Did a fair amount of different things today.

Work on the P.A.

Disassembled mom's bed to make room for a hospital bed from Hospice.

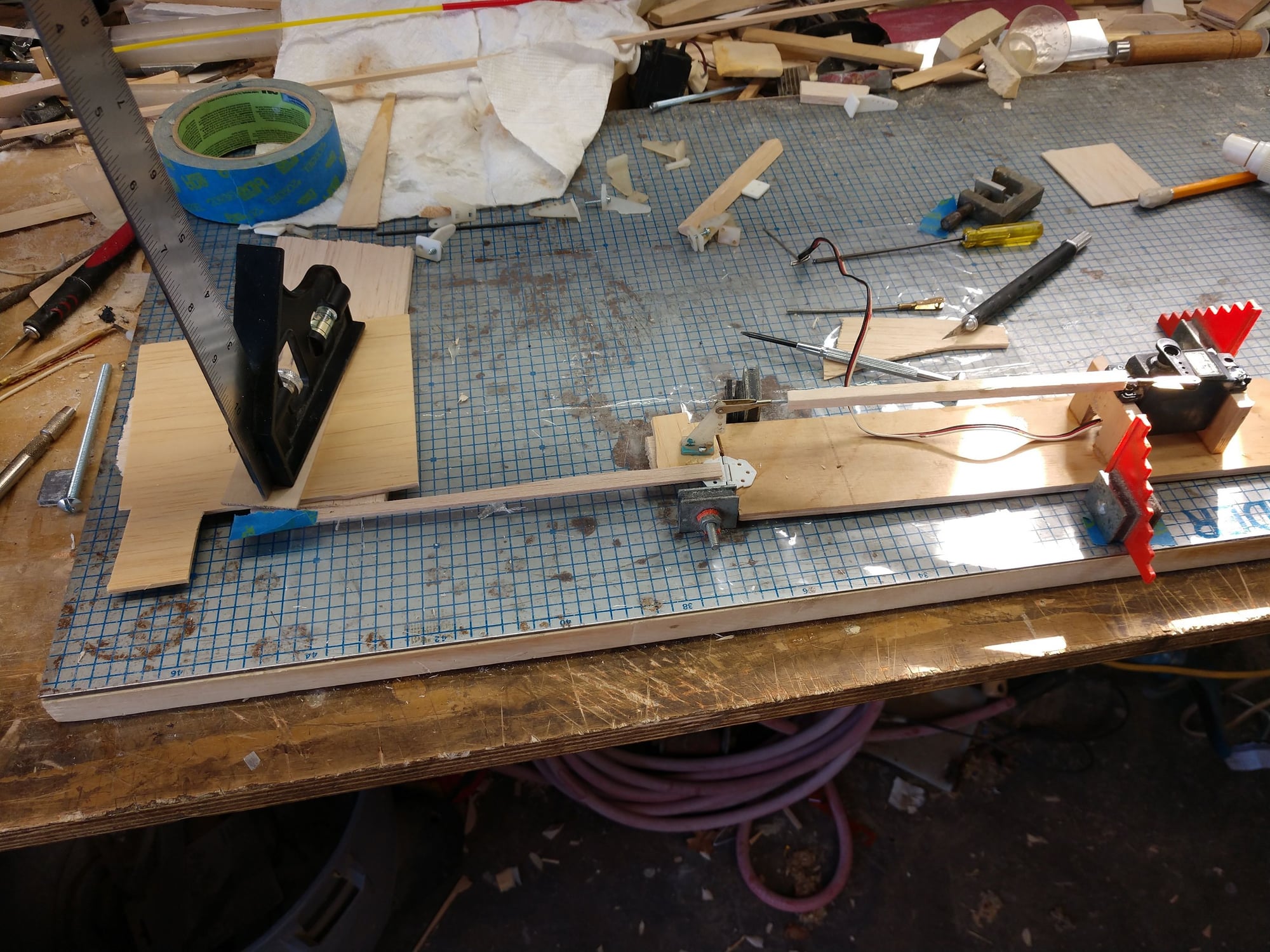

Made test rig to measure multiple Tx rates. Since the output of ta servo is circular and so is the control surface control horn I wanted to know the relative effects of various Tx rates. I'm sure this could be figured out mathematically, but the solution is way beyond me.

I joined the two elevator halves. Glassed the torque rod in. I used 4.25 ounce crows foot weave (Satin weave). I used a piece that overlapped around the torque rod about 1/2", and then a bigger piece that overlapped about half way on each side. Did one side and sat it on the dash of the truck in the warm sun to speed curing. once it was cured I trimmed it and sanded it, and then repeated the process for the other elevator half.

While the elevator half's were curing I made a test rig (very crude) to let me measure the effects of various Tx rate controls. I used scrap material to make the rig. I hinged a scrap piece of balsa that was 9" long to a piece of 1/4" ply,fasted a 1" control arm to it at the hinge line, and then fastened a servo with a 1" arm to the ply. Sat a combo sqaure at the end of the balsa arm to measure throw. I know such a long arm is not what we see with our models but it made it easy to measure. Only need relative throw any way.

So here are the numbers I got.

On 40% rate the throw was 2 inches.

On 70% rate the throw was 3.25 inches.

And on 100% rate the throw was 4.5 inches.

So those particular rates roughly divide the throw more or less evenly.

Then my elevator halves were dry. So I trimmed the Excess fiber glass, and then sanded them.

I have been debating how to handle where the golden rod exits the fuse. I knew I just couldn't let them exit with out some wood around them. So I finally said the heck with it and filled in the last open bay on each side of the fuse. I think the exits line up pretty good with their respective control horn. The inner rod sure runs free.

Ken