Tank half removed from mold.

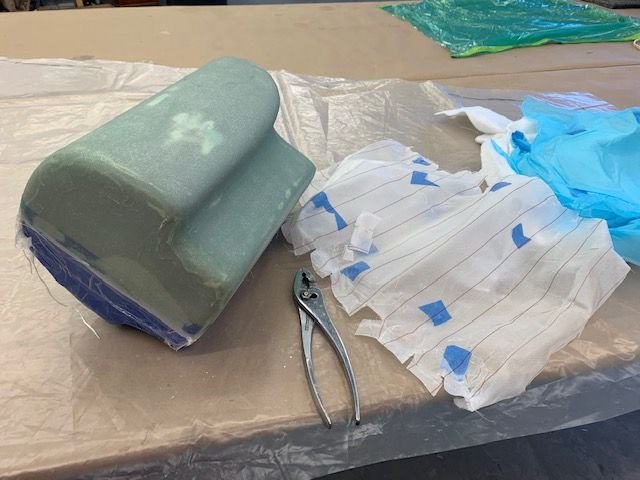

With great anticipation I went to the shop this morning to see what I had. Pulled the tank from the vacuum bag and the fun started. First the breather cloth came off pretty easy with the perforated release film (blue stuff) under it.

Next was the peel ply. It was saturated with epoxy so it was more of a challenge but the pliers really helped grip it and peel it off. Then the fun started. I trimmed off the glass edges as close to the tape line as possible with some small lexan scissors, Next I blew compressed air under the edge of the layup and could see the glass lift off the surface of the plug is most areas. But it would not budge. I found it was solid on the top and bottom corners on the front and back of the tank. I think the problem was too small of corner radius and not enough negative draft angle and it was locked on. I poked, prodded, and pulled with several tools but no luck. After about an hour I thought it was a lost cause getting the part off the plug. It was depressing.

I finally decided to try the Dremel cut off wheel to score the glass right up next to the line and pull off the glass with the pliers. And it started to work.

This is the moment it popped off. I was like a 3 year old kid the just got a candy bar! It worked. I was able to get it off by pulling at the rear of the tank and poof, off it came. I can see my surface prep was good and was not the issue. It was the tight corner radius and poor plug design. Well, it was my first try and I'm learning a lot. Now I understand what Paul meant when he said plug design was everything. Anyway I got this far so I will try it again on the next half.

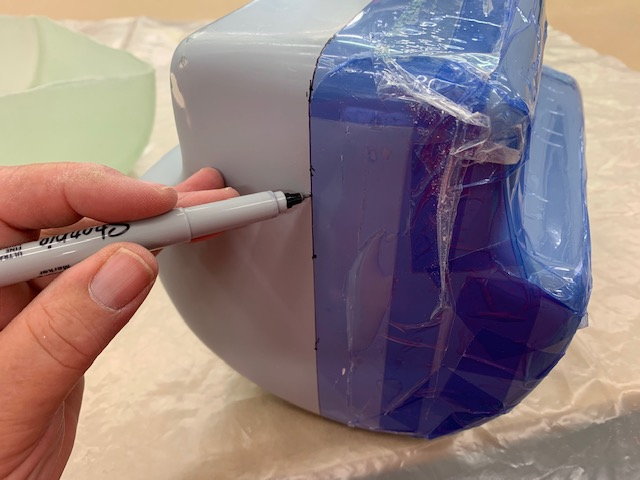

First, I marked the centerline of the plug before I removed the blue flash release tape

Next I marked the inside of the tank half on the tape line for trimming the edge

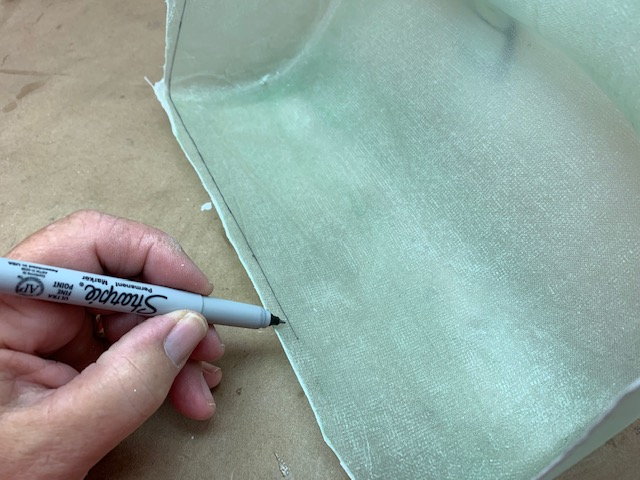

Ready to trim

I found some small cuts on the plug where the cutoff wheel went too deep. None went thru the glass surface on the plug so I just put some glazing putty in the nicks and will sand it smooth again.

Tank half after trimming and sanding the edges

Seemed to be a usable part

Plug ready to sand and re-wax for next half.

Had another pop up weekend trip so it will be next week before I can lay up the next part. More adventure to come...