Loaded Dice II Build Thread

#1

Member

Thread Starter

Join Date: Dec 2004

Location: Ottawa, ON CANADA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

Hello Friends,

After being inspired by many excellent build threads on this site (and others) I think it is time to pay back.

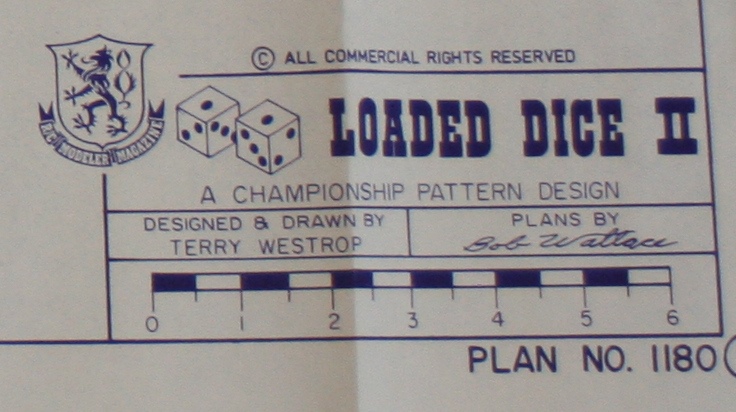

The subject of this build thread is the Loaded Dice II pattern ship, featured in RC Modeler magazine some time back. It is a fairly standard, low-wing, retractable -gear foam-core monoplane with moments and proportions that appear ideal for the precise control needed for pattern flying.

I have been building and flying for many years but I am by no means a master builder. So if you see ways to improve please feel free to chime in to help us all improve our building techniques.

I am a slow builder so please bear with me.

I hope you enjoy the build,

Wayne

After being inspired by many excellent build threads on this site (and others) I think it is time to pay back.

The subject of this build thread is the Loaded Dice II pattern ship, featured in RC Modeler magazine some time back. It is a fairly standard, low-wing, retractable -gear foam-core monoplane with moments and proportions that appear ideal for the precise control needed for pattern flying.

I have been building and flying for many years but I am by no means a master builder. So if you see ways to improve please feel free to chime in to help us all improve our building techniques.

I am a slow builder so please bear with me.

I hope you enjoy the build,

Wayne

#2

Member

Thread Starter

Join Date: Dec 2004

Location: Ottawa, ON CANADA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

I have tried many different glues. For numerous reasons that are often well documented in the many glue threads out there, I prefer to use standard carpenters' glues. My favourite right now is Weldbond. I will use it almost everywhere there is balsa to balsa contact, except in the engine compartment where I use 30 minute epoxy.

Weldbond comes out thick, dries perfectly clear in a jiffy, sands very easily, and doesn't seem to get brittle at all. I do not work for this company- I just like the product...

On this build thus far I have also used Sig bond for the wing skin edge gluing and Super-phatic for some of the pre-clamped fuse joints.

Will discuss more about glue use later as I start gluing things together.

-W

Weldbond comes out thick, dries perfectly clear in a jiffy, sands very easily, and doesn't seem to get brittle at all. I do not work for this company- I just like the product...

On this build thus far I have also used Sig bond for the wing skin edge gluing and Super-phatic for some of the pre-clamped fuse joints.

Will discuss more about glue use later as I start gluing things together.

-W

#3

Member

Thread Starter

Join Date: Dec 2004

Location: Ottawa, ON CANADA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

After studying the plans and choosing engine configurations, one of the first steps for me was to start making templates. There are lots of great ways to do this, from printing out a second set of plans and cutting out the parts (too costly for me) to placing carbon paper under the plans and tracing the parts (waay to difficult) to simply using tracing paper over the plans and gluing the tracings onto the wood.

I settled on the use of tracing paper to trace the parts which are then glued onto poster board, cut to shape, and traced onto the wood. Then I cut the parts. This method does come with an extra step, (gluing the tracing paper to the poster board) but I don't like gluing paper to the parts.

One beauty of scratch-building is your total control over the build. Total control starts here in the choices we make.

W

I settled on the use of tracing paper to trace the parts which are then glued onto poster board, cut to shape, and traced onto the wood. Then I cut the parts. This method does come with an extra step, (gluing the tracing paper to the poster board) but I don't like gluing paper to the parts.

One beauty of scratch-building is your total control over the build. Total control starts here in the choices we make.

W

#4

Member

Thread Starter

Join Date: Dec 2004

Location: Ottawa, ON CANADA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

At this point I should indicate my choice of powerplant. It will be a 6S 4 to 5000 mAh feeding an OS 50 Electric. I will run the numbers on motocalc but I am using this setup on a .60 size Great Planes Zlin Acrobat (weight about 7.5 lbs) and the setup is really nice. Huge vertical (though not unlimited), big round- and square-loops, and easy 8 minute flights with lots of reserve.

And almost whisper quiet. (Although I do love noise as well...)

Anyway, it looks like this setup will fit with no issues...

W

And almost whisper quiet. (Although I do love noise as well...)

Anyway, it looks like this setup will fit with no issues...

W

#7

Member

Thread Starter

Join Date: Dec 2004

Location: Ottawa, ON CANADA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

One thing I should mention is that I am fortunate to have a band saw, scroll saw, drill press, and belt/disk sander to help in cutting the parts.

If you don't have these tools you can still scratch build, but things might take a bit longer and you won't have as much control over the results.

That said, these are great tools to have not only for the hobby but for general use as well.

That's all for now, will post more soon.

W

If you don't have these tools you can still scratch build, but things might take a bit longer and you won't have as much control over the results.

That said, these are great tools to have not only for the hobby but for general use as well.

That's all for now, will post more soon.

W

Last edited by waynek; 04-19-2014 at 09:52 PM.

#14

Member

Thread Starter

Join Date: Dec 2004

Location: Ottawa, ON CANADA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

The plans called for 1/2" balsa along the top and 1/4 and 3/16" balso along the bottom.

I improvised and used laminated 1/4 inch along the top.

Most of the Fuse was constructed with Weldbond. After I had it all clampted together for a trial fit though, I realized that it was so nicely aligned that I didn't want to take it apart. So I dusted off the bottle of Super-Phatic that I've had for some time and gave it a try.

It seemed to work very well. The second photo shows how it sort of wicks into the wood as others have said. You definitely need a tight joint for this glue, but other than that I am pleased with it..

W

I improvised and used laminated 1/4 inch along the top.

Most of the Fuse was constructed with Weldbond. After I had it all clampted together for a trial fit though, I realized that it was so nicely aligned that I didn't want to take it apart. So I dusted off the bottle of Super-Phatic that I've had for some time and gave it a try.

It seemed to work very well. The second photo shows how it sort of wicks into the wood as others have said. You definitely need a tight joint for this glue, but other than that I am pleased with it..

W

#15

Member

Thread Starter

Join Date: Dec 2004

Location: Ottawa, ON CANADA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

Moving slowly forward...

The portion of the fuse below the wing will eventually have to be cut away so I completed this step now while I can see the bulkheads. I left a small bit uncut to keep the structure intact for finish assembly and sanding. Once the fuse is almost complete just a few small cuts and the wing saddle and fuse portion under the wing should just fall away.

I say should...

W

The portion of the fuse below the wing will eventually have to be cut away so I completed this step now while I can see the bulkheads. I left a small bit uncut to keep the structure intact for finish assembly and sanding. Once the fuse is almost complete just a few small cuts and the wing saddle and fuse portion under the wing should just fall away.

I say should...

W

#16

Member

Thread Starter

Join Date: Dec 2004

Location: Ottawa, ON CANADA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

One more for tonight.

Some errors in the bulkheads were correctly quickly and accurately using the Zona pull saw.

This is a very handy tool. Very handy.

Soon we will head out to the garage for some sanding...

Never sand in the house. Trust me.

W

Some errors in the bulkheads were correctly quickly and accurately using the Zona pull saw.

This is a very handy tool. Very handy.

Soon we will head out to the garage for some sanding...

Never sand in the house. Trust me.

W

#17

Member

Thread Starter

Join Date: Dec 2004

Location: Ottawa, ON CANADA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

This wasn't on the plans so I improvised.

Battery tray for a 6S 50000 mAh LiPo.

I tried to keep it light and strong, with openings for velcro straps.

Some holes are better than others. Still learning the fine art of the Forstener bit (sp?)

Very handy once you get the hang of it, m'thinks.

W

Battery tray for a 6S 50000 mAh LiPo.

I tried to keep it light and strong, with openings for velcro straps.

Some holes are better than others. Still learning the fine art of the Forstener bit (sp?)

Very handy once you get the hang of it, m'thinks.

W

#18

Member

Thread Starter

Join Date: Dec 2004

Location: Ottawa, ON CANADA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

At this point I had the fuse top and bottom glued in place and all that remained was to plane and sand. Out in the garage of course.

I love planing, something therapeutic about it.

Get one of these master airscrew mini-planes. Or one like it. I have 2, one with a Wilkinson razor blade for really fine work and foam shaping and one with a standard blade that I use for most balsa tasks.

If you have never done this, ya gotta try it. The fuse started off as a box...

W

I love planing, something therapeutic about it.

Get one of these master airscrew mini-planes. Or one like it. I have 2, one with a Wilkinson razor blade for really fine work and foam shaping and one with a standard blade that I use for most balsa tasks.

If you have never done this, ya gotta try it. The fuse started off as a box...

W

Last edited by waynek; 04-23-2014 at 03:40 PM.

#19

Member

Thread Starter

Join Date: Dec 2004

Location: Ottawa, ON CANADA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

It looked like this. I am sensitive to balsa (what a curse, eh?) so I often use a mask when sanding.

The second photo is more of a before shot...

W

The second photo is more of a before shot...

W

#23

Member

Thread Starter

Join Date: Dec 2004

Location: Ottawa, ON CANADA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

Continued working on the fuse. Just love spreading glue and putting the wood in place. Therapeutic.

Not on the plans, but I decided to use slightly thinner wood on the cockpit portion of the fuse and instead install a horizontal brace, as there was a lot of real estate with not much structural reinforcement in that area. Judgement call.

Weight saving is important, but it's not a 3D bird.

W

Not on the plans, but I decided to use slightly thinner wood on the cockpit portion of the fuse and instead install a horizontal brace, as there was a lot of real estate with not much structural reinforcement in that area. Judgement call.

Weight saving is important, but it's not a 3D bird.

W

#25

Member

Thread Starter

Join Date: Dec 2004

Location: Ottawa, ON CANADA

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

Hey, its starting to look like a fuselage!

See what I mean about the proportions and control moments? The long aft fuselage portion should bring really precise pitch control and I hope a predictable knife-edge as well.

My aim is to have a smooth, predictable, linear machine that goes exactly where I want it to and doesn't 'move' unless told to do so. I love big square loops, precise cuban-8's, and low inverted flybys. I'm stuck in the '80s.

W

See what I mean about the proportions and control moments? The long aft fuselage portion should bring really precise pitch control and I hope a predictable knife-edge as well.

My aim is to have a smooth, predictable, linear machine that goes exactly where I want it to and doesn't 'move' unless told to do so. I love big square loops, precise cuban-8's, and low inverted flybys. I'm stuck in the '80s.

W

Subscribed!

Subscribed!