this:

"Vortex molds for the cowl and canopy are in progress and will be finished soon."

http://www.rcuniverse.com/forum/12547127-post802.html

It will be interesting to see these parts added to a Vortex build soon.

/Bo

#60

My Feedback: (6)

Join Date: Feb 2003

Location: Grand Junction, Colorado

Posts: 1,484

Likes: 0

Received 4 Likes

on

4 Posts

Bem

I'm making the complete kits. I'm just waiting for more Balsa that's on order. All the cut files are ready to laser cut now.I

It's getting tough to get Contest Balsa, Four of my suppliers said they don't have it. They said it may be 2 years before it's harvested and available again.

I'm making the cowl and Canopy with Carbon Fiber.

I'm making the complete kits. I'm just waiting for more Balsa that's on order. All the cut files are ready to laser cut now.I

It's getting tough to get Contest Balsa, Four of my suppliers said they don't have it. They said it may be 2 years before it's harvested and available again.

I'm making the cowl and Canopy with Carbon Fiber.

#61

My Feedback: (1)

Hi,

Great frequent_flyer.

I bet one source for balsa in my country has light "Contest" balsa. The Company is "MBS RC Models" and they have some nice balsakits of "Viggen", "Saab 105", and "Draken". Also on "Tummelisa".

Skalamodeller (MBS) - MBS RC Models

They write this about their balsa sheets:

MBS RC Models balsa is of highest quality (AAA) and can be ordered according to weight below or according to own requirements (e-mail or phone for price info)

The balsa sheets are devided into 5 weight clesses:

1. Weightclass unsorted: a mix of all classes below.

2. Weightclass light: max 90 kg/m³

3. Weightclass light-medium: 91 – 125 kg/m³

4. Weightclass medium: 126 – 155 kg/m³

5. Weightclass hard: min 156 kg/m³

They have own laser cutter. So they can make "kits" from Cdr (Corel Draw), DXF (saved as version 14) and DWG files (not all versions).

I hope You can find proper balsa source for the Vortex kits. 2M F3A machines really need to be reasonably light so the pilot at last stage do not need hunt weight too hard when assembly start. I know too well the weight hunting circus that can start, and be expensive in worse case.

/Bo

Great frequent_flyer.

I bet one source for balsa in my country has light "Contest" balsa. The Company is "MBS RC Models" and they have some nice balsakits of "Viggen", "Saab 105", and "Draken". Also on "Tummelisa".

Skalamodeller (MBS) - MBS RC Models

They write this about their balsa sheets:

MBS RC Models balsa is of highest quality (AAA) and can be ordered according to weight below or according to own requirements (e-mail or phone for price info)

The balsa sheets are devided into 5 weight clesses:

1. Weightclass unsorted: a mix of all classes below.

2. Weightclass light: max 90 kg/m³

3. Weightclass light-medium: 91 – 125 kg/m³

4. Weightclass medium: 126 – 155 kg/m³

5. Weightclass hard: min 156 kg/m³

They have own laser cutter. So they can make "kits" from Cdr (Corel Draw), DXF (saved as version 14) and DWG files (not all versions).

I hope You can find proper balsa source for the Vortex kits. 2M F3A machines really need to be reasonably light so the pilot at last stage do not need hunt weight too hard when assembly start. I know too well the weight hunting circus that can start, and be expensive in worse case.

/Bo

#62

My Feedback: (6)

Join Date: Feb 2003

Location: Grand Junction, Colorado

Posts: 1,484

Likes: 0

Received 4 Likes

on

4 Posts

That's good to hear, I'll call them and see what they have. We have our own 1600 x 1000 lasers also and make everything in house.

Last edited by frequent flyer; 09-02-2019 at 05:14 AM.

#63

Bem

I'm making the complete kits. I'm just waiting for more Balsa that's on order. All the cut files are ready to laser cut now.I

It's getting tough to get Contest Balsa, Four of my suppliers said they don't have it. They said it may be 2 years before it's harvested and available again.

I'm making the cowl and Canopy with Carbon Fiber.

I'm making the complete kits. I'm just waiting for more Balsa that's on order. All the cut files are ready to laser cut now.I

It's getting tough to get Contest Balsa, Four of my suppliers said they don't have it. They said it may be 2 years before it's harvested and available again.

I'm making the cowl and Canopy with Carbon Fiber.

MBS here in sweden is curently cutting a kit for me. Was planing to 3D print canopy and cowl and making a mold and my own carboon parts but depending on price I maby order frome you if I can.

#65

Thread Starter

Thank you Will, you are very kind

And many thanks to Don for his hard work on the molds, looking forward to see his results.

And many thanks to Don for his hard work on the molds, looking forward to see his results.

#67

My Feedback: (121)

Contest Balsa: The older the tree, the lighter the balsa. About 20 years or more for top quality contest balsa. Can't remember where I got that information, maybe Riley Wooton at Lonestar Balsa (long gone). I believe balsa is used in the production of windmill turbine blades which are enormous. One blade filled with contest balsa would probably provide hundreds of airplane kits (much better use, too).

I'm not sure I could afford to have Alex build an airplane for me... :-)

Fortunately, I love to build!

I'm not sure I could afford to have Alex build an airplane for me... :-)

Fortunately, I love to build!

#69

My Feedback: (1)

Hi,

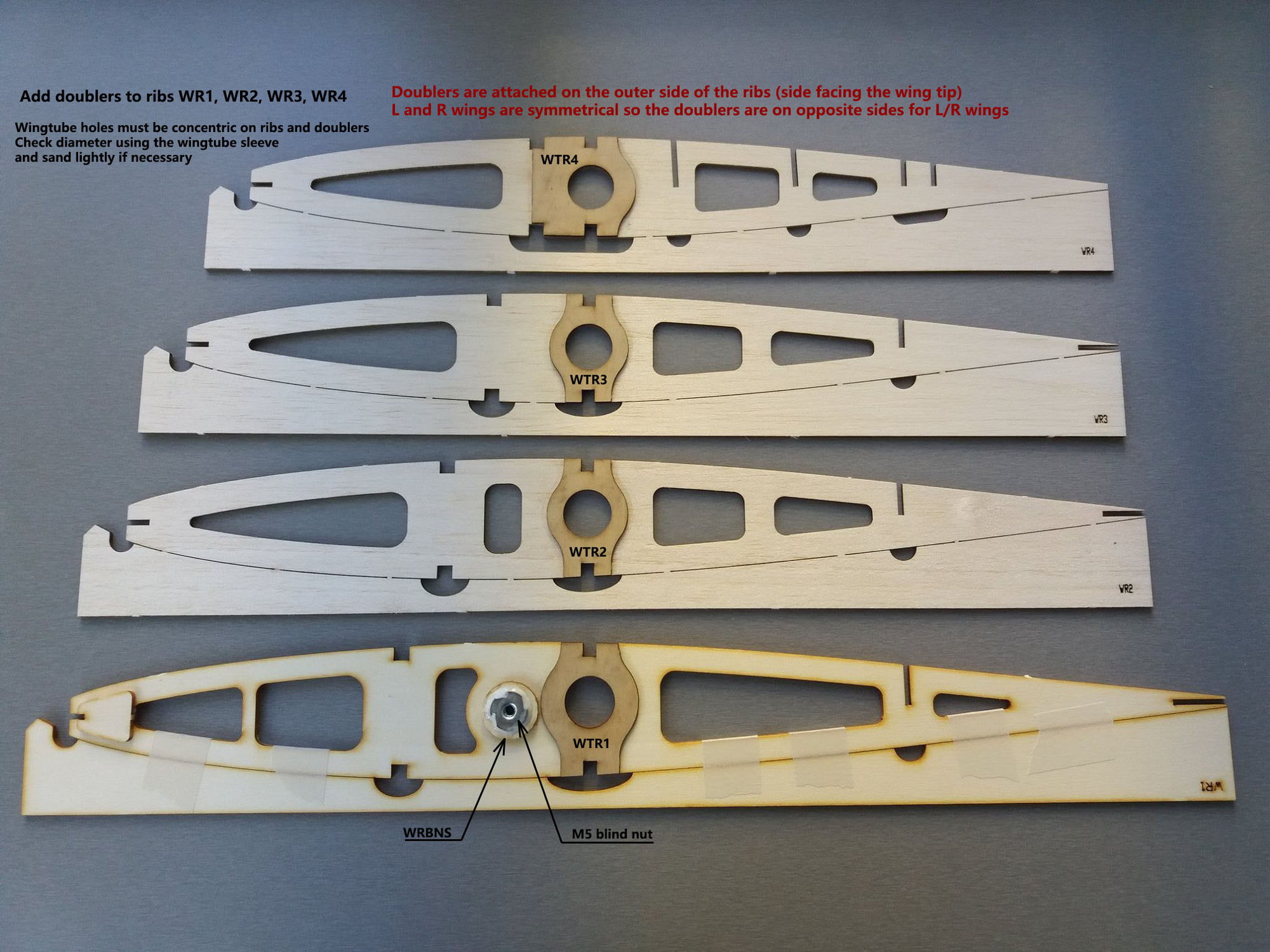

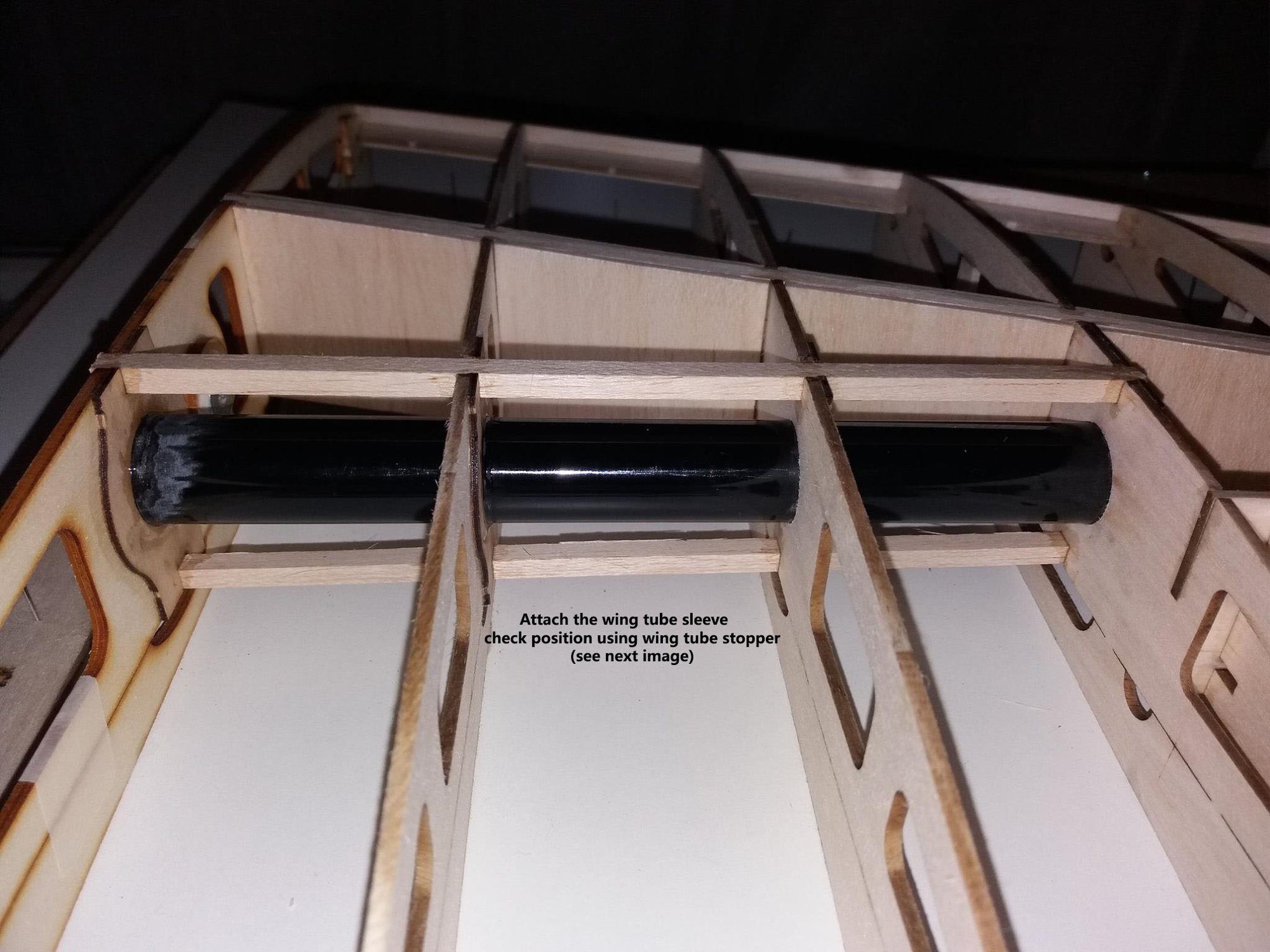

Just curious - how long is the wing tube in the wing?

Why I ask is because I have a plane (Galactika made from factory late 2015 or early 2016) that has a wing tube length of only 145 millimeter that goes into a wing half, and that has caused bending forces on the wing skin structure so cracks appeared. The manufacturer later modified this so the wing tube is longer now. As comparison on a 2M Sebart MythoS Pro (that I have also) the wing tube length in one wing on that is about 240 mm.

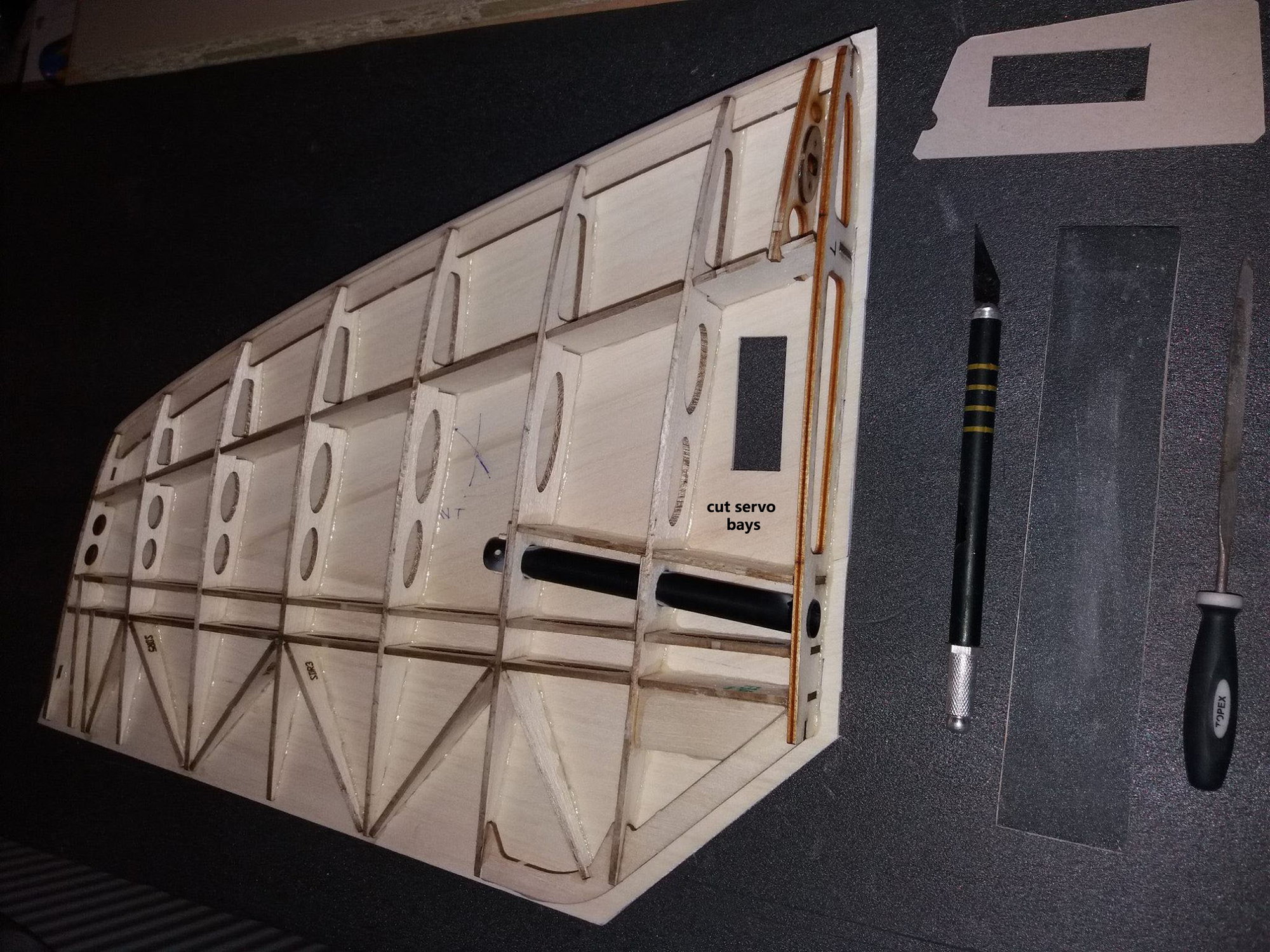

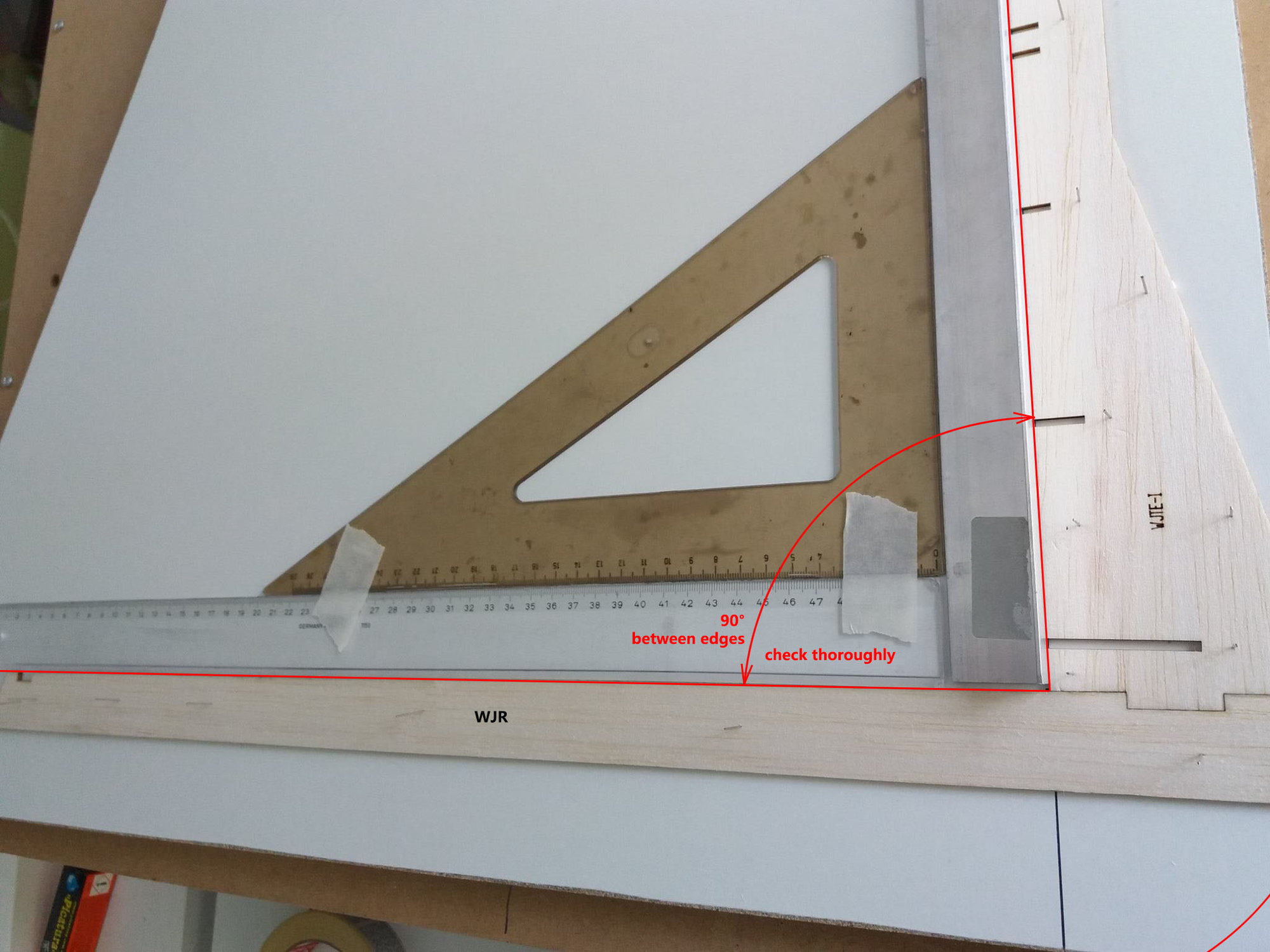

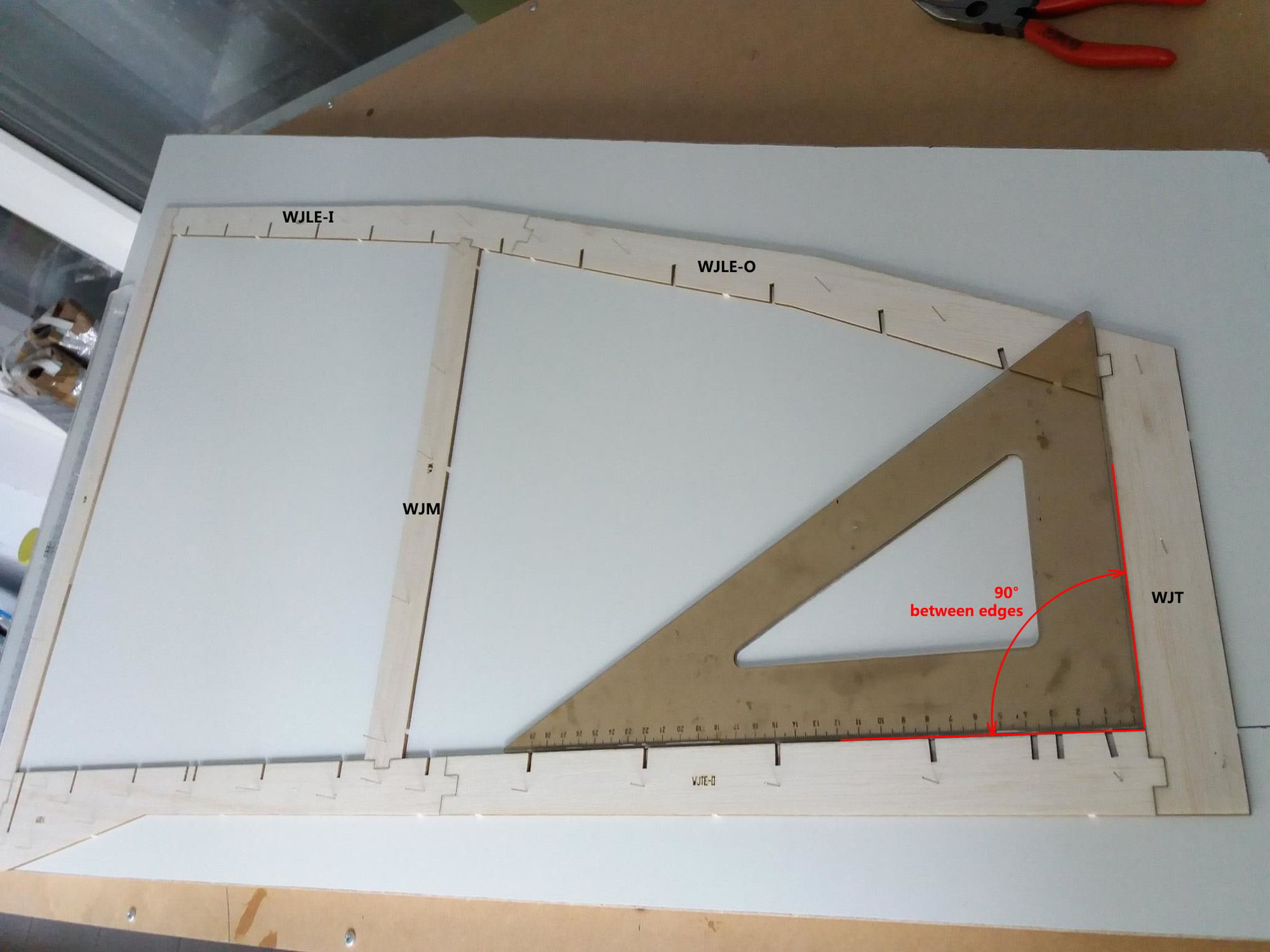

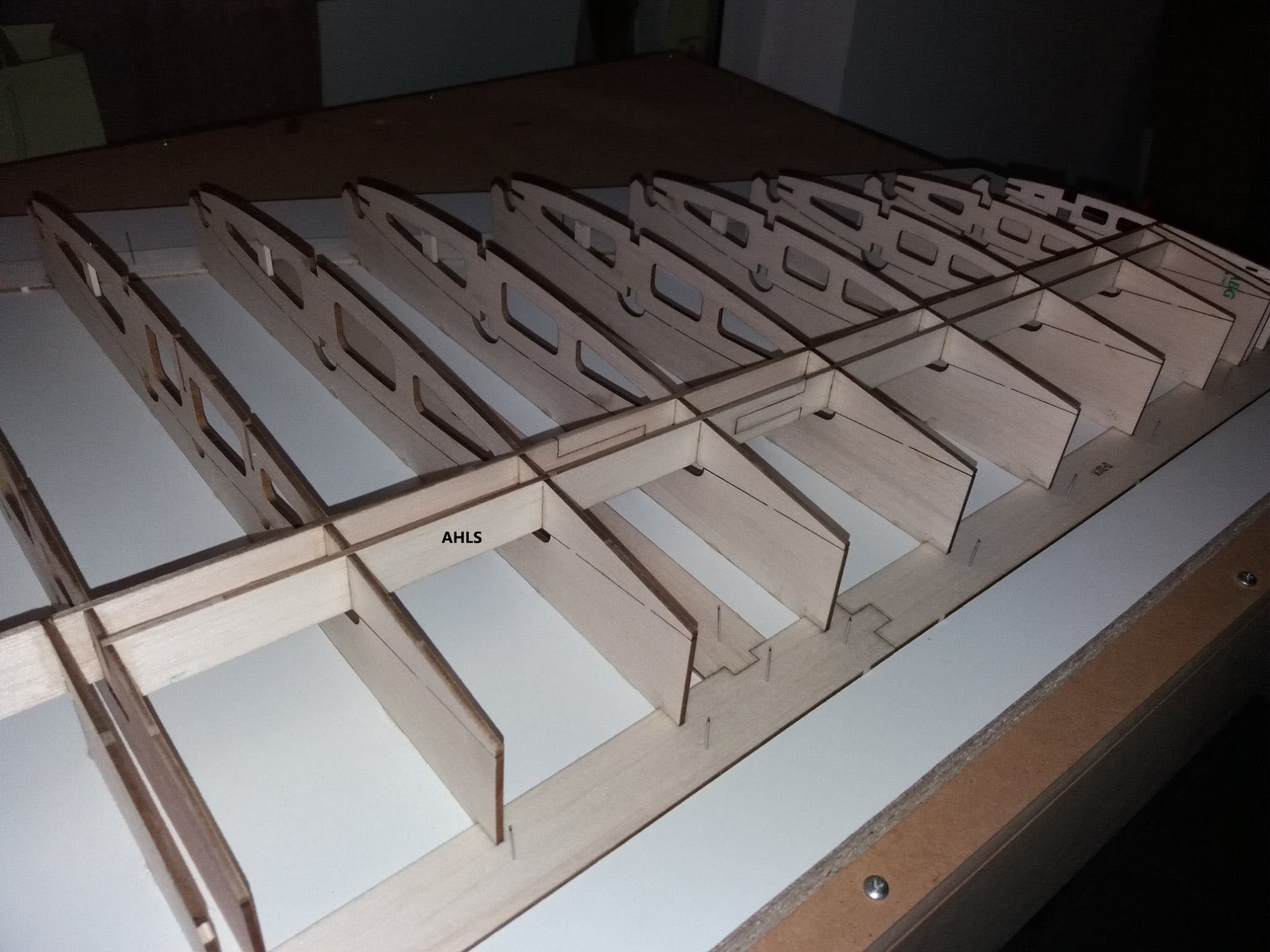

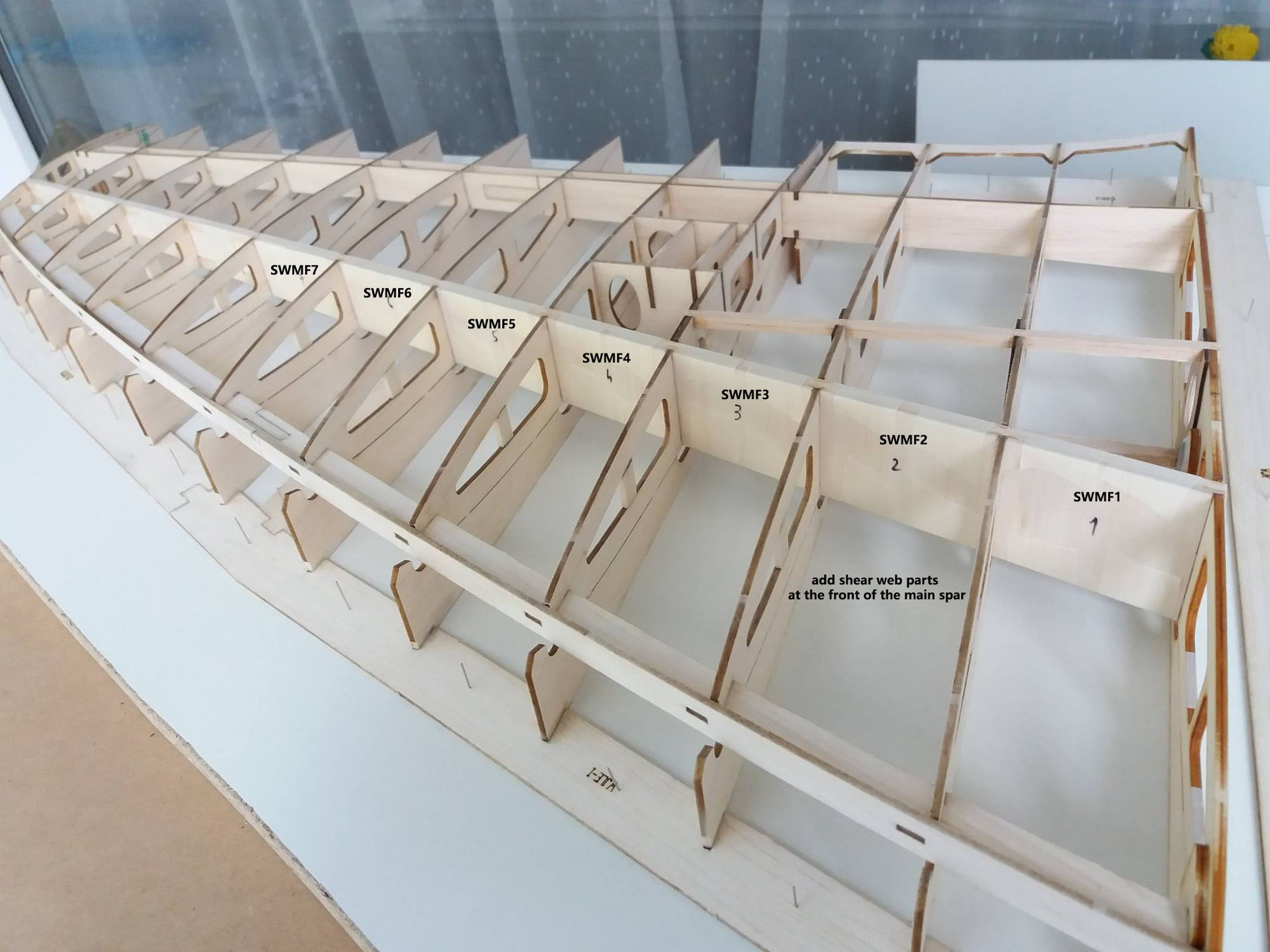

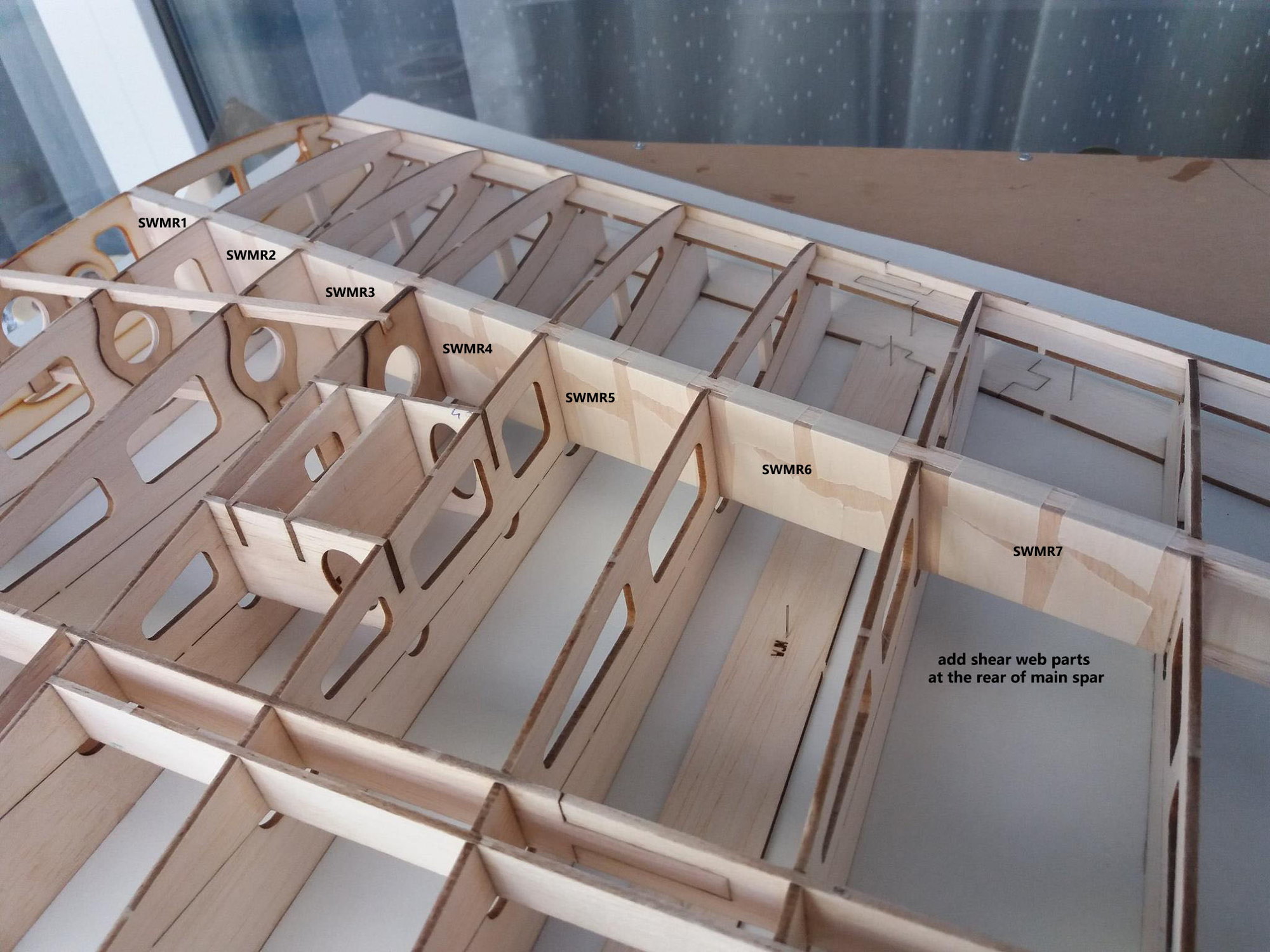

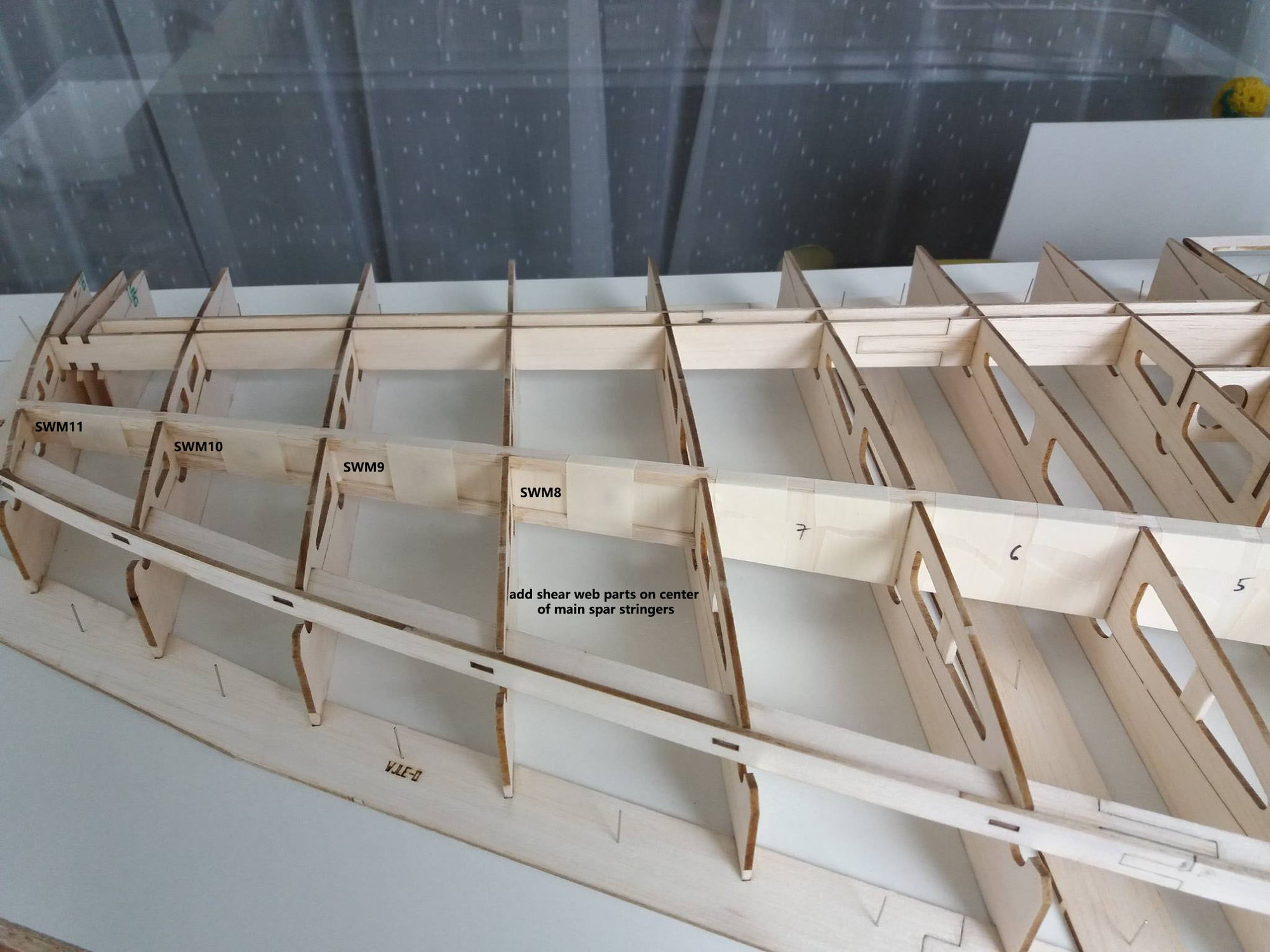

Just thought I would mention this just in case. Maybe You are sure that wing tube length is enough on the Vortex. But it seems maybe little short length in the images You posted? Great wing structure so far in the photos. It will be interesting to see the weight of a ready built and covered wing half later.

/Bo

Just curious - how long is the wing tube in the wing?

Why I ask is because I have a plane (Galactika made from factory late 2015 or early 2016) that has a wing tube length of only 145 millimeter that goes into a wing half, and that has caused bending forces on the wing skin structure so cracks appeared. The manufacturer later modified this so the wing tube is longer now. As comparison on a 2M Sebart MythoS Pro (that I have also) the wing tube length in one wing on that is about 240 mm.

Just thought I would mention this just in case. Maybe You are sure that wing tube length is enough on the Vortex. But it seems maybe little short length in the images You posted? Great wing structure so far in the photos. It will be interesting to see the weight of a ready built and covered wing half later.

/Bo

Last edited by bem; 09-11-2019 at 12:53 AM.

#70

Thread Starter

Hi,

Just curious - how long is the wing tube in the wing?

Why I ask is because I have a plane (Galactika made from factory late 2015 or early 2016) that has a wing tube length of only 145 millimeter that goes into a wing half, and that has caused bending forces on the wing skin structure so cracks appeared. The manufacturer later modified this so the wing tube is longer now. As comparison on a 2M Sebart MythoS Pro (that I have also) the wing tube length in one wing on that is about 240 mm.

Just thought I would mention this just in case. Maybe You are sure that wing tube length is enough on the Vortex. But it seems maybe little short length in the images You posted? Great wing structure so far in the photos. It will be interesting to see the weight of a ready built and covered wing half later.

/Bo

Just curious - how long is the wing tube in the wing?

Why I ask is because I have a plane (Galactika made from factory late 2015 or early 2016) that has a wing tube length of only 145 millimeter that goes into a wing half, and that has caused bending forces on the wing skin structure so cracks appeared. The manufacturer later modified this so the wing tube is longer now. As comparison on a 2M Sebart MythoS Pro (that I have also) the wing tube length in one wing on that is about 240 mm.

Just thought I would mention this just in case. Maybe You are sure that wing tube length is enough on the Vortex. But it seems maybe little short length in the images You posted? Great wing structure so far in the photos. It will be interesting to see the weight of a ready built and covered wing half later.

/Bo

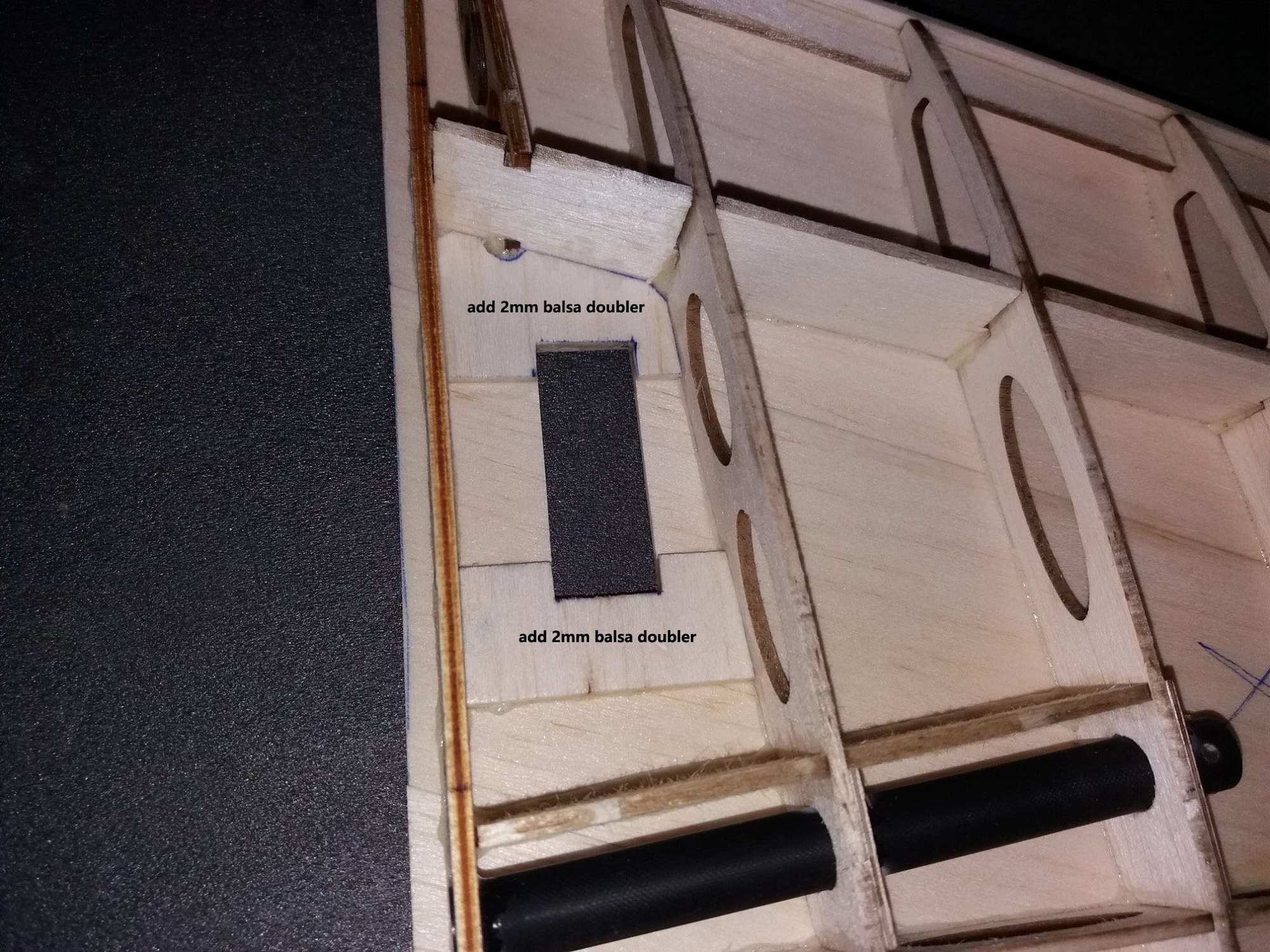

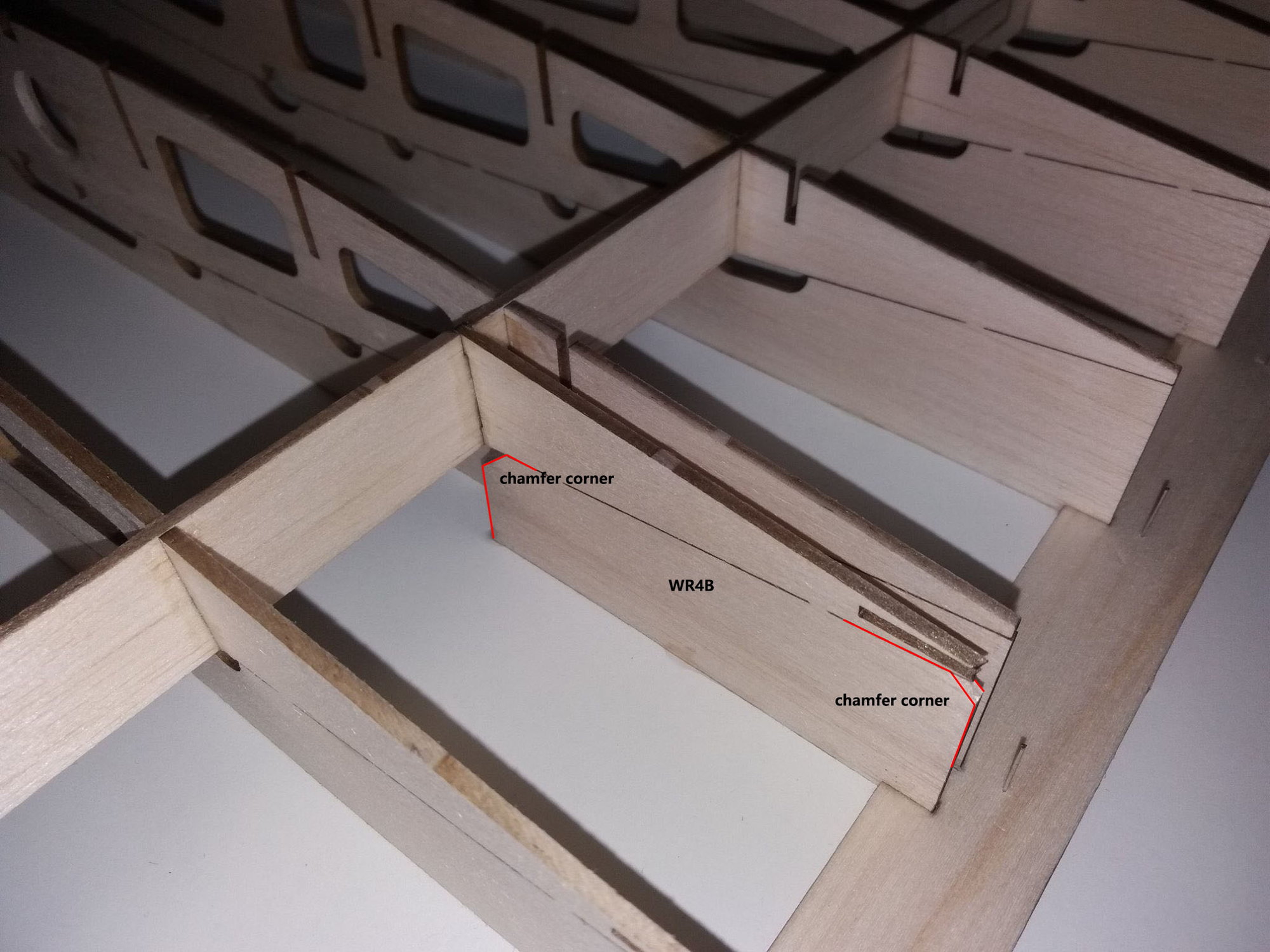

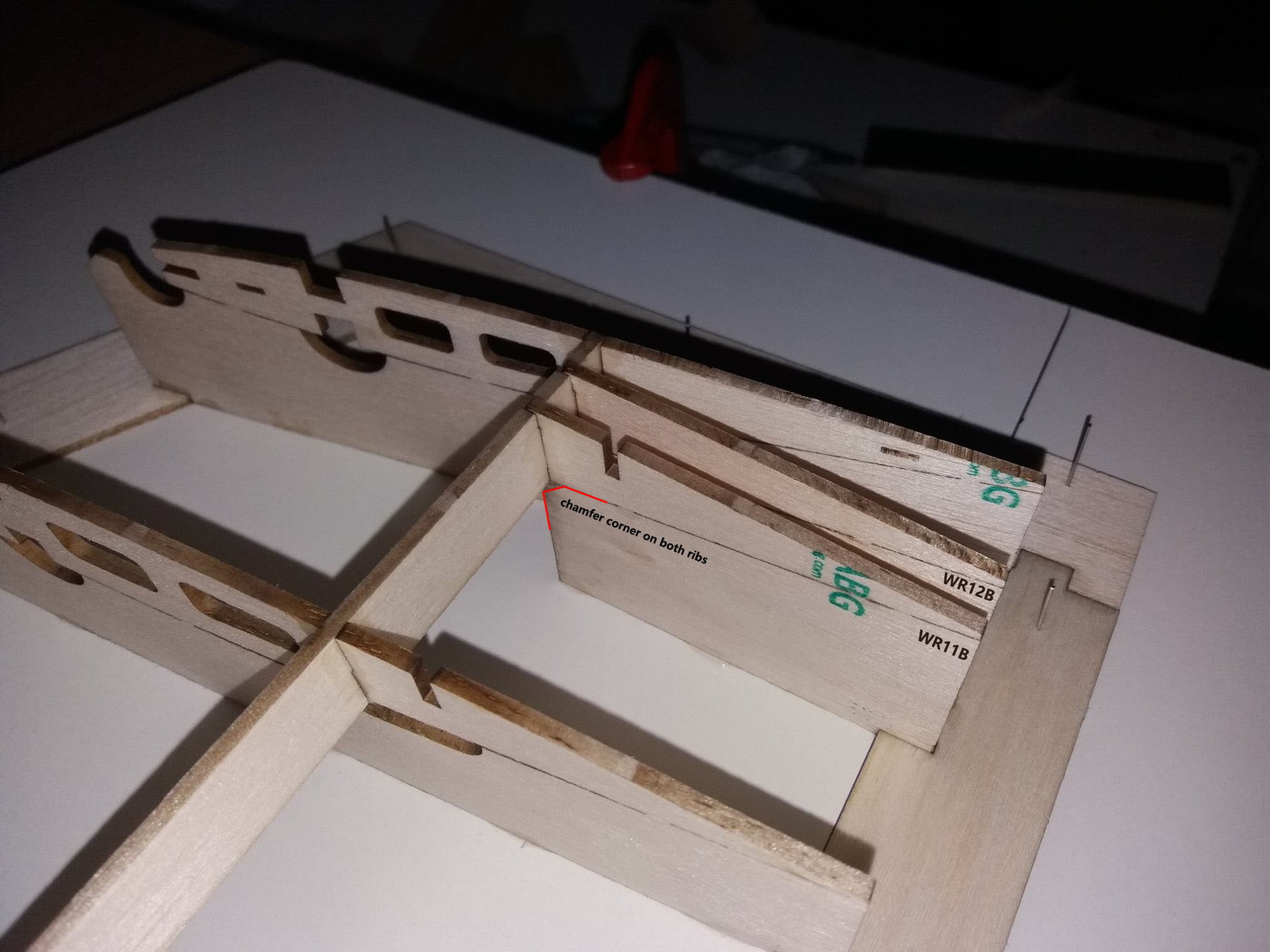

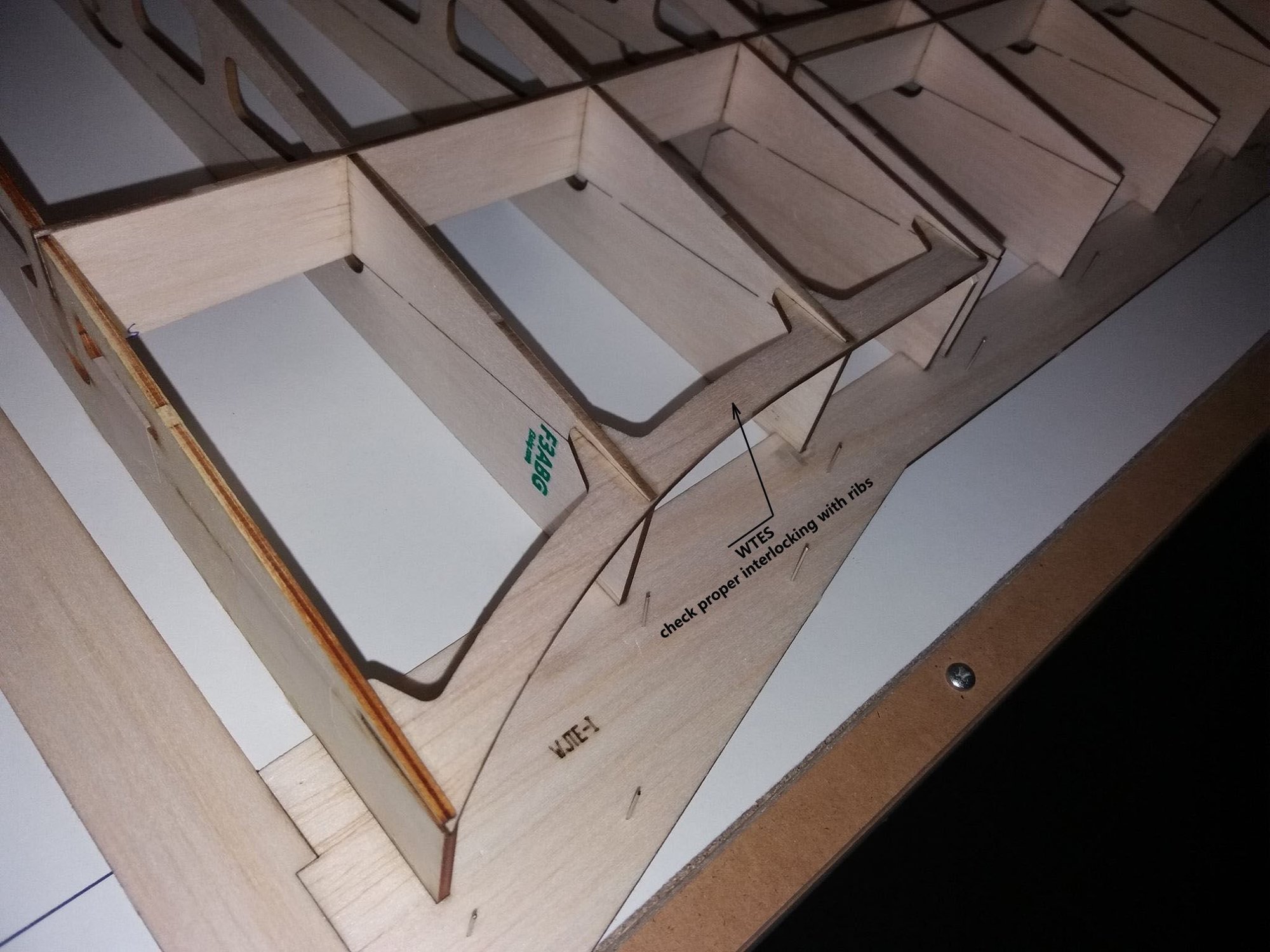

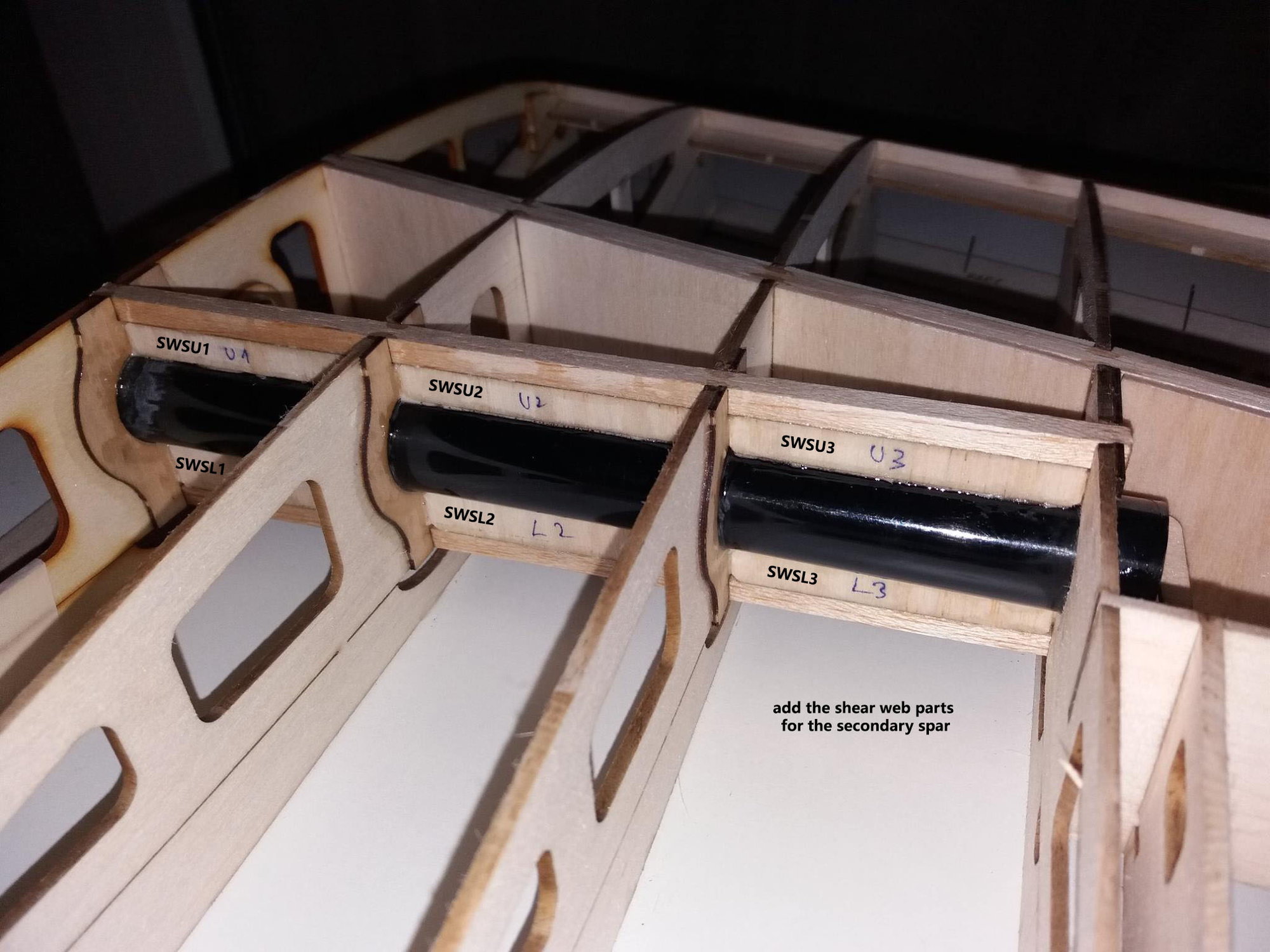

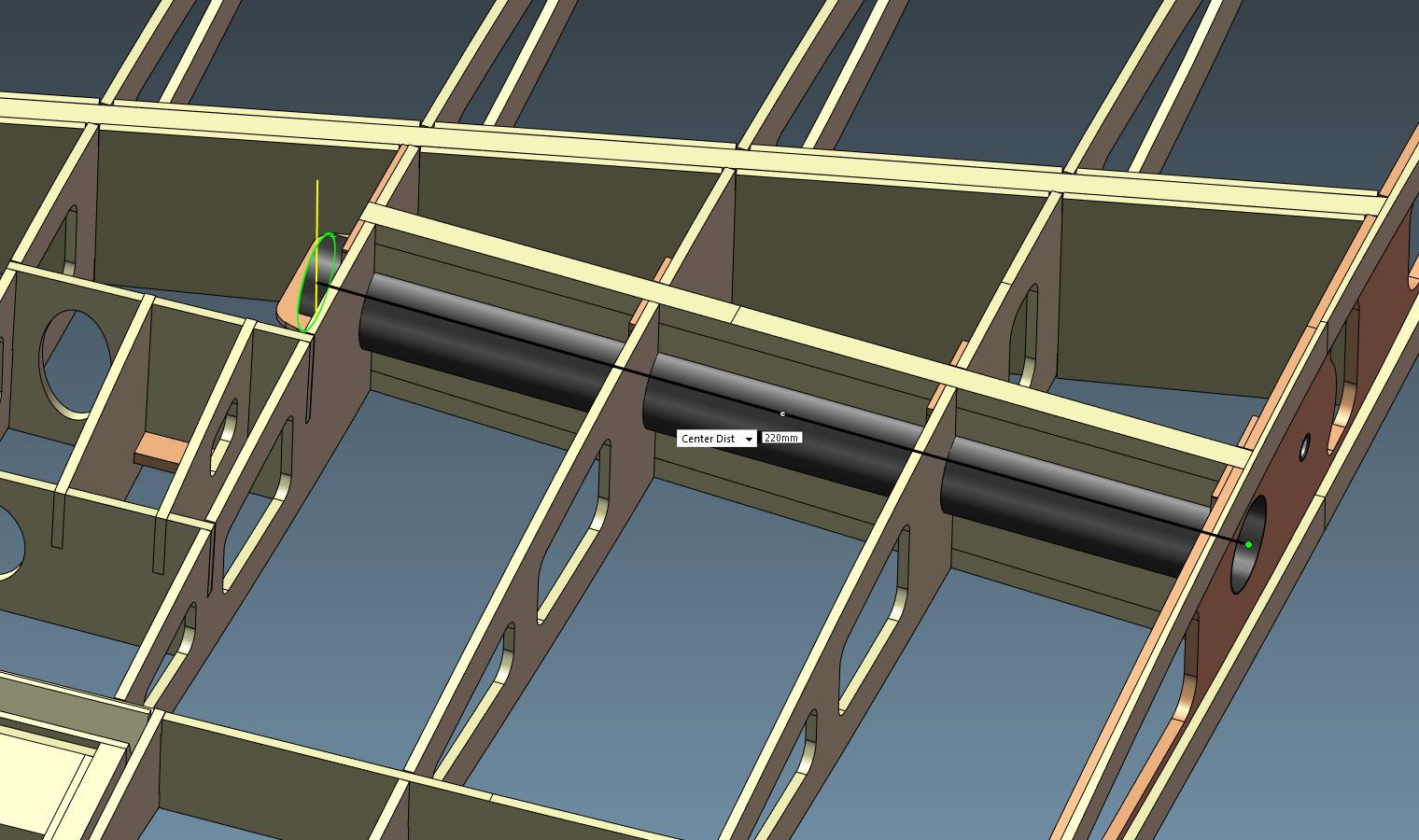

When designing the Vortex wing i added some plywood doublers to the ribs supporting the wingtube so the loads are distributed to the secondary spar and the balsa sheeting. The secondary spar is connected to the main spar through the strong wingroot rib (made of 3mm liteply) and through the plywood rib doubler at the end of the wingtube. This creates quite a strong structure i think and i'm not sure there's more to be done to increase wing strength.

The length of the wingtube inside the Vortex wing is 220mm, which is on the safe side in my opinion (see attached screenshot).

#72

Tube length should be fine.

The wing structure could be even better if the spars and vertical balsa filling would extend to main spar. This would form a triangle and reduce twisting of wing rib at the tube end area.

Weight increase is negligible.

The wing structure could be even better if the spars and vertical balsa filling would extend to main spar. This would form a triangle and reduce twisting of wing rib at the tube end area.

Weight increase is negligible.

#73

Thread Starter

My first design (Radiance) didn't even have a secondary spar, just the plywood rib doublers and i didn't see any sign of structural problems. Other F3A designs only have a plywood doubler at the end of the wingtube and no reinforcements in the wingtube area, so by comparison the Vortex wing should be slightly overbuilt. But the final weight was pretty good, so i don't regret adding the extra strength.

#74

My Feedback: (1)

Any builder reading this thread can, if wanted, modify the wing tube length and the load distribution area until it has "contact" with the main wing spar. Easy modification as far as I can see. That is one of the great things of building a model oneself, there is often room for enhancements and modifications. So if someone thinks it is better safe then sorry in this area it is rather easy to fix and then be able to sleep well at nights

/Bo

/Bo

#75

My Feedback: (1)

Hi Bo. For the sake of clarity, I think you are talking about extending the length of the wing tube "sleeve" until it makes contact with the wing spar. By joining the two (wing sleeve and wing spar) in should increase overall strength and rigidity of each of the wings. I would also increase the overall length of the wing tube to match the extended sleeves of each wing. Hope this makes sense. Wish you continued success.