spad weight

#26

4 AA flat pack. Just from the dollar store. I smacked it up in the fall. Antennae wasn't up on the transmitter. Could have patched it but I have another similar one with a TTiger Pro .40 and a few others to try. It has to be a flat pack because the downspout is cut away for the wing, and it is kind of thin there. That is where it broke too. It is pretty heavey. At about 1/3 throttle it can fall out of the air. Full throttle goes pretty fast for me, it is a very small wing for a .40 and lands pretty hot. 39" x 11" wing and 4 lb. 7 oz.

#28

Another old pic. I think that is the receiver in, not sure if the battery is in that pic. Don't think so. This is the thinner Canadian downspout. A bit more cramped.

#29

They like to break at the hole, don't they? My first Debonair crash broke the fuselage at the opening. Second fuselage I reinforced it between the wing hold down dowels with yardstick pieces epoxied spanning between them. Extra work, but it never broke there again. Now the wing.......

#30

They like to break at the hole, don't they? My first Debonair crash broke the fuselage at the opening. Second fuselage I reinforced it between the wing hold down dowels with yardstick pieces epoxied spanning between them. Extra work, but it never broke there again. Now the wing.......

#31

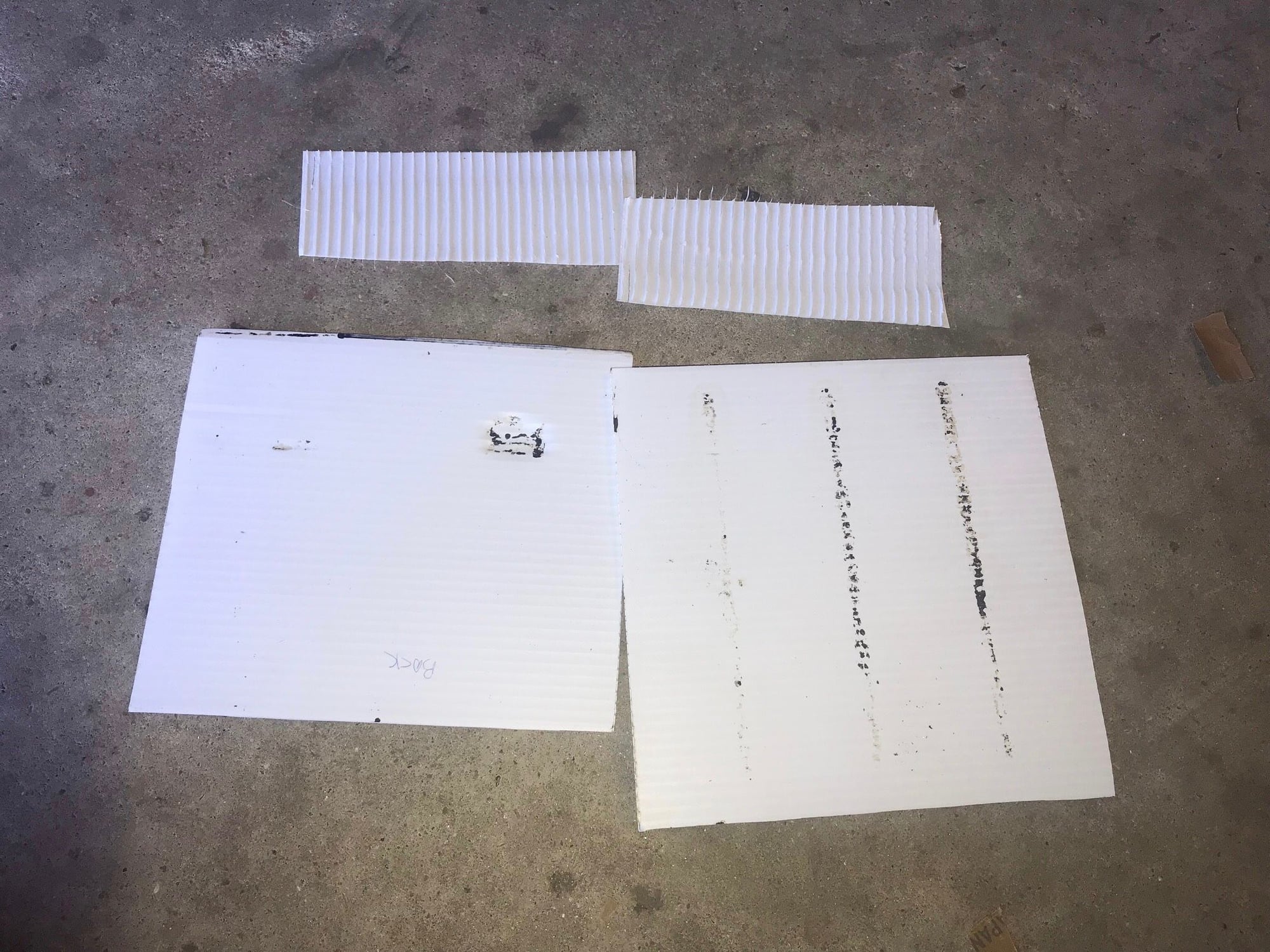

This is just FWIW. I’ve been considering coroplast as a lightweight sheeting. I never got to experiment. However I needed an insulator material in a project and I used 2 small pieces of coroplast. They worked good for my needs but were too thick; 4mm. So I decided to cut the coroplast in two.

I had made a small Mickey Mouse foam cutting bow. Just put together, not glued and a bit flimsy. I added a wire heat regulator using my power supply. I cut 2 good sides out of one piece of Coro. I cut parallel to the flutes and it cut easy.

Now when I have time I need to practice with a wing size panel. Also try cutting perpendicular to the flutes. Maybe it might work for a wing.