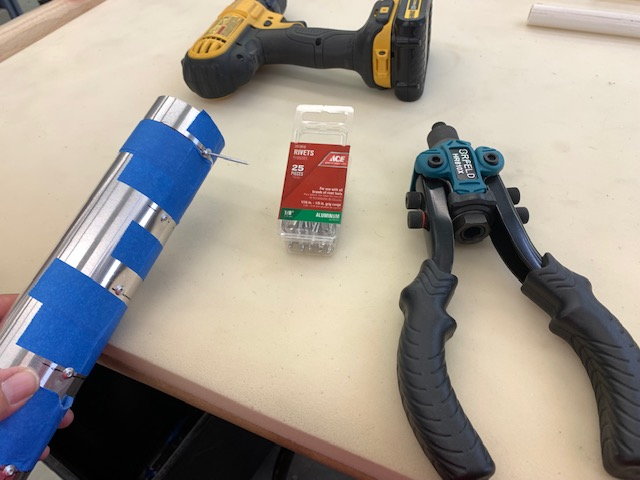

Fabrication of outer pipe

A 12" roll of aluminum roof flashing from Lowe's was used for the outer pipe material. The size for the outer pipe was marked and cut from the roll. 1/8" pop rivets from Ace Hardware were used for fasteners.

Holes drilled and pop rivets installed

Inside the outer pipe the pop rivets are used for stand off supports from the inner pipe

Inside pipe, outside pipe, and 3D printed 52mm sanding mandrel tool shown here.

Dremel sanding drum used to sand down the inside of the pop rivets so inside pipe would fit

Inside pipe fit into outside pipe

Inside pipe recessed 10mm on aft end to generate low pressure and suck cooling air between pipes.

Approximately 3mm gap all around. Not perfect but ok for my first homemade pipe

Test fit mock up works OK

Aluminum holding strap riveted to bottom of outer pipe

Holding strap cut, drilled, and attached to bell mount bolt to fasten outer pipe in place. Once the heat treated bell is printed and attached the bolts will be reversed so that the heads are inside the pipe and nuts are on the outside