1/6 Scale Sherman T48 Tracks - Delrin Injection Molded - Spyker Workshop

#1

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

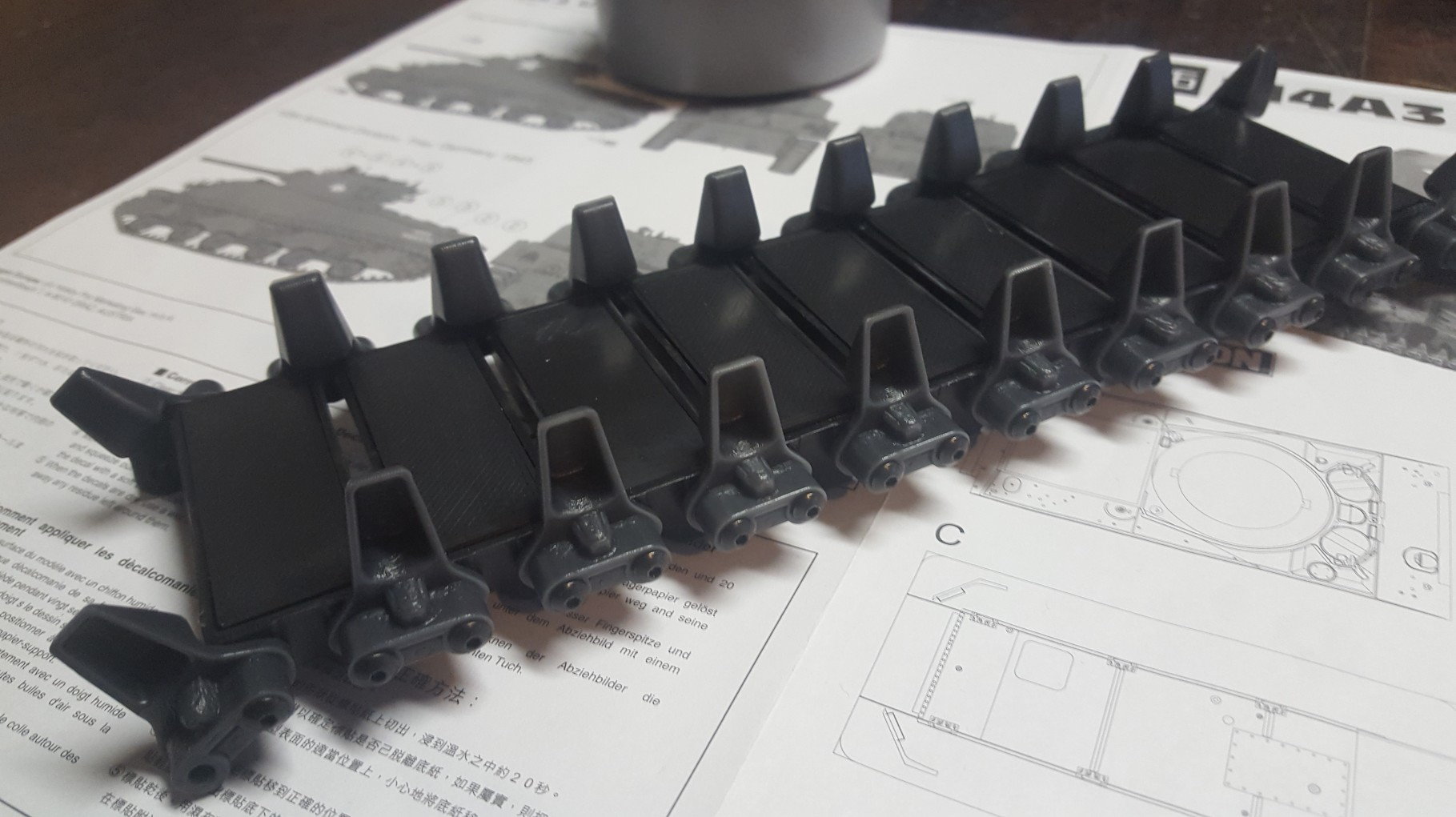

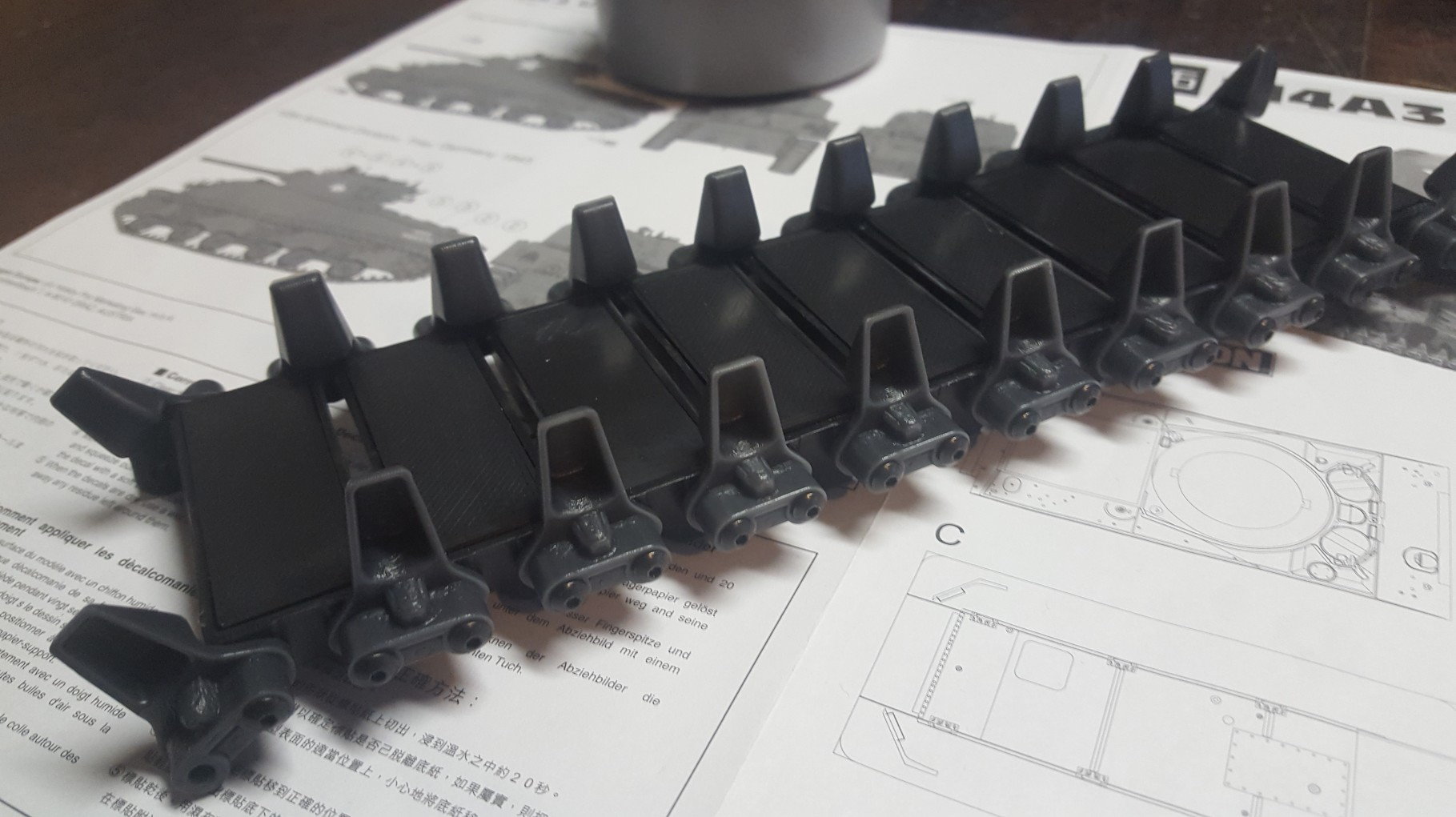

Hey everyone Ryan from Spyker Workshop here, I have been hard at work on a new set of molds for the 1/6 Scale Sherman Tank. The molds are for the T48 style tracks. I will be producing kits for sale for these once I get everything finished. They will be injection molded in Dupont Acetal Delrin which is a ridiculously strong material! I'm cutting all the molds on my CNC mill, and injection molding them all myself in house.

The track pad is made up of 2 pieces to make it hollow, light-weight and easy to mold. The 2 pieces are held together by the same screws that are used to pin the links together. I will be using 4-40 sized button head hex screws in black oxide stainless steel, so they will not rust, and they will look SUPER scale!

I designed a really unique "pin puller" device on my injection machine that draws pins out of the mold after injection to create all the holes in the track pad ready to be screwed in. However the end-connectors holes have to be enlarged with a 1/8" drill bit. I will be including a 3d printed jig that aids in holding the connectors in place while you drill them. (OR option to buy fully assembled RTR tracks from us)

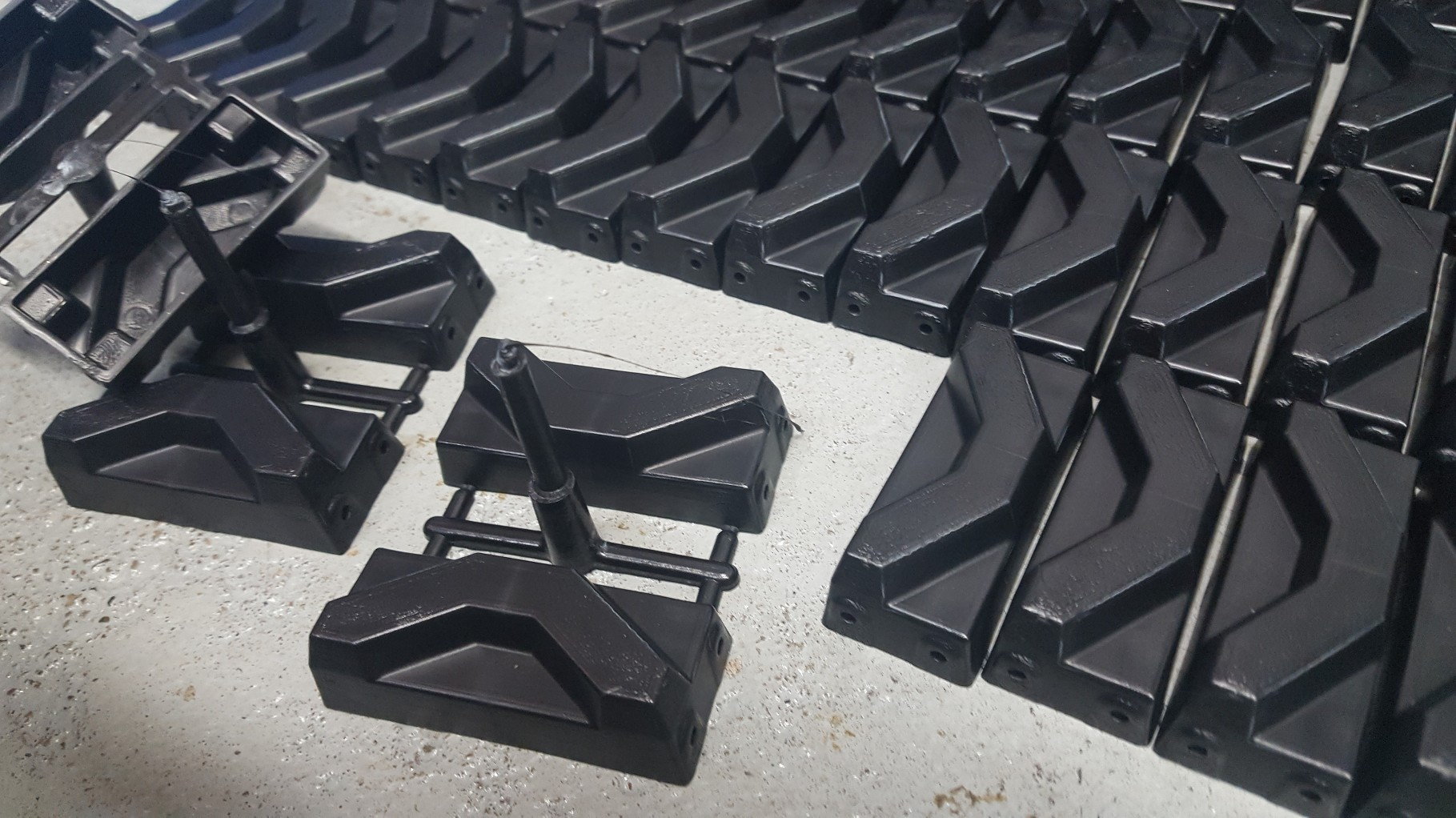

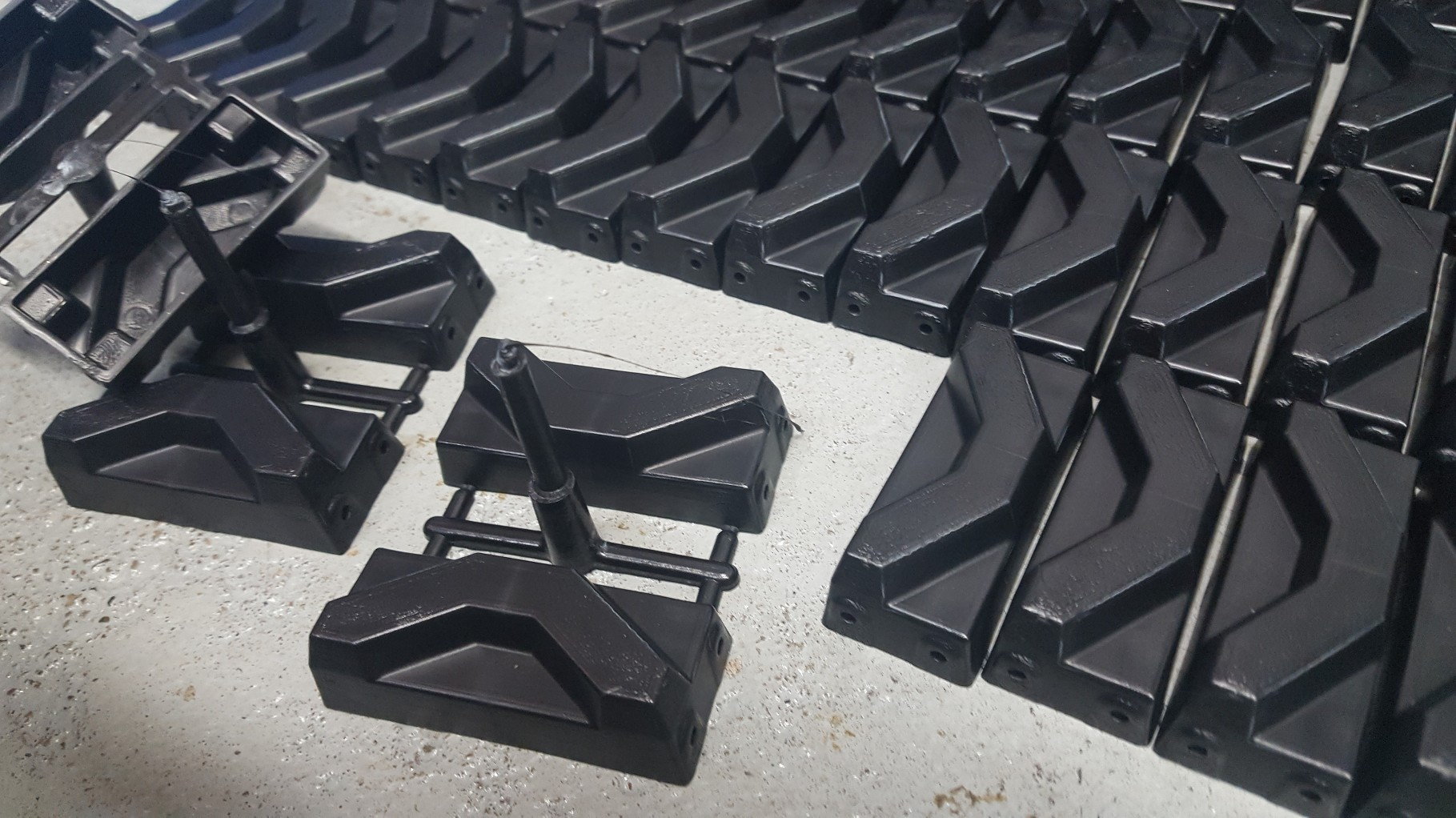

I have one of the molds done right now and just finished doing the first injection run of 800 end connectors (enough for about 2 tanks worth)

The advantages my tracks will have:

- 100% water and rust proof

- Extremely light weight (hollow track pads) (Will not require as much motor power or battery life to drive around)

- STRONG! Delrin is an extremely durable material normally used in gears and bushing

- High detail fully captured in the molds including the wedge, gap, screw and nut!

- Button head hex screws look extremely to scale while providing a strong adjustable connection

What do you think about these?

My website here: https://spykerworkshop.com

I have done another 1/6th scale track here: https://spykerworkshop.com/shop/6sca.../halftrackkit/

The track pad is made up of 2 pieces to make it hollow, light-weight and easy to mold. The 2 pieces are held together by the same screws that are used to pin the links together. I will be using 4-40 sized button head hex screws in black oxide stainless steel, so they will not rust, and they will look SUPER scale!

I designed a really unique "pin puller" device on my injection machine that draws pins out of the mold after injection to create all the holes in the track pad ready to be screwed in. However the end-connectors holes have to be enlarged with a 1/8" drill bit. I will be including a 3d printed jig that aids in holding the connectors in place while you drill them. (OR option to buy fully assembled RTR tracks from us)

I have one of the molds done right now and just finished doing the first injection run of 800 end connectors (enough for about 2 tanks worth)

The advantages my tracks will have:

- 100% water and rust proof

- Extremely light weight (hollow track pads) (Will not require as much motor power or battery life to drive around)

- STRONG! Delrin is an extremely durable material normally used in gears and bushing

- High detail fully captured in the molds including the wedge, gap, screw and nut!

- Button head hex screws look extremely to scale while providing a strong adjustable connection

What do you think about these?

My website here: https://spykerworkshop.com

I have done another 1/6th scale track here: https://spykerworkshop.com/shop/6sca.../halftrackkit/

Last edited by TheGreatestMoo; 08-20-2018 at 09:30 PM.

#3

I'm sure those molds cost a pretty penny. Nice looking tracks though....

#4

I was just Machining some Delrin this morning and I can confirm that it is indeed a very tough and durable material. We use it in the gauges that we make for the big three auto companies and they demand long life from their equipment and Delrin provides that. Great choice of material. Those tracks should last longer than the tank itself.

#5

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

#6

Wow, this is so cool.

#8

Not only Sherman tracks... down the road STUART TRACKS too! If that injection material is as strong, light, and hard as Crius said, it'd be perfect for not only tracks, but suspension housings, roadwheels, idlers, etc.!

Mike

Mike

Last edited by Old MSgt; 08-21-2018 at 02:03 PM.

#9

Join Date: Nov 2010

Location: HamiltonWaikato, NEW ZEALAND

Posts: 937

Likes: 0

Received 78 Likes

on

55 Posts

Hey Moo

Really nice. Might pay to ask Armortek to post this on their site, too.

"Do I have to buy the tank to need your tracks? Would it be crazy just to have the tracks.... drooling." - Not a bad idea - what would a set of 12 links cost?

Mal

Really nice. Might pay to ask Armortek to post this on their site, too.

"Do I have to buy the tank to need your tracks? Would it be crazy just to have the tracks.... drooling." - Not a bad idea - what would a set of 12 links cost?

Mal

#11

Spyker-

Excellent work! Those end connectors are the bee's knee's (ie very cool). Correct me if I'm wrong - but these are for the Dragon Sherman correct? I not sure if they'd hold up with a heavy Armortek Sherman - but heck I'd test a set if you want! The tracks are the weakest link of the Dragon Sherman - and these would be a huge improvement! Very impressive work all around. It would be much easier to make a light duty RC version of the Dragon Sherman with these tracks!

I agree with Mike - there are a ton of people asking for improved tracks for the 21C Stuart! This design/material would be perfect (with a different pad pattern) - LOL

Will this small machine do rubber materials? You could try insert molding rubber onto a metal base track link - that would be awesome to make the smooth rubber block links for the Sherman and Stuart.

Have you considered molding parts for your Scorpion or Spyker Kat vehicle (besides tracks)? You could reduce the 3D printing cost and make stronger parts molding them.

Very impressive to get all that CAD/CAM done with Fusion as well. That is an major accomplishment in itself! Would you consider making a tutorial on the CAM part of Fusion?

Outstanding!

Bob

Excellent work! Those end connectors are the bee's knee's (ie very cool). Correct me if I'm wrong - but these are for the Dragon Sherman correct? I not sure if they'd hold up with a heavy Armortek Sherman - but heck I'd test a set if you want! The tracks are the weakest link of the Dragon Sherman - and these would be a huge improvement! Very impressive work all around. It would be much easier to make a light duty RC version of the Dragon Sherman with these tracks!

I agree with Mike - there are a ton of people asking for improved tracks for the 21C Stuart! This design/material would be perfect (with a different pad pattern) - LOL

Will this small machine do rubber materials? You could try insert molding rubber onto a metal base track link - that would be awesome to make the smooth rubber block links for the Sherman and Stuart.

Have you considered molding parts for your Scorpion or Spyker Kat vehicle (besides tracks)? You could reduce the 3D printing cost and make stronger parts molding them.

Very impressive to get all that CAD/CAM done with Fusion as well. That is an major accomplishment in itself! Would you consider making a tutorial on the CAM part of Fusion?

Outstanding!

Bob

Last edited by RC_BobM; 08-21-2018 at 07:27 PM.

#12

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

Yeah I'm making these for the Dragon 1/6 Sherman (which is on the way in the mail to me, I was doing these tracks for someone and now it got ME to buy this tank...) Depending on how well these sell I could make different track pads for the Sherman, looks like there was MANY made for it. I will be doing at least some RC conversions too, most 3D printed. Not sure what until I get my kit.

I think these tracks should be able to handle anything. My Spyker KAT tracks felt unbreakable in tests I did to them, and these Sherman ones are much more beefy. How heavy do the Armortek ones get? I will be doing a test stress shot in my video I make once they are ready.

This injection machine is pretty limited to do much else on my KAT, only 30 grams max per shot. For my Scorpion parts I tried to mold ABS but it will not work without a heated mold, which also means cooling the mold to get the part out, A LOT involved in that... Delrin however doesn't seem to care about the mold temperature, the castings come out very high quality, its a really weird material.

I doubt I will try to do any rubber injection. Don't all the FOA ones have that already?

Someone had me try to mold the end connectors in a dark grey, since Delrin can't be painted. The dark grey ones offer a contrast to the track pad since the RL ones were steel. I was able to mix white and black Delrin together and it came out really nice. I will be offering black or dark gray end connectors on my store so you can choose which you want, both look really cool!

I think these tracks should be able to handle anything. My Spyker KAT tracks felt unbreakable in tests I did to them, and these Sherman ones are much more beefy. How heavy do the Armortek ones get? I will be doing a test stress shot in my video I make once they are ready.

This injection machine is pretty limited to do much else on my KAT, only 30 grams max per shot. For my Scorpion parts I tried to mold ABS but it will not work without a heated mold, which also means cooling the mold to get the part out, A LOT involved in that... Delrin however doesn't seem to care about the mold temperature, the castings come out very high quality, its a really weird material.

I doubt I will try to do any rubber injection. Don't all the FOA ones have that already?

Someone had me try to mold the end connectors in a dark grey, since Delrin can't be painted. The dark grey ones offer a contrast to the track pad since the RL ones were steel. I was able to mix white and black Delrin together and it came out really nice. I will be offering black or dark gray end connectors on my store so you can choose which you want, both look really cool!

#13

Naw, the Armortek Sherman weighs WAY too much, 200-225 lbs, compared to the Dragon Sherman or Stuart.

And when the Dragon M4 is made in to rc it gets very hefty too. The drive motor system, steel sprockets, hull and suspension bracings, batteries, etc., really add on the pounds QUICKLY. A lot of areas have to get beefed up.

The FOA Dragon Sherman tracks are very strong because they have a steel frame inside attached to the pins. Even with hard driving I never had one link fail but I don't know how they'd hold up to the weight of the Armortek.

Mike

Last edited by Old MSgt; 08-22-2018 at 03:23 AM.

#14

Join Date: Jul 2018

Posts: 62

Likes: 0

Received 0 Likes

on

0 Posts

Glad to see interest in them already! I find it slightly comical that my request has turned into a personal endeavor. 😂 Usually, people's best work is when a project turns personal. Although, that can also drive a person to perfection as well. I'm really looking forward to the final version.

Making the end connectors grey was a great idea!

Making the end connectors grey was a great idea!

#15

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

I would be curious to see if these tracks can handle 200+ lbs.

I made a 3D printed drill jig, if you order a KIT from me it will include this drill jig, works REALLY well actually, its 100% hands off. The connectors stay in place as you drill them, and it does 2 holes at once. They are cast with a small hole, I was just unable to get the part to release with the proper hole size. I had to taper the mold pins, which made the hole too small, only way I could get them to mold. Its really easy and fast to drill them out though, the drill bit basically self-guides into them and enlarges them slightly. There will be no dirlling needed on the actual track pad.

I made a 3D printed drill jig, if you order a KIT from me it will include this drill jig, works REALLY well actually, its 100% hands off. The connectors stay in place as you drill them, and it does 2 holes at once. They are cast with a small hole, I was just unable to get the part to release with the proper hole size. I had to taper the mold pins, which made the hole too small, only way I could get them to mold. Its really easy and fast to drill them out though, the drill bit basically self-guides into them and enlarges them slightly. There will be no dirlling needed on the actual track pad.

#17

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

I won't know until I see how the first cast comes out of the track mold, I hope I designed everything properly to work flawlessly! The end connector mold I had to tweak 4 times back in the mill before I got the castings to actually eject.

My mill is doing an 8 hour finishing pass right now on the last mold. I need to sand blast them only on visible areas too to try and make the shiny parts release easier. So much goes into these molds! Been cutting this one all day, total of 7 tool changes about around 14 hours cutting time.

I need to come up with prices for the kit also which I'm not sure yet. I will be selling them as "KIT" or "RTR". KIT ones you would need to drill and assemble everything, RTR you would get the tracks fully assembled and ready to install to the Dragon Sherman.

My mill is doing an 8 hour finishing pass right now on the last mold. I need to sand blast them only on visible areas too to try and make the shiny parts release easier. So much goes into these molds! Been cutting this one all day, total of 7 tool changes about around 14 hours cutting time.

I need to come up with prices for the kit also which I'm not sure yet. I will be selling them as "KIT" or "RTR". KIT ones you would need to drill and assemble everything, RTR you would get the tracks fully assembled and ready to install to the Dragon Sherman.

#20

#21

And now we all know why injection molding is so expensive and time consuming...

#22

Looks like you manufacture fine products well designed, I was wondering if you considered about to make tracks for the M41 walker bulldog with the right width.

People used to cut them ( with a lot of hard work) but the latest ones are hollow so there is not where to cut in 3 sections and glue.

It’s well know that Heng Long made wider tracks for at least 5 or 6 mm. I have modified few M41 in the past correcting most of the problems but always had the tracks problem as the sponsons and other parts are easy to modify.

http://www.modelersite.com/en/112303...ved-1-16-scale

Mario

People used to cut them ( with a lot of hard work) but the latest ones are hollow so there is not where to cut in 3 sections and glue.

It’s well know that Heng Long made wider tracks for at least 5 or 6 mm. I have modified few M41 in the past correcting most of the problems but always had the tracks problem as the sponsons and other parts are easy to modify.

http://www.modelersite.com/en/112303...ved-1-16-scale

Mario

#23

#24

Thread Starter

Join Date: Mar 2009

Location: Saint Paul, MN

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

I've been hard at work on the track pad mold, I actually had to re-cut the entire mold a second time to fix some issues I ran into (the part not ejecting from the mold properly) I also changed to only mold the track pads, and the top cover plates I ended up 3d printing and they turned out great!

So I made a video showing off the aspects of the tracks and starting at 21:08 in the video I do some INSANE stress tests... It basically took ~450lbs to break the track check the end of the vid out!

Custom sprocket from my friend, I will be doing my own sprocket upgrade soon, shows the mesh is PERFECT!

So I made a video showing off the aspects of the tracks and starting at 21:08 in the video I do some INSANE stress tests... It basically took ~450lbs to break the track check the end of the vid out!

Custom sprocket from my friend, I will be doing my own sprocket upgrade soon, shows the mesh is PERFECT!

Last edited by TheGreatestMoo; 08-27-2018 at 10:41 PM.

#25

Very Cool