Another machining post

#1

Senior Member

Thread Starter

Join Date: Apr 2002

Location: Collierville,

TN

Posts: 2,749

Likes: 0

Received 0 Likes

on

0 Posts

Hello 1/2A guys; I’m not doing much balsa-bashing lately but am generating a decent sized pile of swarf in the metal-mashing division of DickeyBird Aviation.

Bruce put up a machining post a couple weeks ago so I figger it’s OK to do so. Besides, this could be construed as being 1/2A engine related. This gizmo can be used to measure the stroke of small engines. Maybe to check out the engines at the next reedie race to make sure there aren’t any illegal stroker cranks sneaking in don’cha know.

It’s a depth gauge in case you haven’t figgered out what it is. I don’t have a depth mike yet so this will have to do until I get rich and can afford one. I made it from some brass rod scraps a friend gave me when I got my lathe. You loosen the knob, slide the rod down to contact the bottom of a hole, then tighten the knob, remove the gauge and measure the depth with a caliper. I can get pretty close with a caliper but plan to make a fixture using a dial indicator to be more precise.

I turned the body shape 1st, then clamped it in a collet spin indexer on the mill to mill it down flat. Could’a left the body round but thought it might be used at some point up close to a feature and so I made it flat. I rechucked it the lathe & parted it off…man that brass sure cuts nice! I used brass so it wouldn’t mar the surface of whatever’s being measured. The rod is a piece of .078” music wire so it ought’a last a long time. The knurled knob was done using the cheapo Enco scissor knurler I got for Father’s day and it worked very well. Much easier than the regular style knurler that you just jam into the work from the side.

Anyhoo, I hope this interests someone here. I have some more recently completed projects if anybody's interested.

Bruce put up a machining post a couple weeks ago so I figger it’s OK to do so. Besides, this could be construed as being 1/2A engine related. This gizmo can be used to measure the stroke of small engines. Maybe to check out the engines at the next reedie race to make sure there aren’t any illegal stroker cranks sneaking in don’cha know.

It’s a depth gauge in case you haven’t figgered out what it is. I don’t have a depth mike yet so this will have to do until I get rich and can afford one. I made it from some brass rod scraps a friend gave me when I got my lathe. You loosen the knob, slide the rod down to contact the bottom of a hole, then tighten the knob, remove the gauge and measure the depth with a caliper. I can get pretty close with a caliper but plan to make a fixture using a dial indicator to be more precise.

I turned the body shape 1st, then clamped it in a collet spin indexer on the mill to mill it down flat. Could’a left the body round but thought it might be used at some point up close to a feature and so I made it flat. I rechucked it the lathe & parted it off…man that brass sure cuts nice! I used brass so it wouldn’t mar the surface of whatever’s being measured. The rod is a piece of .078” music wire so it ought’a last a long time. The knurled knob was done using the cheapo Enco scissor knurler I got for Father’s day and it worked very well. Much easier than the regular style knurler that you just jam into the work from the side.

Anyhoo, I hope this interests someone here. I have some more recently completed projects if anybody's interested.

#2

Join Date: Oct 2002

Location: Chilliwack, BC, CANADA

Posts: 12,425

Likes: 0

Received 22 Likes

on

19 Posts

That's BEEE-YOOTIFALL!

So you're now a toolmaker. You realize that there's no turning back or salvation for you now.... You're doomed to the shop to turn out similar objects of art for all eternity.

Of all the airplane forums I moderate over or read through the 1/2A group has embraced machine work far more than any other by leagues. As far as I'm concerned this IS the machine work forum until we get a specific one.

It must be that we're all compensating for the small sizes of our engines or sumtin'....

So you're now a toolmaker. You realize that there's no turning back or salvation for you now.... You're doomed to the shop to turn out similar objects of art for all eternity.

Of all the airplane forums I moderate over or read through the 1/2A group has embraced machine work far more than any other by leagues. As far as I'm concerned this IS the machine work forum until we get a specific one.

It must be that we're all compensating for the small sizes of our engines or sumtin'....

#3

Senior Member

Thread Starter

Join Date: Apr 2002

Location: Collierville,

TN

Posts: 2,749

Likes: 0

Received 0 Likes

on

0 Posts

Well, thank you very much Bruce. I'm glad we share a a passion for releasing nifty gizmos from otherwise boring chunks of metal.

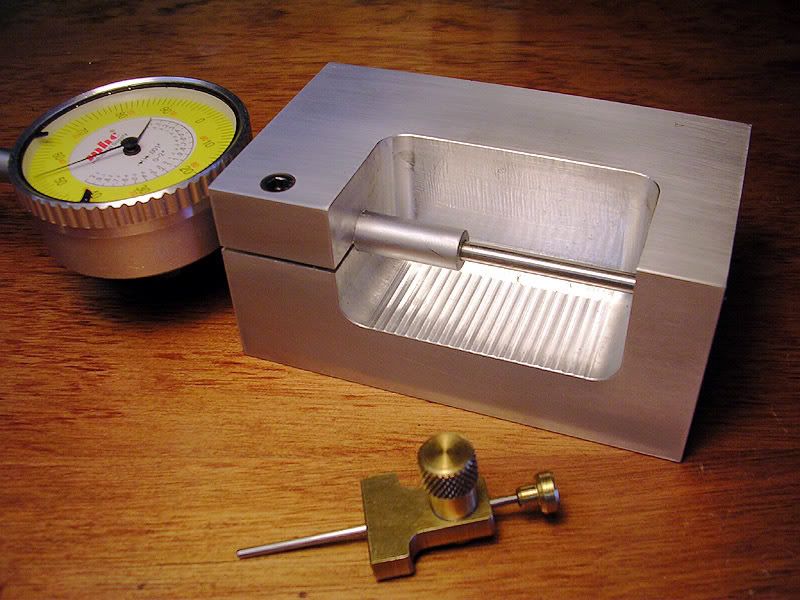

Here's another project I finished a couple weeks ago. It's an adjustable tool-grinding rest that's now mounted up next to my old Craftsman bench grinder. It's a modified version of Mr. Ishimura's design which is posted on the web. It was (for me) a pretty big project and I'm still trying to learn how to use it properly.

It's also made from scraps and parts that I picked up here and there.

Here's another project I finished a couple weeks ago. It's an adjustable tool-grinding rest that's now mounted up next to my old Craftsman bench grinder. It's a modified version of Mr. Ishimura's design which is posted on the web. It was (for me) a pretty big project and I'm still trying to learn how to use it properly.

It's also made from scraps and parts that I picked up here and there.

#4

Join Date: Oct 2002

Location: Chilliwack, BC, CANADA

Posts: 12,425

Likes: 0

Received 22 Likes

on

19 Posts

Yowza... That's nicely done as well. I can just SMELL the hours that went into that.

It's a good thing that time in the shop is not credited against our lifespan. You just gained a lot of extra time on this plane through these projects...

It's a good thing that time in the shop is not credited against our lifespan. You just gained a lot of extra time on this plane through these projects...

#7

Senior Member

My Feedback: (5)

Join Date: Apr 2003

Location: Brunswick,

GA

Posts: 4,867

Likes: 0

Received 0 Likes

on

0 Posts

Well done, DB. I'm interested in the further exploits of the infamous Dickeybird. The depth gauge is a very nice design. Yours?

Bruce, I found some reamers at Harbor Freight for a buck-99. They are the hex bit type, but should work, right?

DB, since you're interested in this stuff, I'll tell you what I've been up to.

http://www.homemachinist.net/hm/dnn/...c/Default.aspx

The current plan is to make another, but without fully drilled holes. All the stuff needed for silicone mold making and resin casting should be here today.

Bruce, I found some reamers at Harbor Freight for a buck-99. They are the hex bit type, but should work, right?

DB, since you're interested in this stuff, I'll tell you what I've been up to.

http://www.homemachinist.net/hm/dnn/...c/Default.aspx

The current plan is to make another, but without fully drilled holes. All the stuff needed for silicone mold making and resin casting should be here today.

#8

Senior Member

Thread Starter

Join Date: Apr 2002

Location: Collierville,

TN

Posts: 2,749

Likes: 0

Received 0 Likes

on

0 Posts

Hi Patrick...nope, I can't claim either of the original designs. I modified other folks' gizmos using the stuff I had on hand so I wouldn't have to spend any money. I'm working on designing a fixture to measure the depth gauge with a dial indicator and if it works, I guess I could say I "designed" it.

The depth gauge idea was copied from one of the many similar types made by Marv Klotz out in California. He's a prolific builder of all kinds of neat metal works of art.

The grinding rest came from Mr. Ishimura's website at http://homepage3.nifty.com/amigos/index-e.html I also built his tilting angle table, again modifying it to utilize my available stock. (Junk)

Hey Mr. Toad, looking at your engine & machining posts, I'm envious of YOU!

The depth gauge idea was copied from one of the many similar types made by Marv Klotz out in California. He's a prolific builder of all kinds of neat metal works of art.

The grinding rest came from Mr. Ishimura's website at http://homepage3.nifty.com/amigos/index-e.html I also built his tilting angle table, again modifying it to utilize my available stock. (Junk)

Hey Mr. Toad, looking at your engine & machining posts, I'm envious of YOU!

#9

Senior Member

My Feedback: (5)

Join Date: Apr 2003

Location: Brunswick,

GA

Posts: 4,867

Likes: 0

Received 0 Likes

on

0 Posts

Hey DB, anytime you start with a blank sheet of paper you get credit for designing it. (or engineering it, whichever you want to call it) Even if you didn't invent it. So get to work and let's see that mechanism.

Here's a pic of something I saw on Enco. I'm gonna make one of these soon and save myself $25. (Kinda crazy, ain't it!) It's limited in usefulness because of the small scale we usually work at, so I may copy yours, too.

Here's a pic of something I saw on Enco. I'm gonna make one of these soon and save myself $25. (Kinda crazy, ain't it!) It's limited in usefulness because of the small scale we usually work at, so I may copy yours, too.

#10

Senior Member

Thread Starter

Join Date: Apr 2002

Location: Collierville,

TN

Posts: 2,749

Likes: 0

Received 0 Likes

on

0 Posts

Is that a caliper holder? Holds the caliper, long end down so it's square to the hole for depth measurement? Pretty clever! Like you say, it's use will be limited in cramped conditions when the work is still in the mill or lathe but still very useful, thanks.

#12

Senior Member

My Feedback: (2)

Join Date: Jun 2002

Location: Mt. Morris, MI

Posts: 1,151

Likes: 0

Received 0 Likes

on

0 Posts

OK guys, this isn't exactly a machinist forum, but you gotta go where the intrest lies, so here's the deal: I have two magnetic sine chucks, and only one surface grinder, so I have the extra on eBay, if you're interested...

#13

Senior Member

My Feedback: (5)

Join Date: Apr 2003

Location: Brunswick,

GA

Posts: 4,867

Likes: 0

Received 0 Likes

on

0 Posts

DB, you guessed it. Should be a fairly quick project for a fellow of your skill.

I like that fella's site. Man, he has made some really nice tooling. The boring head is outstanding.

I like that fella's site. Man, he has made some really nice tooling. The boring head is outstanding.

#14

Senior Member

Join Date: Feb 2003

Location: Slidell,

LA

Posts: 501

Likes: 0

Received 0 Likes

on

0 Posts

Hi DB.

Nice work on the grinder rest, you should indeed be proud, not only of your workmanship but also of your design enhancements. I spent hours last night drawing up your version in cad and then went out to the shop and took a look at the real world version of my grinder and the trash and debris all around it and realized that you can’t make a silk purse out of a sow’s ear. Oh well.

Later, Al

P.S. I wonder if a wave washer under the lever nuts would make it easier to set up the angles? It would tend to help hold things steady while all three pivot points were loose for adjustment. Maybe this is a non issue.

al

Nice work on the grinder rest, you should indeed be proud, not only of your workmanship but also of your design enhancements. I spent hours last night drawing up your version in cad and then went out to the shop and took a look at the real world version of my grinder and the trash and debris all around it and realized that you can’t make a silk purse out of a sow’s ear. Oh well.

Later, Al

P.S. I wonder if a wave washer under the lever nuts would make it easier to set up the angles? It would tend to help hold things steady while all three pivot points were loose for adjustment. Maybe this is a non issue.

al

#15

Senior Member

Thread Starter

Join Date: Apr 2002

Location: Collierville,

TN

Posts: 2,749

Likes: 0

Received 0 Likes

on

0 Posts

Hi Al, thanks for the kind words. My grinder lives in a junky area too. Notice how I cleverly left it out of the picture?

Honestly, it IS a juggle trying to adjust the thing around to the desired angle and get the handles tight enough without them interfering with each other or the table. I hope that like most things, it'll get easier as I use it more.

So far, all I've used it for is to dress my grinding wheel up nice & true. Of course the cloud of abrasive dust got all over the thing and into all the nooks and crannies! I'll have to be diligent with keeping it clean or all those nice fits I labored over will be ground away and turn the thing into a sloppy pile of junk.

Honestly, it IS a juggle trying to adjust the thing around to the desired angle and get the handles tight enough without them interfering with each other or the table. I hope that like most things, it'll get easier as I use it more.

So far, all I've used it for is to dress my grinding wheel up nice & true. Of course the cloud of abrasive dust got all over the thing and into all the nooks and crannies! I'll have to be diligent with keeping it clean or all those nice fits I labored over will be ground away and turn the thing into a sloppy pile of junk.

#16

Senior Member

Thread Starter

Join Date: Apr 2002

Location: Collierville,

TN

Posts: 2,749

Likes: 0

Received 0 Likes

on

0 Posts

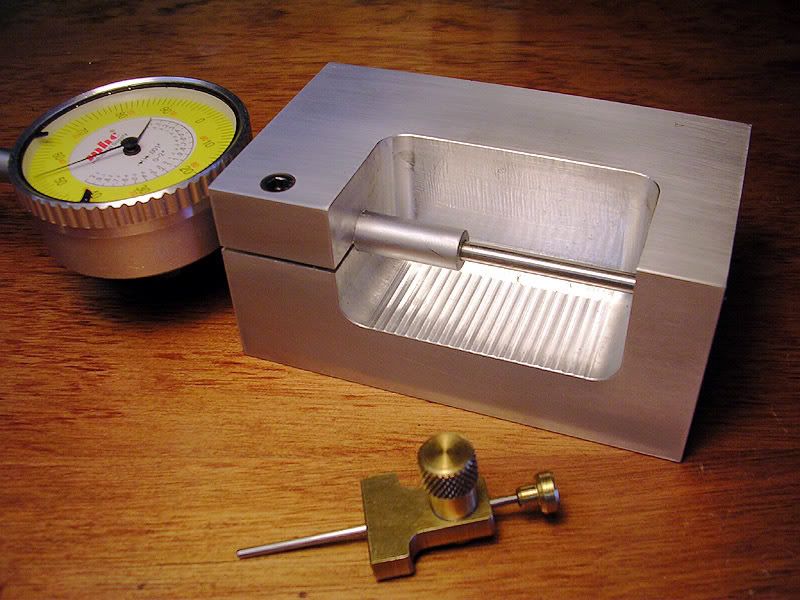

Update on the depth gauge gizmo: Thanks to the kindness of fellow 1/2A'er Brian Sodt, I now have a supply of aluminum chunks to convert into swarf. I made this (admittedly oversized and wasteful of stock) fixture to measure the gauge with.

I've been wanting to try some "pocketing" in the mill so I started whittling away at one of the chunks of 2024 aluminum that Brian sent me. To use it, you slide in a 2" D.I. with the tip sticking out a little, set it down on a smooth surface and zero the gauge. I also got some flat tips to install on the gauge shaft instead of the little roller style one that came with it. When you stick the pre-set gauge in the end, it gives an instant and accurate reading.

I've been wanting to try some "pocketing" in the mill so I started whittling away at one of the chunks of 2024 aluminum that Brian sent me. To use it, you slide in a 2" D.I. with the tip sticking out a little, set it down on a smooth surface and zero the gauge. I also got some flat tips to install on the gauge shaft instead of the little roller style one that came with it. When you stick the pre-set gauge in the end, it gives an instant and accurate reading.

#17

Senior Member

Dickeybird:

Just thought I'd offer up that in the 17 years that I've been a tool and die maker, I've never seen a better tapping lubricant than regular old Crisco, or a better coolant for cutting aluminum than Rubbing Alcohol.

Give 'em a shot!

Just thought I'd offer up that in the 17 years that I've been a tool and die maker, I've never seen a better tapping lubricant than regular old Crisco, or a better coolant for cutting aluminum than Rubbing Alcohol.

Give 'em a shot!

#19

Senior Member

Thread Starter

Join Date: Apr 2002

Location: Collierville,

TN

Posts: 2,749

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Dave & Vic; I've been using Crisco, both the white stuff & the oil, for tapping aluminum for years but haven't tried rubbing alcohol for a coolant. I'll have to try it. Lately I've been using the good ol' Enco #1 blue stuff for coolant and it seems to have a gelled alcohol base. If you put a dab on your finger and smear it around you feel a definite evaporative cooling effect just like alcohol. I also like WD-40 for a cutting fluid on aluminum.

My amateur machining posts must make you experienced guys want to barf.

My amateur machining posts must make you experienced guys want to barf.

#20

WD-40 has been my favorite for cutting and tapping aluminum. For a coolant, on the mill I use a product called Kool Mist, a solution you mix with water. it is sprayed on the tool via air through a nozzle. Anyway, Alchy would work great for tool life I would think. Hate that smell though, makes me wanna drink it.