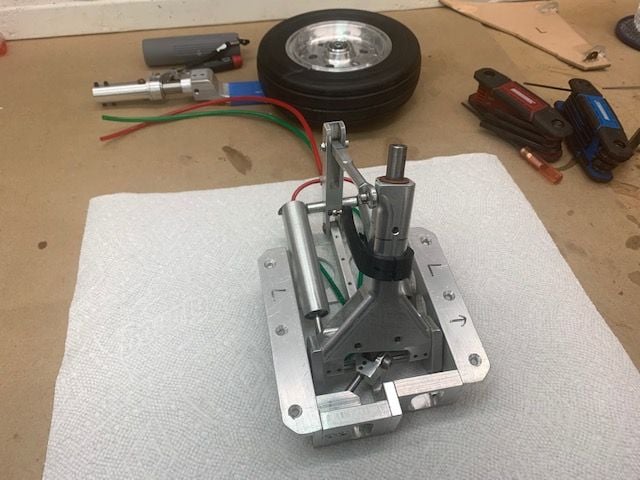

Left main gear disassembly

First I took the lower strut and wheel off to remove the weight. I had always just assumed the gear was stiff because of the weight of the strut, linkage, and big wheel so I wanted to remove the strut and wheel to feel the movement with out the weight. The movement still felt stiff.

Next I disconnected the air cylinder linkage to the strut to get rid of the drag of the linkage. It was still stiff.

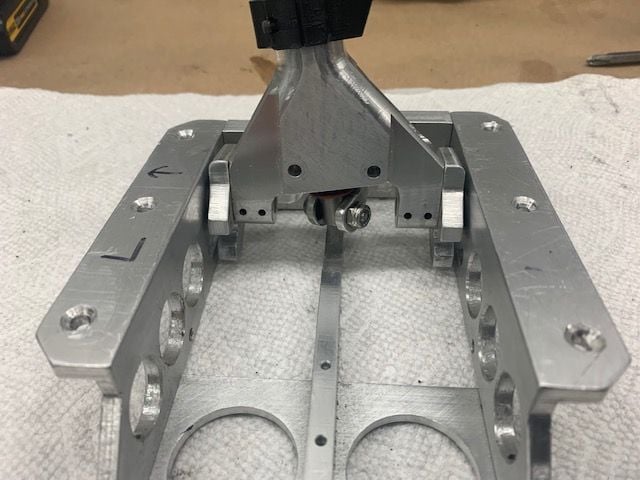

Without any linkage or heavy strut the only movement is in the pins going through the sides of the frame.

This was all that was left connected and it was binding the movement. This is probably the reason the gear will not retract properly.

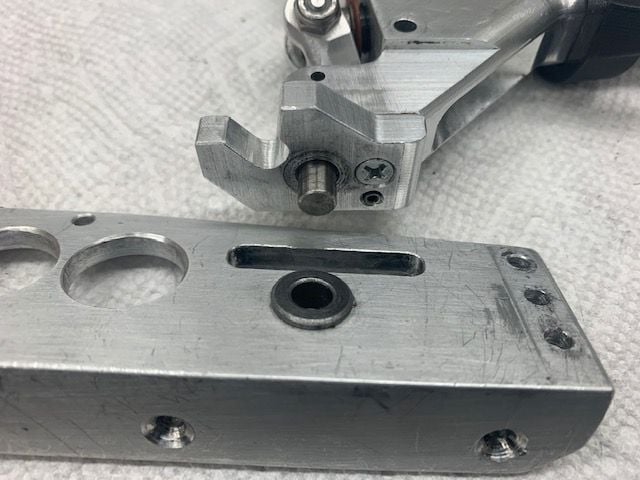

It took about 30 min to get the screws out. They were glued in solid by thread locker probably since manufacture several years ago. I had to use a torch to heat the frame and screws to get the thread locker to let go.

Here is the pin and bushing on one side

And the other side. The pins fit nicely and pivot freely when disassembled.

It seems that the pivot pins are not straight or the frame is not square.

You can feel the pivot pins get tight as the frame screws are tightened so something is binding. The question is how to fix it. I was thinking about trying to enlarge the holes in the bushings but not really sure how to do it. I was afraid to try to drill it and make it too big and have the pivot pins wobble in the hole. Suggestions welcome.

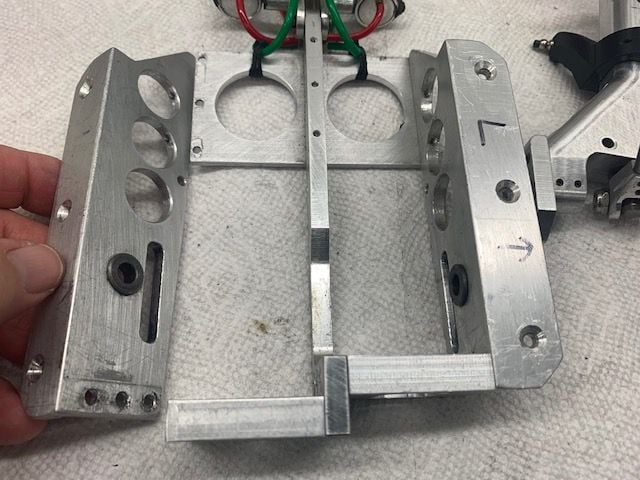

Here is the slide bar with out the strut in place

Air rams are threaded into the slide bar. There is a fair amount of resistance inside the cylinders but I have all ready applied some BVM silicon lube oil and you can here it squishing as you activate the cylinders. Not sure how I can loosen them up.