CARF Galloping Ghost build

#101

Thread Starter

I was able to get it all together to check out the electronics and make sure everything was hooked up right. Also got a quick weight and initial CG. with my setup it comes in right at 46.8 pounds. so call it 47 pound. The CG was really close to what they suggest at 7". About an inch too nose heavy. So, I'm assuming, I'll have to put my two batteries for the RX about midway between the cockpit and the tail. but will get it on the balancer and let you know. They suggested 7" at wing root. I think I'm going to go a little more aft and have around 7.25" to 7.5" . If I didn't put those batteries for the fuel pump and ignition all the way in the back, I would have been really nose heavy. So, if you build for a IL-230, plan for everything back.. Also, I still need to glue in the exhaust stacks. So that will add some weight to the nose. But I think it's working out just about right.

Last edited by rbgetz; 04-28-2018 at 11:25 AM.

The following users liked this post:

orthobird (08-13-2020)

#102

Thread Starter

Oh well. the gear were cycling really nice, but a little too strong. I had one door a little too tight and it snapped the door horn right off. the phonolic horns that came with the kit are OK, but they are not as strong as G10. I fabricated a new one and dremeled out the old broken part. Then Hysoled the new one in place and will let it sit overnight. I'm not suggesting you need to change these out, but I'm really temped to snap the other one off and replace with the G10. It's probably going to be better and stronger. I'll have to see

.

.

Last edited by rbgetz; 04-28-2018 at 05:33 PM.

#104

Thread Starter

I'm hoping I can maiden either next weekend or the following. I only have a few items to finish up on: prop balance, glue exhaust and figure out that CG.. test run the engine in the air frame to make sure I plumbed it all right and should be good to go. I have two planes that need to be maidened, so I don't like to maiden two big planes on the same day. focus on one at a time.

#107

Thread Starter

Well, running into a little bit of a CG issue. So put the plane on the balancer. The CARF prop (SL propeller hub), weights about 30 oz with all the hardware. when you put it on, that really causes a nose heavy condition. Even if I place the two rx batteries midway to the tail, I still may have to add 12 oz of lead in the tail. I guess that's not too bad, going from 47 pounds, total weight, to 48. I also tried the Fiela 28/16 prop I bought for the engine. it weighs about 23 oz, so just about 7 oz less then the SL prop configuration and then only need about half the lead. Overall, not a bit deal.. probably save about a pound of weight going with the Fiela 28/16. So, I don't think I'll get it in the air by next weekend. I'm going to try and see if I can move a few things back, like the fuel pump, but I don't think I'm going to gain too much.

#109

Hello !

Well done sir !!!

Some infos for you :

Check the RPM on ground if you want to use the fiala. I think itís a bit small for this engine.

your CG tells the same story that other customers told me when using the 230. The batteryís need to be placed In the hatch in the back. But donít worry when your CG is a bit in front. My Voodoo is also balanced nose-heavy (depending on manual) and and it still feels not nose heavy. Maybe you stay a bit nose heavy for your maiden flight.

Tell me when you need information to set your engine/carbs

Tom

Well done sir !!!

Some infos for you :

Check the RPM on ground if you want to use the fiala. I think itís a bit small for this engine.

your CG tells the same story that other customers told me when using the 230. The batteryís need to be placed In the hatch in the back. But donít worry when your CG is a bit in front. My Voodoo is also balanced nose-heavy (depending on manual) and and it still feels not nose heavy. Maybe you stay a bit nose heavy for your maiden flight.

Tell me when you need information to set your engine/carbs

Tom

#110

Thread Starter

Hi Tom,

Thank you for the information on the Fiela. I will check the RPM on for that prop on the ground. It is definitely smaller and lighter. I have not tried the Fiela running on the Kolm yet. With the SL prop, I was only getting 4,000 RPM with the CARF recommended pitch . The IL-230 might have been too rich on the high end.

Thank you for the information on the Fiela. I will check the RPM on for that prop on the ground. It is definitely smaller and lighter. I have not tried the Fiela running on the Kolm yet. With the SL prop, I was only getting 4,000 RPM with the CARF recommended pitch . The IL-230 might have been too rich on the high end.

#111

Anytime, no propblem !

4000 sounds a bit less to me, but for sure no problem to fly. The H needle you can only adjust in flight. The Motor doesnít reach the rpms on ground you need to say if itís Ok or not. Improtant is to lift the plane up one time before you start. It engine doesnít quit you are good. Normally the H needle is a bit to rich depending on factory setup.

Would be cool I someone compares the SL with the Ramoser. The guys in Norway says the Ramoser has the better output.

4000 sounds a bit less to me, but for sure no problem to fly. The H needle you can only adjust in flight. The Motor doesnít reach the rpms on ground you need to say if itís Ok or not. Improtant is to lift the plane up one time before you start. It engine doesnít quit you are good. Normally the H needle is a bit to rich depending on factory setup.

Would be cool I someone compares the SL with the Ramoser. The guys in Norway says the Ramoser has the better output.

#112

Thread Starter

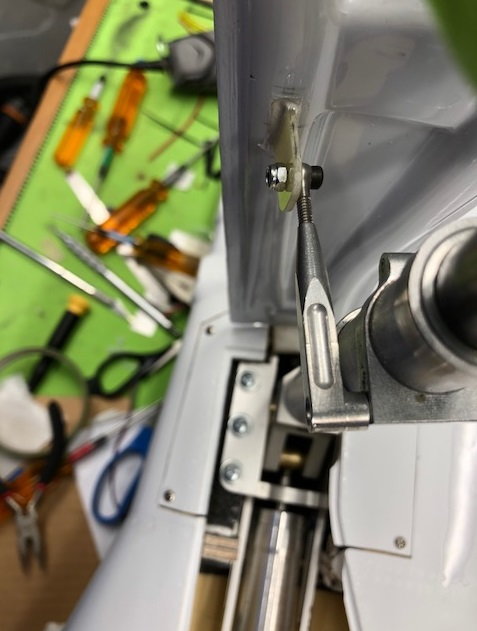

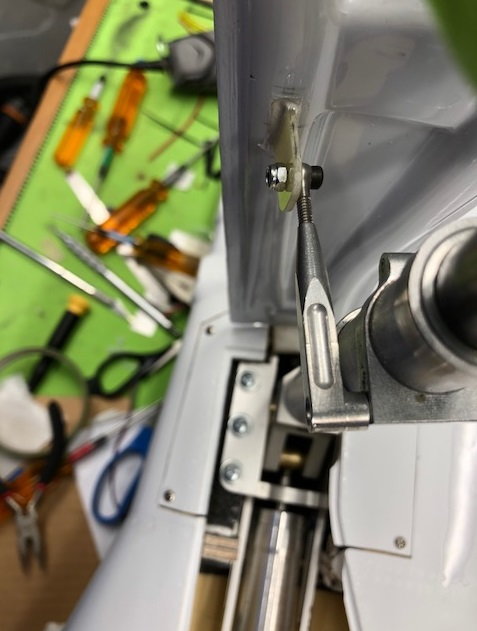

I built a battery tray that will hold both RX batteries in the back of the fuselage in front of the tail wheel area. I built a channel bracket in the back and the battery tray will slide into the channel that then be held in place by two screws on the front bracket. you can see in the pictures. then I made to power harnesses, one for each battery that plug into the rx. I'm using a Jeti CB200 with two satellites. This way the batteries are far back to help with the CG so I don't have to add weight. Also, I don't have to remove batteries to charge them, but really easy to remove.

#113

Thread Starter

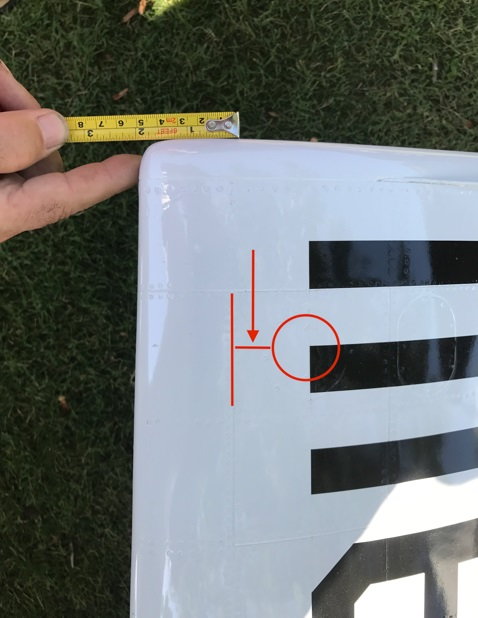

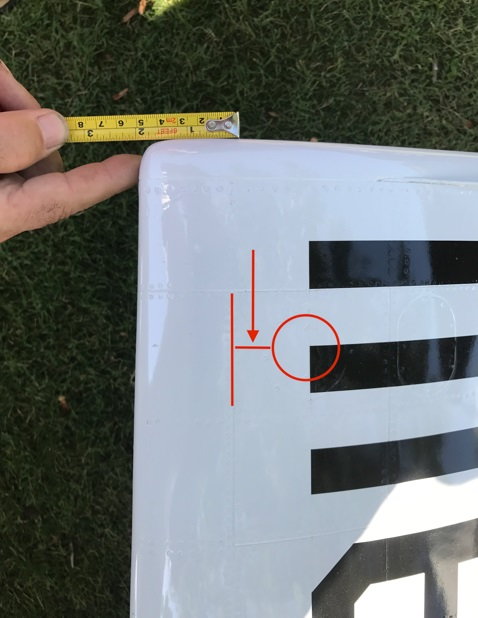

Here's the update on the CG. initially CARF told me the CG should by 7" from the wing root. I just asked again this week and they sent a few photos that I attached. It looks like its more at 6" at wing root. At the wing tip, if you have someone help pick up the plane, it should balance between the fuel cap outline and the panel line shown in the photo. I've made my final decision and going to balance at 6.5" at the wing root. I just split between both suggestions. should be fine to start. Now, with this new information, I will not have to add any lead to the tail. so, I will remain around 47-48 pounds. the plane balances right at 6.5" at wing root.

CARF SUGGESTION

CARF SUGGESTION

CARF SUGGESTION

CARF SUGGESTION

#115

Thread Starter

I think that fairing looks more pronounce in the picture then it is. What you measure along the fuse, it's slightly farther, but not 7". Also, if you following a perpendicular line from the wing tip location in the picture to the wing root, it's at 6" or possibly 6.25 with the fairing. For the most part, I think I'm within a safe range to fly the plane and then decide whether to move the CG back.

#116

Thread Starter

Oh well.. bigger problem... I brought the plane outside today for the first start with everything together for a final test before the maiden. The engine started, but immediately started running bad. I could only get 3,000 RPM at best. really rough running. So, I decided to bring to all back to the shop and check a few things out. I ended up removing the three crankcase covers to look inside. I ended up finding small parts of rubber. Looks like a gasket maker type of material. You can see it in the photo. I have to assume that this stuff is the cause of my issues. Now what do I do???. I'll have to probably pull the whole engine off and look at each carb to see if anything got sucked into it. A major setback as I'm out of time for the next week. with work. tom, any thoughts on what I should do and could this have cause my engine issues? Not sure where this stuff came from.

Crankcase openings where I found the rubber

Rubber pulled from Crankcase.

Crankcase openings where I found the rubber

Rubber pulled from Crankcase.

#118

Thread Starter

Exactly Jon... why is it there???, and where else can it be??. is this the cause of my engine all of a sudden running bad???, Several years back I had a twin 3W 100cc engine. I got some of this gasket maker rubber that got sucked into the carb and literally got stuck around the pop-off valve. It was very thin piece but caused my engine to only go to 1000 RPM as it choke fuel. Took me forever to figure it out. So, I'm very concerned and now think I might have to pull this whole engine out to inspect each carb. Should not be happening to a new $6K engine. But the part that is most frustrating and there is no way to check the engine out without completely pulling it from the air frame. a ton off work to do that!

#119

Morning !

You are good with your CG. Mine on Voodoo is also there. Maybe a bit more in front ...

the material you found in the crankcase is used between all parts of the Motor. But I donít think this cause such a power loss or bad running behavior. Itís not a 2 stroke engine where the gas goes through the case. So take care that your carbs are in factory setting. All 3 cylinders are fireing?

You are good with your CG. Mine on Voodoo is also there. Maybe a bit more in front ...

the material you found in the crankcase is used between all parts of the Motor. But I donít think this cause such a power loss or bad running behavior. Itís not a 2 stroke engine where the gas goes through the case. So take care that your carbs are in factory setting. All 3 cylinders are fireing?

#120

Thread Starter

Hi Tom,

Thanks for getting back quick. I really appreciate it. I'm thinking one cylinder is not firing. I'm going back to the factory setting to make sure they're set the same. In the manual, the factory default setting is 1.5 turns on the High, and 1.75, turns for Low. Is this a good starting point.?

Thanks for getting back quick. I really appreciate it. I'm thinking one cylinder is not firing. I'm going back to the factory setting to make sure they're set the same. In the manual, the factory default setting is 1.5 turns on the High, and 1.75, turns for Low. Is this a good starting point.?

#121

Thread Starter

OK.. I'm back in business. I think I solved issues. There were actually several things needing correction. It's probably more my fault than Kolm. First, I cleaned out the rest of the rubber parts inside of the crank case. All Good. Second, I'm not sure why my low end needles were so lean, but the manual states a good starting point is the Hi 1 1/2 turns out, and the Low, 1 3/4 turns out. My low end needles were all only 1 turn out. Who the heck knows why!! The other problem, totally my fault. the prop screws for the SL prop hub were really loose and the pitch was changed. I should have check since I use these prop hubs and you need to put lock tight on all 12 hub bolts if you're using the CARF setup. I mean you need to check them each time you go to the field. I fixed everything, and the engine started right up. slightly rich on the low end, but just made 1/8 turn lean and the low was great. Getting 4200 rpm on the tach with the CARF recommended pitch. It's best to admit fault then to mislead on this.

#122

Thread Starter

If you're using the SL prop hub with the CARF blades, make sure you use blue lock tight on all 12 screws that hold the blades in place. I've had these and they come loose really easy. However, on the prop hub adapter, as seen the the phone. NEVER put lock tight on these. for some reason, these get really tight on their own. I've had to drill them out on another plane.

Don't use lock tight on these. They get really tight on their own.

Make sure to check all 12 of these each time you go to the field and use blue lock tight. They do come loose easy.

Don't use lock tight on these. They get really tight on their own.

Make sure to check all 12 of these each time you go to the field and use blue lock tight. They do come loose easy.

#125

Thread Starter

Hi BobH, not sure, It looked like excess gasket maker material that is used to seal when assembling the engine components. I pulled the CARB's and found nothing there. So, I'm sure when building and squeezing the engine together, some of it went inside. But all good now. The one good thing about this engine, unlike my Moki, when tuned, it does't take much to start. a few flips on the choke and a few more flips to start. When warm, no choke, just one or two flips.