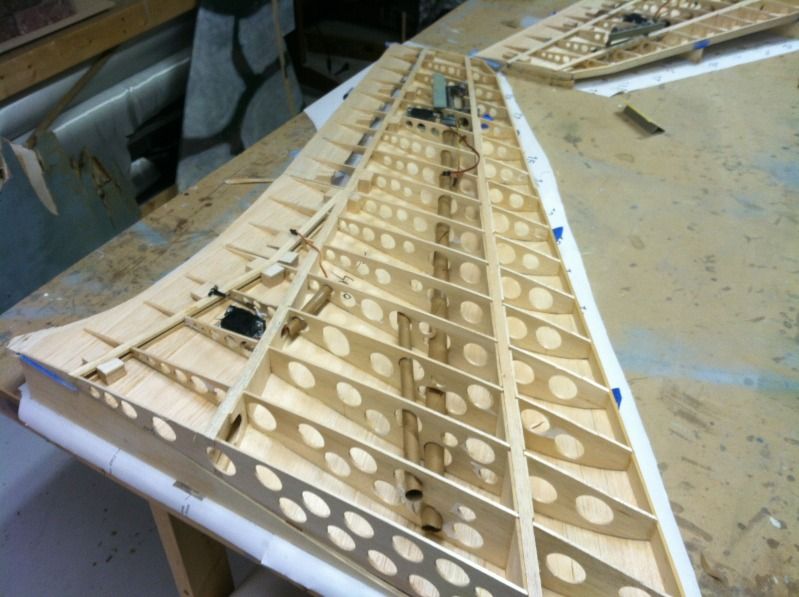

Day 6's progress..

Elevon and drag rudder servo mount plate is installed in both wing panels. The drag rudders are getting an upgraded linkage using ball-links instead of my music wire Z-bend setup in the previous wings. The previous setup had a good bit of slop in its linkages which made for some less than accurate drag rudder extension, the ball link setup should fix that problem and make it easier to maintain as well.

All servo extension conduits are installed.

inboard flap servo's and mounts installed

All hinge and control arm blocking has been cut down and sanded to the correct height and shape as the surrounding wing structure.

The trailing edge has been sanded down to follow the taper of the bottom of the wing ribs. Right now I am debating on adding a piece of 1/64" ply along the TE between the wing sheetings to help prevent hangar rash. I really prefer to, but at the same time, any additional weight behind the CG has a very significant effect.

For instance, it takes 1oz of weight 17" infront of the CG point to move the CG forward 1/2" forward. The very tip of the wings are about 17-19" aft of the CG, so one extra ounce there will require an ounce 17-19" infront of the CG.. and to add to that, the center section repairs will probably add 1 to 3oz of weight 25-30" aft of the CG. So i am apprehensive about adding more weight behind the CG..

The elevon hinge holes have been routed in the elevon hing blocks and the 7/32" brass tube hinge extension tubes have had their holes drilled in the wing side elevon hinge blocks. I also cut out the 1/64" ply wing tip core and the 1/2" balsa wingtip blanks. One of each of these balsa blanks was glued to one of the ply cores and weighted down to dry. tomorrow i'll sand the balsa blank to the same profile shape as the core and then glue the laminate to the other balsa blank.

Other than installing the wing tubes and shaping the LE of the ribs to the correct profile, the wing is now ready to be sheeted. Unfortunately, I am still waiting on my wing tube sockets and my wood order from National Balsa to arrive..

Tomorrow is family night, so the only thing I really plan to do is get the wing tip laminates completed. Saturday I will (hopefully) install the wing tubes if the sockets arrive, setup the new drag rudder linkage's and do the layups for the center section repairs.

Sunday I will probably be going over to Tom's to help him install his wing tubes, then depending on when I get back from that, I'll try and finish up the center section repairs.