Kadet JR Changeling ODO

#126

Thread Starter

Hi Mike

Mom is very forgetful. Could not remember were the pedestrian gate was the other day (at the end of the drive way gate on closed side). Will tell the same story as yesterday.

If we were not here I am sure mom would not be allowed to live by herself.

The drive way gate is electric. I just fixed it last month, (replaced the back rollers), got to fix it again. it is a replacement for on I built many years ago. Moms' Late husband drove thru that one. So this is the replacement. It has been climbed a few times and the bars bent,putting it out of balance. The wheels have roller bearings but no thrust bearings. If I owned a company and one of my employees came to me with a wheel designed like that I would fire him yesterday. With the gate having a bent top bar, it is putting excessive side loads on the wheels. Thrust bearings would protect the wheels.

Well tomorrow I will buy a come along and make a tripod like mount to attach to the gate horizontal bars and winch them back into straight. Just by design the gate will still be out of balance but not nearly as bad. Will also move the upper roller bar up from the middle to the top. That will help also with the side loads on the wheels.

Then the fun part. Dig out the whole gate path, and pour a concrete pad under the opening section of the gate travel. Then put a pair of rubber wheels on the open end of the gate. That will solve it for good I think.

But tonight I got a little more work done. My panel now has a Leading edge. Glue up out of 1/4" x 1/2". The glue line is parallel to the wing. Gives me a nice center line also.

Did not like the shape of stock L.E.s. Not straight, and made from iron wood.

That is as far as I can go tonight.

Ken

Mom is very forgetful. Could not remember were the pedestrian gate was the other day (at the end of the drive way gate on closed side). Will tell the same story as yesterday.

If we were not here I am sure mom would not be allowed to live by herself.

The drive way gate is electric. I just fixed it last month, (replaced the back rollers), got to fix it again. it is a replacement for on I built many years ago. Moms' Late husband drove thru that one. So this is the replacement. It has been climbed a few times and the bars bent,putting it out of balance. The wheels have roller bearings but no thrust bearings. If I owned a company and one of my employees came to me with a wheel designed like that I would fire him yesterday. With the gate having a bent top bar, it is putting excessive side loads on the wheels. Thrust bearings would protect the wheels.

Well tomorrow I will buy a come along and make a tripod like mount to attach to the gate horizontal bars and winch them back into straight. Just by design the gate will still be out of balance but not nearly as bad. Will also move the upper roller bar up from the middle to the top. That will help also with the side loads on the wheels.

Then the fun part. Dig out the whole gate path, and pour a concrete pad under the opening section of the gate travel. Then put a pair of rubber wheels on the open end of the gate. That will solve it for good I think.

But tonight I got a little more work done. My panel now has a Leading edge. Glue up out of 1/4" x 1/2". The glue line is parallel to the wing. Gives me a nice center line also.

Did not like the shape of stock L.E.s. Not straight, and made from iron wood.

That is as far as I can go tonight.

Ken

#127

Thread Starter

Wife and I have been working on something else in the evening also. Designing a Teardrop trailer. I installed a hitch on our car just before starting the lawn sprinkler task. Needed a way to tow home a ditch digger.

So that was step one. Now I am squirrelling away money from our checks. Will be able to buy a Harbor Fright 4 x 8 heavy duty come February.

So after that we can accumulate the build material. Mostly 1/8" ply and white foam, and some Poplar. I have a 1000lb tow limit and 100lb tongue limit.

We are not small people so need a queen bed to be comfortable. Sets the minimum size. A 10'x5.5'TD.

White is such a limit, so before even hoping we could build on I had to figure out the wight. Wrote a spreadsheet to figure it out. So far I am at 600lbs before loading it out with gally, bed and supplies. Looks like I can do it.

I will be able to hauls airplanes in it that I just can't do in the car. So it will be airplane related, sort of.

Wish there was a place on this site to post it.

Ken

So that was step one. Now I am squirrelling away money from our checks. Will be able to buy a Harbor Fright 4 x 8 heavy duty come February.

So after that we can accumulate the build material. Mostly 1/8" ply and white foam, and some Poplar. I have a 1000lb tow limit and 100lb tongue limit.

We are not small people so need a queen bed to be comfortable. Sets the minimum size. A 10'x5.5'TD.

White is such a limit, so before even hoping we could build on I had to figure out the wight. Wrote a spreadsheet to figure it out. So far I am at 600lbs before loading it out with gally, bed and supplies. Looks like I can do it.

I will be able to hauls airplanes in it that I just can't do in the car. So it will be airplane related, sort of.

Wish there was a place on this site to post it.

Ken

#129

Thread Starter

Thanks Mike.

I have been burning up the Teardrops n Tiny Travel Trailers site.

We love to camp and fish. And it would also be nice for hunting. In the past I have been able to combine camping and flying. It don't get much better than that, unless it is camping, float flying, and fishing. Haven't had the chance for that on yet.

I took the wing off of the board and it is very light. A Course the top sheeting is not on, or shear webbing, nor the cap strips.

And I still have to install the hard points for the joiners.

I hung the board back up in the closet for the holidays. It just gets in the way.

Back to it in a day or so.

Ken

I have been burning up the Teardrops n Tiny Travel Trailers site.

We love to camp and fish. And it would also be nice for hunting. In the past I have been able to combine camping and flying. It don't get much better than that, unless it is camping, float flying, and fishing. Haven't had the chance for that on yet.

I took the wing off of the board and it is very light. A Course the top sheeting is not on, or shear webbing, nor the cap strips.

And I still have to install the hard points for the joiners.

I hung the board back up in the closet for the holidays. It just gets in the way.

Back to it in a day or so.

Ken

#130

... Designing a Teardrop trailer. ... Will be able to buy a Harbor Fright 4 x 8 heavy duty come February. ... I will be able to hauls airplanes in it that I just can't do in the car. So it will be airplane related, sort of.

Wish there was a place on this site to post it.

Ken

Wish there was a place on this site to post it.

Ken

As far as a place on this site to post, why not either the Clubhouse or the planes/helis off-topic threads? I think such a project would be just fine in either place.

Dave

#132

Thread Starter

Hi EJ. Been awhile. Good to see ya again.

Speaking of teardrop trailers. Ya know all of the annoying adds that now pop up all over the site and in the middle of post? Well One popped in the middle of this page. It happened to be TD windows on Amazon. Not a bad price, but I bet I can scrounge and find cheaper. Doors I can make, but windows? I am not real confident of. Every thing has got to seal. You can look at it like building a house, although a very tiny house on wheels.

Not a bad price, but I bet I can scrounge and find cheaper. Doors I can make, but windows? I am not real confident of. Every thing has got to seal. You can look at it like building a house, although a very tiny house on wheels.

Now back to the plane.

I pulled the board out of the closet tonight.

I set up the long bits. T.E., bottom L.E sheeting and bottom spar. Also glued up the L.E.

Tonight was all reruns on TV so I made fair progress.

Ken

Speaking of teardrop trailers. Ya know all of the annoying adds that now pop up all over the site and in the middle of post? Well One popped in the middle of this page. It happened to be TD windows on Amazon.

Now back to the plane.

I pulled the board out of the closet tonight.

I set up the long bits. T.E., bottom L.E sheeting and bottom spar. Also glued up the L.E.

Tonight was all reruns on TV so I made fair progress.

Ken

#134

Thread Starter

Hi Mike

yep I have been thinking about how to carry planes in the TD

I am going to have some under floor storage as well as there will be a 1' foot wide storage / bed headboard? area in the front. Most likely will just carry planes on the bed and stash them in the car at night or a on the car roof with a tarp or a some kind of dedicated overnight storage. Believe me I will come up with something. My former wife and I went camping with a popup camp trailer. I took planes. I did have a mini van then though and I just used a pvc pipe transport in the van. Went to the dry lake beds near 29 Palms. Must have been December or February, nice during the day but oh man did it get cold at night. Fantastic flying though. Fly all day nearly taking time to cook 3 meals and just chill out. Spent a week doing that.

Spending a lot of time already thinking through some of the construction of the TD and methods. Solved some of it, and thought of special tool fixtures to build to enable some of it. Time to start a word doc for this sort of thing.

I initially did the wight calculations in my head very roughly to see if the project was even feasible under the TV (tow vehicle) constraints. It got to complex fast, so starting writing a spreadsheet to run the numbers for me. Last page of the spreadsheet is nothing more than look up tables. Wight and cost of the various materials to be used in the build. The spreadsheet will eventually also calculate balance for me. That pesking 100lb tongue limit.

Wife and I both agree that as much of a blessing as this car has been, we need and want something less restrictive, like a mini van or truck. So down the road maybe.

I worked on the plane last night for about 3 hours. Not much to show for my efforts. I did not change out the wax paper and things started sticking and tear off big strips off paper.

So I bit the bullet and took everything off the board. Taped on new wax paper. And the spent the rest of the night getting the long pieces (bottom spar, bottom sheeting, etc) lined back up and true.

I got one rib glued on for the entire night's work.

Tonight will go fast now that every thing is laid out and true. No complaint here though, I enjoyed the work.

Will have to get the spade joiner pockets in before top sheeting and also landing gear blocks. I want the options to install LG to the wing panels in the low wing configuration. I used the planes main LG for another plane and did a lot of bending to get proper prop clearance. So hence new main landing gear is must for ODO

yep I have been thinking about how to carry planes in the TD

I am going to have some under floor storage as well as there will be a 1' foot wide storage / bed headboard? area in the front. Most likely will just carry planes on the bed and stash them in the car at night or a on the car roof with a tarp or a some kind of dedicated overnight storage. Believe me I will come up with something. My former wife and I went camping with a popup camp trailer. I took planes. I did have a mini van then though and I just used a pvc pipe transport in the van. Went to the dry lake beds near 29 Palms. Must have been December or February, nice during the day but oh man did it get cold at night. Fantastic flying though. Fly all day nearly taking time to cook 3 meals and just chill out. Spent a week doing that.

Spending a lot of time already thinking through some of the construction of the TD and methods. Solved some of it, and thought of special tool fixtures to build to enable some of it. Time to start a word doc for this sort of thing.

I initially did the wight calculations in my head very roughly to see if the project was even feasible under the TV (tow vehicle) constraints. It got to complex fast, so starting writing a spreadsheet to run the numbers for me. Last page of the spreadsheet is nothing more than look up tables. Wight and cost of the various materials to be used in the build. The spreadsheet will eventually also calculate balance for me. That pesking 100lb tongue limit.

Wife and I both agree that as much of a blessing as this car has been, we need and want something less restrictive, like a mini van or truck. So down the road maybe.

I worked on the plane last night for about 3 hours. Not much to show for my efforts. I did not change out the wax paper and things started sticking and tear off big strips off paper.

So I bit the bullet and took everything off the board. Taped on new wax paper. And the spent the rest of the night getting the long pieces (bottom spar, bottom sheeting, etc) lined back up and true.

I got one rib glued on for the entire night's work.

Tonight will go fast now that every thing is laid out and true. No complaint here though, I enjoyed the work.

Will have to get the spade joiner pockets in before top sheeting and also landing gear blocks. I want the options to install LG to the wing panels in the low wing configuration. I used the planes main LG for another plane and did a lot of bending to get proper prop clearance. So hence new main landing gear is must for ODO

#135

My Feedback: (6)

Dump the waxed paper! They changed it to make more Microwave oven friendly and now its porous, the CA leaks right through it! Switch to plastic sheet like plastic wrap, Great planes Plans protector, or even the clear backing from Monokote/Ultracote rolls. Before I replaced my windows I use to buy some heat shrinkable plastic to put over the windows to act as a storm window. I use to take it down in the spring and save it to build on.

#136

Thread Starter

Thanks Mike. Now that you mention it I seem to recall something to that effect.

Can't use CA next to the wife. just Tightbond 2

Last project I waxed the wax paper with Carnuba. That worked good.

I also save the plastic backing from Monocoat. But even then CA will sometimes stick if you have scratched and cut it in even a tiny fashion.

Wife was saying we will have to buy a case of wax paper for the TD. of Lots of lay ups involved in building it.

Church tonight (bible study actually), but still intending to get some done. We have missed church now for 3 weeks due to flue, cold or whatever.

Our monthly trip to Sacramento tomorrow. Commissary, mostly meat. But also the hobby shop. More balsa. !/16" sheet mostly. Still have to get enough for the round wing.

And friday back on the stupid gate. New wheels and bend the gate horizontal bars back to straight. I will post a pic of the rig for that. Hopefully the rig won't fly off, it might land a block away. I will chain it., and keep my head out of the way. I tried to bend the bar once already using a ratchet strap. That scared me and I quit.

Ken

Can't use CA next to the wife. just Tightbond 2

Last project I waxed the wax paper with Carnuba. That worked good.

I also save the plastic backing from Monocoat. But even then CA will sometimes stick if you have scratched and cut it in even a tiny fashion.

Wife was saying we will have to buy a case of wax paper for the TD. of Lots of lay ups involved in building it.

Church tonight (bible study actually), but still intending to get some done. We have missed church now for 3 weeks due to flue, cold or whatever.

Our monthly trip to Sacramento tomorrow. Commissary, mostly meat. But also the hobby shop. More balsa. !/16" sheet mostly. Still have to get enough for the round wing.

And friday back on the stupid gate. New wheels and bend the gate horizontal bars back to straight. I will post a pic of the rig for that. Hopefully the rig won't fly off, it might land a block away. I will chain it., and keep my head out of the way. I tried to bend the bar once already using a ratchet strap. That scared me and I quit.

Ken

#139

Thread Starter

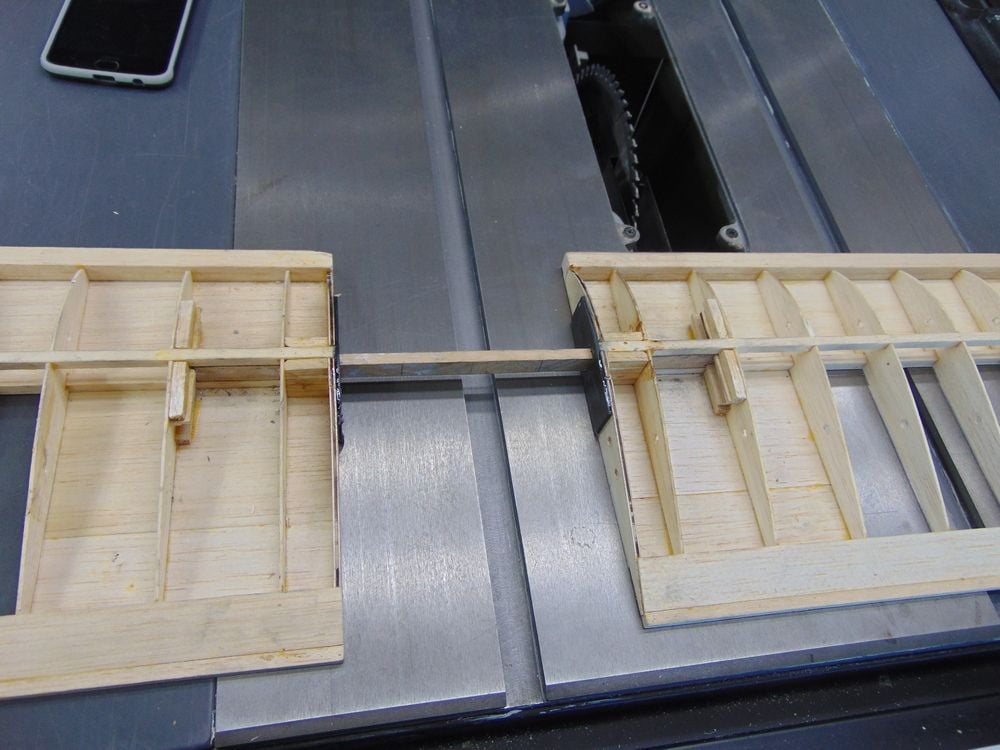

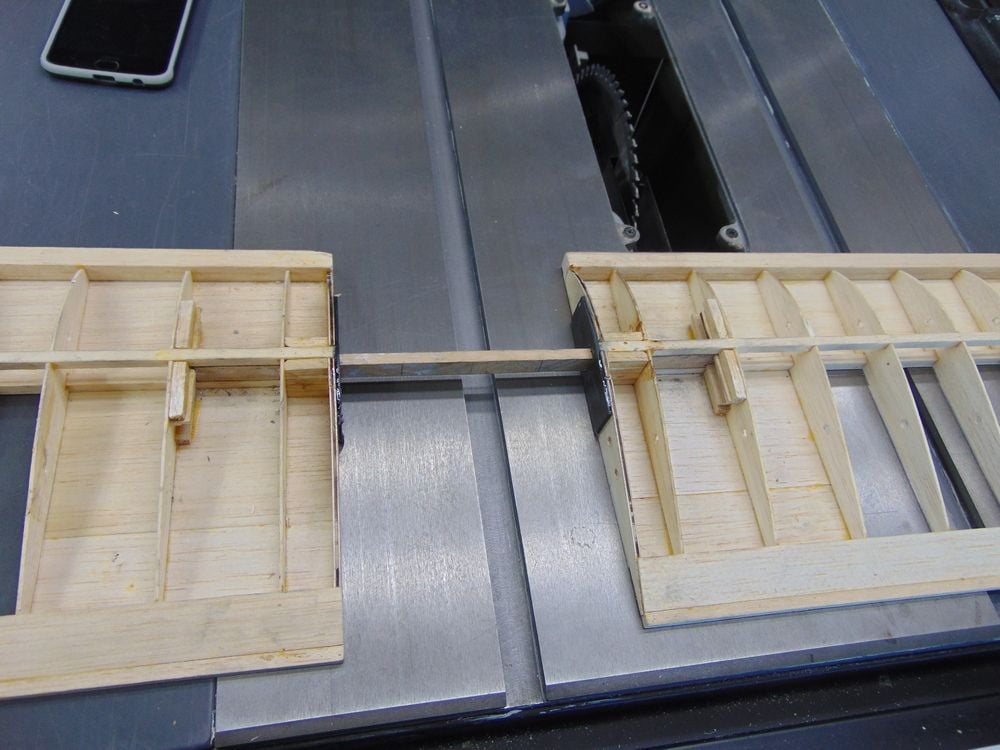

layed the 2 panels on each other bottom to bottom. They lay dead on flat to each other even when I turn them opposite. So me thinks they are true.

I skipped working on the gate for a bit. Correcting the original install mistake has done wonders for it. It should work fine for years with just new wheels.

I have to cut the Maple joiners yet. For the longest time I have tried to figure out how the end of the joiner was going to adequately supported and not just rip thru the top or bottom of the wing 2 ribs in. Finally got it, 2 things. 1 move the joiner location forward instead of on the front of spars. Doing so gives me much more room to wrap the receiver end around the joiner.. #2. I am going to notch the very last 1/4 - 3/8s inch of the joiner down, top and bottom That gives even more room to go completely around the joiner and the tie to the spars. Make it better also for attaching landing gear blocks in the wing.

Been trying to figure out how to SAFELY cut them on my table saw. I got whacked real hard in the face by a 1/4" wide blank joiner a few days ago. I had a full face shield on, so that took the brunt of the blow. Still dazed me. And NO, my hands were no were near the blade. Neither was my face for that matter, but live and learn and no harm done. Will have to make a zero clearance blade plate at some time.

I think I do have the joiner cutting issue resolved in my head. The piece kicked back and up after falling into the blade cut out the blade. Will use a sacrificial rip piece and clamp to it. I have to do repeatable angle cuts to have equal dihedra both sides.

We have been brainstorming the TD (teardrop trailer) a lot. I have a spreadsheet that is now getting hairy with all of the equations in it. one cell equation points to the results of another cells equation, and that in turn points to another. And on and on pointing. This is because the spreadsheet is calculating material used weights. With exception of the plywood is always given in lbs per cubic foot. So many look up table that are each rather cumbersome.

The spreadsheet has at this point point different wall/ceiling thickness based on foam infill thickness, plus whether white or blue foam infill.

It will also eventually calculate not just the weight, and material cost, but the balance as well. Loaded and unloaded.

Ken

I skipped working on the gate for a bit. Correcting the original install mistake has done wonders for it. It should work fine for years with just new wheels.

I have to cut the Maple joiners yet. For the longest time I have tried to figure out how the end of the joiner was going to adequately supported and not just rip thru the top or bottom of the wing 2 ribs in. Finally got it, 2 things. 1 move the joiner location forward instead of on the front of spars. Doing so gives me much more room to wrap the receiver end around the joiner.. #2. I am going to notch the very last 1/4 - 3/8s inch of the joiner down, top and bottom That gives even more room to go completely around the joiner and the tie to the spars. Make it better also for attaching landing gear blocks in the wing.

Been trying to figure out how to SAFELY cut them on my table saw. I got whacked real hard in the face by a 1/4" wide blank joiner a few days ago. I had a full face shield on, so that took the brunt of the blow. Still dazed me. And NO, my hands were no were near the blade. Neither was my face for that matter, but live and learn and no harm done. Will have to make a zero clearance blade plate at some time.

I think I do have the joiner cutting issue resolved in my head. The piece kicked back and up after falling into the blade cut out the blade. Will use a sacrificial rip piece and clamp to it. I have to do repeatable angle cuts to have equal dihedra both sides.

We have been brainstorming the TD (teardrop trailer) a lot. I have a spreadsheet that is now getting hairy with all of the equations in it. one cell equation points to the results of another cells equation, and that in turn points to another. And on and on pointing. This is because the spreadsheet is calculating material used weights. With exception of the plywood is always given in lbs per cubic foot. So many look up table that are each rather cumbersome.

The spreadsheet has at this point point different wall/ceiling thickness based on foam infill thickness, plus whether white or blue foam infill.

It will also eventually calculate not just the weight, and material cost, but the balance as well. Loaded and unloaded.

Ken

#140

Thread Starter

Made a zero insert (or some what close to it) for the table saw. Some scrap plexiglass. Crude and, ugly, but it works. I really did not like getting slapped in the face by a piece of ejected wood.

Also making a sled to rip the joiners on, or at least trying to. Will clamp with screws and penny washers the stock at the desired angle. A back stop will also be clamped to the sled. I think I can make repeatable cuts. There are four faces to cut that form the tongues that actually go into the wing panels. Those and the end notch have to be accurate. Well actually so do the 2 inner faces (inside of fuse). Or the wings will not sit even. Hence I am trying to jig the cuts.

I am kind of wanting to get the joiners made before going forward on the wing panels.

Ken

Also making a sled to rip the joiners on, or at least trying to. Will clamp with screws and penny washers the stock at the desired angle. A back stop will also be clamped to the sled. I think I can make repeatable cuts. There are four faces to cut that form the tongues that actually go into the wing panels. Those and the end notch have to be accurate. Well actually so do the 2 inner faces (inside of fuse). Or the wings will not sit even. Hence I am trying to jig the cuts.

I am kind of wanting to get the joiners made before going forward on the wing panels.

Ken

#141

Thread Starter

Spent time time trying to jig the joiner cuts. Like I said trying. Got to rethink it a bit.

Will try to set up a jig attached to the cross cut miter on the bandsaw. at lest with the cross cut miter I can set an angle.

So I made some lit ply doublers. Still have to make a square hole for the joiner. And have to make a birch doubler to add around the square hole.

Oh and the notch for the bass lg block.

Ken

Will try to set up a jig attached to the cross cut miter on the bandsaw. at lest with the cross cut miter I can set an angle.

So I made some lit ply doublers. Still have to make a square hole for the joiner. And have to make a birch doubler to add around the square hole.

Oh and the notch for the bass lg block.

Ken

#142

My Feedback: (3)

Join Date: Sep 2008

Location: Hoodsport, WA

Posts: 599

Likes: 0

Received 0 Likes

on

0 Posts

Hey Ken,

Another hobby of mine is woodworking. I subscribe to Chesapeake Light Craft (CLC) a great outfit that offers plans and kits for how built boats. Well, I guess you sent their ears ringing with your tear drop trailer project:

http://www.clcboats.com/teardrop?utm...an+2016+BBU+G4

Interesting, no?

Another hobby of mine is woodworking. I subscribe to Chesapeake Light Craft (CLC) a great outfit that offers plans and kits for how built boats. Well, I guess you sent their ears ringing with your tear drop trailer project:

http://www.clcboats.com/teardrop?utm...an+2016+BBU+G4

Interesting, no?

#143

Thread Starter

That is kinda neat EJ.

We watched this guy "Scott's Workshop" through all 48 videos in two evenings. Got lots of ideas and info. And some "I ain't doing it that ways".

About the only work I have done on the TD is more look up table work. 2 7 by 16 cell tables. They are not nothing but equations that that point back to a 12"x12"x12" blocks of poplar and white pine. If you want to know what a particular stick of wood of such and such a size and length, the tables are what do it.

I have not started the balance calculation part of the spreadsheet. Frankly I still have to figure out the math.

I bought more balsa but have not cut any yet. Have to make some joiners at this point. Just have not spent long periods out in the garage. And the time I have spent out there has been on other projects.

I have had plenty of other projects (but alas not plane related).

The projects have been done in between getting sick. and general pain levels.

Had a really bad episode with the neuropathy. Almost wanted to cut my feet off the pain was so bad.Sure am glade narcotics don't touch that kind of pain. Be way to risky of addiction. Surprisingly enough I did find a otc that helped (took a few days, but any help is great).

So sorry guys that I do not have anything build related to post.

More non plane work ahead. The danged fence came down. So 4 trips to Home Depot today for supplies. The reason for 4 trips Is limited carry capacity. Also made more tv antenna parts. Going to super size it so to speak.

Starting the research for a more robust vehicle that meets are needs. Maybe late this year.

Ken

We watched this guy "Scott's Workshop" through all 48 videos in two evenings. Got lots of ideas and info. And some "I ain't doing it that ways".

About the only work I have done on the TD is more look up table work. 2 7 by 16 cell tables. They are not nothing but equations that that point back to a 12"x12"x12" blocks of poplar and white pine. If you want to know what a particular stick of wood of such and such a size and length, the tables are what do it.

I have not started the balance calculation part of the spreadsheet. Frankly I still have to figure out the math.

I bought more balsa but have not cut any yet. Have to make some joiners at this point. Just have not spent long periods out in the garage. And the time I have spent out there has been on other projects.

I have had plenty of other projects (but alas not plane related).

The projects have been done in between getting sick. and general pain levels.

Had a really bad episode with the neuropathy. Almost wanted to cut my feet off the pain was so bad.Sure am glade narcotics don't touch that kind of pain. Be way to risky of addiction. Surprisingly enough I did find a otc that helped (took a few days, but any help is great).

So sorry guys that I do not have anything build related to post.

More non plane work ahead. The danged fence came down. So 4 trips to Home Depot today for supplies. The reason for 4 trips Is limited carry capacity. Also made more tv antenna parts. Going to super size it so to speak.

Starting the research for a more robust vehicle that meets are needs. Maybe late this year.

Ken

#144

My Feedback: (6)

Hey Ken,

Another hobby of mine is woodworking. I subscribe to Chesapeake Light Craft (CLC) a great outfit that offers plans and kits for how built boats. Well, I guess you sent their ears ringing with your tear drop trailer project:

http://www.clcboats.com/teardrop?utm...an+2016+BBU+G4

Interesting, no?

Another hobby of mine is woodworking. I subscribe to Chesapeake Light Craft (CLC) a great outfit that offers plans and kits for how built boats. Well, I guess you sent their ears ringing with your tear drop trailer project:

http://www.clcboats.com/teardrop?utm...an+2016+BBU+G4

Interesting, no?

#145

Thread Starter

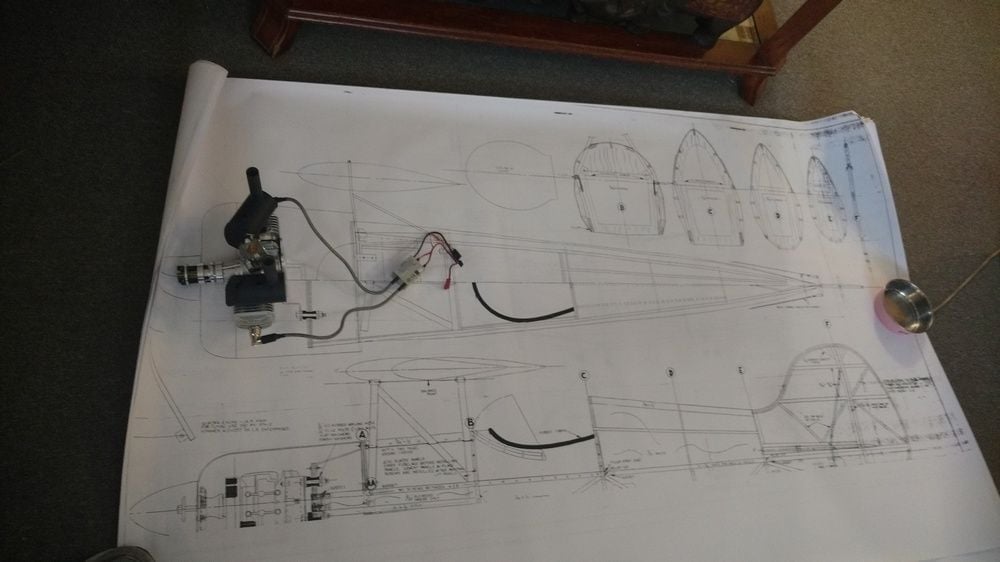

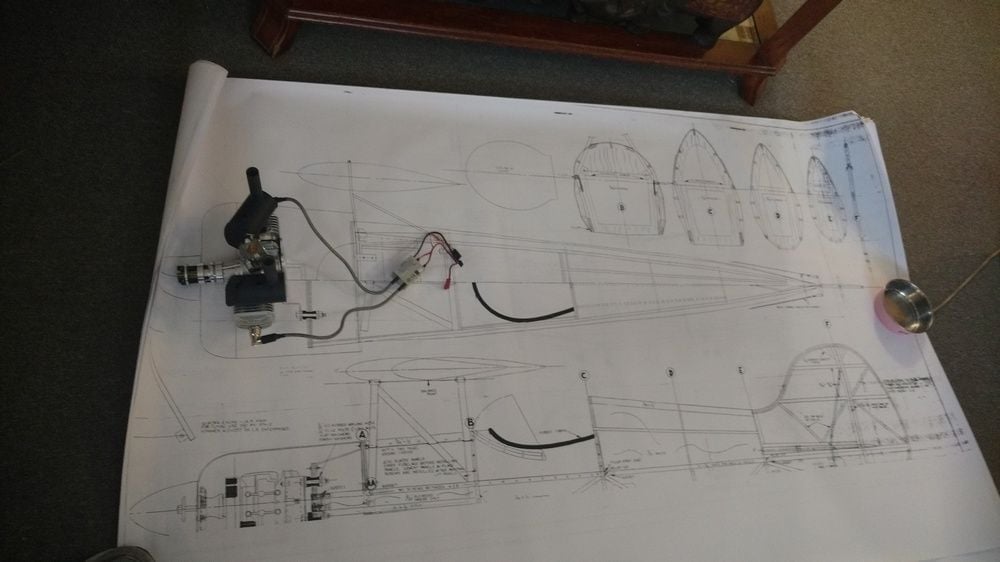

I restarted work on the Odo wings this month.

I know this is an old thread, but there have been a lot of changes to life around here. And I now find myself in a position to work on planes a bit now. Going to finish up some old projects, then I have a big project to start. I have the plans for a 1/3 scale Pitts. Bought a 60cc DLE engine, and a new radio. A FrSky Horus X10.

I decided to finish the Odo wing panels before starting work on a replacement wing for the basic trainer with plug-in dihedral panels. That wing came out rather warped. Required hard aileron and lots of rudder to keep level and turn. Turns out that my balsa building board has a pronounced warp to it.

I know this is an old thread, but there have been a lot of changes to life around here. And I now find myself in a position to work on planes a bit now. Going to finish up some old projects, then I have a big project to start. I have the plans for a 1/3 scale Pitts. Bought a 60cc DLE engine, and a new radio. A FrSky Horus X10.

I decided to finish the Odo wing panels before starting work on a replacement wing for the basic trainer with plug-in dihedral panels. That wing came out rather warped. Required hard aileron and lots of rudder to keep level and turn. Turns out that my balsa building board has a pronounced warp to it.

#146

Thread Starter

Added in the spade joiner box and reinforced the first rip and 3rd to take the loads from the joiner. And then I ripped (actually cut) all of that out. I kept imagining doing aerobatics and the joiner snapping. So, I made 2 pair of ribs from1/8’ aircraft ply and 2 pair from 1/32’ balsa. The first and third ribs will be were the joiner enters and ends in the wing. That is were the load point should manifest on the wing structure. I will add some carbon fiber plate to ply ribs around the joiner. And then I reread some of this thread and saw where I thought the joiner was good for 15 Gs. Oh Well. I just made the joiner ½’ vice ¼’ wide. That will for darn sure take any loads encountered.

Oh and the saw is unplugged.

Oh and the saw is unplugged.

Last edited by flyingagin; 06-30-2019 at 04:51 PM. Reason: clarification

#147

Thread Starter

The sections were the joiner passes into the wing panels now needs ½”x1/4” spar sections. Those are being built up from some ¼”x1/4” bass I have in my plane wood bin. Glued two pieces together to get 1/”x1/4”. Then there is 1/32” birch ply laminated to the inside of the new spar sections. I will have to add a ¼’x1/4” pies to the original spar ends that I cut down for the redone joiner boxes. Then add ply shear web between the two spar sections.

#148

Thread Starter

Moms Dementia is far worse, often confused about the day of the week and the time of day. If we weren’t here taking care of her, she would be in a home. Starting to not know day of the week or what part of the day it is.

Shortly after the past work stoppage on this project we started taking over everything from mom. Bought a big tv for the living room, put our recliner couch in the living. If we were going to be responsible for everything then we were not going to be stuck living in our bedroom.

Shortly after the past work stoppage on this project we started taking over everything from mom. Bought a big tv for the living room, put our recliner couch in the living. If we were going to be responsible for everything then we were not going to be stuck living in our bedroom.

I replaced all the fencing. We replaced the roof. Installed new counters and backsplash in the kitchen, new stove top (went from electric to gas), and a new microwave. Also had lots of repairs to make after a water pipe sprung a leak, hope to never go thru that again. Repainted all but one room in the house. It is occupied by a room mate that is helping us take care of mom.

Built a chicken coop. sort of up scale housing for our birds. Just hens. We had 12, but for reasons that elude us, three died. Our favorite was the first. She was so gentle a laid back. I could pick her up and walk around petting her. She was also the queen of the roost. Still have the other two that I we have taken a liking to, miss pics a lot and miss cheeky bird. Miss pecks a lot would have been eaten early on if she had been big enough. She would see us in the backyard, come over and peck our legs. She still does, but now she does not peck hard. A lot of the time she simply pulls my pants. I decided it is simply her wanting attention, FOOD, TREATS. She better watch herself now though, she is big enough to make a nice pot of dumplings. Miss cheeky bird got her name from jumping up on my shoulder to eat treats out of my hand.