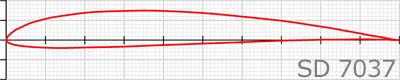

Time to make some wings. I'm no expert when it comes to airfoils so I did some research online. Taking advice from several sailplane forums I ended up concluding this puppy was the ticket...

Using my CAD software I printed then contact-cemented the rib shapes onto my wood. I used a scroll-saw to rough cut each then went to the belt sander to finalize the shape...

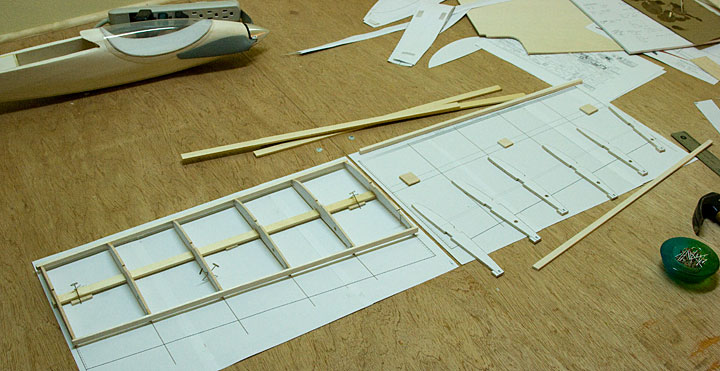

Next I printed up the wing center section plans & began assembly...

As this is not a flat bottomed airfoil I added tabs to the ribs to help keep them at the correct AOA. They will be sanded off once the basic frame-up is complete...

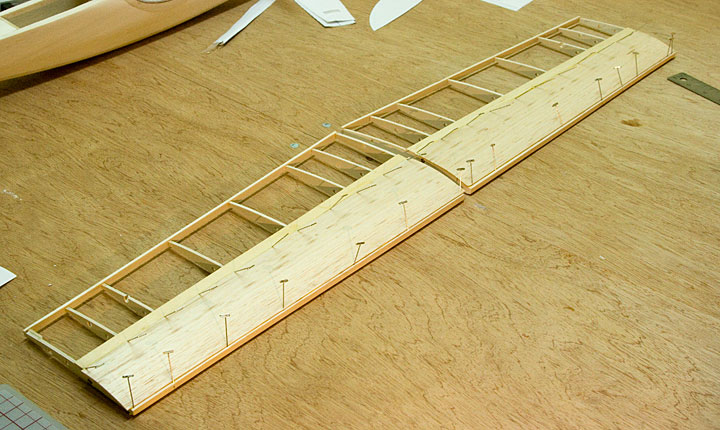

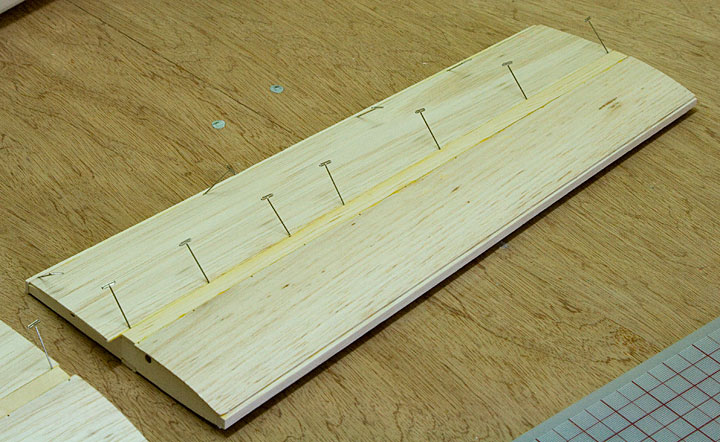

Seeing as I went to all the trouble of choosing a fancy airfoil I thought sheeting would be a good idea. Saggy covering can do terrible things to a wing's shape, especially on the top leading edge area...

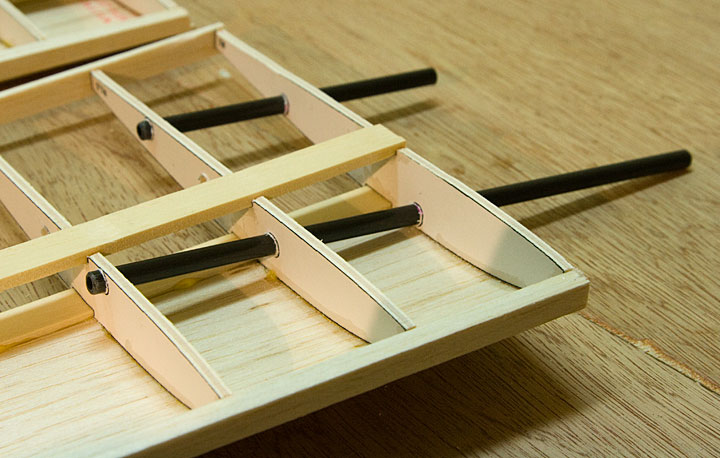

As much as I like this SD 7023 airfoil, it is one thin SOB. There's not a lot of room in there for joinery so once again I opted for some CF reinforcement. I also made these end ribs from plywood to help support the CF rods...

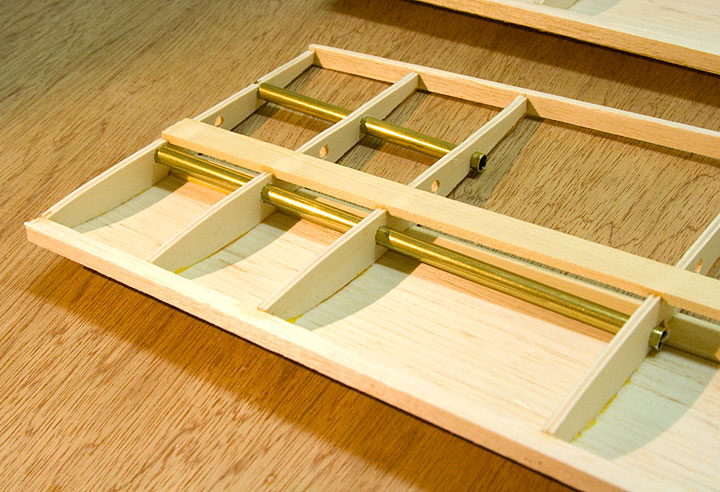

The two center sections of my gull-wing will be glued together. The outboard sections will be joined using CF rods indexing these brass tubes. Again with the thin airfoil thing, I was limited in how much dihedral could be built in & still use rods to connect the sections. Best I could do was 7° dihedral in the middle & 4° down where the outboard gull-wing sections join. As this will be an aileron ship so I'm not too worried about built-in roll stability or rudder only turns anyway...

Once again with the thinness issue I'm a little worried about structural strength. For the inboard sections at lease I chose to fully sheet the top. I'm debating whether the bottom could benefit from sheeting too. I don't want to end up building a flying brick either, weight is always concern...

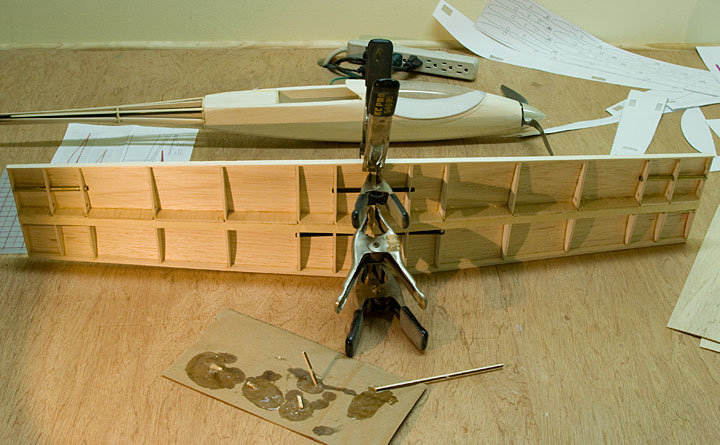

The center sections are clamped & glued together, now we're getting somewhere!..

Servo wire is run for the ailerons & flaps...