Making New Formers

Former patterns were transferred to file folder card stock and tested for fit in proper locations. Then 1/4" foam patterns were made for mock up

fitting. Final patterns were transferred to 1/4" plywood and cut for final fitting prior to being glued in with Hysol and epoxy fiber mix.

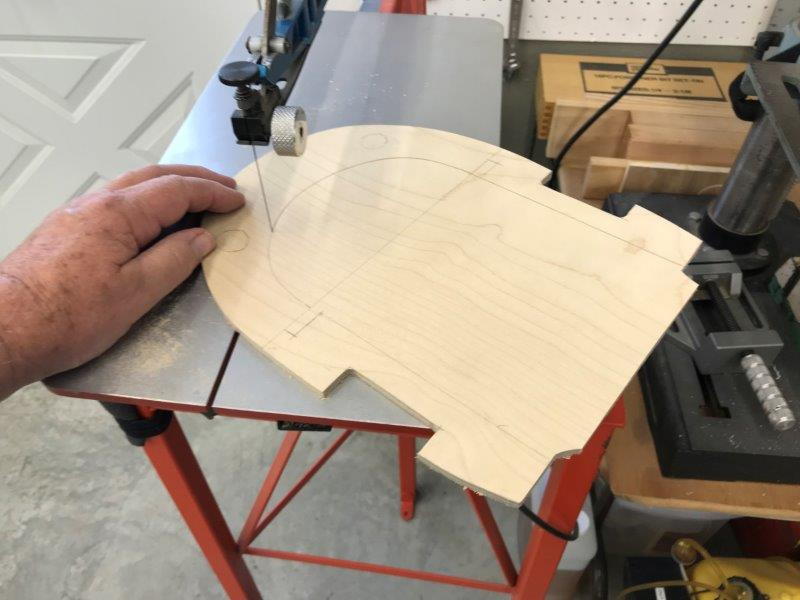

Transfer patterns to card stock

Close enough fit after several adjustments

Middle turbine former designed to keep fuse from compressing from trailing edge wing pressures.

Copies of card stock made to paper and transferred to pink foam

After final mock ups pink foam patterns transferred to 1/4" plywood

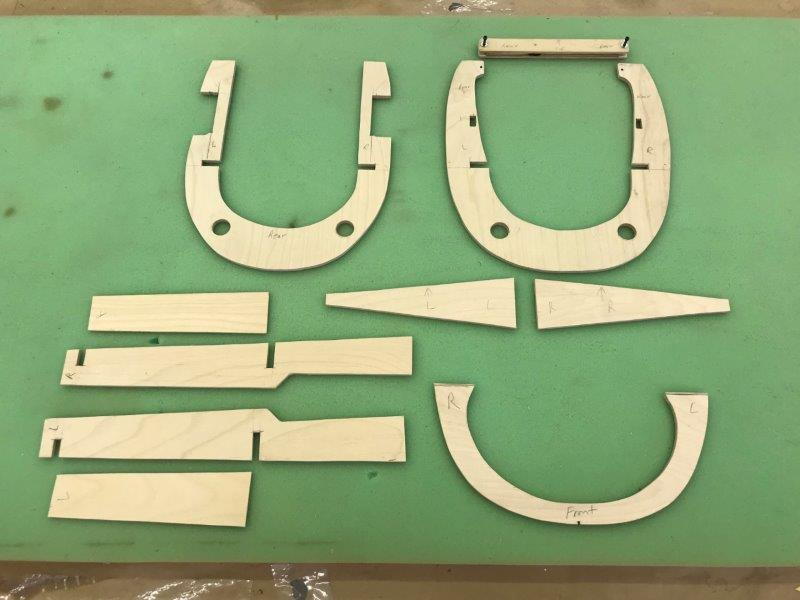

Plywood formers cut out

Turbine rails designed by same process using turbine and bell mouth templates

All wood parts cut and dry fit. Bridge across mid former fabricated and bolts installed

Final wood part dry fit. Aluminum bar ensured alignment with hole in nozzle cone on rear of fuse. Cross piece clamped ensured turbine rails level with each other.

Formers glued in with wing trailing edge hard points on each side. Turbine rails will be glued in later after pipe arrives and proper spacing determined for mounting