Electronic solutions to modifying glow engines of all sizes to gasoline

#827

Senior Member

Thread Starter

Yeeeeeup, the Rcexl CDI I got from ZYHobbies is defective. Put a CH CDI on the 200Ti and it runs perfect. Nice increase in fuel economy over GI too. Now I can move on.

Interestingly, it spools up a Xoar 18x8 lightning fast from idle, similar to YS 4S engines, but only reaches 7350 peak rpm. Advancing the timing from 33° to 34° offered no increase in peak rpm but no detonation even when overly leaned either.

Typically when I see super fast transitions like this I also see over revving, reaching max peak rpm for the engine, and prop for a little more static load. Not so with the 200Ti.

Interestingly, it spools up a Xoar 18x8 lightning fast from idle, similar to YS 4S engines, but only reaches 7350 peak rpm. Advancing the timing from 33° to 34° offered no increase in peak rpm but no detonation even when overly leaned either.

Typically when I see super fast transitions like this I also see over revving, reaching max peak rpm for the engine, and prop for a little more static load. Not so with the 200Ti.

[size=13px]

[/size]

Congrats, Lonnie! That engine has put up a brave fight, but you finallly have it running.

#829

My Feedback: (1)

SO.... A little experimenting today. Made some "restrictors" and fitted them to the Straight pipes. Simple brass cups that I brazed on to my homemade straight pipes. Instant improvement in top end fuel feed - Now have headroom and a more regular looking curve.

The restrictors did come with a 100-rpm loss on the top end though - I think an expansion chamber might be a better fix

Here is a quick run - I recently upgraded my phone and is does a weird sound attenuation now on noisy sounds and it makes the engine sound more "crackly" than it is in real life -

While playing with exhaust I did notice an issue that could be causing my issue with the lower compression on the front cylinder. When playing around I noticed a slight suction the Exhaust port on #1 that wasn't apparent on #2 - Timing is on the power downstroke so I think I have a non sealing exhaust on that cylinder - valve lash is OK - Will investigate

In other News.... I had a visitor Today... A fellow club member just bought this cutie. He brought it over for "inspection" and tips. Can't wait to hear it run. Its an FG 11.

The restrictors did come with a 100-rpm loss on the top end though - I think an expansion chamber might be a better fix

Here is a quick run - I recently upgraded my phone and is does a weird sound attenuation now on noisy sounds and it makes the engine sound more "crackly" than it is in real life -

While playing with exhaust I did notice an issue that could be causing my issue with the lower compression on the front cylinder. When playing around I noticed a slight suction the Exhaust port on #1 that wasn't apparent on #2 - Timing is on the power downstroke so I think I have a non sealing exhaust on that cylinder - valve lash is OK - Will investigate

In other News.... I had a visitor Today... A fellow club member just bought this cutie. He brought it over for "inspection" and tips. Can't wait to hear it run. Its an FG 11.

#830

Sounds great Chris, flyable for sure!

What type of tubing did you use for the DIY exhaust?

RE Saito FG11: It will run glass smooth from idle to WOT once broken in. I've found that a little throttle slowdown is necessary for transition off idle on all four of my FG singles.

What type of tubing did you use for the DIY exhaust?

RE Saito FG11: It will run glass smooth from idle to WOT once broken in. I've found that a little throttle slowdown is necessary for transition off idle on all four of my FG singles.

#831

Yeeeeeup, the Rcexl CDI I got from ZYHobbies is defective. Put a CH CDI on the 200Ti and it runs perfect. Nice increase in fuel economy over GI too. Now I can move on.

Interestingly, it spools up a Xoar 18x8 lightning fast from idle, similar to YS 4S engines, but only reaches 7350 peak rpm. Advancing the timing from 33° to 34° offered no increase in peak rpm but no detonation even when overly leaned either.

Typically when I see super fast transitions like this I also see over revving, reaching max peak rpm rating for the engine, and prop for a little more static load. Not so with the 200Ti.

Interestingly, it spools up a Xoar 18x8 lightning fast from idle, similar to YS 4S engines, but only reaches 7350 peak rpm. Advancing the timing from 33° to 34° offered no increase in peak rpm but no detonation even when overly leaned either.

Typically when I see super fast transitions like this I also see over revving, reaching max peak rpm rating for the engine, and prop for a little more static load. Not so with the 200Ti.

PRODUCT SPECIFICATIONS

Type:4-strokeDisplacement:2.00 cu in (33.00 cc)Bore:1.10 in (28.20mm)Stroke:1.03 in (26.40mm)Cylinders:Inline twin, chrome platedEngine (Only) Weight:51.5 ozCrankshaft Threads:M8x1.25mmBenchmark Prop:17 x 8 APC @ 8,900Prop Range:16x8 - 18x10RPM Range:2,000 to 9,200Fuel:10%-30% syntheticMounting Dimensions:160 x 110 x 142mmMuffler Type:PipeCylinder Type:16.5cc x 2 / AACCarb Type:Barrel, 2-needle valveCrank Type:Ball bearingI have had many deep thoughts about posting my ign timing sketch, or the complete ign sys with the hi energy output... but then I keep getting reminded why not to.

,

,Last edited by John_M_; 09-19-2022 at 06:38 PM.

#832

My Feedback: (1)

Sounds great Chris, flyable for sure!

What type of tubing did you use for the DIY exhaust?

RE Saito FG11: It will run glass smooth from idle to WOT once broken in. I've found that a little throttle slowdown is necessary for transition off idle on all four of my FG singles.

What type of tubing did you use for the DIY exhaust?

RE Saito FG11: It will run glass smooth from idle to WOT once broken in. I've found that a little throttle slowdown is necessary for transition off idle on all four of my FG singles.

Few questions on the FG's - Oil type and content and quick rundown on break in requirements. The fellow is new to "wet fuel" and I think I will be the "guidance counsellor" for this one...

#833

SO.... A little experimenting today. Made some "restrictors" and fitted them to the Straight pipes. Simple brass cups that I brazed on to my homemade straight pipes. Instant improvement in top end fuel feed - Now have headroom and a more regular looking curve.

The restrictors did come with a 100-rpm loss on the top end though - I think an expansion chamber might be a better fix

Here is a quick run - I recently upgraded my phone and is does a weird sound attenuation now on noisy sounds and it makes the engine sound more "crackly" than it is in real life -

While playing with exhaust I did notice an issue that could be causing my issue with the lower compression on the front cylinder. When playing around I noticed a slight suction the Exhaust port on #1 that wasn't apparent on #2 - Timing is on the power downstroke so I think I have a non sealing exhaust on that cylinder - valve lash is OK - Will investigate

In other News.... I had a visitor Today... A fellow club member just bought this cutie. He brought it over for "inspection" and tips. Can't wait to hear it run. Its an FG 11.

The restrictors did come with a 100-rpm loss on the top end though - I think an expansion chamber might be a better fix

Here is a quick run - I recently upgraded my phone and is does a weird sound attenuation now on noisy sounds and it makes the engine sound more "crackly" than it is in real life -

While playing with exhaust I did notice an issue that could be causing my issue with the lower compression on the front cylinder. When playing around I noticed a slight suction the Exhaust port on #1 that wasn't apparent on #2 - Timing is on the power downstroke so I think I have a non sealing exhaust on that cylinder - valve lash is OK - Will investigate

In other News.... I had a visitor Today... A fellow club member just bought this cutie. He brought it over for "inspection" and tips. Can't wait to hear it run. Its an FG 11.

#834

Well ductile iron is a dark grey to black when heat treated... watching that JonneyQ90 guy install the rings in his engine, they seem to be pretty tough, I almost thought he had broken one as he fought to get it in the ring groove, made a loud snap as it popped into the groove.... When you look at the rings in the 160 boxer, there is no comparison in the amount of tension, smaller diameter piston rings don't need a lot of tension... their thickness can be wide, especially for a single ring, but the tension expansion should be small, thats done during tempering... they expand the ring in a jig and heat to temper... the thicker the ring the stiffer it will be, and will need less tension.

#835

My Feedback: (1)

Can you imagine what kinda restrictions that keleo exhaust has with the thick wall long header tubes, and collapsed at the bends... when you lengthen the exhaust, you always increase the ID... Cut the original headers to 1/4" - 5/16" stubs, then come off that with 8mm ID and expand it to 12mm ID to length.

I think the solution is the threaded in "adaptors" that get you a full 8mm ID plus right out of the port Then into an expansion chamber with an outlet sized to give just the right tank pressure - My tubes are 6.6 ID and I squeezed to 5.8.. the Keleo probably has half that area going around the corner..

Another 160 just came up on the classified forum up here - Magnum flavour this time - MUST RESIST!!!!!! - Will watch it for a while but if it doesn't move I might have to consider a "backup".... Did I mention I think I might have an engine holding issue.

#836

Senior Member

Thread Starter

Well ductile iron is a dark grey to black when heat treated... watching that JonneyQ90 guy install the rings in his engine, they seem to be pretty tough, I almost thought he had broken one as he fought to get it in the ring groove, made a loud snap as it popped into the groove.... When you look at the rings in the 160 boxer, there is no comparison in the amount of tension, smaller diameter piston rings don't need a lot of tension... their thickness can be wide, especially for a single ring, but the tension expansion should be small, thats done during tempering... they expand the ring in a jig and heat to temper... the thicker the ring the stiffer it will be, and will need less tension.

I did compare these rings WRT dimensions to the ring and liner of a .52 single I had laying around.

The cross section of both rings is fairly identical at approx 1 x 1 mm.

But... the .52 single has a bore of 23 mm, and the ring is in relaxed condition about 24 mm diameter. it really takes care and focus to snap such a ring in place without breaking it, because the ring needs to be expanded quite a bit in order to pass over the piston top.

The Toyan engine has a bore of 16,6 mm, and the ring in relaxed condition has an outer diameter of slightly over 18 mm, which means that in relaxed condition the inside diameter of the ring is just barely smaller than the outside diameter of the piston. Just enough to not fall off by itself...

Because of that relatively large relaxed diameter, the rings slip farly easily over the piston, and they HAVE to, because there is due to the small dimensions, barely any room to pry the rings open without putting undue strain and deforming them.

As you probably know, rings need to be forced open by excerting a torque at the ends rather than just pulling the ends apart, because the latter concentrates the bending moment at the middle of the ring, leading to ovalizing the ring.

With a "20 mm +" ring, I can do that (excerting a moment on the ring ends, I mean) but rings below that, it basically becomes impossible: my fingers simply are too big...

It is just a guess, but I think, that is the reason why Toyan opted for those wide rings.

Whatever the case, it is what it is, and all I can to is forbearingly awaiting break-in...

Last edited by 1967brutus; 09-20-2022 at 12:52 AM.

#837

Senior Member

Thread Starter

SO.... A little experimenting today. Made some "restrictors" and fitted them to the Straight pipes. Simple brass cups that I brazed on to my homemade straight pipes. Instant improvement in top end fuel feed - Now have headroom and a more regular looking curve.

The restrictors did come with a 100-rpm loss on the top end though - I think an expansion chamber might be a better fix

The restrictors did come with a 100-rpm loss on the top end though - I think an expansion chamber might be a better fix

Expansion chambers generate pressure because of Bernouilli's law, the opposite of a pressure drop in a venturi: the gas velocity in the expansion chamber lowers, and that increases pressure. This pressure rise is derived from the energy present in the gasses itself and theoretically should not come with an RPM penalty.

#838

Lonnie , The tubing is a fairly thin wall 8mm (5/16") steel brake line I can get locally - handles and bends well. Thinner wall than the older typical brake line. Probably a little thicker wall than the original but not by much..

Few questions on the FG's - Oil type and content and quick rundown on break in requirements. The fellow is new to "wet fuel" and I think I will be the "guidance counsellor" for this one...

Few questions on the FG's - Oil type and content and quick rundown on break in requirements. The fellow is new to "wet fuel" and I think I will be the "guidance counsellor" for this one...

The 4 stroke break in routine I use:

10 minutes at 4000 as rich as it will run without quitting.

10 minutes at 5000 a little leaner but still rough running.

10 minutes at 6000 still a touch rich but smoother running.

10 minutes spending most of it's time at 7000. Tuning for idle and wot during this period.

Some will mount, retune and fly at this point but my personal preference is to continue running on the stand until stable idle and wot settings can be achieved.

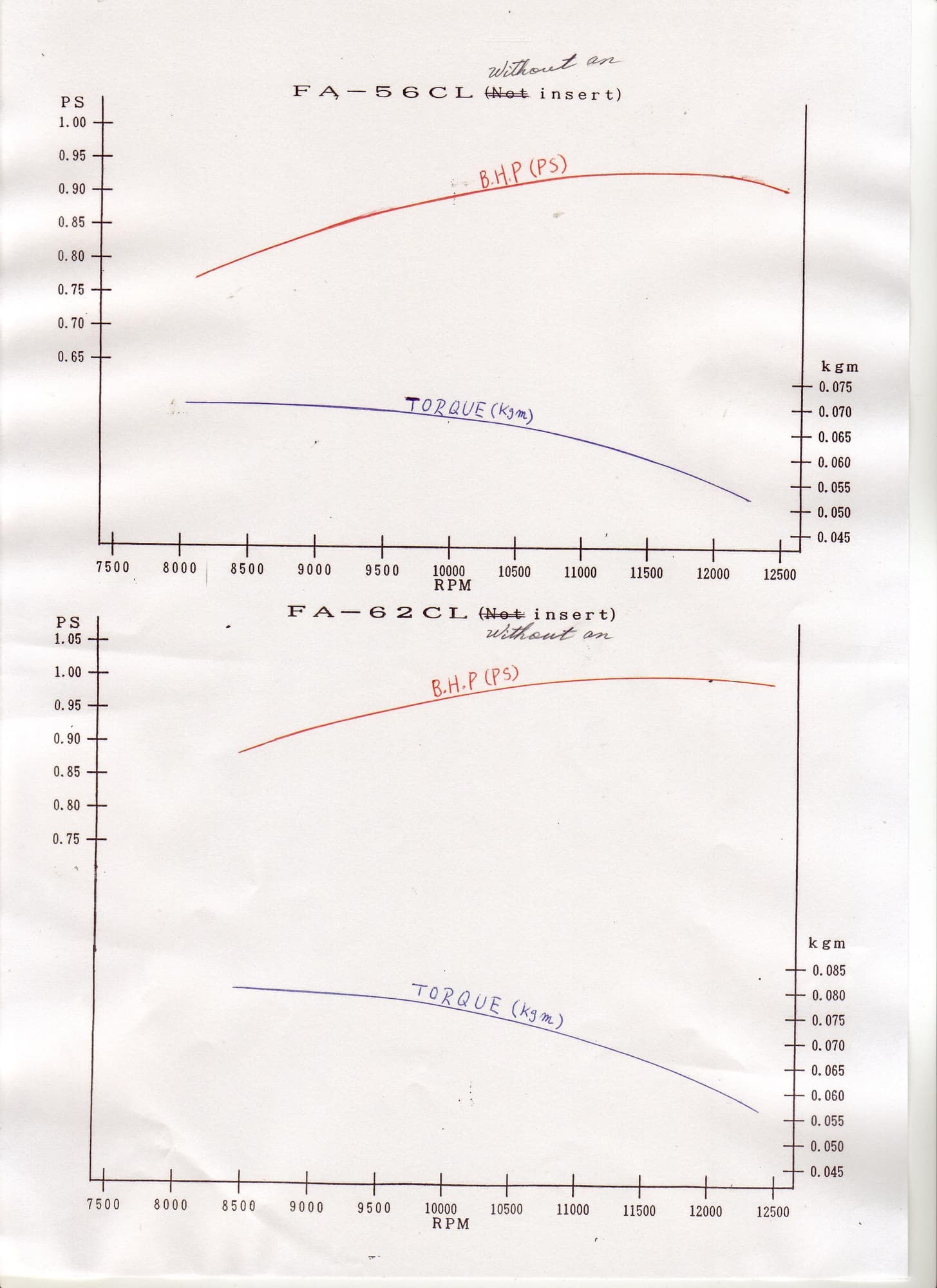

The FG11 is for all practical purposes an FA62 gas conversion, although the bore is increased netting .66 cu. in. The rpm for peak power output may surprise some.

Last edited by Glowgeek; 09-20-2022 at 12:54 PM.

#839

Wouldn't that be something if the original owner gave up and sold the engine for that reason, unknowing that the ign was defective... makes you wonder... its not that CH as the edge, its just RCxel lacks the quality control CH offers.

I have had many deep thoughts about posting my ign timing sketch, or the complete ign sys with the hi energy output... but then I keep getting reminded why not to. ,

,

I have had many deep thoughts about posting my ign timing sketch, or the complete ign sys with the hi energy output... but then I keep getting reminded why not to.

,

,Anyway, the defective CDI was a brand new RCexl unit I ordered from ZYhobby. We'll see what they will do for me.

#840

The was the one with a "stripped" glow plug hole, the owner never ran it on CDI. The pics on his ad showed four OS type F glow plugs in the engine, claiming one hole was stripped out. Of course it was more complicated than that AND it shipped with no glow plugs. He wouldn't make it right, so shame on him.

Anyway, the defective CDI was a brand new RCexl unit I ordered from ZYhobby. We'll see what they will do for me.

Anyway, the defective CDI was a brand new RCexl unit I ordered from ZYhobby. We'll see what they will do for me.

#841

Most definitely: The restrictors work because they generate backpressure, and that comes at the cost of power.

Expansion chambers generate pressure because of Bernouilli's law, the opposite of a pressure drop in a venturi: the gas velocity in the expansion chamber lowers, and that increases pressure. This pressure rise is derived from the energy present in the gasses itself and theoretically should not come with an RPM penalty.

Expansion chambers generate pressure because of Bernouilli's law, the opposite of a pressure drop in a venturi: the gas velocity in the expansion chamber lowers, and that increases pressure. This pressure rise is derived from the energy present in the gasses itself and theoretically should not come with an RPM penalty.

#842

That's true. Swapping out long bent headers for a shorter header and an expansion chamber type muffler will increase peak power and provide higher tank pressure. RC specialies sells nice mufflers, called turbo headers. Bolt on power, usually providing 200 rpm or higher gains in peak power over Saito's baffled mufflers. I haven't compared the turbo header with the non baffled OS style expansion chamber mufflers, so can't comment.

Last edited by Glowgeek; 09-20-2022 at 12:50 PM.

#843

That RC specialties is an interesting muffler... I bet the inlet tube extends into the expansion chamber, leaving a space between the end of the inlet tube and the outlet, creating a trap cavity... they claim to have a US patent on their design, but an anti reversion trap is not that unique in design... another means to baffle sound is with a perforated tube pass-through a expansion chamber, but anything that restricts gas flow creates back pressure... where as the anti reversion trap allows the exhaust gases to flow outwards, but trapping any rebounding pressure wave... and those conical ( megaphone style ) stinger exhaust are anti reversion by design, as the exhaust gas pressure wave can only move forward along the ever expanding cone, and any rebounding wave can't return back up the cone... propagating the wave to move forward.

#844

That Keleo Exhaust looks like trouble - I was tempted to throw it on today just to see how bad it was - the engine reacted badly to a slight squeeze from my restrictor caps so I would say its already choked with the straight pipes.

I think the solution is the threaded in "adaptors" that get you a full 8mm ID plus right out of the port Then into an expansion chamber with an outlet sized to give just the right tank pressure - My tubes are 6.6 ID and I squeezed to 5.8.. the Keleo probably has half that area going around the corner..

Another 160 just came up on the classified forum up here - Magnum flavour this time - MUST RESIST!!!!!! - Will watch it for a while but if it doesn't move I might have to consider a "backup".... Did I mention I think I might have an engine holding issue.

I think the solution is the threaded in "adaptors" that get you a full 8mm ID plus right out of the port Then into an expansion chamber with an outlet sized to give just the right tank pressure - My tubes are 6.6 ID and I squeezed to 5.8.. the Keleo probably has half that area going around the corner..

Another 160 just came up on the classified forum up here - Magnum flavour this time - MUST RESIST!!!!!! - Will watch it for a while but if it doesn't move I might have to consider a "backup".... Did I mention I think I might have an engine holding issue.

Don't we all, although the wife manages my addiction to the hobby with ominous looks of discontent.

#845

My Feedback: (1)

RC specialies sells nice mufflers, called turbo headers. Bolt on power, usually providing 200 rpm or higher gains in peak power over Saito's baffled mufflers. I haven't compared the turbo header with the non baffled OS style expansion chamber mufflers, so can't comment.

That RC specialties is an interesting muffler... I bet the inlet tube extends into the expansion chamber, leaving a space between the end of the inlet tube and the outlet, creating a trap cavity... they claim to have a US patent on their design, but an anti reversion trap is not that unique in design... another means to baffle sound is with a perforated tube pass-through a expansion chamber, but anything that restricts gas flow creates back pressure... where as the anti reversion trap allows the exhaust gases to flow outwards, but trapping any rebounding pressure wave... and those conical ( megaphone style ) stinger exhaust are anti reversion by design, as the exhaust gas pressure wave can only move forward along the ever expanding cone, and any rebounding wave can't return back up the cone... propagating the wave to move forward.

I think I might take a stab at building some custom Chambers for the twin... Autumn is upon us here and I probably won't get into the air with the twin before the cold sets in... some R&D time this winter...

Chris

#846

Senior Member

Thread Starter

Just a general question to the metallurgists here:

I need to bend and shape aluminium tubing, the stuff is rather rigid and not very malleable 5 mm OD, 4,1 mm ID

Is there some heat-treatment or anything to make aluminium soft and malleable?

I need to bend and shape aluminium tubing, the stuff is rather rigid and not very malleable 5 mm OD, 4,1 mm ID

Is there some heat-treatment or anything to make aluminium soft and malleable?

#847

Anneal it Bert in and oven preferably... around 700-800 degrees... you can use a torch, but a more even heat source is preferred... I anneal aluminum sheet in a normalizing oven.. if you have a self cleaning oven for cooking, you can place the aluminum tubes in the oven and run them through a clean cycle... normally the self cleaning mode is around 500c, should anneal it nicely... the only draw back is you have to wait for the cool down for the oven door to unlock.

Last edited by John_M_; 09-20-2022 at 09:49 PM. Reason: Boo Boo

#848

Has anyone set Eyes on a turbo header? - just wondering as their Patent Language is very odd - I searched the patent and the claim is an "ornamental design for an exhaust manifold" and makes no claim or does not document any internal structure design. Seems like the patent only covers "how it looks" not what's inside... Is it just a Header?

I think I might take a stab at building some custom Chambers for the twin... Autumn is upon us here and I probably won't get into the air with the twin before the cold sets in... some R&D time this winter...

Chris

I think I might take a stab at building some custom Chambers for the twin... Autumn is upon us here and I probably won't get into the air with the twin before the cold sets in... some R&D time this winter...

Chris

Last edited by John_M_; 09-20-2022 at 09:36 PM. Reason: Boo Boo

#850

Senior Member

Thread Starter

Anneal it Bert in and oven preferably... around 700-800 degrees... you can use a torch, but a more even heat source is preferred... I anneal aluminum sheet in a normalizing oven.. if you have a self cleaning oven for cooking, you can place the aluminum tubes in the oven and run them through a clean cycle... normally the self cleaning mode is around 500c, should anneal it nicely... the only draw back is you have to wait for the cool down for the oven door to unlock.

But I think I can simply use a piece of steel pipe, put the Alu inside and heat the pipe to dull red for a few minutes. That should be about 500 deg C andspread the heat fairly evenly, especially if I pre-cut the aluminium tube to pieces of approx 10 cm

How long to maintain the temperature? Slow cool or rapid cool to anneal Aluminium?

I anneal copper a lot (where you cool the item in water in order to maintain annealed state, but never did that with aluminium.

Edit: I assume at least that this stuff is annealable, since I think this type of tubing is made by extruding.

Can it be re-hardened, and if so, how? Heating again then rapid cooling?

Last edited by 1967brutus; 09-20-2022 at 11:45 PM.