The future has arrived.

#1

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Grande Prairie,

AB, CANADA

Posts: 8,976

Likes: 0

Received 4 Likes

on

4 Posts

Recently I was surfing Shapeways and stumbled across a couple of guys doing parts in 1/35 scale. I emailed both of them and this is the result

https://www.shapeways.com/model/2897...html?li=aeTabs

https://www.shapeways.com/model/2892...ml?li=shortUrl

The guy making the periscope guards( Mike) is also going to do Sherman headlight and tail light guards as well.

Cool

https://www.shapeways.com/model/2897...html?li=aeTabs

https://www.shapeways.com/model/2892...ml?li=shortUrl

The guy making the periscope guards( Mike) is also going to do Sherman headlight and tail light guards as well.

Cool

Last edited by YHR; 11-27-2014 at 05:27 AM.

#2

It's about time. I've been waiting for the future for a while now.

Seriously, at an AMPS show back in '05 or '06, a guy had workable 1/48 tracks that were printed assembled. Of course it was from high end machines beyond anything a hobbyist could afford and even the tracks themselves were too expensive to market, but it showed the potential.

My son asked for a 3D printer for Xmas, I suggested a gift certificate to Shapeways instead so he could learn the CAD before he dealt with the frustrations of the affordable home systems.

Seriously, at an AMPS show back in '05 or '06, a guy had workable 1/48 tracks that were printed assembled. Of course it was from high end machines beyond anything a hobbyist could afford and even the tracks themselves were too expensive to market, but it showed the potential.

My son asked for a 3D printer for Xmas, I suggested a gift certificate to Shapeways instead so he could learn the CAD before he dealt with the frustrations of the affordable home systems.

#3

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Grande Prairie,

AB, CANADA

Posts: 8,976

Likes: 0

Received 4 Likes

on

4 Posts

Same here for me. I am finally going to retire soon and I have promised myself to get up to speed on CAD, before I shell out money for a printer. This shapeways option is pretty cool though. Find guys who have the skills, and they are quite receptive to building what you need.

I contacted these two guys, and within a week they had parts in 1/16 scale ready to sell. Talk about opening the door on the possibilities.

Yes these two items I doubt could be done on a home printer. I might be wrong though, the technology is changing so fast.

I contacted these two guys, and within a week they had parts in 1/16 scale ready to sell. Talk about opening the door on the possibilities.

Yes these two items I doubt could be done on a home printer. I might be wrong though, the technology is changing so fast.

Last edited by YHR; 11-27-2014 at 05:45 AM.

#4

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Grande Prairie,

AB, CANADA

Posts: 8,976

Likes: 0

Received 4 Likes

on

4 Posts

Re Periscope guards.

What I did on my Cromwell was use a flanged bearing in the hull as a periscope base. These periscope guards are then attached to the bearing, and you have a nice smooth turning periscope.

What I did on my Cromwell was use a flanged bearing in the hull as a periscope base. These periscope guards are then attached to the bearing, and you have a nice smooth turning periscope.

Last edited by YHR; 11-27-2014 at 05:51 AM.

#7

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Grande Prairie,

AB, CANADA

Posts: 8,976

Likes: 0

Received 4 Likes

on

4 Posts

??? LOL. You and me both then. I contacted him a couple of weeks ago suggested he up scale. I have a set on the way. I guess if these guys are getting multiple request for 1/16 scale parts it drives the point home there is a market that needs serving

#9

I've just started putting some of my stuff up there.

https://www.shapeways.com/shops/WarrenHudson

You can't judge a print off the renders as small details like the small bolts just won't print out.

Just read the info on the Frosted Ultra Detail and the smallest detail is 0.1mm x 0.1 mm (my printer is 0.1 x 0.2mm). Have to look into the pricing a bit more though.

https://www.shapeways.com/shops/WarrenHudson

You can't judge a print off the renders as small details like the small bolts just won't print out.

Just read the info on the Frosted Ultra Detail and the smallest detail is 0.1mm x 0.1 mm (my printer is 0.1 x 0.2mm). Have to look into the pricing a bit more though.

Last edited by Wozwasnt; 11-27-2014 at 01:44 PM.

#11

As mentioned before on other 3D printing threads here, take a look at what Pat Matthews has been doing for the past 5 years for the model boating crowd. He's considering doing the same for tanks so feel check out some of his work over at RC Groups.

http://www.rcgroups.com/forums/showthread.php?t=1088812

http://www.rcgroups.com/forums/showthread.php?t=1088812

#13

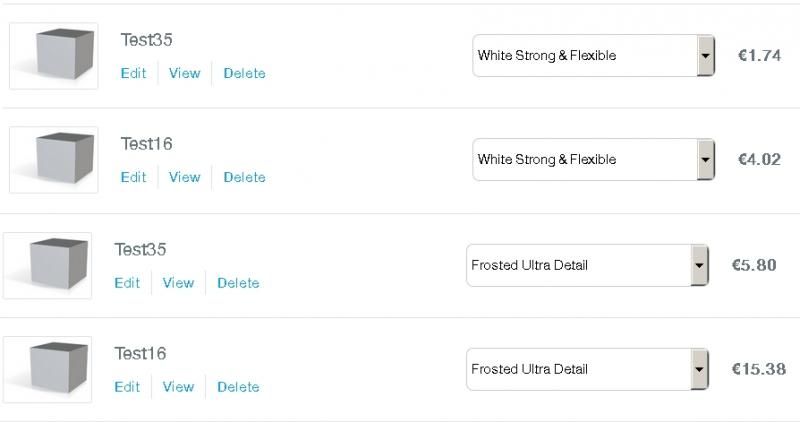

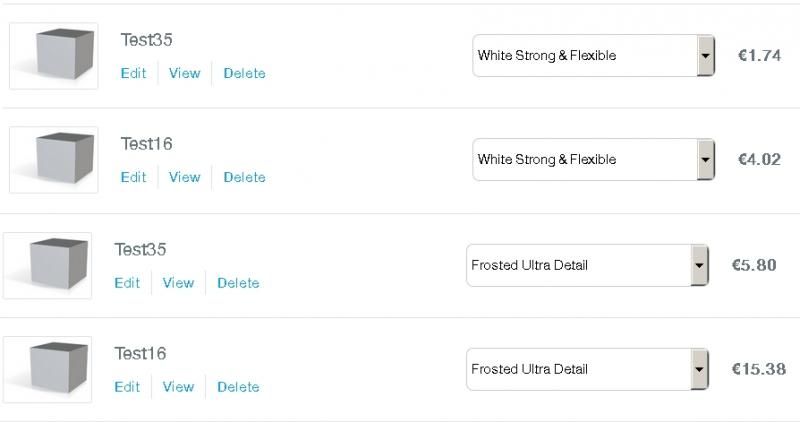

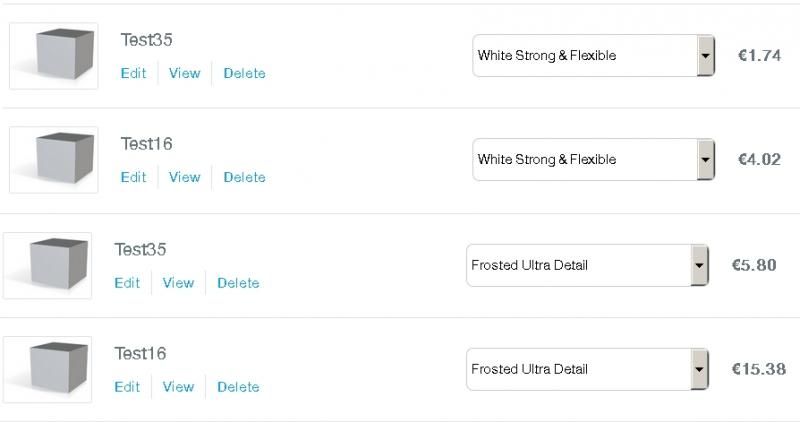

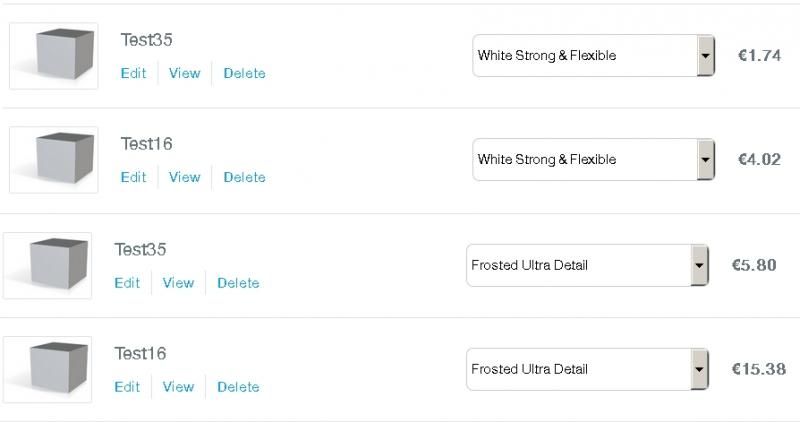

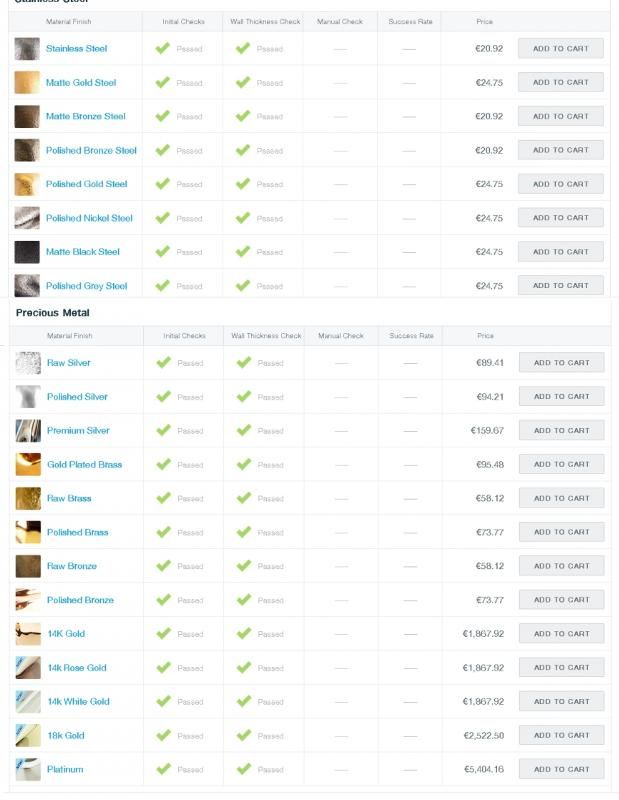

Question - How much are you guys willing to pay for this stuff?

I've done a bit of testing on Shapeways.

I made a 30cm hollow box (1 foot) in 1/35 (so thats 8.57mm cubed) with 1mm thick walls then rescaled it to 1/16.

then put both up on Shapeways and checked out the prices (test35 is 1/35 and test16 is 1/16)-

For basic shapes like this box then "Strong and Flexible" will do but for detailed stuff with nuts and bolts you'll need to use the Frosted Ultra Detail and thats getting expensive.

P.S. if anyone fancies the 1/16 box printed in platinum then I can do a special deal for forum members $ 5404.15

I've done a bit of testing on Shapeways.

I made a 30cm hollow box (1 foot) in 1/35 (so thats 8.57mm cubed) with 1mm thick walls then rescaled it to 1/16.

then put both up on Shapeways and checked out the prices (test35 is 1/35 and test16 is 1/16)-

For basic shapes like this box then "Strong and Flexible" will do but for detailed stuff with nuts and bolts you'll need to use the Frosted Ultra Detail and thats getting expensive.

P.S. if anyone fancies the 1/16 box printed in platinum then I can do a special deal for forum members $ 5404.15

Last edited by Wozwasnt; 11-28-2014 at 05:29 AM.

#14

Join Date: Aug 2011

Location: Cambridge ON, CANADA

Posts: 1,063

Likes: 0

Received 0 Likes

on

0 Posts

Silly question, As cheap as possible of course. If you can do platinum can you do metals?

Question - How much are you guys willing to pay for this stuff?

I've done a bit of testing on Shapeways.

I made a 30cm hollow box (1 foot) in 1/35 (so thats 8.57mm cubed) with 1mm thick walls then rescaled it to 1/16.

then put both up on Shapeways and checked out the prices (test35 is 1/35 and test16 is 1/16)-

For basic shapes like this box then "Strong and Flexible" will do but for detailed stuff with nuts and bolts you'll need to use the Frosted Ultra Detail and thats getting expensive.

P.S. if anyone fancies the 1/16 box printed in platinum then I can do a special deal for forum members $ 5640.15

I've done a bit of testing on Shapeways.

I made a 30cm hollow box (1 foot) in 1/35 (so thats 8.57mm cubed) with 1mm thick walls then rescaled it to 1/16.

then put both up on Shapeways and checked out the prices (test35 is 1/35 and test16 is 1/16)-

For basic shapes like this box then "Strong and Flexible" will do but for detailed stuff with nuts and bolts you'll need to use the Frosted Ultra Detail and thats getting expensive.

P.S. if anyone fancies the 1/16 box printed in platinum then I can do a special deal for forum members $ 5640.15

#15

I know you want it cheap but 3D printing isn't cheap. Anyone could make my test cube out of plasticard at a fraction of the cost of a printed cube. I've designed loads of 1/16 stuff but I hadn't put it on Shapeways because I thought they were too expensive.

Last edited by Wozwasnt; 11-28-2014 at 05:27 AM.

#16

The metals aren't actually metals, right? Just materials mixed into the extruded material to simulate what's desired?

I can add metal powder to resin and it will appear to be bronze, etc, have actual bronze in it, but it won't be a furnace cast piece of bronze with all the attributes.

Kind of like particle board versus plywood.

I can add metal powder to resin and it will appear to be bronze, etc, have actual bronze in it, but it won't be a furnace cast piece of bronze with all the attributes.

Kind of like particle board versus plywood.

#17

The metals aren't actually metals, right? Just materials mixed into the extruded material to simulate what's desired?

I can add metal powder to resin and it will appear to be bronze, etc, have actual bronze in it, but it won't be a furnace cast piece of bronze with all the attributes.

Kind of like particle board versus plywood.

I can add metal powder to resin and it will appear to be bronze, etc, have actual bronze in it, but it won't be a furnace cast piece of bronze with all the attributes.

Kind of like particle board versus plywood.

To build steel models, special 3D printers deposit small drops of glue onto layers of stainless steel powder, one layer at a time, until the print is complete. We carefully remove these models from the printer. At this stage of the process, the objects are very fragile, similar to wet sand. The models then go through an infusion process that replaces the glue with bronze, creating a full metal product. Models are then processed to achieve your desired finish, sprayed with a sealant, and shipped to you.

Gold models are 3D printed using a complex five-step process. First, the model is printed in wax using a specialized high-resolution 3D printer. It is then put in a container where liquid plaster is poured in around it. When the plaster sets, the wax is melted out in a furnace, and the remaining plaster becomes the mold.

Molten Gold is poured into this mold and set to harden. The plaster is broken away, revealing your new product. The product is then carefully cleaned and hand-polished to give it the trademark Gold luster. Please be aware that polishing can wear down or fill in very fine details and edges. Polishing also removes a bit of material from your product in order to smooth it out, so the exact volume may be slightly smaller than that of your digital model.

#19

They use different processes for each metal-

To build steel models, special 3D printers deposit small drops of glue onto layers of stainless steel powder, one layer at a time, until the print is complete. We carefully remove these models from the printer. At this stage of the process, the objects are very fragile, similar to wet sand. The models then go through an infusion process that replaces the glue with bronze, creating a full metal product. Models are then processed to achieve your desired finish, sprayed with a sealant, and shipped to you.

Gold models are 3D printed using a complex five-step process. First, the model is printed in wax using a specialized high-resolution 3D printer. It is then put in a container where liquid plaster is poured in around it. When the plaster sets, the wax is melted out in a furnace, and the remaining plaster becomes the mold.

Molten Gold is poured into this mold and set to harden. The plaster is broken away, revealing your new product. The product is then carefully cleaned and hand-polished to give it the trademark Gold luster. Please be aware that polishing can wear down or fill in very fine details and edges. Polishing also removes a bit of material from your product in order to smooth it out, so the exact volume may be slightly smaller than that of your digital model.

To build steel models, special 3D printers deposit small drops of glue onto layers of stainless steel powder, one layer at a time, until the print is complete. We carefully remove these models from the printer. At this stage of the process, the objects are very fragile, similar to wet sand. The models then go through an infusion process that replaces the glue with bronze, creating a full metal product. Models are then processed to achieve your desired finish, sprayed with a sealant, and shipped to you.

Gold models are 3D printed using a complex five-step process. First, the model is printed in wax using a specialized high-resolution 3D printer. It is then put in a container where liquid plaster is poured in around it. When the plaster sets, the wax is melted out in a furnace, and the remaining plaster becomes the mold.

Molten Gold is poured into this mold and set to harden. The plaster is broken away, revealing your new product. The product is then carefully cleaned and hand-polished to give it the trademark Gold luster. Please be aware that polishing can wear down or fill in very fine details and edges. Polishing also removes a bit of material from your product in order to smooth it out, so the exact volume may be slightly smaller than that of your digital model.

In the gold, it's just making a master and the rest is the age old method. Very cool.

The steel is 'space age'. Might not be as strong as real steel, but probably a lot stronger than what I was thinking the process was. Again, very cool. I, like probably every tank builder here has dreams of getting sprockets and track links in metal for whatever we desire. That's always the brick wall for a scratch design, workable tracks that'll stand up to the punishment. Traditional methods of alloy casting is beyond most and even the hardest resins or ABS won't stand up once you get smaller than a Pz III link.

Thanks for that description.

#20

#21

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Grande Prairie,

AB, CANADA

Posts: 8,976

Likes: 0

Received 4 Likes

on

4 Posts

A little expensive, but isn't this a great development. Ordering exaclty what you need, I have purchased the periscope guards and the jerry can racks. I'll post pictures when they arrive.

#22

I sent a message to RanchRX as well asking if he would be interested in up scaling all his 1/35 parts for the M50/M51. His parts are nice!!!

#24

Senior Member

Thread Starter

Join Date: Nov 2006

Location: Grande Prairie,

AB, CANADA

Posts: 8,976

Likes: 0

Received 4 Likes

on

4 Posts

When I contact him and Mike their replies were quick and absolutely yes. I micro'd a Tamiya jerry can in 1/16 scale, and got a reply from him in a couple of days it could now be purchased. When you think about it why wouldn't they. Maybe they hadn't realized the demand in 1/16 scale. If all of us are now asking for parts I guess they know we are out here now!!!

#25

I invited RanchRx to take a look at this thread and our tank forum. Gave him the links. Maybe he will stop by???