Tamiya FO Panzer IV kit

#1

Thread Starter

Join Date: May 2013

Location: Point of Rocks, MD

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

I was wondering if anyone else would like to see this kit come back? Do you think Tamiya is retooling the line, or is it gone forever? Also is it me or is the aftermarket parts slowly going away? less parts being offered, which tells me that the hobby is also dying?. Thoughts?

#2

IMHO opinion It would be great to see all Tamiya kits back, but with everything updated and improved. Parts with more detail, opening hatches, better elevation, rotation and recoil units and so on, and of course all the flaws ironed.

The Sherman for example came back like 4 times, with upgrades after each comeback. Probably not true, but it is said the molds of some of the kits were shipped to China and the boat is sunk somewhere between Japan and China, hence the stop in production. Some others say it was the low sales what made the production shut off, that, I do believe. Or maybe they are updating the entire line (cross fingers!) who knows.

Replacement parts are indeed unobtainable at most, which lead me to have sitting ducks in the shelves, partially killing my hobby. Not what you expect when you have to invest such a sum in a toy. Some details can be 3D printed, but for example the suspension arms in my PIV are wearing fast, like I have read in this forum several times, so it is better to not to touch it and almost forget I have that tank, so painfully it is, because it was my favourite. https://radindustries.wordpress.com/...anzer-iv-zorn/

The Sherman for example came back like 4 times, with upgrades after each comeback. Probably not true, but it is said the molds of some of the kits were shipped to China and the boat is sunk somewhere between Japan and China, hence the stop in production. Some others say it was the low sales what made the production shut off, that, I do believe. Or maybe they are updating the entire line (cross fingers!) who knows.

Replacement parts are indeed unobtainable at most, which lead me to have sitting ducks in the shelves, partially killing my hobby. Not what you expect when you have to invest such a sum in a toy. Some details can be 3D printed, but for example the suspension arms in my PIV are wearing fast, like I have read in this forum several times, so it is better to not to touch it and almost forget I have that tank, so painfully it is, because it was my favourite. https://radindustries.wordpress.com/...anzer-iv-zorn/

#3

Regarding those PZ IV suspension arms. Seek out someone, probably an artist who makes small castings for jewelry, and see if, using one of the suspension arms as a master, they would cast some copies of it in brass for you.

#4

The issue with those suspension arms is they are made of a too cheap metal with too much play straight from factory, so they wear super fast. You can see the outer wheels don't touch the track almost since day 1 (and if you don't see, slid a piece of paper in between the wheel and the track and you will see how it slides through)... and that goes from bad to worse over time. It can also be noted in the tracks wear, it wears way faster in the inner side of the tracks than in the outer side.

I never remember his exact nick, he was called something like ManchuInf or something like that, he documented this issue in this forum as well. I thought it was caused because of Danvile's playground which seems to grind everything, but I only ran my tank over super clean surfaces and I have the same issue.

It is heart breaking, even more when there are no replacement parts available.

#5

You might be surprised by the cost. I remember, years ago when I was fencing, I wanted some custom grips for my epees. I made a master, molded exactly to my hand, using polymer clay. I took it to a local foundry and had three sand cast copies made in aluminum. They were no more expensive than generic epee pistol grips that I could order from a fencing supply catalog. The work that drives up prices is making the master. Do that part yourself.

The following users liked this post:

Conan_the_Hungarian (05-04-2023)

#7

Rad, Find a guy in your area that can do this for you. Use one of the existing suspension arms as a master and make copies like this. I've poured metal this way. They will take some clean up with a file after they are cast, and you will want to redrill the holes because holes tend to get smaller during casting.

#8

With casting in metal, don't you need to increase the size of the part by like 10% to compensate for shrinkage?

#9

This is getting interesting. The problem of using my own parts as mold is they are already a bit worn.

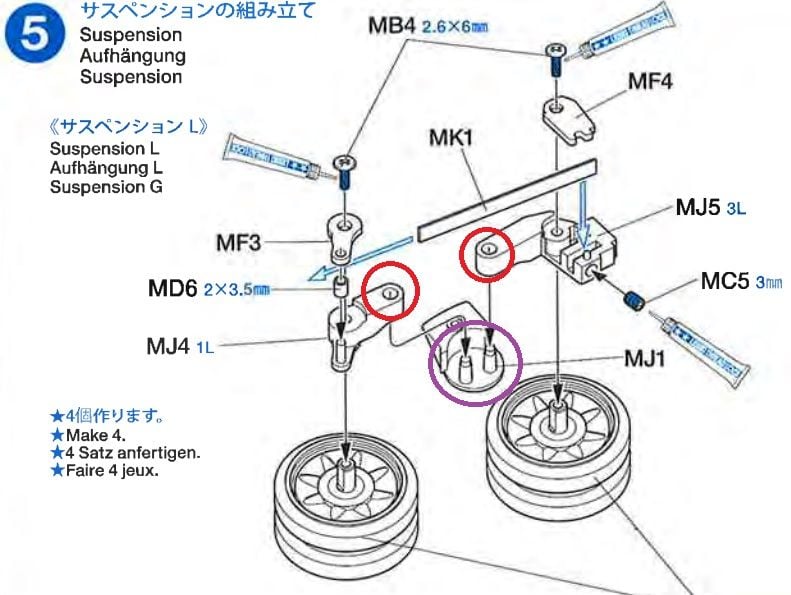

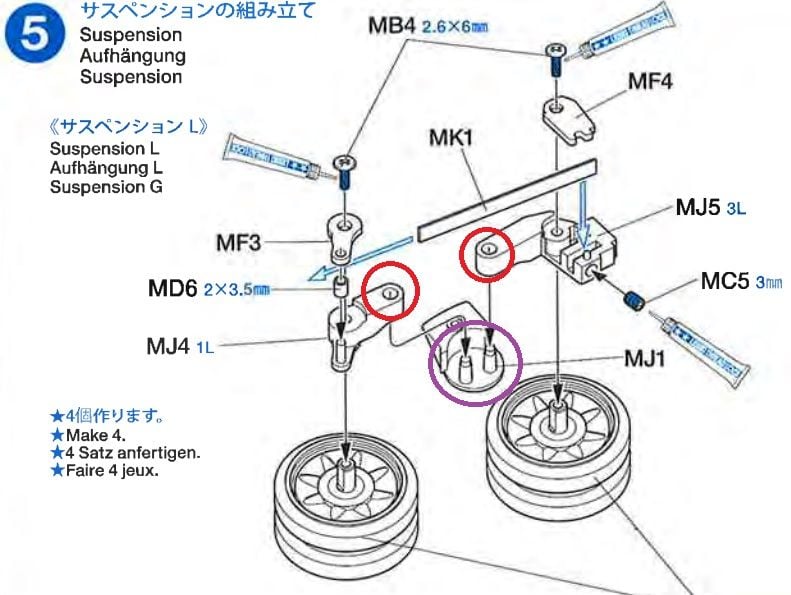

Take a look at the following manual screenshot. The parts I highlighted in red, were round from factory, but they take an oval shape, and the part I highlighted in purple takes a conical shape. I guess you can always machine some sort of brass bushing for the red parts, but so far nobody seems to have a good idea how to fix the purple parts.

No mention those 2,6x6mm bolts are made of a super soft metal and removing them is almost impossible. If you put thread lock on it, you better heat the bolt with a soldering iron.

I replaced those bolts with quality laptop steel bolts, but that size was damn hard to find.

I

Take a look at the following manual screenshot. The parts I highlighted in red, were round from factory, but they take an oval shape, and the part I highlighted in purple takes a conical shape. I guess you can always machine some sort of brass bushing for the red parts, but so far nobody seems to have a good idea how to fix the purple parts.

No mention those 2,6x6mm bolts are made of a super soft metal and removing them is almost impossible. If you put thread lock on it, you better heat the bolt with a soldering iron.

I replaced those bolts with quality laptop steel bolts, but that size was damn hard to find.

I

#10

ZAMAK appears to be a suitable option when it comes to creating your own Cast Parts... It's what I used for making my E-100 Swing Arms to deal with the weight of the Model causing Material Creep on the previously SLA 3D Printed Arms:

ZAMAK flows incredibly well into all nooks and crannies when hot enough ( mine managed to flow through a less than 1mm diameter venting hole causing a bit of a mess in one of my attempts 😑 ) but will at that temperature also rapidly degrade the High Temperature Silicone Mould ( should you go that route ) and necessitate a different approach for things like the Pins on MJ1 the two MJ4/5 hook into.

ZAMAK flows incredibly well into all nooks and crannies when hot enough ( mine managed to flow through a less than 1mm diameter venting hole causing a bit of a mess in one of my attempts 😑 ) but will at that temperature also rapidly degrade the High Temperature Silicone Mould ( should you go that route ) and necessitate a different approach for things like the Pins on MJ1 the two MJ4/5 hook into.

#11

Why use metal? Engineering resin or glass bead infused pla works great.

example, I had the Merkava arms redrawn for my hooben and uploaded them to shapeways and made them there with the glass bead infused pla. I guarantee you I drive that tank harder than you will ever drive your panzer 4 and my Merkava is very likely much heavier than your panzer.

engineering resin is another solution. You just need to find a shop doing that kind of work like JVM3d concepts or battleground models and others. I have collaborated with both of these shops on multipule projects to produce products for myself they later took to market when perfected.

If you really want metal you can even 3d print that on shapeways but after testing both pla and metal arms from shapeways on my Merkava the metal was a waste of money.

You start with a person that can draw cad, send them your old arm and point out what changes need to be made to it and then draw and print test parts till you get it right.

Tamiya has discontinued nearly all their tanks due to lost molds or lack of sails or just because they feel like it.

They claim they are still producing 5 kits.

tiger 1

tiger 2

abrams

centurion

leopard 2

the rest are probably gone forever.

As soon as I learned what tanks were going away that I liked, I stocked up on spare parts like wheels, rubber tires, track, etc etc that will last me the rest of my life I’m sure of that.

example, I had the Merkava arms redrawn for my hooben and uploaded them to shapeways and made them there with the glass bead infused pla. I guarantee you I drive that tank harder than you will ever drive your panzer 4 and my Merkava is very likely much heavier than your panzer.

engineering resin is another solution. You just need to find a shop doing that kind of work like JVM3d concepts or battleground models and others. I have collaborated with both of these shops on multipule projects to produce products for myself they later took to market when perfected.

If you really want metal you can even 3d print that on shapeways but after testing both pla and metal arms from shapeways on my Merkava the metal was a waste of money.

You start with a person that can draw cad, send them your old arm and point out what changes need to be made to it and then draw and print test parts till you get it right.

Tamiya has discontinued nearly all their tanks due to lost molds or lack of sails or just because they feel like it.

They claim they are still producing 5 kits.

tiger 1

tiger 2

abrams

centurion

leopard 2

the rest are probably gone forever.

As soon as I learned what tanks were going away that I liked, I stocked up on spare parts like wheels, rubber tires, track, etc etc that will last me the rest of my life I’m sure of that.

#12

When you consider how blamed awful the suspension on the PZ4 was it might be a better idea to fit the prototype PZ4s suspension which was a torsion bar set up,

This was refused by the purse string holders forcing the fitting of the awful 1/4 elliptic springs on the production tank.

This was refused by the purse string holders forcing the fitting of the awful 1/4 elliptic springs on the production tank.

#13

Herr Durahl and Herr Rich: The pints that Herr Durahl pointed I believe are way too thin and small for being plastic or resin. Even when I treat with special care and love the toys, I don't see those pins lasting if made of plastic.

Herr Jarndice: Fun fact is I considered fitting the prototype suspension on this tank, lol

Hummm... It might be not too hard to cast new parts... Nowadays there are a lot of people with 3D scanners which make an exact copy of the real thing. Once scanned, fixing the wear in those files should be super easy to do... I have to give it a long thought and make numbers.

Herr Jarndice: Fun fact is I considered fitting the prototype suspension on this tank, lol

Hummm... It might be not too hard to cast new parts... Nowadays there are a lot of people with 3D scanners which make an exact copy of the real thing. Once scanned, fixing the wear in those files should be super easy to do... I have to give it a long thought and make numbers.