wing sheeting contact cement?

#1

I am building an old Stafford P-51. The foam core wings did not come with a shuck so I will attempt to sheet them by hand. But, what I will need is a good, spreadable contact glue to adhere the balsa skin to the foam for a good instant bond. What are you using for sheeting foam wings in the contact department? I have heard NO 30 is great but I do not want to buy $40 worth. I also heard that the 3M 77 formula has changed making it not compatible with foam. Any idea`s would be greatly appreciated.

Thanks

Bill

Thanks

Bill

#3

Gorilla Glue! Did my first foam wing last year and it went very well. Spread the glue on the wood and lightly spray water on the foam and slap together and place into the foam bed and weigh it down overnight. Good use for all your old airplane magazines! The glue foams a little and sticks like crazy. Doesn't cost an arm and a leg and does not smell bad. Excess sands easy.

Skyhawk

Skyhawk

#4

It's generally a good idea to read carefully a post before you respond to it.Did I miss something here? When Skylane42 said that the foam cores didn't come with "shucks" that means he did not have the "foam bed".

#7

I agree. But if you are set on contact cement, I recommend Weld wood contact cement that you get at a hardware store or Home Depot. I usually mixed some food coloring into the cement so I could see it against the white foam. You want to get a even coat of contact cement.

#9

R Ward. I respectfully disagree. On a symmetrical wing It would be nearly impossible to keep from distorting the airfoil shape while applying pressure to the skins to achieve full surface contact. I would be interested in a brief description of your methods for doing it correctly Maybe your process works on a fat airfoil, but might not work on the Stafford P51, which has a thin section. Not that you would persuade me to change the way I would do it, but it might help someone else.

#10

If you are using a flat table, place the trailing edge down on the wing skin and slowly roll the foam core forward keeping it flat on the table.

The contact cement will bond immediately and you won't get a second chance to get it right. but if you keep the foam straight and flat on the table you can do it without warping the wing

No if you are using epoxy, you must use the shucks to lay the wings into with weights to hold the wing skin tight against the foam core while the epoxy cures.

I have used contact cement many times using the method that I described above.

Frank

The contact cement will bond immediately and you won't get a second chance to get it right. but if you keep the foam straight and flat on the table you can do it without warping the wing

No if you are using epoxy, you must use the shucks to lay the wings into with weights to hold the wing skin tight against the foam core while the epoxy cures.

I have used contact cement many times using the method that I described above.

Frank

#11

R Ward. I respectfully disagree. On a symmetrical wing It would be nearly impossible to keep from distorting the airfoil shape while applying pressure to the skins to achieve full surface contact. I would be interested in a brief description of your methods for doing it correctly Maybe your process works on a fat airfoil, but might not work on the Stafford P51, which has a thin section. Not that you would persuade me to change the way I would do it, but it might help someone else.

#12

Just a quick thought... what about applying a fiberglass cloth directly over the foam cores? First coat could be lightweight cloth followed with a heaver cloth. Again, just a thought...

Skyhawk

Skyhawk

#13

Skyhawk940. Your "thought" about applying glass cloth to the foam cores has been done in many variations. The most common procedure is to place cloth between the balsa skins, and the foam cores. This is done to strengthen the wing. Next would be to just glass the foam, which might require significant sanding. What was done before vacuum bagging got popular, was to apply glass and resin to the foam, and then apply a very smooth shiny Mylar film over the glass and smooth it out. Once the resin had cured, the Mylar was peeled off. The problem with this, and other glass skinned wings is that they are heavy. Today if I was determined to make a glass skinned wing I would vacuum bag it. The last two airplanes I built were EF1 racers that had 2oz.glass cloth between the foam, and balsa skins. They were vacuumed bagged without the shucks.

RWard Sorry but I don't understand your response to my inquiry of how you keep from distorting a thin airfoil when skinning a wing with contact cement, without the shucks. Specifically I don't understand your comment about shaping Formica with heat. Are you suggesting that Formica is a desirable wing skin material? And I do have experience with bonding laments (like Formica) to counter tops.

Countilaw. I didn't say that the procedure would warp (twist) the wing. I said I was concerned that it would distort the airfoil.

I'm not familiar with the Stafford P51 wing, but I know that the Stafford Formula 1 Minnow had an under cambered airfoil at the tip. A lot of those Minnows were built with 3M77 with the skins applied with the wing cores in the shucks. If the Stafford P51 has an under cambered airfoil, I would continue to recommend vacuum bagging over contact cement, particularly if there aren't

any shucks.

RWard Sorry but I don't understand your response to my inquiry of how you keep from distorting a thin airfoil when skinning a wing with contact cement, without the shucks. Specifically I don't understand your comment about shaping Formica with heat. Are you suggesting that Formica is a desirable wing skin material? And I do have experience with bonding laments (like Formica) to counter tops.

Countilaw. I didn't say that the procedure would warp (twist) the wing. I said I was concerned that it would distort the airfoil.

I'm not familiar with the Stafford P51 wing, but I know that the Stafford Formula 1 Minnow had an under cambered airfoil at the tip. A lot of those Minnows were built with 3M77 with the skins applied with the wing cores in the shucks. If the Stafford P51 has an under cambered airfoil, I would continue to recommend vacuum bagging over contact cement, particularly if there aren't

any shucks.

#14

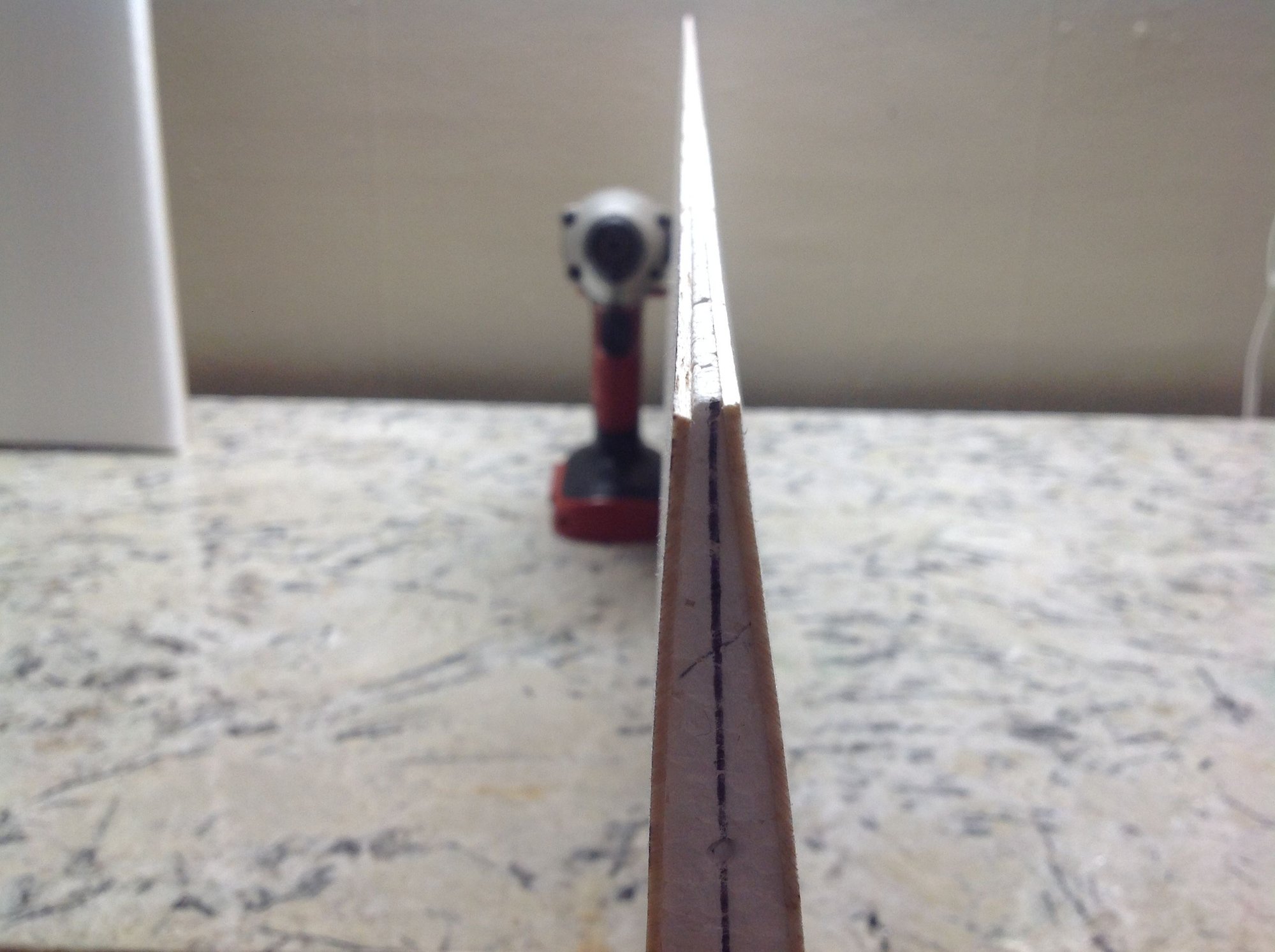

My Feedback: (29)

I can certainly understand the appeal to do things quickly however that is not always the best way to go. If you plan to build a couple foam wings a year then a vacuum system IMO is a worthwhile investment. The EZ Vac from Aerospace Composites Products is inexpensive and will work for most applications. As Greg has pointed out, with contact cements it is easy to change the airfoil shape. This is something I had even done myself. While the pictured wing(s) were sheeted in the shucks, I have done wings without shucks via vacuum bagging without issues. It is also possible to check the wing for straightness after vacuum is pulled and you have plenty of time to correct prior to the epoxy setting.

#15

No shucks? You could try the Skyhawk's suggestion in post #3 but use a suitable density foam rubber on a flat table with a piece of plywood on top with a weight. Magazines, batteries, or whatever it takes. I would guess it would end up without a twist. If you want a certain amount of washoutt, then IDK. A piece of poly around the balsa would keep the polyurethane glue out of the foam rubber. It would be cheaper than the vacuum pump even if you ruin the wing. (which I doubt, but no warranty on my advise.) Have you done it yet?

#16

Skyhawk940. Your "thought" about applying glass cloth to the foam cores has been done in many variations. The most common procedure is to place cloth between the balsa skins, and the foam cores. This is done to strengthen the wing. Next would be to just glass the foam, which might require significant sanding. What was done before vacuum bagging got popular, was to apply glass and resin to the foam, and then apply a very smooth shiny Mylar film over the glass and smooth it out. Once the resin had cured, the Mylar was peeled off. The problem with this, and other glass skinned wings is that they are heavy. Today if I was determined to make a glass skinned wing I would vacuum bag it. The last two airplanes I built were EF1 racers that had 2oz.glass cloth between the foam, and balsa skins. They were vacuumed bagged without the shucks.

RWard Sorry but I don't understand your response to my inquiry of how you keep from distorting a thin airfoil when skinning a wing with contact cement, without the shucks. Specifically I don't understand your comment about shaping Formica with heat. Are you suggesting that Formica is a desirable wing skin material? And I do have experience with bonding laments (like Formica) to counter tops.

Countilaw. I didn't say that the procedure would warp (twist) the wing. I said I was concerned that it would distort the airfoil.

I'm not familiar with the Stafford P51 wing, but I know that the Stafford Formula 1 Minnow had an under cambered airfoil at the tip. A lot of those Minnows were built with 3M77 with the skins applied with the wing cores in the shucks. If the Stafford P51 has an under cambered airfoil, I would continue to recommend vacuum bagging over contact cement, particularly if there aren't

any shucks.

RWard Sorry but I don't understand your response to my inquiry of how you keep from distorting a thin airfoil when skinning a wing with contact cement, without the shucks. Specifically I don't understand your comment about shaping Formica with heat. Are you suggesting that Formica is a desirable wing skin material? And I do have experience with bonding laments (like Formica) to counter tops.

Countilaw. I didn't say that the procedure would warp (twist) the wing. I said I was concerned that it would distort the airfoil.

I'm not familiar with the Stafford P51 wing, but I know that the Stafford Formula 1 Minnow had an under cambered airfoil at the tip. A lot of those Minnows were built with 3M77 with the skins applied with the wing cores in the shucks. If the Stafford P51 has an under cambered airfoil, I would continue to recommend vacuum bagging over contact cement, particularly if there aren't

any shucks.

#17

Join Date: Oct 2016

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

Just started Sig Kougar and sheeted wings last night with original Gorilla Glue. 1 st time I sheeted foam cores and it went fine. I actually saw Gorilla Glue Spray at my local ACE Hardware and bought it for sheeting but despite bottle saying foam safe, a test spray melted foam! Be careful. Original gorilla glue worked fine. Thanks

#18

probably the propellant was attacking the foam,.....the glue itself is foam safe. I guess, shame on the manufacturer for what I would consider, "false advertising". that,.... or the manufacturer probably searched long and hard before they found a foam that the glue didn't attack, just so they could write "foam safe" on the can....... all you have to do is find that same foam.... he, he.