ASP/Magnum .15 Blue Head

#2

Thread Starter

OK I put a slash in the crank like the car guys do, and radiused the rod a bit, and it goes 18,200 rpm. I spent a couple of days making some Turbo heads and put one on this motor. 20,500 rpm. I blew the plug, but shaved a bit off the combustion chamber and added another .005" shim, so hopefully that will stop. BUT over 2,000 rpm extra makes me happy. I made one for my AP .09 and .15 too. Now this is my best motor on this prop, equalling the $250 Fora. I am sure it will win out on the toothpick props though.

#4

Thread Starter

I just used a dremel tool. I didn't make a very big slash because the crank is pretty hard and the stone was wearing fast. Probably a good idea to put a piece of fuel tubing over the crankpin so it doesn't get nicked, and steady the dremel with on finger resting on the crank so it doesn't slip. I think the next time I will make two slashes centred on the crank at about 20 degrees and flared out like my Fora .049 is. Those guys seem to know what they are doing more so than the car guys IMHO at least for WOT applications. I think the FAI Speed motors have something similar too. I think the radius on the rod made more difference than the slash though, it removes mass and lets the fuel go by easier. I hardly put more than a .015" rad on and polished it with just 600 sandpaper. I will get a pic. when the wife gets back and after I go flying. She will be gone for three weeks with the camera on Monday so I better not forget. edit. Jeez, I charged up the radios and two planes. both on channel 54, and they were the wrong radios. I have three on 54 and one was Airtronics. Senior moment, and no flying today. The first pic is the Fora .049 turbo cut. The ASP .15 head and the OS LA .15 ar pretty much interchangeable, but the ASP/Magnum head seems to make a bigger change. Likely because of the bigger ports and ball bearings.

Last edited by aspeed; 09-28-2013 at 01:34 PM.

#5

Thread Starter

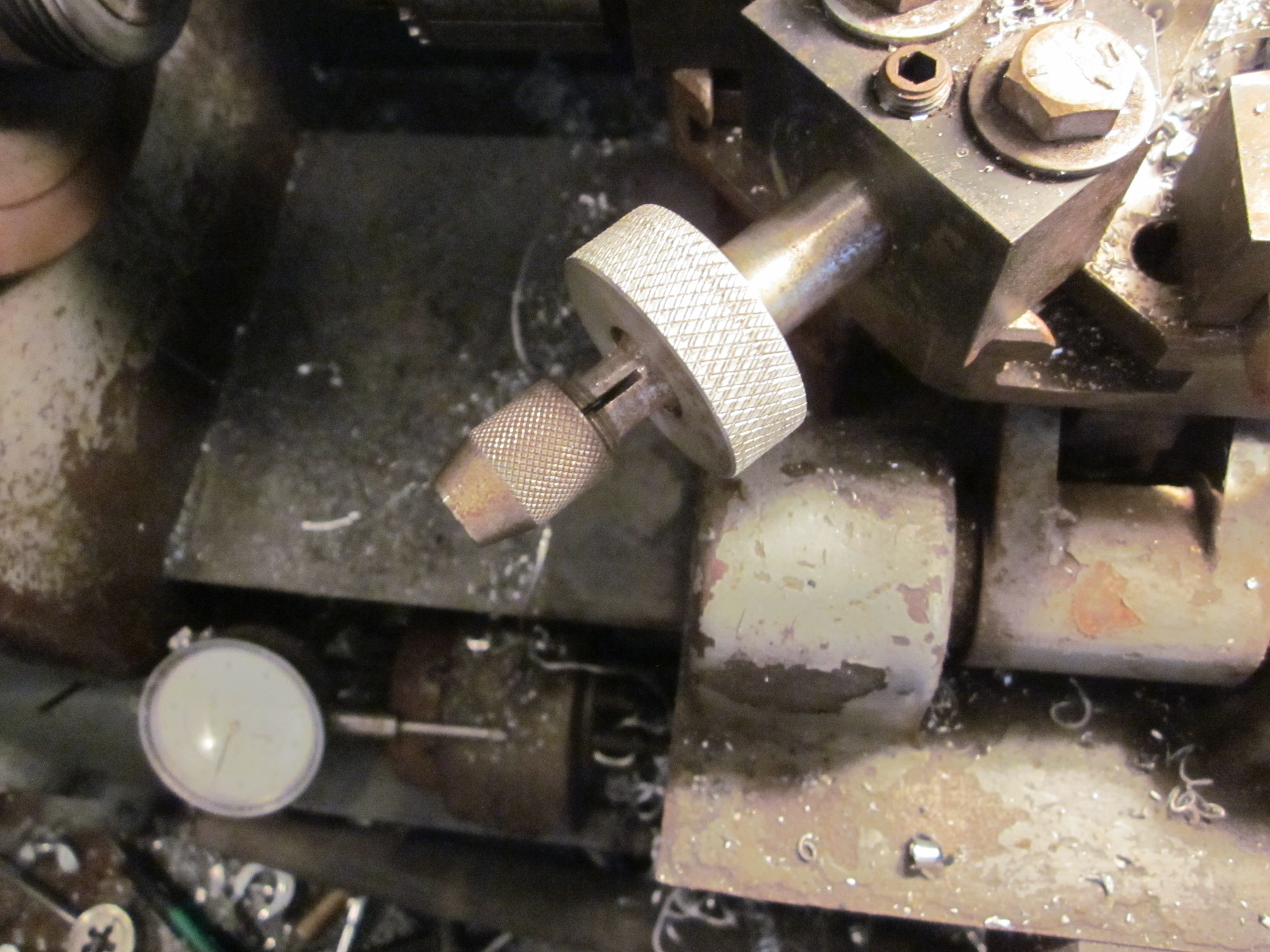

I made the cutter from an old chipped 7/16th inch endmill and ground a radius the end. It is good for .07 to maybe a .40 size combustion chamber. The old Hardinge

turret lathe has 8 turret positions and 8 stops. It is older than me. 1952. The last pic. is the first operation. I made14 blanks with the turbo thread prepared and a few different diameters for some .07 to .15 motors I wanted to try. There is a .500" step for holding in the collet to make the second operation. Henry Nelson used to sell blanks like that for his plugs. It seemed like a good idea to me.

turret lathe has 8 turret positions and 8 stops. It is older than me. 1952. The last pic. is the first operation. I made14 blanks with the turbo thread prepared and a few different diameters for some .07 to .15 motors I wanted to try. There is a .500" step for holding in the collet to make the second operation. Henry Nelson used to sell blanks like that for his plugs. It seemed like a good idea to me.