Yard Sign Coro 3D-Design

#1

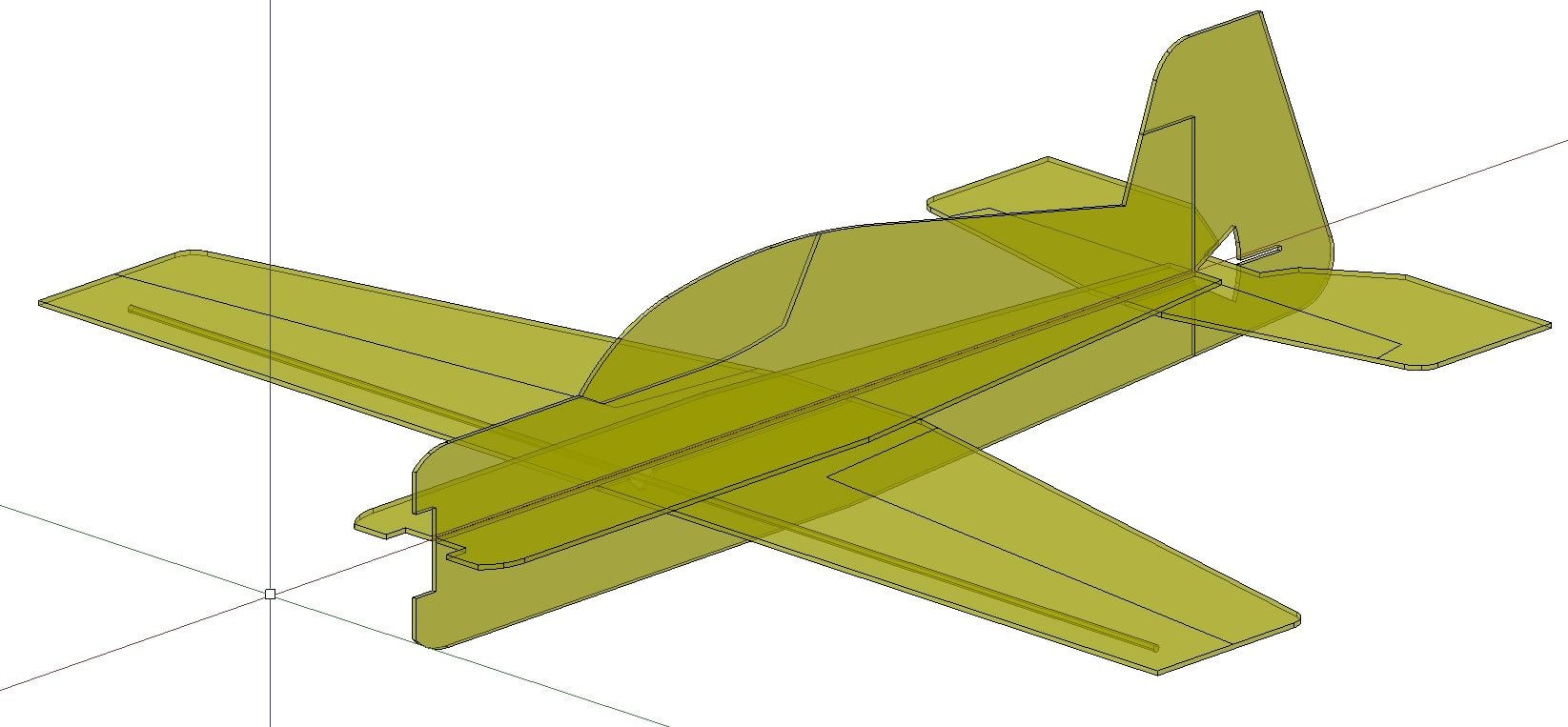

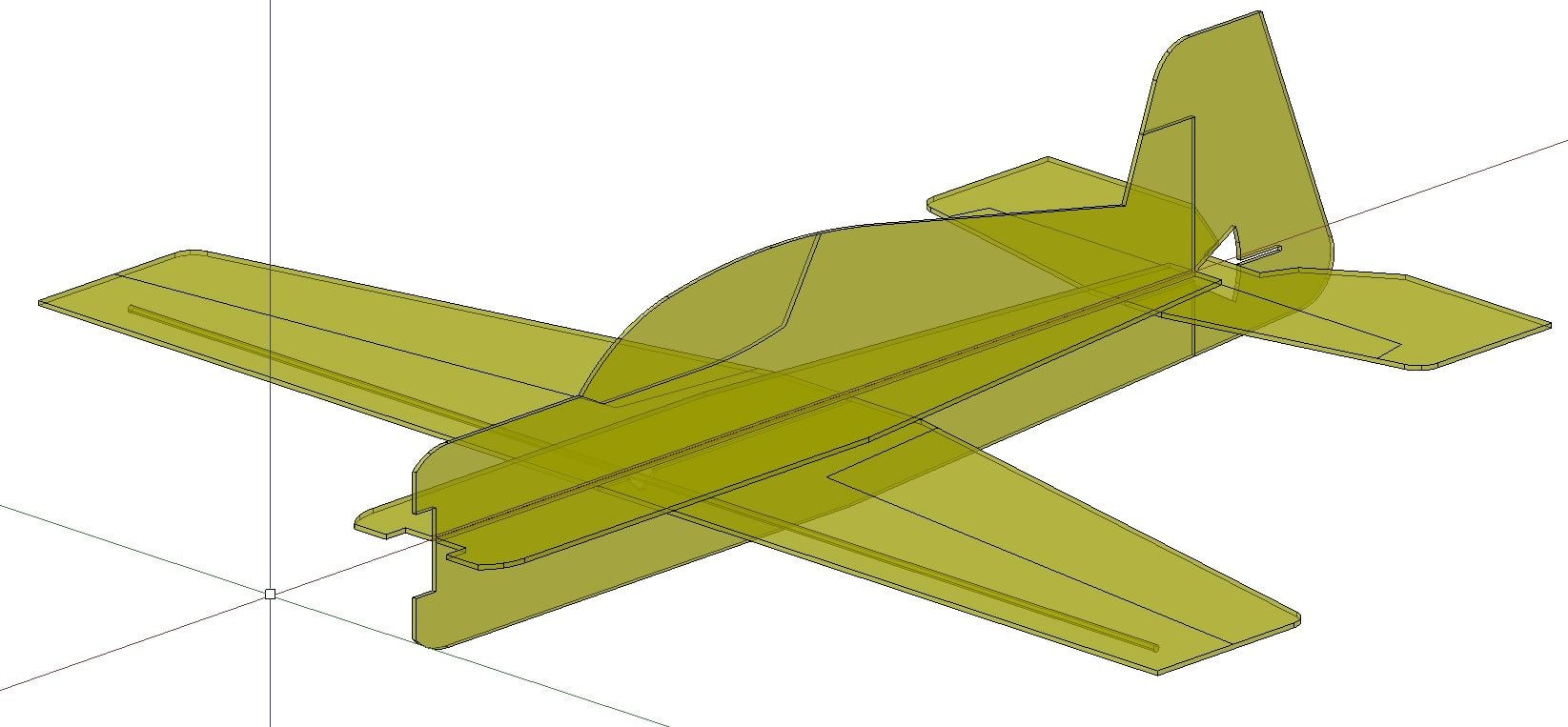

This is my first attempt at building an RC Airplane since 1981. I decided to take the frugal route, so I am using a discarded yard sign from the last local elections. I designed it in AutoCAD and made it as simple as I could. Since all I had was 4mm thick coroplast I decided to make it as big as I could because of the weight. I have an 8' piece of clear sheet rock corner protector I am going to cut to make the motor mount and connect all the pieces together. I plan to use a coat hanger to form the landing gear. I decided to cut the pieces out from the plotted full size template, so I could position the wing, fuse and elevator to try to get colors from the sign that will look a little more stylish. That way I won't have to paint it and it will still look like it was made from a yard sign.

I bought one of those reflectors you use to mark you dirveway. It is on a 44" 1/4" x 44" round fiberglass rod. I am going to zip tie it to the bottom of the wing to stiffen the wing. I have a 3D Printer and I was going to print all the connecting parts and motor mount, but I decided to do it with common hardware, because most people don't have a 3D Printer. I ordered al electronics from BangGood, so they are coming on a slow boat from China I guess.

I ordered motor, prop, ESC, servos and battery.

I will post more pics as I do more.

This is not a beginner plane and I am a beginner, so I will have a friend help me get it flying. I am logging a lot of flight sim hours on RF8 with similar 3D planes as this, so I hope I don't crash it too beyond repair. If I do, I have 4 more 48" x 48" signs to cut out more parts.

TIP: I cut the plastic coro with a rolling fabric cutter from Wallmart and it cut so east. I cut it over a rubber door mat I got from DollarTree and that worked great.

3D AutoCAD rendering of Yard Sign Airplane

I laid the printed plans on the sign.

I decided to cut out the parts from the plans so I could position the wing, fuse and elevator on parts of the sign that may look better.

Here are the 4 main parts. Next I need to cut the slots to insert the wing and elevator. I also need to cut one side out to the rudder, elevator and ailarons can move.

This being my first design / build I am crossing my fingers. Comments and suggestion are welcomed of course.

I am thinking about naming the airplane "Tim" for some reason.

I bought one of those reflectors you use to mark you dirveway. It is on a 44" 1/4" x 44" round fiberglass rod. I am going to zip tie it to the bottom of the wing to stiffen the wing. I have a 3D Printer and I was going to print all the connecting parts and motor mount, but I decided to do it with common hardware, because most people don't have a 3D Printer. I ordered al electronics from BangGood, so they are coming on a slow boat from China I guess.

I ordered motor, prop, ESC, servos and battery.

I will post more pics as I do more.

This is not a beginner plane and I am a beginner, so I will have a friend help me get it flying. I am logging a lot of flight sim hours on RF8 with similar 3D planes as this, so I hope I don't crash it too beyond repair. If I do, I have 4 more 48" x 48" signs to cut out more parts.

TIP: I cut the plastic coro with a rolling fabric cutter from Wallmart and it cut so east. I cut it over a rubber door mat I got from DollarTree and that worked great.

3D AutoCAD rendering of Yard Sign Airplane

I laid the printed plans on the sign.

I decided to cut out the parts from the plans so I could position the wing, fuse and elevator on parts of the sign that may look better.

Here are the 4 main parts. Next I need to cut the slots to insert the wing and elevator. I also need to cut one side out to the rudder, elevator and ailarons can move.

This being my first design / build I am crossing my fingers. Comments and suggestion are welcomed of course.

I am thinking about naming the airplane "Tim" for some reason.

Last edited by johnnymax; 12-11-2018 at 05:52 AM.

#3

Can I get it at the hardware store?

Is there another name for it?

What size would I need?

UPDATE: At lunch I went to the local Ace Hardware and they had 0.078 x 36" music wire. I bought a pack of 3 for just $2.78

Last edited by johnnymax; 12-11-2018 at 11:20 AM.

#4

I pieced it together and it looks like a plane. I was surprised how flimsy the wings are. I am thinking about adding a lot of wire spars and I may be able to go glow instead of electric.

#5

Join Date: Oct 2002

Location: Chilliwack, BC, CANADA

Posts: 12,425

Likes: 0

Received 22 Likes

on

19 Posts

Wire is heavy and unless you use music wire it's not springy so it'll bend and stay bent. Instead I'd suggest two or three round carbon rods sized that you can push them through the corrugations from end to end. I'd set them up so there is one at the first tube you can use that runs the full span and then a second one that is almost back at the aileron hinge line. And perhaps a third closer to the front one. That should stiffen things up nicely without creating any external drag that could mess things up.

#6

Coroplast airplanes were popular some years back, kind of like foamboard planes are now. A lot of techniques were used to stiffen the wing including folding back the leading edge to give a deeper surface and inserting every thing from thin dowels to music wire to carbon fiber into the wing to stiffen it. Given that carbon fiber is a lot cheaper and more available than it was a decade or so ago I would agree with the poster above. Hard music wire is the next best choice. One note about coroplast is that it will glue MUCH more effectively if you wipe it down with acetone first. IIRC there is a molding lubricant on the surface of the plastic that interferes with glue adhesion. Most of the coroplast planes that I recall and the couple that I built were held together by screws or other mechanical means. No matter what you do the plane will be kind of floppy as compared to a balsa airplane. That is actually a feature as they will tolerate some pretty rough landings. Glow power can be done ( look up pizza box flier) but you will need to add a spine to tie the engine mount to the rest of the airplane.