Future Arriving or Losing the Past?

#1

Senior Member

Thread Starter

Join Date: Nov 2004

Location: minneapolis,

MN

Posts: 386

Likes: 0

Received 0 Likes

on

0 Posts

3D printing is coming on fast and strong... learn to draw, design a part and have it printed.

Will the ability to carve, shape, assemble, solder, use a lathe, mill, Dremel, etc. become a thing of the past? Many parts can be made by hand - maybe slow and tedious, but making a working drawing can be slow and tedious, too.

Anyway, I think the eventual reduction of manual scratch-building in our modeling hobbies would be a bit sad.

Will the ability to carve, shape, assemble, solder, use a lathe, mill, Dremel, etc. become a thing of the past? Many parts can be made by hand - maybe slow and tedious, but making a working drawing can be slow and tedious, too.

Anyway, I think the eventual reduction of manual scratch-building in our modeling hobbies would be a bit sad.

#2

Senior Member

Join Date: Nov 2006

Location: Grande Prairie,

AB, CANADA

Posts: 8,976

Likes: 0

Received 4 Likes

on

4 Posts

I tend to agree with you. .

Like all advances, there is a sadness for the art and skills left behind, and unfortunately "left behind" is exactly is happening.

3D printing is also changing marketing strategies. Buy directly from the designer through the web based manufacturers( Shapeways)

Like all advances, there is a sadness for the art and skills left behind, and unfortunately "left behind" is exactly is happening.

3D printing is also changing marketing strategies. Buy directly from the designer through the web based manufacturers( Shapeways)

#3

I believe those that can scratch build will continue to do so but the 3-D printing will draw more new blood into the hobby just for the fact they are not able to or take the time to scratch build.

3-D Printing is just another tool available for those that can afford and want to excel in the hobby... most certainly will not grandfather those with the skills to do something different.

Jeff

3-D Printing is just another tool available for those that can afford and want to excel in the hobby... most certainly will not grandfather those with the skills to do something different.

Jeff

#4

It's just another tool in the box, bringing more flexilbilty to modelers.

3D printing won't replace the use of photo-etch, etc since some details in scale are just tool small to be programmed or rendered. You'll never print an antenna or tarp.

As a sculptor, I can produce a Michael Wittman in U-boat leathers in any scale from 1/48 and up with little effort. You know what I can't sculpt? His binoculars. It will literally take me as long to scratch build a set of scale binoculars as it would to do the rest of the master. I'm just finishing up a 1/16 tanker head and the most time consuming part has been the stooooopid goggles.

Even the best builders have trouble with bolt patterns, etc. In scale any slight lack of precision in placement is apparent, this is where this 3D printing shines.

The other, other side is look at all the 3D printed fuel drums. Nice right? How many fuel drums do you see in ref photos that have no dents? Randon dents are hard to design into something, but easy to add after, so modeling skill will always be a part of the equation.

3D printing won't replace the use of photo-etch, etc since some details in scale are just tool small to be programmed or rendered. You'll never print an antenna or tarp.

As a sculptor, I can produce a Michael Wittman in U-boat leathers in any scale from 1/48 and up with little effort. You know what I can't sculpt? His binoculars. It will literally take me as long to scratch build a set of scale binoculars as it would to do the rest of the master. I'm just finishing up a 1/16 tanker head and the most time consuming part has been the stooooopid goggles.

Even the best builders have trouble with bolt patterns, etc. In scale any slight lack of precision in placement is apparent, this is where this 3D printing shines.

The other, other side is look at all the 3D printed fuel drums. Nice right? How many fuel drums do you see in ref photos that have no dents? Randon dents are hard to design into something, but easy to add after, so modeling skill will always be a part of the equation.

#5

To me, nothing is more fun than scratch building. PayPal and opening a box costs less and takes less time than scratch building, but the pleasure I get from building something that isn't available as a kit or RTR is priceless, nothing else evens comes close.

However, there are some details about scratch building that I think I could live without if items like this become available in 1/16. WOW !

rex

However, there are some details about scratch building that I think I could live without if items like this become available in 1/16. WOW !

rex

#6

Join Date: Aug 2011

Location: Cambridge ON, CANADA

Posts: 1,063

Likes: 0

Received 0 Likes

on

0 Posts

learning the CAD curve will be a lot more daunting than most expect. For us scratch builders I am thinking the 3D printing will just become another tool to use. I highly doubt the vast majority of people will go through the time and expense of being able to 3D print.

#7

I agree with Freaky, as a sort of graphics guy in our promotional company using CorelDraw and Illustrator programs I can tell you that the rendering in 3D is a tough, tough thing to master. BUT, that is only 1/2 the equation. Once you have it rendered there are parameters that you must do to make it 3D printer ready and that is another whole new learning experience. Then there is the cost to do it which we all know will come down with time but right now can be a little steep from beginningto end.

All that being said there are some guys on here starting to make parts so it will be interesting to watch. I personally am looking into it myself as though I love scratch building there are a lot of things that would just be easier and better done with a 3D printer...

All that being said there are some guys on here starting to make parts so it will be interesting to watch. I personally am looking into it myself as though I love scratch building there are a lot of things that would just be easier and better done with a 3D printer...

#8

Anyone who's feeling daunted by CAD should check out OPENSCAD

I had no CAD experience and was able to build things within a few hours of downloading the program (there's plenty of tutorials). The real beauty is that it is one of the easiest programs for making printable objects.

I don't think 3D printers will kill off scratch building but it will allow those people who don't have the skill/time to scratch build parts to be able to build custom tanks.

I had no CAD experience and was able to build things within a few hours of downloading the program (there's plenty of tutorials). The real beauty is that it is one of the easiest programs for making printable objects.

I don't think 3D printers will kill off scratch building but it will allow those people who don't have the skill/time to scratch build parts to be able to build custom tanks.

#10

Senior Member

Join Date: Nov 2006

Location: Grande Prairie,

AB, CANADA

Posts: 8,976

Likes: 0

Received 4 Likes

on

4 Posts

To me, nothing is more fun than scratch building. PayPal and opening a box costs less and takes less time than scratch building, but the pleasure I get from building something that isn't available as a kit or RTR is priceless, nothing else evens comes close.

However, there are some details about scratch building that I think I could live without if items like this become available in 1/16. WOW !

rex

However, there are some details about scratch building that I think I could live without if items like this become available in 1/16. WOW !

rex

In thinking this through, perhaps this will actually encourage scratch building. Building a tank with Styrene card is not that daunting if you can get all the hatches and persicopes etc, printed in 3D. Maybe it wlil have the opposite effect and open the door to creativity.

For myself personally, this is one of the things I am really looking at learning when I retire from my real job in a few months. It will be nice to dive in, learn the software and see if I can work with this technology, Woz's comments give me hope, but I am just happy to know there is a growing number of people who are capable of generating the parts we need. Even if I fall flat on my face in the design part, I will be happy to pick myself up and order parts from others.!!!!. I bought a couple of WOZ's 3 piece transmission covers and coldn't be happier with them.

I think the real money is in the design file. instead of actually buying the made part I can see paying for the file and printing them out on you own machine. However some of the machines being used on Shapeways are abviously high end 150K printers. Out of scope for the hobbyist

Last edited by YHR; 11-28-2014 at 10:02 AM.

#11

From a different perspective I'm not certain what the effect of 3D printing will be on my primary scale of 1:10.

Perhaps the rendering of master patterns for casting parts could stand to be improved. Even more uncertain

regarding 3D printing in metal that was mentioned, I've read that is a metal sintering process but I also doubt

that it would be anywhere close to a process a hobbyist could afford in the foreseeable future.

I'll probably rely on my slow old fashioned ways of making things for some time to come.

Jerry

Perhaps the rendering of master patterns for casting parts could stand to be improved. Even more uncertain

regarding 3D printing in metal that was mentioned, I've read that is a metal sintering process but I also doubt

that it would be anywhere close to a process a hobbyist could afford in the foreseeable future.

I'll probably rely on my slow old fashioned ways of making things for some time to come.

Jerry

#12

Join Date: Aug 2011

Location: Cambridge ON, CANADA

Posts: 1,063

Likes: 0

Received 0 Likes

on

0 Posts

From a different perspective I'm not certain what the effect of 3D printing will be on my primary scale of 1:10.

Perhaps the rendering of master patterns for casting parts could stand to be improved. Even more uncertain

regarding 3D printing in metal that was mentioned, I've read that is a metal sintering process but I also doubt

that it would be anywhere close to a process a hobbyist could afford in the foreseeable future.

I'll probably rely on my slow old fashioned ways of making things for some time to come.

Jerry

Perhaps the rendering of master patterns for casting parts could stand to be improved. Even more uncertain

regarding 3D printing in metal that was mentioned, I've read that is a metal sintering process but I also doubt

that it would be anywhere close to a process a hobbyist could afford in the foreseeable future.

I'll probably rely on my slow old fashioned ways of making things for some time to come.

Jerry

#13

I don't have a feeling for how large or small a metal printer could be made but sintering temps for steel or even iron have to be pretty high. I remember a fellow I worked with at Varian in the 1970s; a Swiss born metallurgist who used to come to our facility once a week made the suggestion that I consider having tracks made by sintered iron. Made the suggestion but never provided a practical

solution to having it done. Never followed up on it as my naive perception of the methodology at the time was that it was expensive beyond my means. Plus I didn't want to approach anyone about making tracks just to be laughed at. The only parts I was aware of back then were sintered iron cylinders for tuning electrical coils and torroid cores.

Jerry

solution to having it done. Never followed up on it as my naive perception of the methodology at the time was that it was expensive beyond my means. Plus I didn't want to approach anyone about making tracks just to be laughed at. The only parts I was aware of back then were sintered iron cylinders for tuning electrical coils and torroid cores.

Jerry

#14

3d printing at the moment has a few drawbacks and restrictions by far the best quality parts you will find are made on machines far outside the reach of your average modeller, cheaper machines don’t offer the quality that most will want and the cost of these machines are not going to fall anything like as fast as some people dream for instance look at computers.

Software is a problem that you must use to make a part in the first place if you can’t build a part on a computer then you can’t print the part and obviously the better the software the better the part I can see 3d printing taking another 10 years before it will be common practice to use them and then I can still see a place for model kits, just how many people are going to spend hundreds of hours designing a model kit.

As I understand it making parts in printed metal will never fully take over casting metal the strength and cost per unit will prevent this

Software is a problem that you must use to make a part in the first place if you can’t build a part on a computer then you can’t print the part and obviously the better the software the better the part I can see 3d printing taking another 10 years before it will be common practice to use them and then I can still see a place for model kits, just how many people are going to spend hundreds of hours designing a model kit.

As I understand it making parts in printed metal will never fully take over casting metal the strength and cost per unit will prevent this

#16

a. Can't see if it has a memory card slot which means it needs to be plugged into you PC when printing and if your PC has a fit, goes into sleep it may effect the print.

b. Filament cartridges restricts the size of the reel you can use which may end up costing you more . Just did a quick google search and Davinci 600g reel is £32 and a nonbranded 1kg reel is £25 (the 1kg reel won't fit in the Davinci)

#17

Senior Member

Thread Starter

Join Date: Nov 2004

Location: minneapolis,

MN

Posts: 386

Likes: 0

Received 0 Likes

on

0 Posts

It's $2000, but looks pretty amazing. Anybody familiar with this....

https://www.lulzbot.com/products/lul...z-4-3d-printer

Still, I can't imagine I would ever master the drawing software to make detail parts.

What's needed is very simple, intuitive software.

Or maybe go the 3D scanner route...

https://www.indiegogo.com/projects/t...orm-3d-scanner

http://www.nextengine.com/

https://www.lulzbot.com/products/lul...z-4-3d-printer

Still, I can't imagine I would ever master the drawing software to make detail parts.

What's needed is very simple, intuitive software.

Or maybe go the 3D scanner route...

https://www.indiegogo.com/projects/t...orm-3d-scanner

http://www.nextengine.com/

Last edited by danlrc; 11-30-2014 at 06:23 AM.

#18

Member

Join Date: Mar 2013

Location: Roswell, GA

Posts: 91

Likes: 0

Received 0 Likes

on

0 Posts

Just had a quick look and I think it looks OK but two things concern me-

a. Can't see if it has a memory card slot which means it needs to be plugged into you PC when printing and if your PC has a fit, goes into sleep it may effect the print.

b. Filament cartridges restricts the size of the reel you can use which may end up costing you more . Just did a quick google search and Davinci 600g reel is £32 and a nonbranded 1kg reel is £25 (the 1kg reel won't fit in the Davinci)

a. Can't see if it has a memory card slot which means it needs to be plugged into you PC when printing and if your PC has a fit, goes into sleep it may effect the print.

b. Filament cartridges restricts the size of the reel you can use which may end up costing you more . Just did a quick google search and Davinci 600g reel is £32 and a nonbranded 1kg reel is £25 (the 1kg reel won't fit in the Davinci)

What about resolution? How much detail can one get with .1mm?

Cheers, Joe

#19

0.1mm layer is as good as Shapeways. The Lulzbot is 0.75mm which is as good as I've seen anywhere (even high end industrial machines).

But you also have to take into acount the nozzle size-

0.4mm is standard. The Lulzbot is 0.35mm and Shapeways print at 0.2mm down to 0.1mm.

My printer has a 0.4mm nozzle but I'm changing one nozzle to 0.2mm (it's a dual extruder).

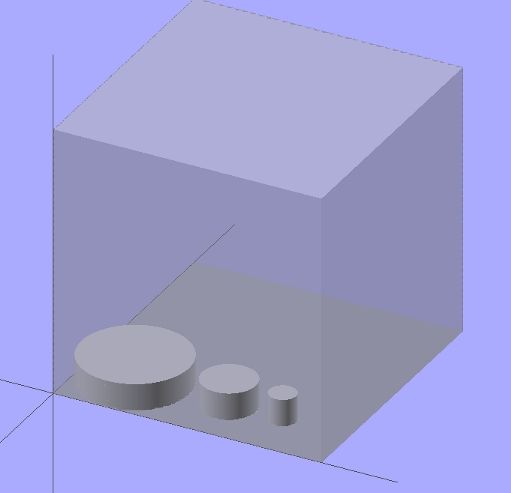

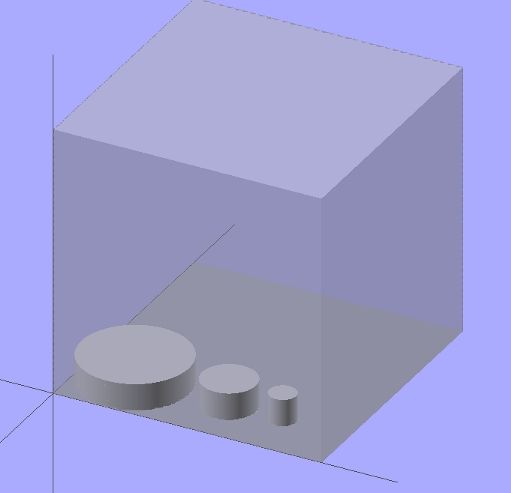

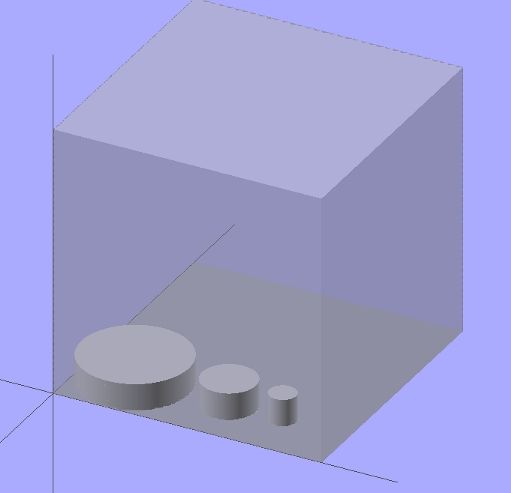

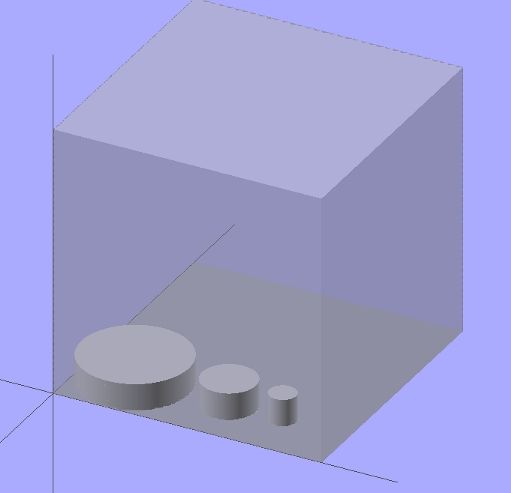

To give you an idea of the sizes I'm talking about the box in the image below is a 1mm cube and the cylinders are 0.4, 0.2 and 0.1mm (all 0.1mm high)

But you also have to take into acount the nozzle size-

0.4mm is standard. The Lulzbot is 0.35mm and Shapeways print at 0.2mm down to 0.1mm.

My printer has a 0.4mm nozzle but I'm changing one nozzle to 0.2mm (it's a dual extruder).

To give you an idea of the sizes I'm talking about the box in the image below is a 1mm cube and the cylinders are 0.4, 0.2 and 0.1mm (all 0.1mm high)

#20

Member

Join Date: Mar 2013

Location: Roswell, GA

Posts: 91

Likes: 0

Received 0 Likes

on

0 Posts

0.1mm layer is as good as Shapeways. The Lulzbot is 0.75mm which is as good as I've seen anywhere (even high end industrial machines).

But you also have to take into acount the nozzle size-

0.4mm is standard. The Lulzbot is 0.35mm and Shapeways print at 0.2mm down to 0.1mm.

My printer has a 0.4mm nozzle but I'm changing one nozzle to 0.2mm (it's a dual extruder).

To give you an idea of the sizes I'm talking about the box in the image below is a 1mm cube and the cylinders are 0.4, 0.2 and 0.1mm (all 0.1mm high)

But you also have to take into acount the nozzle size-

0.4mm is standard. The Lulzbot is 0.35mm and Shapeways print at 0.2mm down to 0.1mm.

My printer has a 0.4mm nozzle but I'm changing one nozzle to 0.2mm (it's a dual extruder).

To give you an idea of the sizes I'm talking about the box in the image below is a 1mm cube and the cylinders are 0.4, 0.2 and 0.1mm (all 0.1mm high)

#22

Member

Join Date: Mar 2013

Location: Roswell, GA

Posts: 91

Likes: 0

Received 0 Likes

on

0 Posts

#23

I think they mean it can print PLA but they don't sell PLA cartridges. Any printer that can print ABS can also print PLA. PLA prints at a lower temp, doesn't need a hot plate and is less likely to clog the heads.

#24

If you are going to 3D print then you have to spend a few extra bucks to get a good printer. Get a Makerbot, they have awesome service, good machines, and lots of options. They are probably the top 3D printer manufacturer and for a reason. All parts I have seen printed on Makerbots are flawless and the software is nice since they upgraded it. They also have a nice 3D scanner but it is kinda expensive for what it does.

3D printing is nice, but it is hard to perfect. First, even at .1mm resolution you will always have lines unless you sand them or vapor bath the parts. Vapor bathing will also strengthen the part by melding the seams together, but can effect small parts adversely. Second is the design aspect... Software is pretty easy to come by and some open source software will make that free... but printing these guys can be a pain. The best thing I see the printers being used for now (by personal builders, not just tankers but others) is reverse molds. Then you can use the molds for resin/aluminum/whatever casting. There is a nice video online of a guy casting aluminum from a 3D printed part. I think it was called Lost PLA casting or something close. You do also have to account for the materials expanding or shrinking in the process too.

I love 3D printers, but I agree with the other guys saying it is just another tool in the box. It may be a very valued tool, and used by some more than others, but by no means a DIY killer yet.

3D printing is nice, but it is hard to perfect. First, even at .1mm resolution you will always have lines unless you sand them or vapor bath the parts. Vapor bathing will also strengthen the part by melding the seams together, but can effect small parts adversely. Second is the design aspect... Software is pretty easy to come by and some open source software will make that free... but printing these guys can be a pain. The best thing I see the printers being used for now (by personal builders, not just tankers but others) is reverse molds. Then you can use the molds for resin/aluminum/whatever casting. There is a nice video online of a guy casting aluminum from a 3D printed part. I think it was called Lost PLA casting or something close. You do also have to account for the materials expanding or shrinking in the process too.

I love 3D printers, but I agree with the other guys saying it is just another tool in the box. It may be a very valued tool, and used by some more than others, but by no means a DIY killer yet.