Spitfire arf 95" phoenix assembly

#177

My Feedback: (1)

I got two more flights on the Spitfire yesterday, and I'm very happy with it. Landings are easy because the plane flies so light. With only a few runs on the engine the 23x10 prop may be a bit more load than the engine likes. It pulled the plane fine, and was fairly fast. I think the DLE-61 was a bit happier with the 23x8 and had better vertical performance. In any case the engine ran perfectly through both flights without missing a beat. I'm looking forward to taking it to some of the Midwest events this year.

#178

Finally started the assembly.

Actually read the instructions.

Wings:

A plastic bag with the 4 control horns and hardware.

Some 20mm long screws to secure the control horns to the flaps and 30mm for the ailerons.

Horns and pin hinges are nice quality.

They used screws as hinges on the pin hinges so, in theory, you could remove them.

Put oil on the center of the hinges to keep out the epoxy.

Need to put the horns on first before epoxying the flaps to the wing as little room for access with a hex driver (need a metric for it).

Initially, thought the hinges were epoxied but they aren't.

Impressed by how many hinges on the ailerons.

Hinged the flaps/ailerons and, after the epoxy hardened, they were epoxied to the wings.

I held the control horns while applying the epoxy as it's easy to get epoxy on the wing, flaps and aileron's surfaces.

I still had to use alcohol to clean up all the surfaces of oil and epoxy.

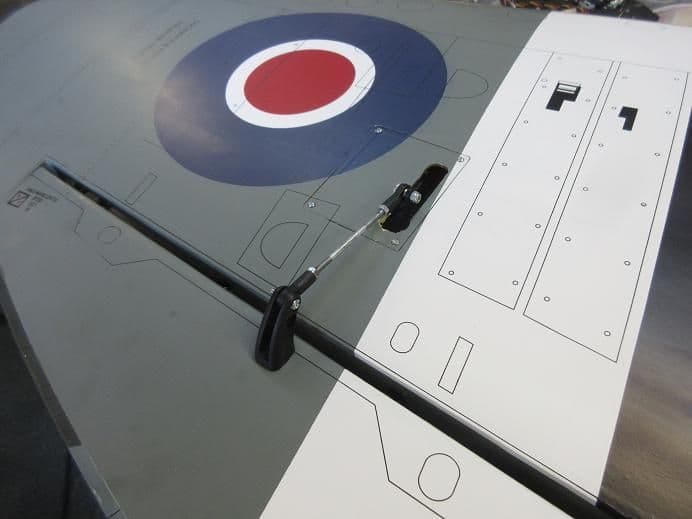

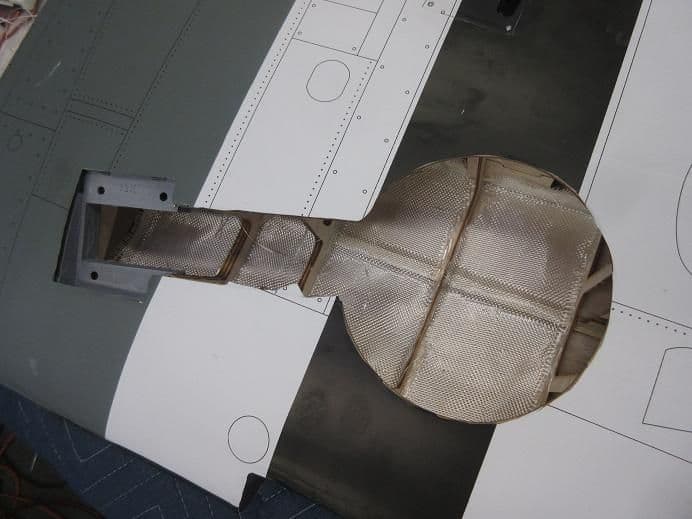

Filled the radiator vents with spray foam as, sooner or later, I'll land with the gear up and this will prevent from damaging the radiators: (may come off the wing but will be in one piece).

One of the radiators was deformed but it shouldn't be noticeable under the wing.

Last edited by samparfitt; 07-06-2018 at 10:23 AM.

#179

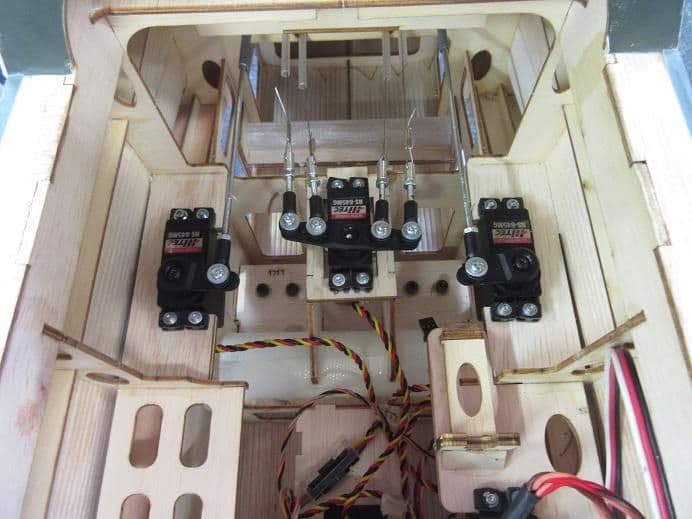

wings (cont)

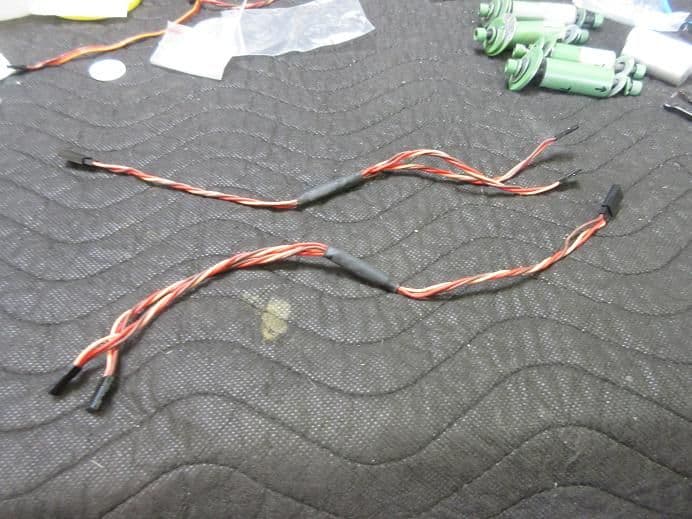

Made 4 extensions for the flaps and ailerons.

Right wing install of servos and hardware and adjusted with receiver.

Set ailerons about 3/4" and about 45 degrees on the flaps.

Made 2 Y extensions to lead to each wing half for flaps and ailerons.

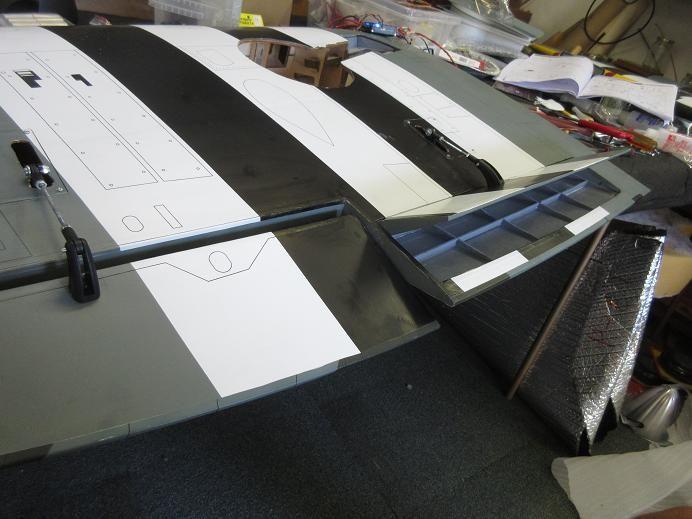

This is a 2 piece wing where the each wing connects to the side of the fuse versus the bottom.

Left wing completed.

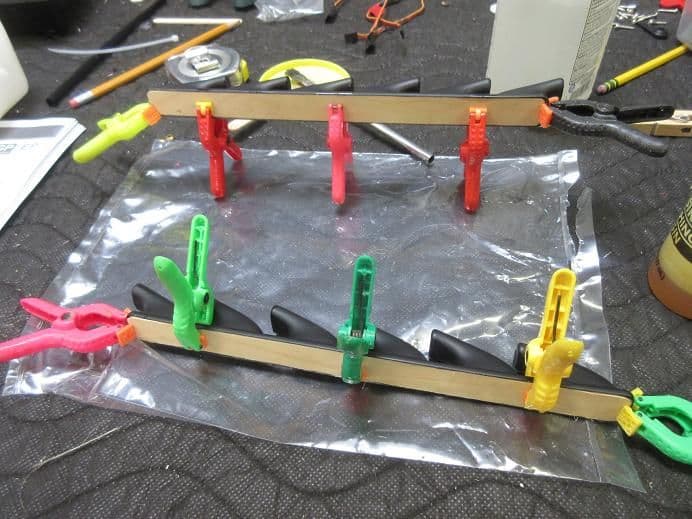

In case I do something stupid, heavy duty FG cloth from my local auto shop and some finishing resin.

Let that 'cook' overnight.

Actually, until Monday since I'm going to a local flyin on Saturday plus railroading on Sunday.

#180

Wings (cont)

Gear:

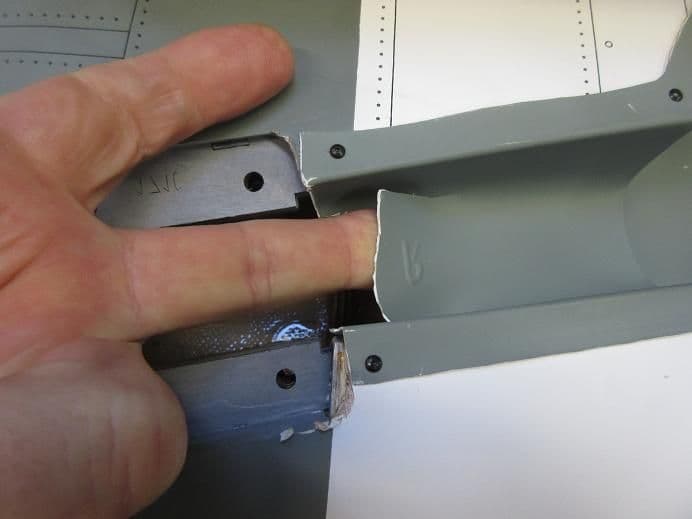

Trimmed up the gear inserts and screwed them in for easy future repairs.

Had to slice each side of insert so the gear would slide under it.

Also, one side of the wing needed a notch in the wood for gear clearance.

No compression at all on the gear.

Initially, thought no spring but, after removing side retaining screw, the spring came out.

Went to ACE hardware and got two shorter springs (they didn't have any long ones) for each side and now the oleos seem to work just right.

Added some lithium grease while they were apart.

Never had success with off brand valve systems which is provided with this ARF.

Was able to heat and force some robart air hose over the gear nipple.

The nipples are much larger than used on 'normal' gears so only able to get the air hose on part way but past the first ridge so it should stay on, hopefully!

Will have to look back on this thread and see if anyone has had problems with the provided air system and any solutions.

Last edited by samparfitt; 07-08-2018 at 07:20 AM.

#181

Wings (cont)

Didn't see any remarks on using different air lines for the gear and no one has responded so I guess the kit provided parts are OK.

Left wings in the sun and, surprisingly, they didn't wrinkle that much.

Had the iron at 325 degrees but too much: 275 seems about right without damaging the covering.

A few spots had air bubbles and they got damaged by the high heat. The rest of the wrinkles 'did good'!

Tail wheel:

I see a few had their tail wheel supports break off so I'm replacing the original 4 bolts with longer hex head bolts that will go into the fuse former. Had to used a drill bit CA'ed into some brass tubing to be able to drill holes into the existing holes and into the fuse former. Will also be putting extra epoxy and cloth around that area.

Figured it would be easiest to, first, add the tail gear and pull wires to the black plastic support before re-attaching it into the fuse.

There's a two piece black plastic provided that is CA'ed to the tail wheel oleo.

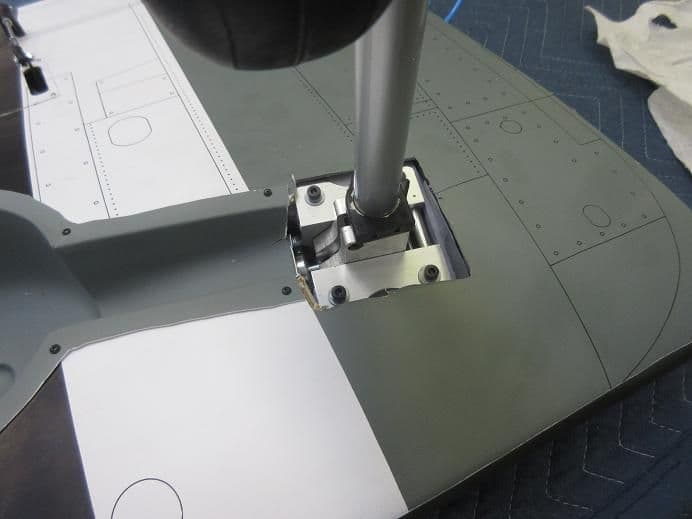

Wings to fuse:

Figure it was non too soon to, actually, insure the wings fit onto the fuse.

Two aluminum tubes and 2 metal slots to into the fuse and wing and 4 screws hold the wings to the fuse.

I used a felt tip to mark the metal slots along the fuse so I can visually know when they are aligned correctly.

I made the flap/aileron extensions extra long so they can easily be routed into the fuse.

The bottom of the wing has a nice alignment with the fuse.

The top, not so: there is about an 1/8" gap between the wing and fuse.

Last edited by samparfitt; 07-10-2018 at 08:10 AM.

#182

Tail feathers:

As another has noted and I have been doing is installing the control horns before gluing the moving surfaces to the plane.

The elevators needed some extra sanding with a rat tail file to enlarge the holes for the control horns.

Also, one screw holds both control horns on the rudder. Since all the control horns are made for threading, one of the control horns were drilled out so the bolt slides through that control horn and, easily, screwed into the control horn on the other side of the rudder.

Hinges were oiled at the center and epoxied to the rudder and elevators and left at a 90 degree angle to insure correct alignment.

I used a heat gun to remove the center section of material of the horizontal stab where it's glued to the fuse. That center recess is perpendicular but the fuse is angled so some extra filing of the fuse and stab was needed to get the stab into the back of the fuse. There is no 'play' in the fit and, fortunately, the stab appears parallel to the wings. The back of the stab needs to be flush with the back of the fuse.

There is no gap on the bottom where the stab meets the fuse but there is one on the top side.

A little 'dry fitting' to make sure stab, elevators and rudder fit OK.

Last edited by samparfitt; 07-10-2018 at 08:28 AM.

#183

Tail feathers:

Horizontal stab:

epoxied to fuse.

Tail wheel:

Glassed that area and put larger hex head screws that went through the fuse former.

The instructions show just looping the pull/pull wires directly to the tail wheel control arm:

There is no room to make adjustments at the servo end so clevises with adjustable ends were used at both tail wheel end and servo end.

This holds, also, for the rudder.

Elevators:

The two provided push rods were connected to the elevators and servos.

The servos need to be rotated 180 degrees to use provided push rods to move the servo arm towards the front of the fuse.

I used a Y reverser on the two elevator servos to have them operate in unison.

I'm using all HS-645 servos.

On the right side, I put the screw in on the opposite side to secure the ball link so it can be removed as, from the other side, the fuse is in the way.

The screw only secures on the 'head' end but I see no problem with that.

Rudder:

Fuse put on end and rudder epoxied in place.

Tail wheel:

Clevises and hatch in last two pictures.

#184

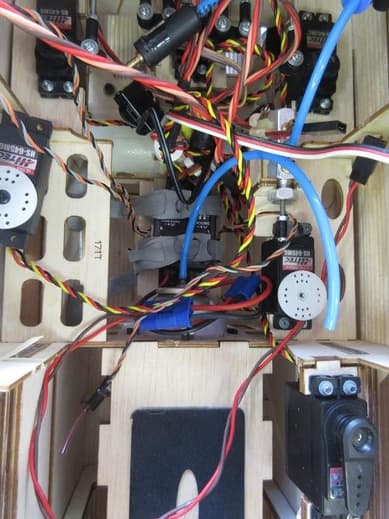

Fuse (cont)

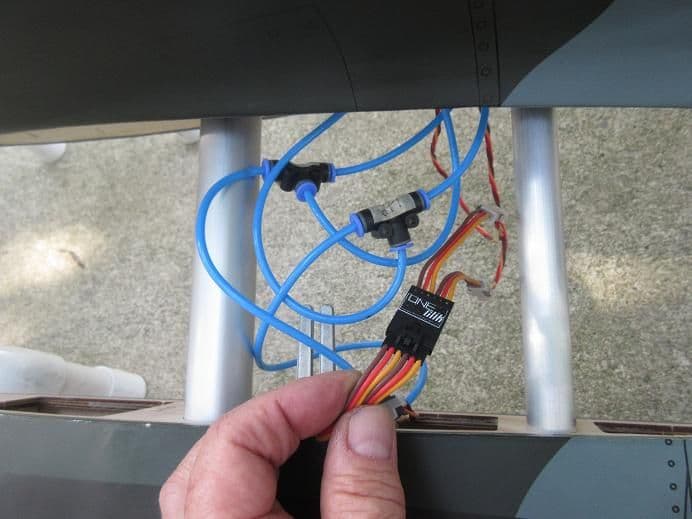

Velcro'ed the receiver to the same tray that the air tank is on.

Since it's difficult to insert any wires into the tray'ed receiver, the last two servos (gear and choke) were connected.

The air tank to a festo fastener was also connected.

One air line to the air valve was connected and placed into it's spot on the servo tray.

Needed my hot air gun to soften the blue air line to get it on the nipples.

Presently, I'm leaving the other air lines off that go to the wings as it appears I can make them extra long with the festo fittings resting by the fuse where the wings join. Hopefully, I can, then, easily just connect the wing air lines where the wings join versus trying to route them through all the tail surface rods/wires. Same with the flap/aileron connections.

Re-enforced the nose area with FG cloth and resin plus make it fuel proof.

No need to put the usual screws into the sides to hold the front engine former as they did a nice job of dado'ing the former into the sides of the fuse.

Last edited by samparfitt; 07-18-2018 at 12:34 PM.

#185

Fuse (cont)

Receiver:

Made up some Y harnesses to connect the two batteries to the receiver plus a charging outlet.

At one of the flyins, I picked up 100 safety clips.

Two batteries for the receiver installed.

Nice that there were holes for easy install of velcro straps.

Got most of the wires rearranged around the receiver tray.

Servo tray still needs to be installed on the left side to hold the choke servo.

The right side will get another tray for receiver switch, charging outlets and ignition switch.

They provide stand offs that are hollow and cut in half.

Two of them are 2 3/4" long which is needed to get the front of the DLE-61 6 3/4" from the fire wall.

The provide bolts are too short to hold the engine, stand offs and go into the provide blind nuts. I could go to fastenal and get some longer bolts but ordered a set of DLI standoffs.

Pilots:

Plan on using the left pilot to replace the ugly right pilot provided in the kit.

Last edited by samparfitt; 07-19-2018 at 10:36 AM.

#187

SOMETHING'S NOT RIGHT!

I went to ACE hardware and got some longer bolts. Got 1/4" versus the metric 5 MM diameter and needed 4" long ones.

The engine was mounted using their standoffs for a total of 6 3/4" per the instructions but the cowl is past the front of the engine by about 1 1/4".

Can't cut the cowl in the back as there are some raised areas in the rear of it.

Appears the only solution is to build a new fire wall about 1 1/4" out.

Also, had to rotate the engine throttle arm 180 degrees to miss the standoffs plus cut out some of the fire wall for throttle/choke linkage.

Last edited by samparfitt; 07-19-2018 at 10:39 AM.

#188

Engine area (cont)

Engine:

Instead of adding another fire wall, I used some DLE engine mounts plus half of the ARF's supplied mounts to get the proper distance for the spinner to align with the cowl.

Never used mounts that long in the past: hope the engine doesn't vibrate.

Cowl.

Took multiply mountings to get all the holes cut out for the engine head, side muffler and exhaust pipes.

Used a pop cycle stick for gaping the spinner to the cowl.

The exhaust pipes were cut to just extend past the cowl.

Also, cut a hole in the back of the cowl for air exit.

I'm figuring the holes should be enough as I've never had an engine over heat as long as the head is sticking out of the cowl.

Last edited by samparfitt; 07-21-2018 at 08:58 AM.

#190

My Feedback: (1)

I just reviewed the assembly manual on Tower's website and it indicated a 170 mm distance from the firewall to the thrust washer and showed the back of the carb adjacent to the firewall. It would seem that you received a mis-built fuselage. Nothing in the assembly manual appears similar to what you have had to construct.

#191

Dan,

I'm going to try it with the long standoffs and, if there's vibration, I'm hoping I can use some L bracket (the kind for garage openers with the holes) and cross brace to form a triangle, which is very strong.

======

Lifer,

I took a few measurements for others to let me know what their readings are:

Cowl length: 16"

Engine mount box is 6" (gray part).

LE of wing to front of where standoffs are is 9" of left side and 8.5" on the left side (lots of right thrust).

I've been disappointed in not hearing from others who have assembled this plane on my inquire on if they used the original air system or modified it and whether they had this same engine mount problem.

================

Engine:

Linkages for throttle and choke connected using sullivans golden rod and their easy connect ball linkage on the engine side. A new tray was made for the choke servo as none is supplied.

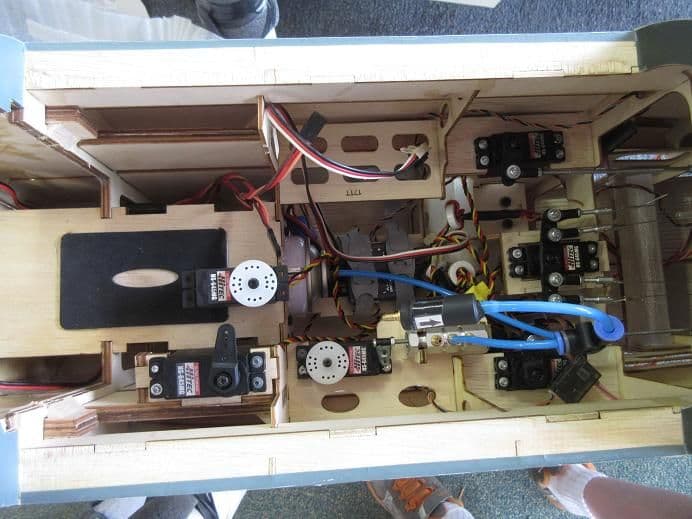

Servo tray area:

Right side got the soft switch for the receiver and two charging jacks on an existing tray.

Above that was a new tray for the ignition switch.

A tray was made and velcro'ed to the engine standoffs and the ignition module velcro'ed to it.

Retracts:

I took some brass tubing and made a transition tube from the large blue air line to robarts smaller airline so I could pump up the air with my normal robart connector.

Don't follow this exact setup as you'll find out later in another post.

Another tray epoxied to the fuse for the air filler.

Last edited by samparfitt; 07-22-2018 at 03:40 PM.

#192

Gear:

I cut the blue air lines 24" and 28" for the back and front nipples on the retracts.

They provide nice metric bolts and the blind nuts are already installed so one gets a good, secure mount of the retracts.

Time to assemble to check the retracts.

The remaining blue air line was cut in half so I had two long lines so the T festo fittings could be located by the wings.

I'm thinking this will be easier to connect the air lines versus trying to route them up through the fuse for each time at the field.

Both wheels were 'toe out'.

There are two small set screws for rotational adjustment.

There's a large bolt which, initially, I thought was for rotational adjustment but not true.

I had to add the gear doors to keep the door collars from rotating and inhibiting the retracts from going into the UP position.

#193

Retract test:

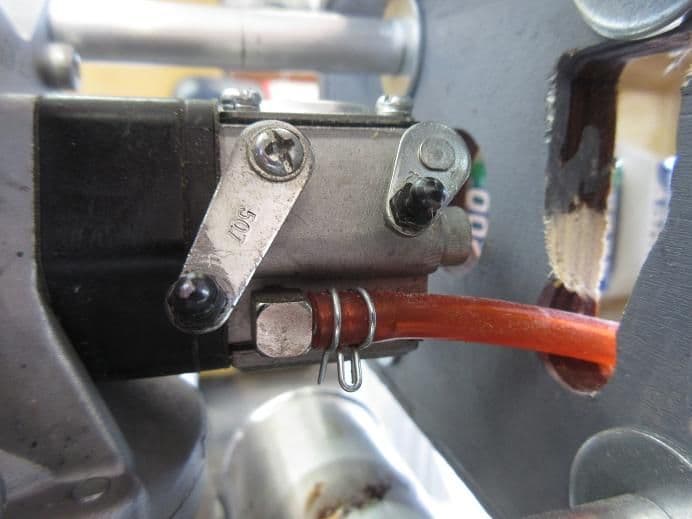

I used an HS-645 to throw the supplied kit air valve. It is very stiffl and needs power plus the instructions says such. I used a metal clevis and a ball link for the linkage to the air valve. They supply a stiff wire and one of those easy connects where there is a set screw that holds a wire in a hole.

After filling up the tank with air, the retracts worked great but I noticed the robart air gauge going down to zero.

Initially, I thought I had a leak but, quickly realized, that with the supplied one way valve, this is going to happen.

I'll have to route the gauge on the other side of the one way valve.

Well, she's on her feet and she looks pretty good.

After putting the plane on the ground, now there's too much toe in. Must be some slop in the set screw for the oleos.

Stuff to do:

Install fuel tank.

Secure cowl.

Cockpit detail.

Guns and radiator details.

Tomorrow, will go to Dave Brown's place (only about 15 miles away) and get an extension so I can secure his spinner to the DLE-61.

Last edited by samparfitt; 07-22-2018 at 03:38 PM.

#194

Cowl update:

While 'cleaning up' the work bench, I found a set of DLE standoffs. The standoffs were under a box. I now have any extra set as I thought I needed them for the engine mount.

Since the DLE standoffs were included plus the extra standoffs that are half lengths, plus the fact that the included mounting bolts just happen to be the right length to secure the engine and 1/2 length standoffs to the full length DLE standoffs, I'm guessing this is how the engine is to be mounted (even though the instruction book doesn't show it).

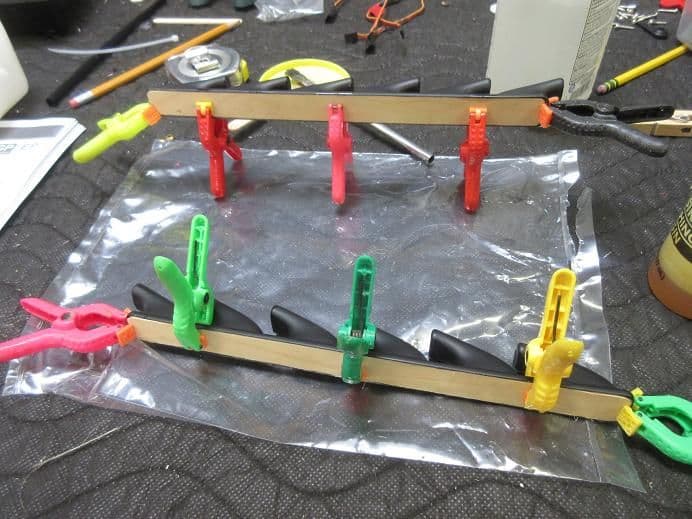

Fake exhausts:

I sanded away excess molding along the inside of the black exhaust pipes and cut some 3/32" thick ply and epoxied the ply into the back of the exhaust pipes. This will give me a mechanical as well as glue bond to the cowl.

Fuel tank:

I'm sure the kit came with a fuel stopper but can't find it. The tank is a 'near' identical to dubro's 32 oz so a new one will be made.

W

While 'cleaning up' the work bench, I found a set of DLE standoffs. The standoffs were under a box. I now have any extra set as I thought I needed them for the engine mount.

Since the DLE standoffs were included plus the extra standoffs that are half lengths, plus the fact that the included mounting bolts just happen to be the right length to secure the engine and 1/2 length standoffs to the full length DLE standoffs, I'm guessing this is how the engine is to be mounted (even though the instruction book doesn't show it).

Fake exhausts:

I sanded away excess molding along the inside of the black exhaust pipes and cut some 3/32" thick ply and epoxied the ply into the back of the exhaust pipes. This will give me a mechanical as well as glue bond to the cowl.

Fuel tank:

I'm sure the kit came with a fuel stopper but can't find it. The tank is a 'near' identical to dubro's 32 oz so a new one will be made.

W

Last edited by samparfitt; 07-23-2018 at 04:58 AM.

#196

Tank lines readied.

Over flow just above hole in cowl.

With a nut used to secure the overflow, a separate piece of ply needed to secure it to the fuse.

My 'tools of the trade' for fuel lines.

Some velcro to secure the tank.

Yesterday, I got my spinner extension from Dave Brown.

Used the supplied CG checker.

I usually balance with gear up but 'close enough'.

Put remaining parts on plane to check CG.

Surprised it was 'spot on' as the Brits say.

This should also confirm that, indeed, the engine standoffs are another 1/ 1/4" longer than indicated in the instructions.

Painted the doors with camouflage paint and will add supplied covering, later.

The supplied screws are a little too long to secure the doors so some fuel tubing used.

Can't bottom out the screws as they hit the oleo which secures the collars.

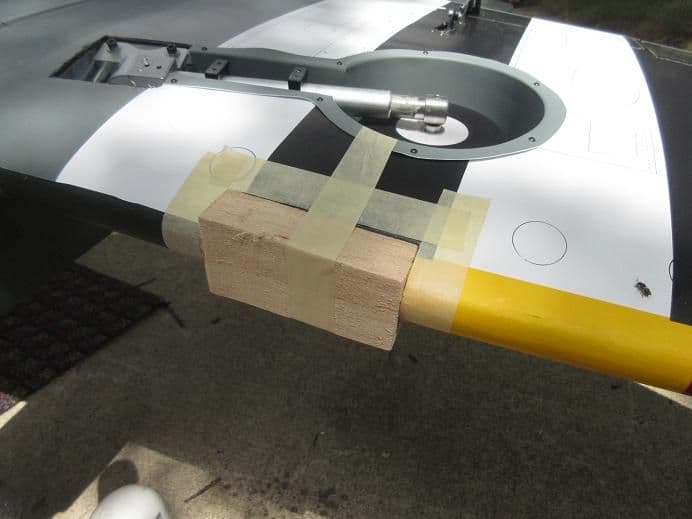

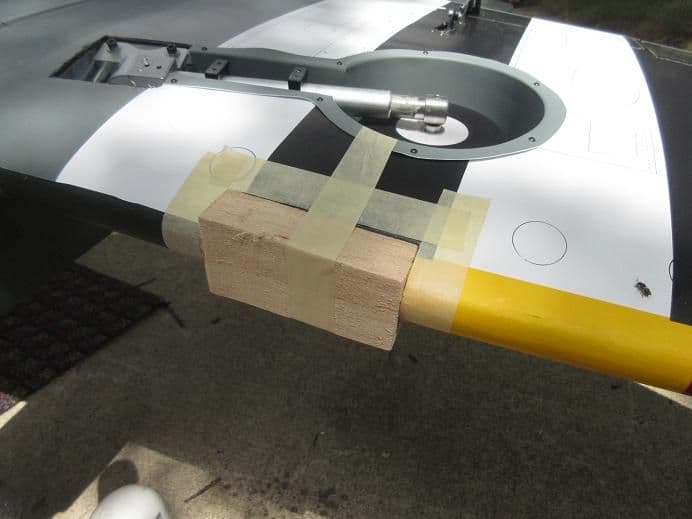

I think they 'over thought' the gun placement.

I epoxied some block balsa in the gaps.

A planer and sand paper made quick work of matching the balsa block to the LE.

The ABS plastic guns are hollow so the balsa block makes they more stable.

Some button head screws to secure them to the wing.

Radiators also secured using button head screws.

Hope to do the maiden, tonight.

Rebound the receiver and charging the batteries.

Maiden will be done without cowl. Cowl is light enough not to affect the CG with it off.

Just discovered that one needs to first down load the pictures and then comments can then be inserted between pictures.

Over flow just above hole in cowl.

With a nut used to secure the overflow, a separate piece of ply needed to secure it to the fuse.

My 'tools of the trade' for fuel lines.

Some velcro to secure the tank.

Yesterday, I got my spinner extension from Dave Brown.

Used the supplied CG checker.

I usually balance with gear up but 'close enough'.

Put remaining parts on plane to check CG.

Surprised it was 'spot on' as the Brits say.

This should also confirm that, indeed, the engine standoffs are another 1/ 1/4" longer than indicated in the instructions.

Painted the doors with camouflage paint and will add supplied covering, later.

The supplied screws are a little too long to secure the doors so some fuel tubing used.

Can't bottom out the screws as they hit the oleo which secures the collars.

I think they 'over thought' the gun placement.

I epoxied some block balsa in the gaps.

A planer and sand paper made quick work of matching the balsa block to the LE.

The ABS plastic guns are hollow so the balsa block makes they more stable.

Some button head screws to secure them to the wing.

Radiators also secured using button head screws.

Hope to do the maiden, tonight.

Rebound the receiver and charging the batteries.

Maiden will be done without cowl. Cowl is light enough not to affect the CG with it off.

Just discovered that one needs to first down load the pictures and then comments can then be inserted between pictures.

#197

My Feedback: (1)

Good luck on your Maiden. Be aware that the carb is deep inside the cowl, which can cause some heat soak issues. I had to add some airflow to get air to it. On a hot day it's difficult to get air inside there. Your cutouts around the cylinder and muffler are tight, it may not provide much airflow to the carb. If it runs good with cowl off, but starts running poorly after a few minutes with it on you'll know it's heat soak. I don't have photos, but I added some holes right in front of the exhaust stacks and opened up the back of the scoop even more.

I noticed this plane flies nice, but when there is any turbulence it sure bounces around. In part because it's light, but the other issue is those large scoops. I pulled mine off and painted on some "virtual" scoops. It tracks better and is faster.

"Virtual" scoops

Coming in for a landing with flaps down

I noticed this plane flies nice, but when there is any turbulence it sure bounces around. In part because it's light, but the other issue is those large scoops. I pulled mine off and painted on some "virtual" scoops. It tracks better and is faster.

"Virtual" scoops

Coming in for a landing with flaps down

#200

Todd,

Thanks for the info, especially about the cowl.

That pictures is nice as it shows where the bottom of the cowl wraps around the LE of the wing.

It sure balanced nice with the engine way out 1 1/4" farther.

I haven't mounted the cowl yet so I maybe removing the extra standoffs. I need to see if the top hatch is removable with the cowl over it. Also, looking at the cowl mounting page, looking at their measurements, it appears the cowl is suppose to be farther out. It's late now, I'll re-check all that, tomorrow.

======

The maiden went well.

I flew without the cowl so I could check all the bolts, etc after each flight.

Needed lots of aileron trim: 1/4" is way too much. Disappointed in needing that much trim.

Before the 2nd flight, checked the engine mounts and all stiff but in flight, couldn't get any full throttle so landed quickly and found two of the left mounting bolts on the back of the fire wall were loose. I only tightened them with a hex screw driver as it was hard to reach with an L hex tool.

A very easy plane to take off and land. No down elevator trim was needed for the flaps.

Full size Jungmeister flew over our field, which also is a full size runway but never used.

I

Thanks for the info, especially about the cowl.

That pictures is nice as it shows where the bottom of the cowl wraps around the LE of the wing.

It sure balanced nice with the engine way out 1 1/4" farther.

I haven't mounted the cowl yet so I maybe removing the extra standoffs. I need to see if the top hatch is removable with the cowl over it. Also, looking at the cowl mounting page, looking at their measurements, it appears the cowl is suppose to be farther out. It's late now, I'll re-check all that, tomorrow.

======

The maiden went well.

I flew without the cowl so I could check all the bolts, etc after each flight.

Needed lots of aileron trim: 1/4" is way too much. Disappointed in needing that much trim.

Before the 2nd flight, checked the engine mounts and all stiff but in flight, couldn't get any full throttle so landed quickly and found two of the left mounting bolts on the back of the fire wall were loose. I only tightened them with a hex screw driver as it was hard to reach with an L hex tool.

A very easy plane to take off and land. No down elevator trim was needed for the flaps.

Full size Jungmeister flew over our field, which also is a full size runway but never used.

I

Last edited by samparfitt; 07-24-2018 at 05:22 PM.