48" X cat design and build

#51

Senior Member

Join Date: Jan 2005

Location: blackpool, UNITED KINGDOM

Posts: 11,390

Likes: 0

Received 2 Likes

on

2 Posts

Hi Daz looking good mate,i can see what Cobus is talking about but i agree you dont need to use gelcoat.A trick ive used is to run a bead of clay arround that seam line to seal and also make it a slight (tiny) concave shape this makes for a nice smooth edge.Another good way is to use sheet wax on the whole flange area but its expensive.Or you could also try this wax and run some of this round that join and use a filleting tool same as with clay.Either way im sure youll do a good job as allways.

Mart

http://www.ecfibreglasssupplies.co.u...lock-650g.aspx

Mart

http://www.ecfibreglasssupplies.co.u...lock-650g.aspx

#52

Thread Starter

Join Date: Sep 2010

Location: Staffs, UNITED KINGDOM

Posts: 895

Likes: 0

Received 0 Likes

on

0 Posts

Will effect neatness of split line if you planning on molding color and not painting.

http://www.rcuniverse.com/forum/spee...ethically.html

http://www.rcuniverse.com/forum/spee...boat-hull.html

http://www.rcuniverse.com/forum/spee...ethically.html

http://www.rcuniverse.com/forum/spee...boat-hull.html

Understand what you saying and appreciate it not planning to much yet main thing is get it moulded and 1st 1 out will be just plain white finish and get it tested

Ill do 2 coats of tooling gelcoat so will wetsand it back also which will finish the flanges off

Hi Daz looking good mate,i can see what Cobus is talking about but i agree you dont need to use gelcoat.A trick ive used is to run a bead of clay arround that seam line to seal and also make it a slight (tiny) concave shape this makes for a nice smooth edge.Another good way is to use sheet wax on the whole flange area but its expensive.Or you could also try this wax and run some of this round that join and use a filleting tool same as with clay.Either way im sure youll do a good job as allways.

Mart

http://www.ecfibreglasssupplies.co.u...lock-650g.aspx

Mart

http://www.ecfibreglasssupplies.co.u...lock-650g.aspx

#53

Thread Starter

Join Date: Sep 2010

Location: Staffs, UNITED KINGDOM

Posts: 895

Likes: 0

Received 0 Likes

on

0 Posts

#54

Thread Starter

Join Date: Sep 2010

Location: Staffs, UNITED KINGDOM

Posts: 895

Likes: 0

Received 0 Likes

on

0 Posts

#55

Thread Starter

Join Date: Sep 2010

Location: Staffs, UNITED KINGDOM

Posts: 895

Likes: 0

Received 0 Likes

on

0 Posts

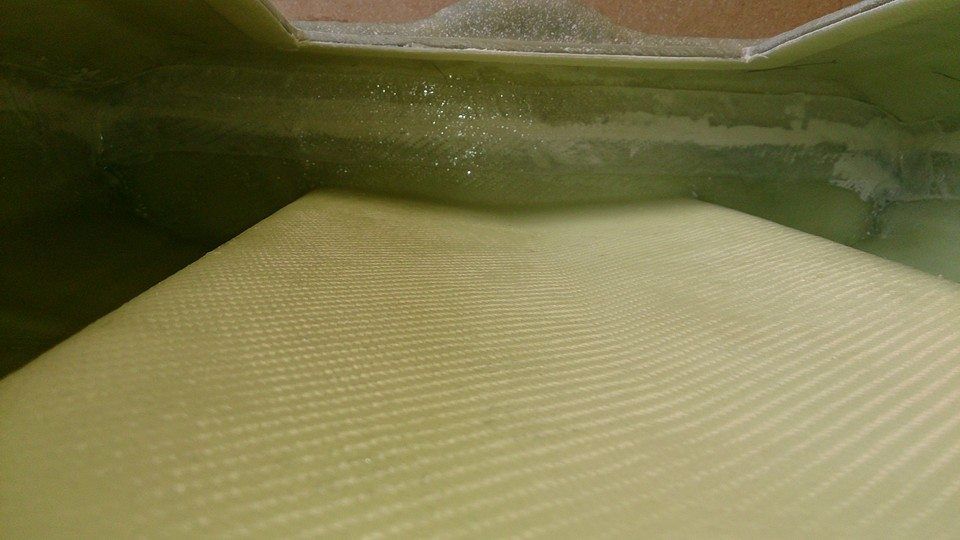

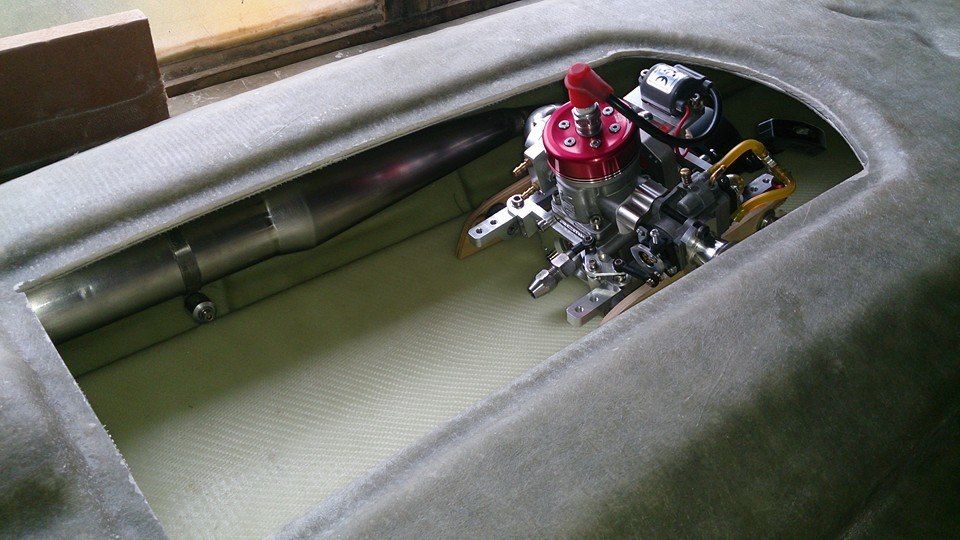

Made 1st hatch for this build,only thin layup to break in the mould but also 1st time test fit and check clearances round the engine ,fits nice and clearance is not an an issue so pretty happy

Also now moulded the bottom of this build,fingers crossed releases ok in a week or so ,then wont be long before laying up and pulling the 1st hull

Also now moulded the bottom of this build,fingers crossed releases ok in a week or so ,then wont be long before laying up and pulling the 1st hull

#56

Thread Starter

Join Date: Sep 2010

Location: Staffs, UNITED KINGDOM

Posts: 895

Likes: 0

Received 0 Likes

on

0 Posts

#60

Thread Starter

Join Date: Sep 2010

Location: Staffs, UNITED KINGDOM

Posts: 895

Likes: 0

Received 0 Likes

on

0 Posts

#62

Senior Member

Join Date: Apr 2007

Location: Cape Town, , SOUTH AFRICA

Posts: 822

Likes: 0

Received 0 Likes

on

0 Posts

I know you guys may not have exposed exhaust have you consider moving the motor back and having the radio box in front of it with the tune pipe running forward and exiting through the deck? Had a guy here do it and although it looked funny the thing went like stink. You can then run a normal header.

Cobus

Cobus

Last edited by Hesco Racing; 04-04-2014 at 04:44 AM.

#64

Junior Member

Join Date: Jan 2012

Location: Fairfax,

VA

Posts: 20

Likes: 0

Received 0 Likes

on

0 Posts

#65

Thread Starter

Join Date: Sep 2010

Location: Staffs, UNITED KINGDOM

Posts: 895

Likes: 0

Received 0 Likes

on

0 Posts

Hi espressoo

used a stanley blade ,very carefully and at the right angle just as the FG goes green state of curing

dont need to remove it from mould to do it

used a stanley blade ,very carefully and at the right angle just as the FG goes green state of curing

dont need to remove it from mould to do it

#66

Junior Member

Join Date: Jan 2012

Location: Fairfax,

VA

Posts: 20

Likes: 0

Received 0 Likes

on

0 Posts

Wow, so you just use a box cutter as the FG is curing? That's brilliant and saves a lot of FG dust in the workshop. Do you cut it to the edge of the mold and is there any shrinkage of the hull during the curing process?

#67

Thread Starter

Join Date: Sep 2010

Location: Staffs, UNITED KINGDOM

Posts: 895

Likes: 0

Received 0 Likes

on

0 Posts

yes bud ,its the the inbetween of to soft an cured

catch it just right trims dead easy anf use the flange/edge carefully holding the blade at the right angle so it doesnt damage the mould

ot had much shrinkage on smaller versions ,this is the 1st one of these but so far so good

catch it just right trims dead easy anf use the flange/edge carefully holding the blade at the right angle so it doesnt damage the mould

ot had much shrinkage on smaller versions ,this is the 1st one of these but so far so good

#69

Thread Starter

Join Date: Sep 2010

Location: Staffs, UNITED KINGDOM

Posts: 895

Likes: 0

Received 0 Likes

on

0 Posts

Cheers wetneck

Stringers can be added either or after ,iv done a few after no problems ,plan is once released the hull and sorted placement of everything for CG ill finish the stringers then make templates,that way when i layup another hull they will be installed while still in the mould

Seam is already done and joined just waiting to release it now ,problem have to be pretty quick when joining them like this ,but ill try and get pics next time round

Stringers can be added either or after ,iv done a few after no problems ,plan is once released the hull and sorted placement of everything for CG ill finish the stringers then make templates,that way when i layup another hull they will be installed while still in the mould

Seam is already done and joined just waiting to release it now ,problem have to be pretty quick when joining them like this ,but ill try and get pics next time round

#72

My Feedback: (3)

I know you guys may not have exposed exhaust have you consider moving the motor back and having the radio box in front of it with the tune pipe running forward and exiting through the deck? Had a guy here do it and although it looked funny the thing went like stink. You can then run a normal header.

Cobus

Cobus

F1 - Cat looks awesome. Great effort!!

#73

Thread Starter

Join Date: Sep 2010

Location: Staffs, UNITED KINGDOM

Posts: 895

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Jaw

im pretty happy with the way it came out just hope it performs well ,been a long on going project but getting there now haha

@ Mike2735

Thanks Mike ill be posting vids etc and will keep you posted bud

im pretty happy with the way it came out just hope it performs well ,been a long on going project but getting there now haha

@ Mike2735

Thanks Mike ill be posting vids etc and will keep you posted bud