Invert's Fiberglassing Technique 101

#52

Join Date: Jun 2004

Location: Alice Springs, AUSTRALIA

Posts: 191

Likes: 0

Received 0 Likes

on

0 Posts

Cheers Thomas,

With your FW-190 flap in the videos do you then coat inside each bay with your thinned down left over resin or do you prefer to use sanding sealer so you can paint the inside of the flap? I suppose it doesn't really matter as it's just to seal the wood fibres...Cheers,

Dave

With your FW-190 flap in the videos do you then coat inside each bay with your thinned down left over resin or do you prefer to use sanding sealer so you can paint the inside of the flap? I suppose it doesn't really matter as it's just to seal the wood fibres...Cheers,

Dave

#53

Dave,

I will probably use some thinned down resin. I've used the sanding sealer, and it doesn't give a completely filled and smooth surface on wood unless you put multiple coats on. With thinned resin, I get a smooth surface with one application.

I will probably use some thinned down resin. I've used the sanding sealer, and it doesn't give a completely filled and smooth surface on wood unless you put multiple coats on. With thinned resin, I get a smooth surface with one application.

#54

Tom,is there a certain style of polyester that you use? I found this source http://www.distinctivefabric.com/fab...roduct=SATSHM1

#58

Member

Join Date: Mar 2005

Location: North Canton,

OH

Posts: 31

Likes: 0

Received 0 Likes

on

0 Posts

I used your method last weekend and it turned out great! I recommend wetting the polyester a little and putting into the dryer (on Low) to get the fold wrinkles out. Nice even application of resin!

Thanks Thomas!

Thanks Thomas!

#60

Member

Join Date: Mar 2005

Location: North Canton,

OH

Posts: 31

Likes: 0

Received 0 Likes

on

0 Posts

If you think about it, post some detail pictures of that gun kit. I'm at the stage where I could start putting that in my Pica 190d9.

Thanks again!

Dan

Thanks again!

Dan

#61

ORIGINAL: rsdriver1

If you think about it, post some detail pictures of that gun kit. I'm at the stage where I could start putting that in my Pica 190d9.

Thanks again!

Dan

If you think about it, post some detail pictures of that gun kit. I'm at the stage where I could start putting that in my Pica 190d9.

Thanks again!

Dan

#62

My Feedback: (35)

Join Date: Mar 2002

Location: West Monroe,

LA

Posts: 1,161

Likes: 0

Received 0 Likes

on

0 Posts

First attempt was a failure. 100% Poly, which is more of a fabric than cloth. On my first test plank, when I attempted to pull the poly from the plank, the dried resin and glass cloth both came up with the poly. Not good. Since I had made up two planks, I tried the other. The poly on it, too, was extremely hard to pull away. At this point I'm thinking that if I tried this on a wing, it would probably pull the sheeting away from the ribs, because it is that hard to peel away from the plank. Once I got it removed, the appearance was not all that great. After cleaning it up with sand paper, I could still see the weave of the 3/4 ounce cloth I'm using. I put on two coats of high build primer, but the weave was still visible. I was not happy at how it turned out.

Today, it tried something a tad bit different. The poly I'm using has a satin side to it. I didn't use this side during the first attempt. I made up two more test planks, using the satin side of the cloth.

I call myself doing this by the book. If anyone has any input on what I may be doing wrong, I'm all ears. The poly I'm using appears to be more thick than that in the tutorial, but as long as it's poly, it shouldn't matter, right?

Today, it tried something a tad bit different. The poly I'm using has a satin side to it. I didn't use this side during the first attempt. I made up two more test planks, using the satin side of the cloth.

I call myself doing this by the book. If anyone has any input on what I may be doing wrong, I'm all ears. The poly I'm using appears to be more thick than that in the tutorial, but as long as it's poly, it shouldn't matter, right?

#63

ORIGINAL: yard-dart

First attempt was a failure. 100% Poly, which is more of a fabric than cloth. On my first test plank, when I attempted to pull the poly from the plank, the dried resin and glass cloth both came up with the poly. Not good. Since I had made up two planks, I tried the other. The poly on it, too, was extremely hard to pull away. At this point I'm thinking that if I tried this on a wing, it would probably pull the sheeting away from the ribs, because it is that hard to peel away from the plank. Once I got it removed, the appearance was not all that great. After cleaning it up with sand paper, I could still see the weave of the 3/4 ounce cloth I'm using. I put on two coats of high build primer, but the weave was still visible. I was not happy at how it turned out.

Today, it tried something a tad bit different. The poly I'm using has a satin side to it. I didn't use this side during the first attempt. I made up two more test planks, using the satin side of the cloth.

I call myself doing this by the book. If anyone has any input on what I may be doing wrong, I'm all ears. The poly I'm using appears to be more thick than that in the tutorial, but as long as it's poly, it shouldn't matter, right?

First attempt was a failure. 100% Poly, which is more of a fabric than cloth. On my first test plank, when I attempted to pull the poly from the plank, the dried resin and glass cloth both came up with the poly. Not good. Since I had made up two planks, I tried the other. The poly on it, too, was extremely hard to pull away. At this point I'm thinking that if I tried this on a wing, it would probably pull the sheeting away from the ribs, because it is that hard to peel away from the plank. Once I got it removed, the appearance was not all that great. After cleaning it up with sand paper, I could still see the weave of the 3/4 ounce cloth I'm using. I put on two coats of high build primer, but the weave was still visible. I was not happy at how it turned out.

Today, it tried something a tad bit different. The poly I'm using has a satin side to it. I didn't use this side during the first attempt. I made up two more test planks, using the satin side of the cloth.

I call myself doing this by the book. If anyone has any input on what I may be doing wrong, I'm all ears. The poly I'm using appears to be more thick than that in the tutorial, but as long as it's poly, it shouldn't matter, right?

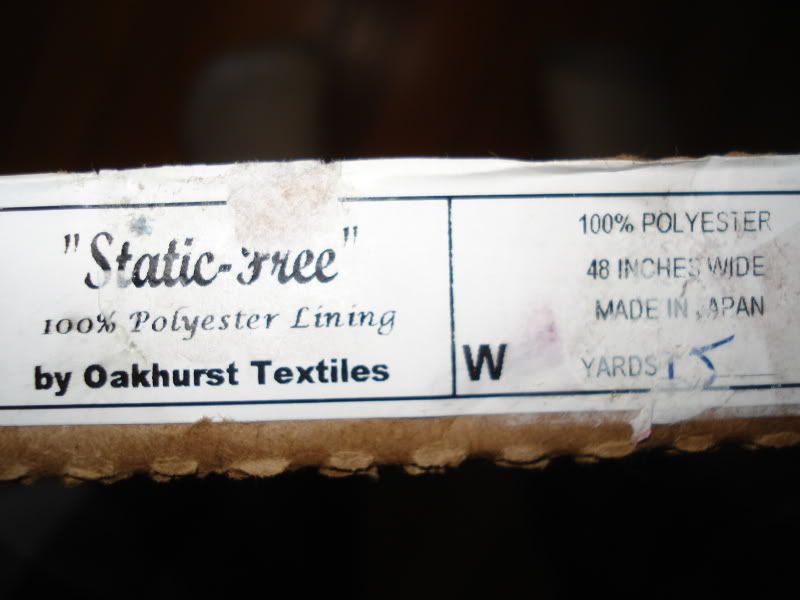

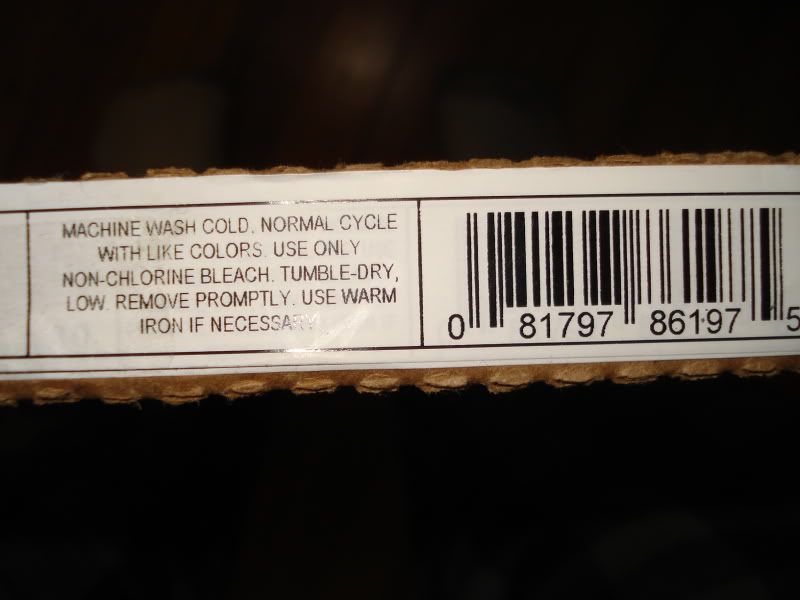

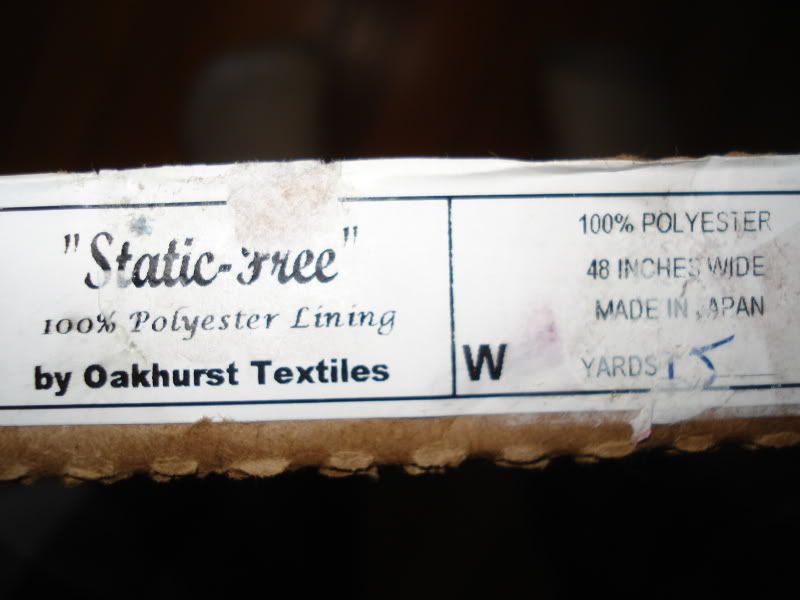

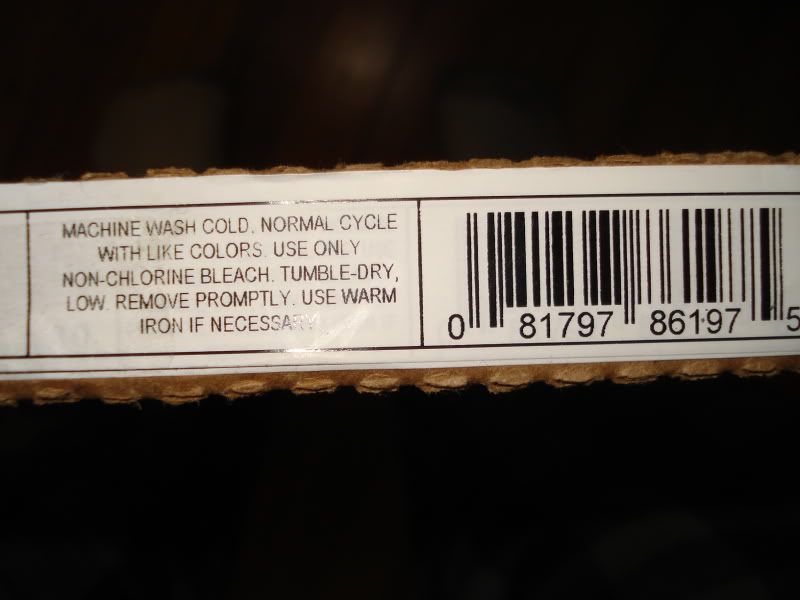

The correct poly cloth should be a solid color (no patterns) and have a wax papery feel to it. The next time i get to a fabric store to pick some up, ill get a photo of the fabric batt and post it for everyone.

#64

My Feedback: (35)

Join Date: Mar 2002

Location: West Monroe,

LA

Posts: 1,161

Likes: 0

Received 0 Likes

on

0 Posts

I'm thinking the same thing. Like I said, what I have is more like fabric, in fact it is fabric. On the other hand, it's 100% Polyester. It definately doesn't have a waxy feel to it. Once the resin dries, this stuff doesn't want to let go. I got this from Hobby Lobby, as the local Walmarts here have gotten rid of their fabric sections. I'm needing to know how to get the right thing. Does the correct material come in a bag/pre-packed package, or is it purchased by the yard? What is the exact description of it as it appears on the package/shelf tag?

#65

ORIGINAL: yard-dart

I'm thinking the same thing. Like I said, what I have is more like fabric, in fact it is fabric. On the other hand, it's 100% Polyester. It definately doesn't have a waxy feel to it. Once the resin dries, this stuff doesn't want to let go. I got this from Hobby Lobby, as the local Walmarts here have gotten rid of their fabric sections. I'm needing to know how to get the right thing. Does the correct material come in a bag/pre-packed package, or is it purchased by the yard? What is the exact description of it as it appears on the package/shelf tag?

I'm thinking the same thing. Like I said, what I have is more like fabric, in fact it is fabric. On the other hand, it's 100% Polyester. It definately doesn't have a waxy feel to it. Once the resin dries, this stuff doesn't want to let go. I got this from Hobby Lobby, as the local Walmarts here have gotten rid of their fabric sections. I'm needing to know how to get the right thing. Does the correct material come in a bag/pre-packed package, or is it purchased by the yard? What is the exact description of it as it appears on the package/shelf tag?

It is sold by the yard. The tag just said 100% polyester cloth. Im not sure it said anything else. If you can give me a day or two, i can get that picture of the tag for you. But like i said, the stuff is thin, solid color with a waxy feel to it.

#66

My Feedback: (35)

Join Date: Mar 2002

Location: West Monroe,

LA

Posts: 1,161

Likes: 0

Received 0 Likes

on

0 Posts

Looks like I may have to buy it online. I've looked everywhere in this town for Polyester cloth with a wax-like finish to it and I've had no luck whatsoever. I found some sheer polyester window drape material, but it has no waxy finish to it. I'm thinking that if I lay this down on resin, it's gonna stay there once the resin's dry.

If you can shoot me a close-up pic of what you have, that may help.

If you can shoot me a close-up pic of what you have, that may help.

#67

ORIGINAL: yard-dart

Looks like I may have to buy it online. I've looked everywhere in this town for Polyester cloth with a wax-like finish to it and I've had no luck whatsoever. I found some sheer polyester window drape material, but it has no waxy finish to it. I'm thinking that if I lay this down on resin, it's gonna stay there once the resin's dry.

If you can shoot me a close-up pic of what you have, that may help.

Looks like I may have to buy it online. I've looked everywhere in this town for Polyester cloth with a wax-like finish to it and I've had no luck whatsoever. I found some sheer polyester window drape material, but it has no waxy finish to it. I'm thinking that if I lay this down on resin, it's gonna stay there once the resin's dry.

If you can shoot me a close-up pic of what you have, that may help.

#68

My Feedback: (1)

Hi Yard-Dart,

I purchased the drap material at Wallmart and it worked fine. The brand name is Mainstays (Marjorie) and it states 100% polyester. I have used a different method. I place the glass cloth on the surfase then add the resign over the coth and spread it with form rubber in a paper clamp. This is the method I have used for years. It spreads the resin out and pulls out any folds in the glass cloth. After it has dried I trim it and hit it lightly with some fine sandpaper.

I now use the polyester cloth for a second coat of resin. I pour the resin on and spread it with the foam then cover it with the polester cloth. I then use some waxpaper to get out any air bubbled and push the cloth tight. When it cures I remove the polester material and the finish looks almost like a gellcoat. A light dry sanding then primer.

Hope this helps, P51Tom

I purchased the drap material at Wallmart and it worked fine. The brand name is Mainstays (Marjorie) and it states 100% polyester. I have used a different method. I place the glass cloth on the surfase then add the resign over the coth and spread it with form rubber in a paper clamp. This is the method I have used for years. It spreads the resin out and pulls out any folds in the glass cloth. After it has dried I trim it and hit it lightly with some fine sandpaper.

I now use the polyester cloth for a second coat of resin. I pour the resin on and spread it with the foam then cover it with the polester cloth. I then use some waxpaper to get out any air bubbled and push the cloth tight. When it cures I remove the polester material and the finish looks almost like a gellcoat. A light dry sanding then primer.

Hope this helps, P51Tom

#69

I can't help but believe that this results in a thicker (read heavier) finish that the old way. I have been appling the glass (as you describe above) trying to keep the resin to an absolute minimum. A light sanding after curing and another minimum coat of resin over that to fill the weave. Then prime. I think the key to a light finish is sanding each coat of primer, until the cloth can't be seen when held up to the light at an angle. Just my technique. I don't plan to try to learn another technique now after twenty five years of success.

I'm sure this results in filling the glass in less steps, but I"m sure it takes more resin and results in a thicker finish.

Dash

I'm sure this results in filling the glass in less steps, but I"m sure it takes more resin and results in a thicker finish.

Dash

#70

ORIGINAL: Dash7ATP

I can't help but believe that this results in a thicker (read heavier) finish that the old way. I have been appling the glass (as you describe above) trying to keep the resin to an absolute minimum. A light sanding after curing and another minimum coat of resin over that to fill the weave. Then prime. I think the key to a light finish is sanding each coat of primer, until the cloth can't be seen when held up to the light at an angle. Just my technique. I don't plan to try to learn another technique now after twenty five years of success.

I'm sure this results in filling the glass in less steps, but I''m sure it takes more resin and results in a thicker finish.

Dash

I can't help but believe that this results in a thicker (read heavier) finish that the old way. I have been appling the glass (as you describe above) trying to keep the resin to an absolute minimum. A light sanding after curing and another minimum coat of resin over that to fill the weave. Then prime. I think the key to a light finish is sanding each coat of primer, until the cloth can't be seen when held up to the light at an angle. Just my technique. I don't plan to try to learn another technique now after twenty five years of success.

I'm sure this results in filling the glass in less steps, but I''m sure it takes more resin and results in a thicker finish.

Dash

The only way any method is going to result in a Thicker finish, is by extremely over-saturating the cloth and having the cloth "float" in a layer of epoxy resin. If the fiberglass and epoxy ratio is correct (or close to it) the saturated fiberglass will be resting on the part surface. Without any peel-ply, as the epoxy resin cures it produces what is called an "amine bloom" which has to be removed before any other bonding or painting is done on this surface. This is a waxy layer that builds up on the outer surface layer of the epoxy resin. The peel ply is mostly used to remove this waxy layer of resin, the sucking up of the extra excess resin is just a bonus.

Now.. you CAN add the extra epoxy "filler coat" of resin as well by putting on the coat of resin, and then putting another layer of peel-ply down.

I have done both ways and by using a quality "filler" primer, you add no more weight with just primer than you do by putting down the filler coat of resin and then the primer.

#71

My Feedback: (1)

Hi Dash7ATP,

Like you, I have for the past 35 years used the two coat method of glassing my models. I believe I use less resin on my second coat with the polyester method then before. Also it takes much less primer with this method to get a perfect finish. After removing the poly cloth you can see the weave on the fiberglass but cannot feel it. Before I spent hours wet sanding the resin with 220 paper and using angled light to check for bad spots. I have been building RC for over 43 years and I am always willing to try new methods. I am thankful that I tried this method the results are remarkable and I believe will be lighter.

Good Luck, P51Tom

Like you, I have for the past 35 years used the two coat method of glassing my models. I believe I use less resin on my second coat with the polyester method then before. Also it takes much less primer with this method to get a perfect finish. After removing the poly cloth you can see the weave on the fiberglass but cannot feel it. Before I spent hours wet sanding the resin with 220 paper and using angled light to check for bad spots. I have been building RC for over 43 years and I am always willing to try new methods. I am thankful that I tried this method the results are remarkable and I believe will be lighter.

Good Luck, P51Tom

#72

My Feedback: (35)

Join Date: Mar 2002

Location: West Monroe,

LA

Posts: 1,161

Likes: 0

Received 0 Likes

on

0 Posts

ORIGINAL: p51tom

Hi Yard-Dart,

I purchased the drap material at Wallmart and it worked fine. The brand name is Mainstays (Marjorie) and it states 100% polyester. I have used a different method. I place the glass cloth on the surfase then add the resign over the coth and spread it with form rubber in a paper clamp. This is the method I have used for years. It spreads the resin out and pulls out any folds in the glass cloth. After it has dried I trim it and hit it lightly with some fine sandpaper.

I now use the polyester cloth for a second coat of resin. I pour the resin on and spread it with the foam then cover it with the polester cloth. I then use some waxpaper to get out any air bubbled and push the cloth tight. When it cures I remove the polester material and the finish looks almost like a gellcoat. A light dry sanding then primer.

Hope this helps, P51Tom

Hi Yard-Dart,

I purchased the drap material at Wallmart and it worked fine. The brand name is Mainstays (Marjorie) and it states 100% polyester. I have used a different method. I place the glass cloth on the surfase then add the resign over the coth and spread it with form rubber in a paper clamp. This is the method I have used for years. It spreads the resin out and pulls out any folds in the glass cloth. After it has dried I trim it and hit it lightly with some fine sandpaper.

I now use the polyester cloth for a second coat of resin. I pour the resin on and spread it with the foam then cover it with the polester cloth. I then use some waxpaper to get out any air bubbled and push the cloth tight. When it cures I remove the polester material and the finish looks almost like a gellcoat. A light dry sanding then primer.

Hope this helps, P51Tom

So, this material won't stick to the resin?

And, thanks for the info.

#73

ORIGINAL: yard-dart

Well, the problem here is that both Walmarts have eliminated their fabric department. I don't know if that is where you find the drape material ro not, but if it is, I'm out of luck. I'll check with the local fabric store to see if they have what you're talking about.

So, this material won't stick to the resin?

And, thanks for the info.

ORIGINAL: p51tom

Hi Yard-Dart,

I purchased the drap material at Wallmart and it worked fine. The brand name is Mainstays (Marjorie) and it states 100% polyester. I have used a different method. I place the glass cloth on the surfase then add the resign over the coth and spread it with form rubber in a paper clamp. This is the method I have used for years. It spreads the resin out and pulls out any folds in the glass cloth. After it has dried I trim it and hit it lightly with some fine sandpaper.

I now use the polyester cloth for a second coat of resin. I pour the resin on and spread it with the foam then cover it with the polester cloth. I then use some waxpaper to get out any air bubbled and push the cloth tight. When it cures I remove the polester material and the finish looks almost like a gellcoat. A light dry sanding then primer.

Hope this helps, P51Tom

Hi Yard-Dart,

I purchased the drap material at Wallmart and it worked fine. The brand name is Mainstays (Marjorie) and it states 100% polyester. I have used a different method. I place the glass cloth on the surfase then add the resign over the coth and spread it with form rubber in a paper clamp. This is the method I have used for years. It spreads the resin out and pulls out any folds in the glass cloth. After it has dried I trim it and hit it lightly with some fine sandpaper.

I now use the polyester cloth for a second coat of resin. I pour the resin on and spread it with the foam then cover it with the polester cloth. I then use some waxpaper to get out any air bubbled and push the cloth tight. When it cures I remove the polester material and the finish looks almost like a gellcoat. A light dry sanding then primer.

Hope this helps, P51Tom

So, this material won't stick to the resin?

And, thanks for the info.

Thomas

#75

Alright guys.. Here's 2 photo's of the label on the fabric bolt/batten. I asked the lady in the fabric department what kind of fabric you would classify this, and she said it would be used for linings and things of that nature. Hopefully this will help you guys find the right stuff.