Kadet JR Changeling ODO

#51

Thread Starter

Since the maple with out any carbon fiber produces such great results I won't bother going that route.

I have no way to measure what one of these joiners weighs, but it very little. That is also a surprise.

Now To make and test joiner pockets

Will like use carbon fiber cross plates top and bottom.

The point loads on these thing is got to be insane.

Ken

I have no way to measure what one of these joiners weighs, but it very little. That is also a surprise.

Now To make and test joiner pockets

Will like use carbon fiber cross plates top and bottom.

The point loads on these thing is got to be insane.

Ken

#52

Thread Starter

Dave posted this info and pic and the Kadet Brotherhood

This little bird is a porky thing, 4.75 lbs or 2.375 lbs per wing panel.

So a revised estimate is then a 10 G load test was done. 23.7 lbs is what I added. I did push down a little at the end of the test so I still think it is more than good.

I may rerun the test on a scrap piece of joiner material. If so I push it till failure.

Ken

This little bird is a porky thing, 4.75 lbs or 2.375 lbs per wing panel.

So a revised estimate is then a 10 G load test was done. 23.7 lbs is what I added. I did push down a little at the end of the test so I still think it is more than good.

I may rerun the test on a scrap piece of joiner material. If so I push it till failure.

Ken

#53

Thread Starter

I have more blank stock for joiners made. I use little dots of epoxy to hold 2 together for shaping 2 at a time to keep them the same. After they a fully shaped then the epoxy taps will be cut off and that will give me 2 matching parts.

Well that is the theory any way.

Rethinking the assembly a bit. I will make the center wing section next. That give me something to work with for getting the spade joiner pockets correct. Dug out a supply of carbon fiber plate.

Ken

Well that is the theory any way.

Rethinking the assembly a bit. I will make the center wing section next. That give me something to work with for getting the spade joiner pockets correct. Dug out a supply of carbon fiber plate.

Ken

#54

My Feedback: (3)

Join Date: Sep 2008

Location: Hoodsport, WA

Posts: 599

Likes: 0

Received 0 Likes

on

0 Posts

Maple is really tough stuff. Dense, although with that, comes weight. I this application, IMHO, it's not a big deal. If weight was more a critical factor, basswood would suffice. That being said, birch plywood gives the best weight-to-strength performance, as far as wood is concerned.

#55

Thread Starter

Got to agree EJ. Maple is some really strong stuff. I did test a 1/2" piece of birch AC ply. It failed much sooner. I suspect because it being ply and not all of the grain being in the longitudinal direction, its bending load was thus less. I am limited in space with JR. My maple joiners are only 1/4" thick and 5/8" tall. Pretty small.

The wight of this small piece of maple is not very much at all. I am going to be hard pressed to keep the wight of 6 joiner pockets (well actually 8, two in bottom of fuse also) to such low wight as the joiners. 2 pockets per wing panel, 2 pockets in wing center section that bolts on in place of the old wing, and I am going to add 2 pockets to the bottom of the fuse for low configuration.

Ken

The wight of this small piece of maple is not very much at all. I am going to be hard pressed to keep the wight of 6 joiner pockets (well actually 8, two in bottom of fuse also) to such low wight as the joiners. 2 pockets per wing panel, 2 pockets in wing center section that bolts on in place of the old wing, and I am going to add 2 pockets to the bottom of the fuse for low configuration.

Ken

#57

Thread Starter

That is why it is such a changeling.

The wing panels will work either high or low wing And various dihedral angles. The spade joiners pairs will also fit both the flat bottom and symmetrical wing panels in both high and low wing configurations.

The anti rotation pins will most likely give me a giant head ache. I will cross that bridge when I get there.

I worked a little bit today but I just can't seem to stay focused and interested today. Wife is under the weather and I just want to stay near her. So it is time to que up another episode of Voyager

Ken

The wing panels will work either high or low wing And various dihedral angles. The spade joiners pairs will also fit both the flat bottom and symmetrical wing panels in both high and low wing configurations.

The anti rotation pins will most likely give me a giant head ache. I will cross that bridge when I get there.

I worked a little bit today but I just can't seem to stay focused and interested today. Wife is under the weather and I just want to stay near her. So it is time to que up another episode of Voyager

Ken

#58

Thread Starter

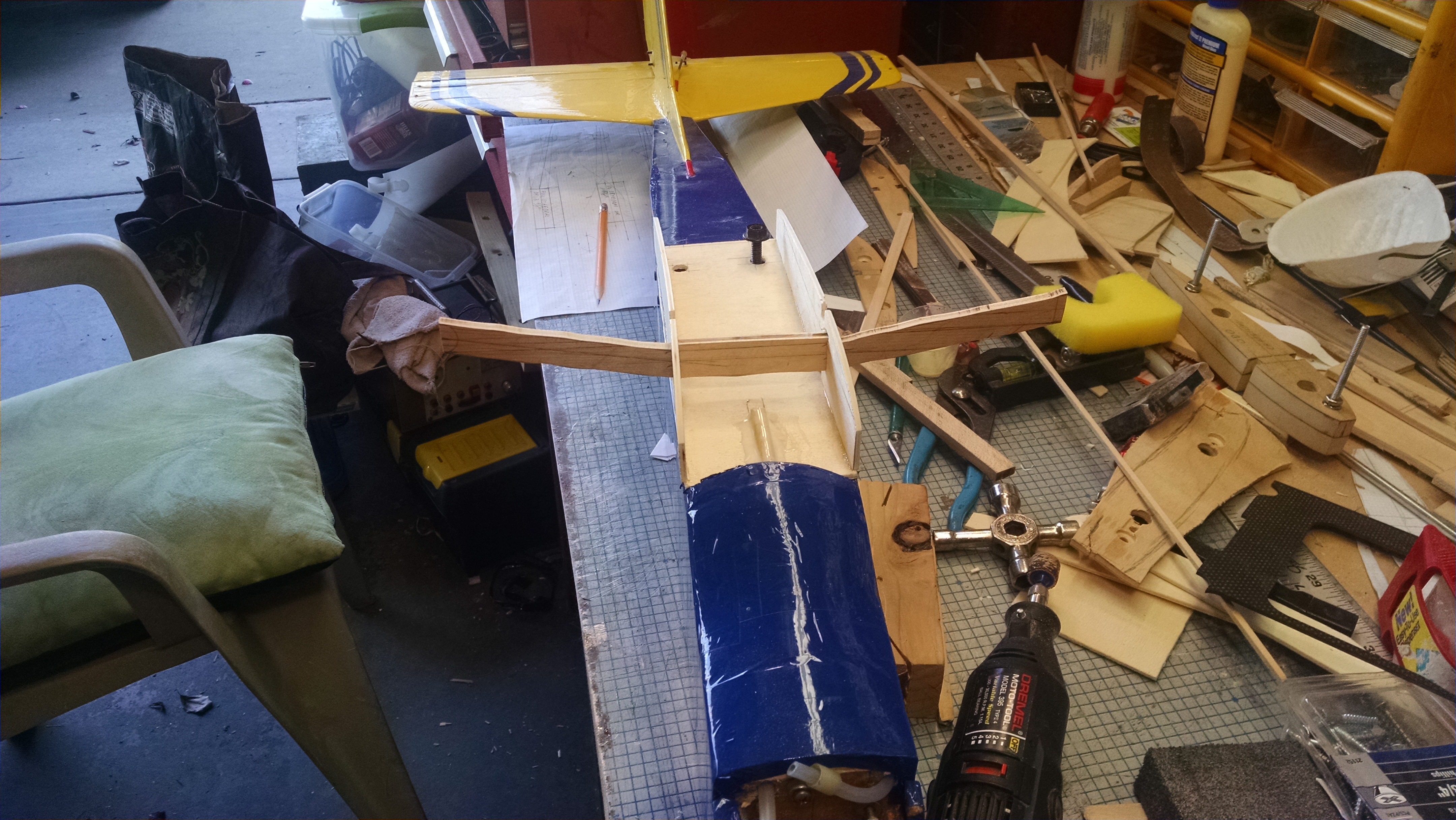

The new center section. Front hold down down pin and the bolts will line up just like they did with the original wing. No fuse mods, yet.

It is light ply. Will add a center balsa rib or 2 for the top sheeting. Still have to cut the holes for the joiners and the add the joiner pockets.

I really am figuring out some of this as I go

The fuse has a 1/32 birch ply doubler from fire wall to wing T.E. I can just cut the joiner holes and add joiner pockets in the bottom of fuse for the low wing

Ken

It is light ply. Will add a center balsa rib or 2 for the top sheeting. Still have to cut the holes for the joiners and the add the joiner pockets.

I really am figuring out some of this as I go

The fuse has a 1/32 birch ply doubler from fire wall to wing T.E. I can just cut the joiner holes and add joiner pockets in the bottom of fuse for the low wing

Ken

#60

Thread Starter

Heck yeah, always. It is a very old one and I need to make new fixtures. Someday, a few things first though.

Saw it demonstrated at a show in LA. Bought it on the spot.

Saw it demonstrated at a show in LA. Bought it on the spot.

#61

Thread Starter

I realize I simply could have just installed joiner pocket at the top of the fuse just below the bottom of the wing saddle. But that would have lowered the high wing a fair amount. That is why a new wing center section. Not the easy way, But then I would have just made new wings.

Also just realized I do not have any spar stock. I can cut some from some 1/4" stock I have or get some spar stock (8) in a few days.

Ken

Also just realized I do not have any spar stock. I can cut some from some 1/4" stock I have or get some spar stock (8) in a few days.

Ken

#66

#67

Thread Starter

Who me? talk about you? naaahhhh

I been trying to get my wife's broke off tooth taken care of.she is in a lot pain, but would not let me use my pliers

So tomorrow morning she gets it out.

That is why not much work done.

But I have some drawing to doe and a mock up. I think I have a simpler set up for the joiners.

Does not change the project. Just like normal for me. I start down a road and the see a better way. Let ya know this afternoon. Maybe a single joiner per dihedral. So that would be 3 joiner and that is for both wing sets.

Ken

I been trying to get my wife's broke off tooth taken care of.she is in a lot pain, but would not let me use my pliers

So tomorrow morning she gets it out.

That is why not much work done.

But I have some drawing to doe and a mock up. I think I have a simpler set up for the joiners.

Does not change the project. Just like normal for me. I start down a road and the see a better way. Let ya know this afternoon. Maybe a single joiner per dihedral. So that would be 3 joiner and that is for both wing sets.

Ken

#68

Thread Starter

Made a joiner for the 1/2" dihedral and made cut outs for the joiners in the center section. Will be adding some carbon fiber plate in there and gusseting real good.

And the I went "oh crud". I forgot to check if the stock dihedral joiner would go through. So I made a mock up. And yes it goes through. the high point (the end) has already cleared the center section before the taller part of the joiner enters. A question of geometry. I just was not sure till I tried it.

So no more nonsense of two joiners for a single wing. I was going to put them on opposite sides of the spar.

Now it gets much simpler and easier.

Well other than that as you recall I epoxied, at the ends, the joiner blanks together in pairs, so as I could shape them together for accuracy. Well guess what I need them apart now. Looks like I get to buy more maple. This time a narrower piece, but longer. Being as the others were only a foot long and a 1/4" wide they kept dropping through the blade insert. I have not yet made a zero clearance insert for my table saw. I have lots of things to make for my table saw.

I still have to do a couple of more load test. I have to make sure the joiner pockets are strong enough and also that they are not rip loose. Also I realized with these new joiners I have another stress riser. Right at the center of the joiner, not just at the pockets. I seriously think it will be OK, as the joiner is a bit thicker in the center section, so that should handle it just fine.

Well I knew this was going to be a learning experience. I do these dumb things so you don't have to. yeah right

Ken

And the I went "oh crud". I forgot to check if the stock dihedral joiner would go through. So I made a mock up. And yes it goes through. the high point (the end) has already cleared the center section before the taller part of the joiner enters. A question of geometry. I just was not sure till I tried it.

So no more nonsense of two joiners for a single wing. I was going to put them on opposite sides of the spar.

Now it gets much simpler and easier.

Well other than that as you recall I epoxied, at the ends, the joiner blanks together in pairs, so as I could shape them together for accuracy. Well guess what I need them apart now. Looks like I get to buy more maple. This time a narrower piece, but longer. Being as the others were only a foot long and a 1/4" wide they kept dropping through the blade insert. I have not yet made a zero clearance insert for my table saw. I have lots of things to make for my table saw.

I still have to do a couple of more load test. I have to make sure the joiner pockets are strong enough and also that they are not rip loose. Also I realized with these new joiners I have another stress riser. Right at the center of the joiner, not just at the pockets. I seriously think it will be OK, as the joiner is a bit thicker in the center section, so that should handle it just fine.

Well I knew this was going to be a learning experience. I do these dumb things so you don't have to. yeah right

Ken

#71

My Feedback: (6)

My father served over 3 years on an AAF base in the Pacific as head armorer during WWII and his teeth rotted out due to living off C-rashions for 6 months and had to have them taken out. He had to choices go to a field hospital and have oral surgery or drink a quart of whiskey and have an old vet break the teeth off with pliers and pull the roots out like he did for the Army Mules. Dad had started his Army career training mules in Colorado Springs in 1940 so he went with the vet. The vet had better success and a lot few infections afterwards then the hospital did. Dad wasn't alone in picking the vet. The WWII generation had a lot of guts in those days!

#72

Thread Starter

Yeah they where a tough bunch Mike.

Well I told her I could clean my automotive pliers up with alcohol. And if she was worried about it hurting to much I could give her very loveing tap on the head with my rubber mallet.

I then quickly made a strategic withdrawal from the room!

We did get it accomplished yesterday and she feels much better now. She had a 7:30 am appointment. But when we got there the receptionist said she needed a different proof of income. those papers ares some wheres in storage) and offered no help or suggestions. At that point my wife was in tears and really angry. We left and I told my wife to just bear with me, I was going to get this done. A trip to the bank for a a printout and a and then a 30 minute trip to there other office. Spoke to the supervisors. She made some calls and demanded to know why my wife was not seen. Said go back to the other office and my wife would be taken care of. And indeed she was, said the dentist was really great.

So maybe by later today or tomorrow back to building Odo.

And to add a little about this design work, these ideas and methods will find there way over to my Kadet SR in the future. But just fo a fixed dihedral, low wing conversion. May remove the tail on it and make it removable for easier transport in my car.

Ken

Well I told her I could clean my automotive pliers up with alcohol. And if she was worried about it hurting to much I could give her very loveing tap on the head with my rubber mallet.

I then quickly made a strategic withdrawal from the room!

We did get it accomplished yesterday and she feels much better now. She had a 7:30 am appointment. But when we got there the receptionist said she needed a different proof of income. those papers ares some wheres in storage) and offered no help or suggestions. At that point my wife was in tears and really angry. We left and I told my wife to just bear with me, I was going to get this done. A trip to the bank for a a printout and a and then a 30 minute trip to there other office. Spoke to the supervisors. She made some calls and demanded to know why my wife was not seen. Said go back to the other office and my wife would be taken care of. And indeed she was, said the dentist was really great.

So maybe by later today or tomorrow back to building Odo.

And to add a little about this design work, these ideas and methods will find there way over to my Kadet SR in the future. But just fo a fixed dihedral, low wing conversion. May remove the tail on it and make it removable for easier transport in my car.

Ken

#74

Thread Starter

I go to Sac about once a month to shop at the commissary. Stock up on meat.

Used to fly @ SAM before going to Texas. Going to have to fly there again sometime.

Ken

Used to fly @ SAM before going to Texas. Going to have to fly there again sometime.

Ken

#75

Oh boy! I'm late to the party Ken, it's going to take me a while to catch up. As a matter of fact, I'm way behind on all the forums I'm subscribed to. It's that work thing, always getting in the way! But it's slowing down now... for a while at least.