It's been a while but I'm back working on this project, woohoo!

Motor Selection

I did some chatting with my buddies over at

RCAerotowing.com & after considerable deliberation, I ended up acquiring this bloody great hunk of copper & aluminum...

This L19 is not going to be lacking for power *evil grin*

I check out the real thing

Here's a real Bird Dog aerotowing at the Wurtsboro 1-26 Fun Fly last weekend...

YouTube Video - Click to Play

More goodies arrived...

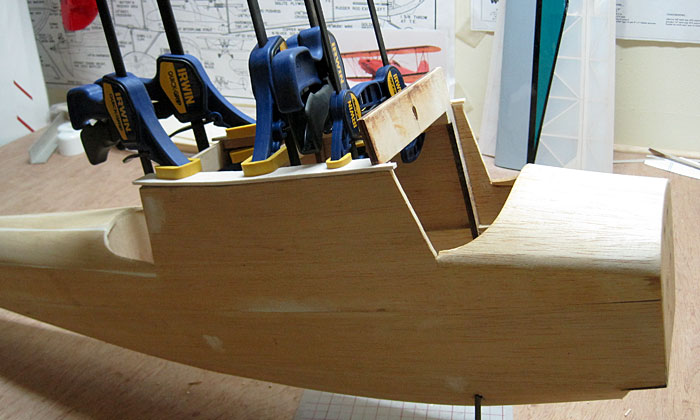

Started work on the wing saddle area. The stock setup seemed pretty wimpy, especially as I'll be removing much of the side planking for the windows. So I'm reinforcing the area some...

Bellcranks? Umm no

Bellcranks? Umm no

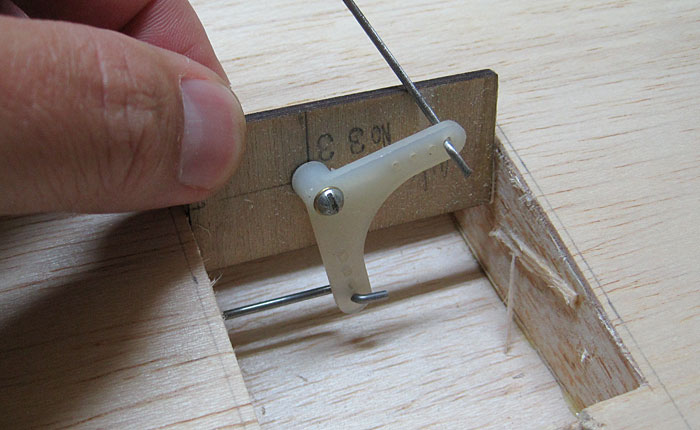

The wing's ailerons & flaps are hooked up via old school bellcrank linkages connected to a couple of servos mounted in the center of the wing. I'm going to modernize things by installing four servos, one for each control surface. First order of business is to go digging for bellcranks...

How quaint...

Anyone need bellcranks?..

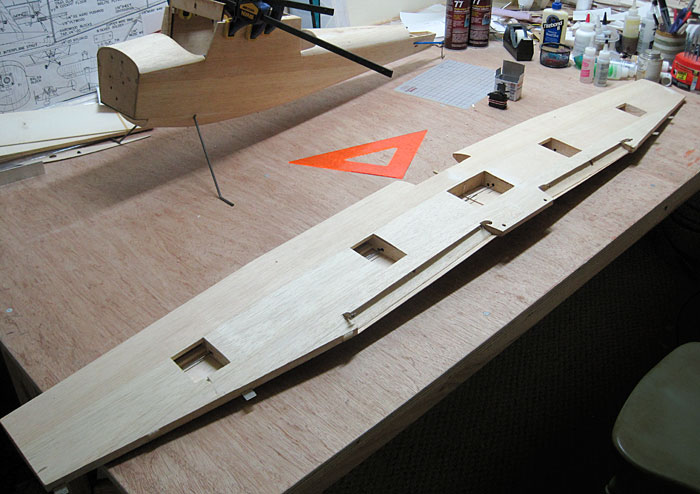

The old linkage system is out. Holes are cut ready to install the four servos...

Corrugation

Corrugation

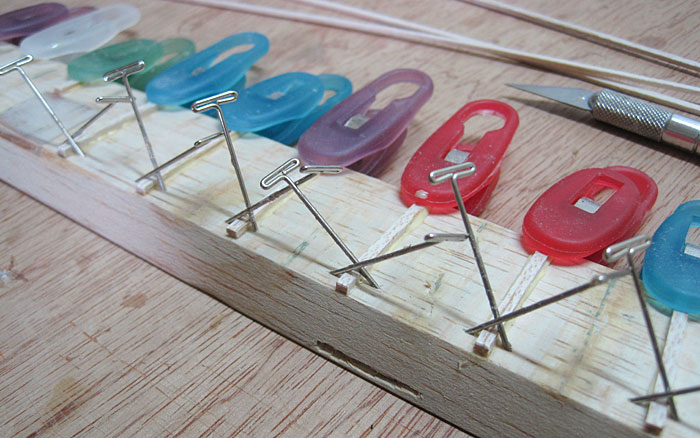

Looking at the reference photos I took at Wurtsboro the other day, you can clearly see corrugations in the control surfaces...

My L19 has corrugations too...

Having recently spent a LOAD of time glassing, finishing & painting another project I'm not in the mood to paint this one too. Instead I'm simply going to cover her with Ultracote. Those cool corrugations I figured would be a problem so I decided to get rid of them...

What was I doing? The corrugations are cool, leave them be!

What was I doing? The corrugations are cool, leave them be! After hacking up just one aileron thankfully I came to my senses.

I decided to do a quick test & see how they'd look covered with Ultracote...

Okay so that doesn't look exactly like the real corrugations but it kinda works. It's certainly more interesting than a without them. I'm sold, lets keep the corrugations. Only problem is I'd already hacked them off one aileron.

Two hours later I had a new found respect for Joe, the original builder. Wow corrugations are a LOT of work, cutting, sticking, trimming, sanding...

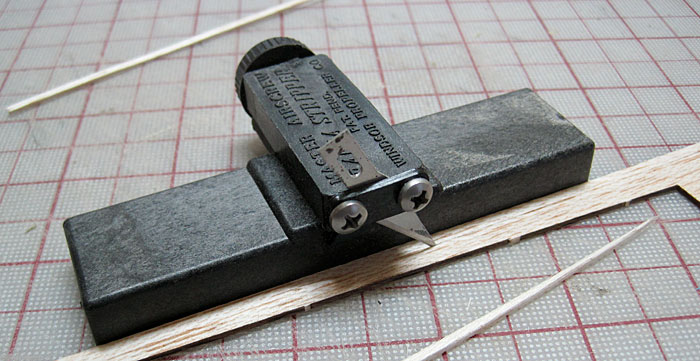

On the plus side I got to use my nifty strip cutting tool...

Remind me, never to go hacking up other people's hard work before putting some serious thought into it...

Servo Hatches

Servo Hatches

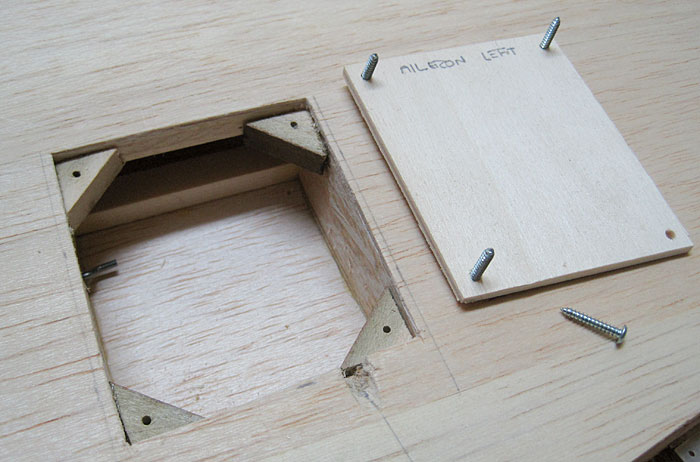

With the aileron restored to its former corrugated glory I turned my attention to the wing's servos. Triangle pieces of hardwood were added to each servo bay...

I created servo hatch covers & drilled holes for the mounting hardware...

I was hoping to get the servos installed but spent most of my time messing with the corrugation issue instead. Hope to get more accomplished tomorrow...