1/14 LaFerrari toy to hobby grade conversion (Rastar 50100)

#1

picked up a 1/14 Rastar 50100 LaFerrari at my value village for four Canadian Pesos (three Freedom Bucks™), I want to convert it to hobby grade electronics, and as a plus i already have a 3d printer. i forgot to take pictures before i tore it apart, sorry. anyway, i figured i'd ask for some help with electronics as I have no experience with anything smaller than a Stampede. It has a full interior so space is tight, but if i have to cut the floor out of the passenger seat i guess i have to lol. I plan to use a ProModeler DS145CLHV for my servo (small and high torque from a great company), so that leaves motor and esc (and receiver, but I'll probably just get a takeoff TTX200 and rx). i haven't drawn up the existing chassis yet (in Inventor) but i'm pretty sure a 540 size motor will not fit unless i cut off half the interior (the motor that shows through the back window) and part of the webbing on the chassis

#3

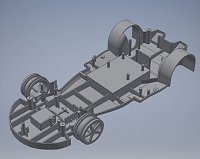

just about got the chassis roughed in, soon the fun part will begin

in terms of electronics i have ordered three motors, plus the 3650-2900kv i already own. two (three) inrunners and one outrunner, just for fun,

https://hobbyking.com/en_us/b28-57-1...er-1700kv.html

https://hobbyking.com/en_us/kd-30-13...er-1000kv.html

https://hobbyking.com/en_us/turnigy-...-inrunner.html

I have a Mamba Micro X on the way, as well as a ProModeler DS145CLHV micro servo, which is probably the best micro servo on the planet.

anyone know where i can get some really short shocks?

in terms of electronics i have ordered three motors, plus the 3650-2900kv i already own. two (three) inrunners and one outrunner, just for fun,

https://hobbyking.com/en_us/b28-57-1...er-1700kv.html

https://hobbyking.com/en_us/kd-30-13...er-1000kv.html

https://hobbyking.com/en_us/turnigy-...-inrunner.html

I have a Mamba Micro X on the way, as well as a ProModeler DS145CLHV micro servo, which is probably the best micro servo on the planet.

anyone know where i can get some really short shocks?

#6

#7

i went to my LHS yesterday and found some really short shocks, they're for the latrax rally 1/18, #7560. they're 35mm eye to eye with a diameter of about 10mm, but they are basically just springs (oilless). if they work for me i can get the oil filled ones that traxxas makes as an upgrade (7560X or 7561). I'm also thinking I may want to just get this thing running before i try to get the interior to fit. the motors from hobbyking showed up a couple days ago, i'll try and upload a pic soon.

#9

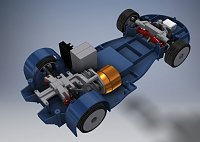

sorry for the really late update, I just didn't feel I'd made enough progress to actually make one before. anyway, I've got almost everything ironed out, aside from final ESC and RX placement. I'm going to be using s3m belts and pulleys for the drivetrain between the motor and the diff. speaking of which, I went with the stock diff from a 1/16 Traxxas slash, which has an aftermarket if it proves insufficient (i was toying with a full size slash 4x4 diff, but that thing is completely huge in comparison). the rear suspension did not require nearly as much work to fit in as the front did.

#10

#12

Good timing lol, today I made some progress on the pulleys, no pics right now though, sorry. the 3d printed chuck didn't work (unsurprisingly), so instead I drilled the 16t pulley with a 3.3mm bit (usually for m4 taps) then took it the rest of the way with a metric step bit (smallest tier was a little over 4mm, so it's a little loose on it's shaft). for the 18t pulley I took an old 15/64" (I think that's what it was, it was around 6 mm) drill bit, and grinding it down to about 5mm od (until it just fit through a 5mm bore pinion I had), I then sharpened it on a bench grinder (which I had to redo 4 times as I bored the pinion, it was my first time sharpening a bit), and drilled out the pulley  it ended up having tighter tolerances than the pinion i used to size the bit. i also tapped the 4-40 threads to m3, I'm not sure how well those will hold, i might have to drill new holes. I think I forgot to mention, these pulleys (and 120mm 40t belt) are from FingerTech Robotics (in Canada), they are aluminum, s3m pitch, only come in 3mm bore, and the grub screws are 4-40 (wat).

it ended up having tighter tolerances than the pinion i used to size the bit. i also tapped the 4-40 threads to m3, I'm not sure how well those will hold, i might have to drill new holes. I think I forgot to mention, these pulleys (and 120mm 40t belt) are from FingerTech Robotics (in Canada), they are aluminum, s3m pitch, only come in 3mm bore, and the grub screws are 4-40 (wat).

it ended up having tighter tolerances than the pinion i used to size the bit. i also tapped the 4-40 threads to m3, I'm not sure how well those will hold, i might have to drill new holes. I think I forgot to mention, these pulleys (and 120mm 40t belt) are from FingerTech Robotics (in Canada), they are aluminum, s3m pitch, only come in 3mm bore, and the grub screws are 4-40 (wat).

it ended up having tighter tolerances than the pinion i used to size the bit. i also tapped the 4-40 threads to m3, I'm not sure how well those will hold, i might have to drill new holes. I think I forgot to mention, these pulleys (and 120mm 40t belt) are from FingerTech Robotics (in Canada), they are aluminum, s3m pitch, only come in 3mm bore, and the grub screws are 4-40 (wat).

#13

Join Date: Mar 2015

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

Good timing lol, today I made some progress on the pulleys, no pics right now though, sorry. the 3d printed chuck didn't work (unsurprisingly), so instead I drilled the 16t pulley with a 3.3mm bit (usually for m4 taps) then took it the rest of the way with a metric step bit (smallest tier was a little over 4mm, so it's a little loose on it's shaft). for the 18t pulley I took an old 15/64" (I think that's what it was, it was around 6 mm) drill bit, and grinding it down to about 5mm od (until it just fit through a 5mm bore pinion I had), I then sharpened it on a bench grinder (which I had to redo 4 times as I bored the pinion, it was my first time sharpening a bit), and drilled out the pulley  it ended up having tighter tolerances than the pinion i used to size the bit. i also tapped the 4-40 threads to m3, I'm not sure how well those will hold, i might have to drill new holes. I think I forgot to mention, these pulleys (and 120mm 40t belt) are from FingerTech Robotics (in Canada), they are aluminum, s3m pitch, only come in 3mm bore, and the grub screws are 4-40 (wat).

it ended up having tighter tolerances than the pinion i used to size the bit. i also tapped the 4-40 threads to m3, I'm not sure how well those will hold, i might have to drill new holes. I think I forgot to mention, these pulleys (and 120mm 40t belt) are from FingerTech Robotics (in Canada), they are aluminum, s3m pitch, only come in 3mm bore, and the grub screws are 4-40 (wat).

it ended up having tighter tolerances than the pinion i used to size the bit. i also tapped the 4-40 threads to m3, I'm not sure how well those will hold, i might have to drill new holes. I think I forgot to mention, these pulleys (and 120mm 40t belt) are from FingerTech Robotics (in Canada), they are aluminum, s3m pitch, only come in 3mm bore, and the grub screws are 4-40 (wat).

it ended up having tighter tolerances than the pinion i used to size the bit. i also tapped the 4-40 threads to m3, I'm not sure how well those will hold, i might have to drill new holes. I think I forgot to mention, these pulleys (and 120mm 40t belt) are from FingerTech Robotics (in Canada), they are aluminum, s3m pitch, only come in 3mm bore, and the grub screws are 4-40 (wat).

#14

Sorry this is an old thread but saw your work and was curious have you done any more work with these rastar cars. Any thingiverse links I'm wanting to try turn 1/14 and 1/24 scale rastars into hobbies grade cars. And the suspension is what sucks once you have the esc motor etc in.

I'm too lazy to post any files right now, so I'll have to get back to you. (keep in mind that I've designed it to work with the tolerances of my own 3D printer)

anyway, here's the latest cad screenshot

#15

Join Date: Mar 2015

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

I did actually finish this one. I don't drive it much, mostly because it doesn't handle too well, which is mostly because it's too fast. (plus I would have to make custom tires, as none are available off the shelf.)

I'm too lazy to post any files right now, so I'll have to get back to you. (keep in mind that I've designed it to work with the tolerances of my own 3D printer)

anyway, here's the latest cad screenshot

I'm too lazy to post any files right now, so I'll have to get back to you. (keep in mind that I've designed it to work with the tolerances of my own 3D printer)

anyway, here's the latest cad screenshot

That's fair man.

If I could I'd design myself some suspension parts or mounting items for suspension, the factory rastar stuff it awful.

You design looks pretty cool. Nice work .